¶ AI Agents for Inventory Management

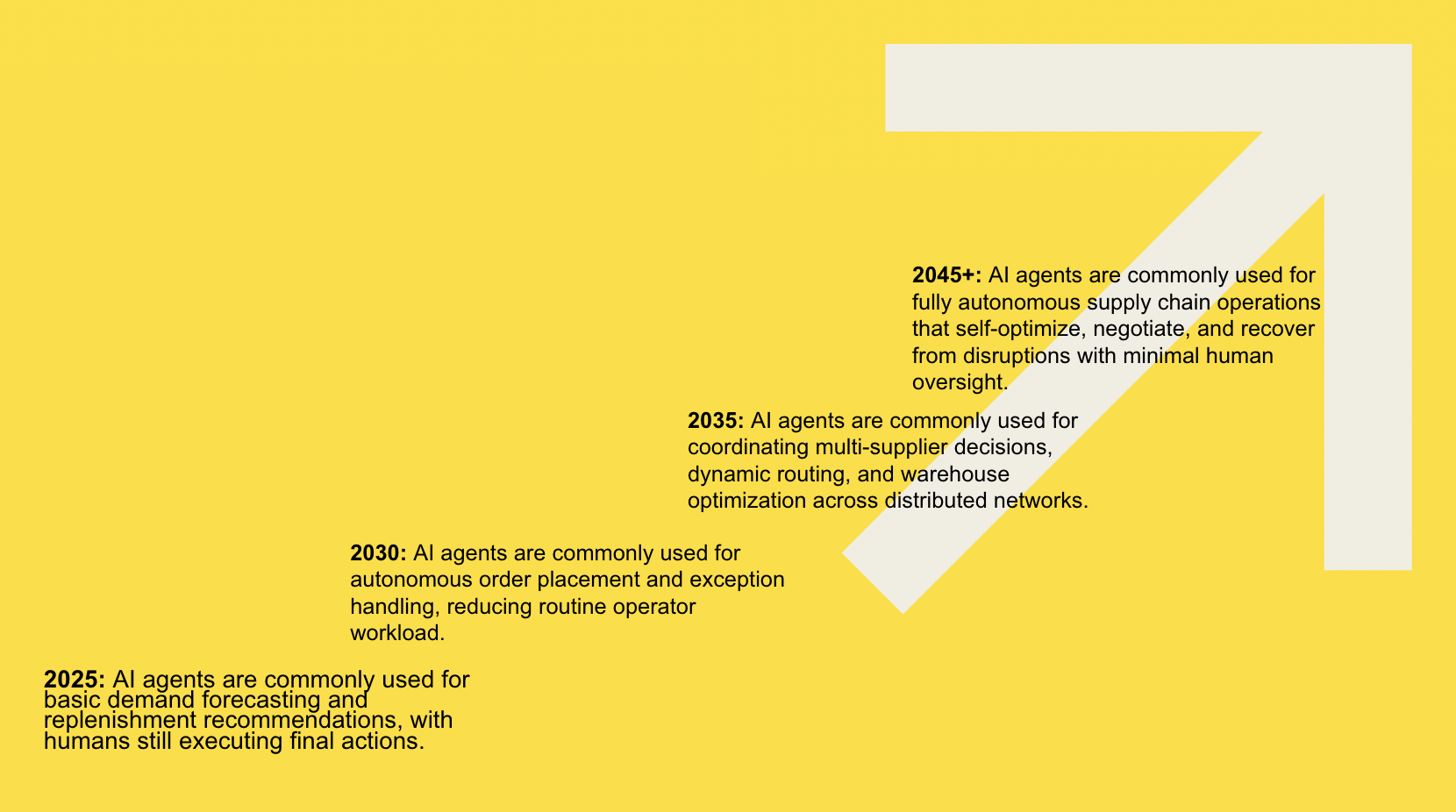

¶ 1. Roadmap Overview

Agentic AI refers to artificial intelligence systems that go beyond information analysis or content generation and can take autonomous actions in pursuit of defined goals. Unlike traditional AI, which primarily provides outputs or recommendations for human decision-making, agentic AI systems can plan, reason, and execute tasks with minimal human intervention. These systems incorporate advanced components such as reinforcement learning, large language models, and autonomous tool calling to interact dynamically with their environment. A defining feature of agentic AI is its ability to chain together multiple steps and adapt strategies in real time.

In inventory management, agentic AI can transform operations by autonomously monitoring stock levels, predicting demand, and placing restock orders without human micromanagement. For example, such a system might continuously analyze demand data, seasonal trends, and supplier lead times, then automatically adjust order quantities to minimize both shortages and overstocking. It could also negotiate with multiple suppliers, optimize warehouse space, and even re-route shipments when disruptions occur. This level of autonomy reduces costs, improves supply chain resilience, and frees up human managers to focus on strategic decisions rather than day-to-day logistics. By integrating reasoning and adaptive planning, agentic AI represents a shift from reactive inventory tracking toward proactive, self-managing supply networks.

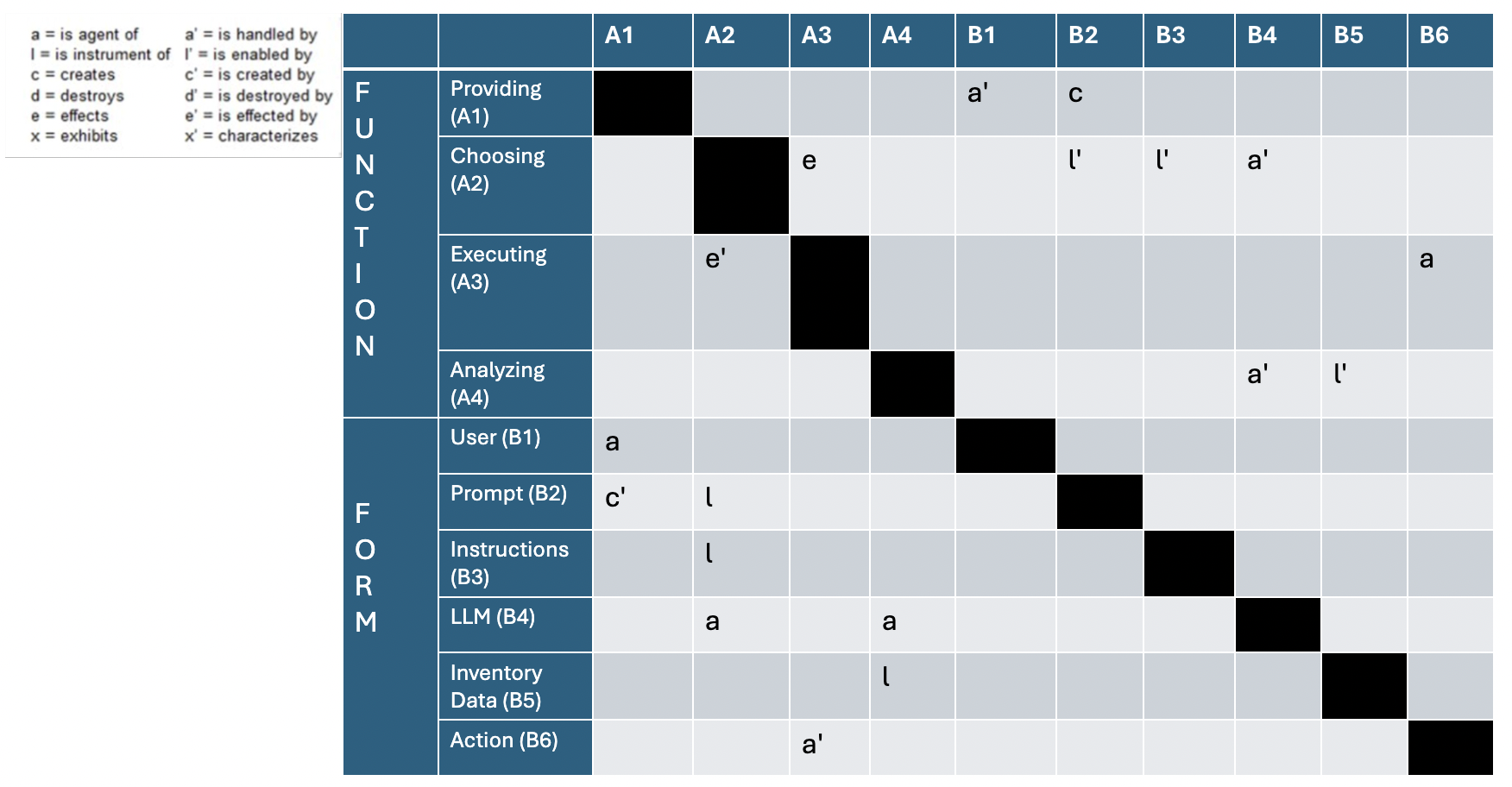

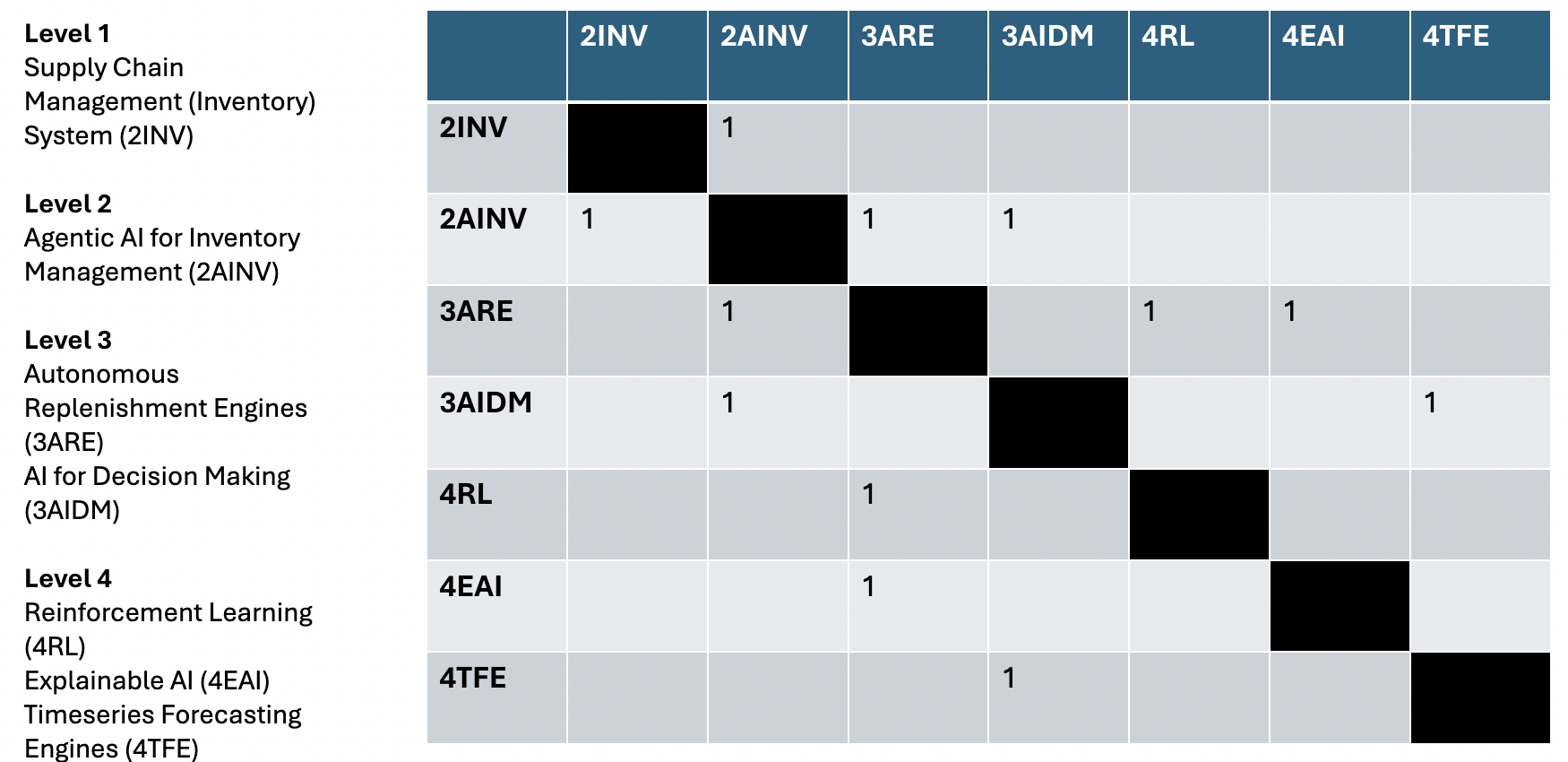

¶ 2. Design Structure Matrix (DSM) Allocation

Relation to other tech roadmaps:

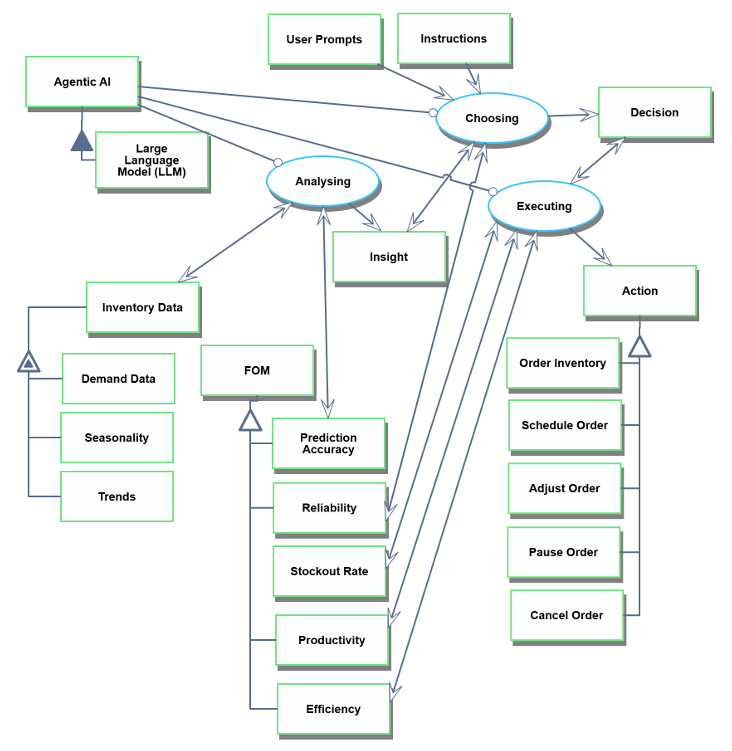

¶ 3. Roadmap Model using OPM

1. User Prompts is a physical and systemic object.

2. Instructions is a physical and systemic object.

3. Inventory Data is a physical and systemic object.

4. Demand Data of Inventory Data is an informatical and systemic object.

5. Seasonality of Inventory Data is an informatical and systemic object.

6. Trends of Inventory Data is an informatical and systemic object.

7. Agentic AI is a physical and systemic object.

8. Large Language Model is a physical and systemic object.

9. Insight is a physical and systemic object.

10. Action is a physical and systemic object.

11. Decision is a physical and systemic object.

12. Order Inventory is a physical and systemic object.

13. Schedule Order is a physical and systemic object.

14. Adjust Order is a physical and systemic object.

15. Pause Order is a physical and systemic object.

16. Cancel Order is a physical and systemic object.

17. FOM is a physical and systemic object.

18. Prediction Accuracy is a physical and systemic object.

19. Stockout Rate is a physical and systemic object.

20. Reliability is a physical and systemic object.

21. Productivity is a physical and systemic object.

22. Efficiency is a physical and systemic object.

23. Inventory Data exhibits Demand Data, Seasonality, and Trends.

24. Agentic AI consists of Large Language Model.

25. Adjust Order, Cancel Order, Order Inventory, Pause Order, and Schedule Order are Actions.

26. Efficiency, Prediction Accuracy, Productivity, and Reliability are FOMS.

27. Analysing is a physical and systemic process.

28. Analysing requires Agentic AI.

29. Analysing affects Inventory Data and Prediction Accuracy.

30. Analysing yields Insight.

31. Choosing is a physical and systemic process.

32. Choosing requires Agentic AI.

33. Choosing affects Insight and Reliability.

34. Choosing consumes Instructions and User Prompts.

35. Choosing yields Decision.

36. Executing is a physical and systemic process.

37. Executing requires Agentic AI.

38. Executing affects Decision, Efficiency, Productivity, and Stockout Rate.

39. Executing yields Action.

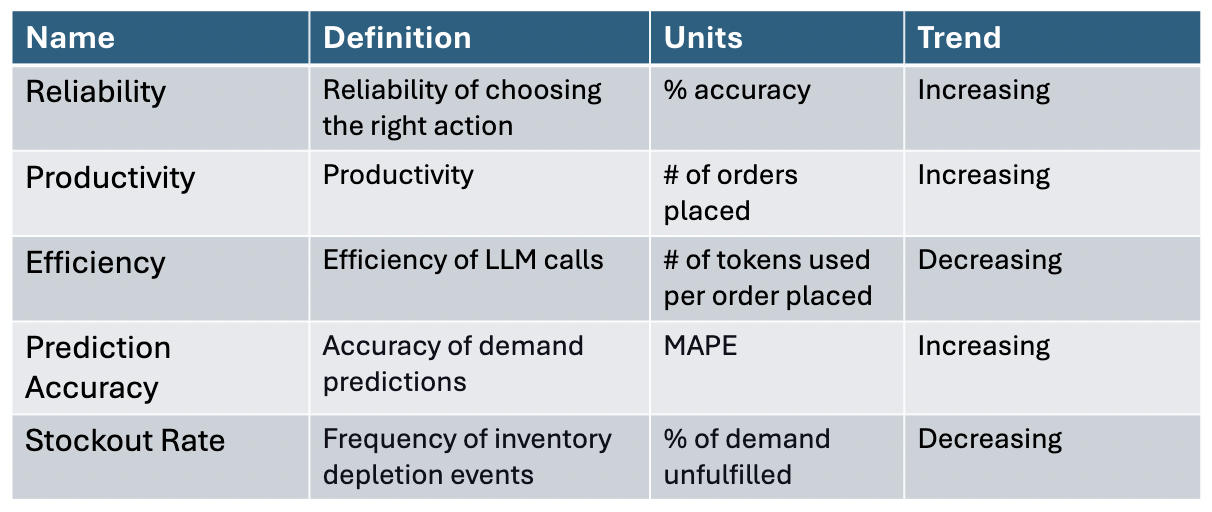

¶ 4. Figures of Merit (FOM)

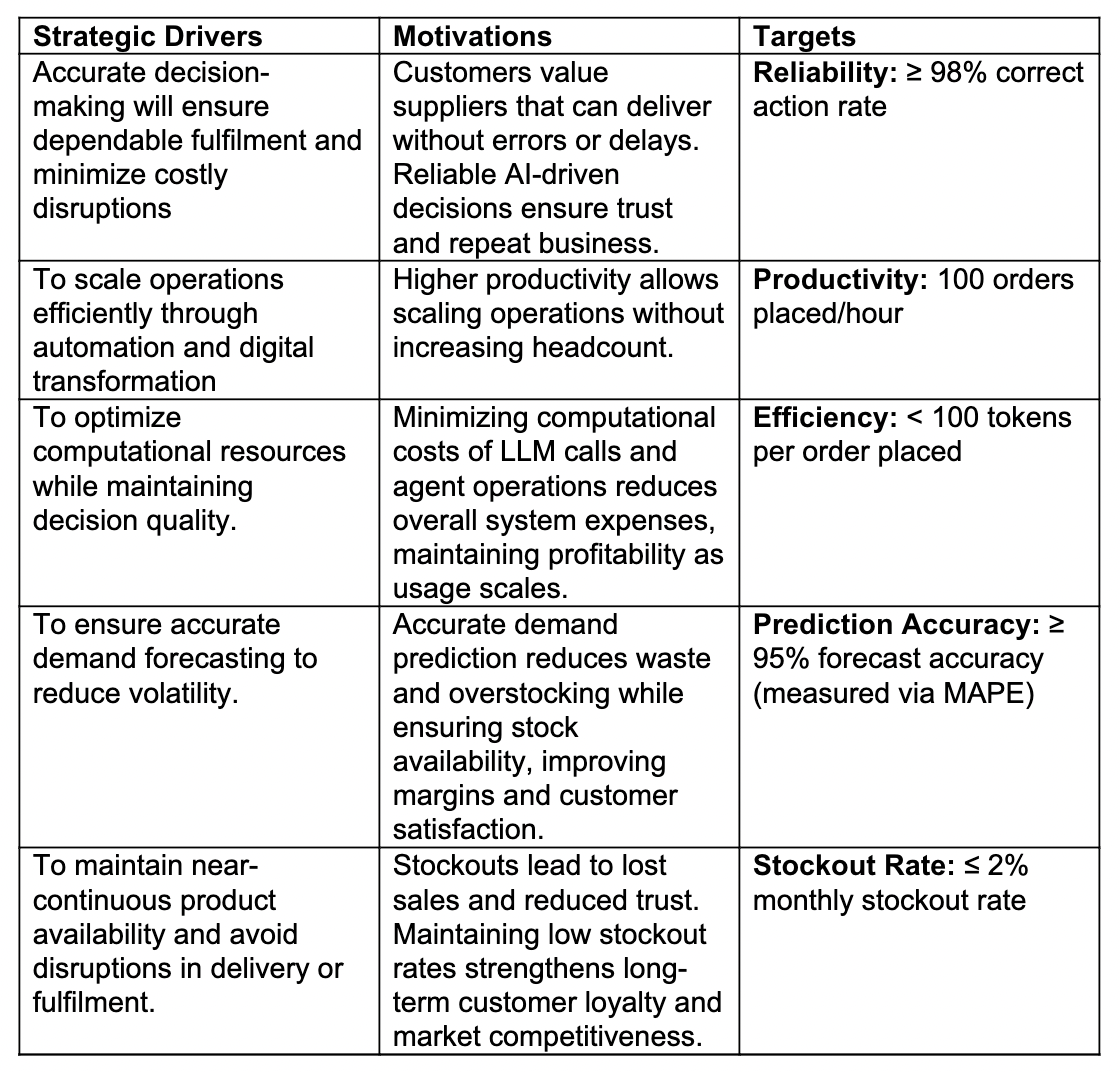

¶ 5. Alignment of Strategic Drivers: FOM Targets

For AI agents for inventory management, the strategic drivers that will enable success in the inventory management and optimization industry are listed below. Our hypothetical company is a supplier that is using AI agents for inventory management including ordering inventory, scheduling orders, adjusting orders, pausing orders, or cancelling orders.

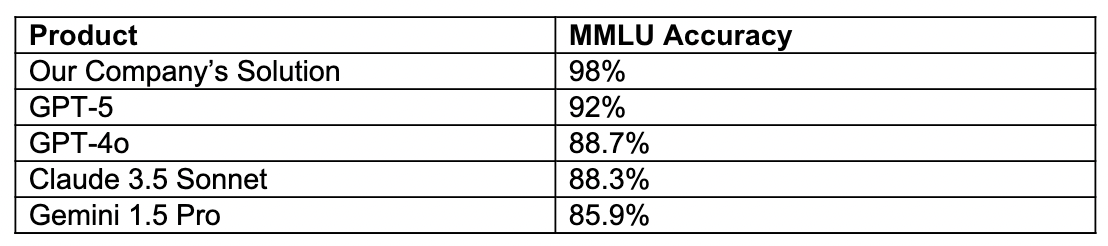

¶ 6. Positioning of Organization vs. Competition: FOM charts

The chart below compares reliability/accuracy with other “competitors”. In reality, these products are not competitors but may be the chosen LLM powering the AI agents for inventory management.

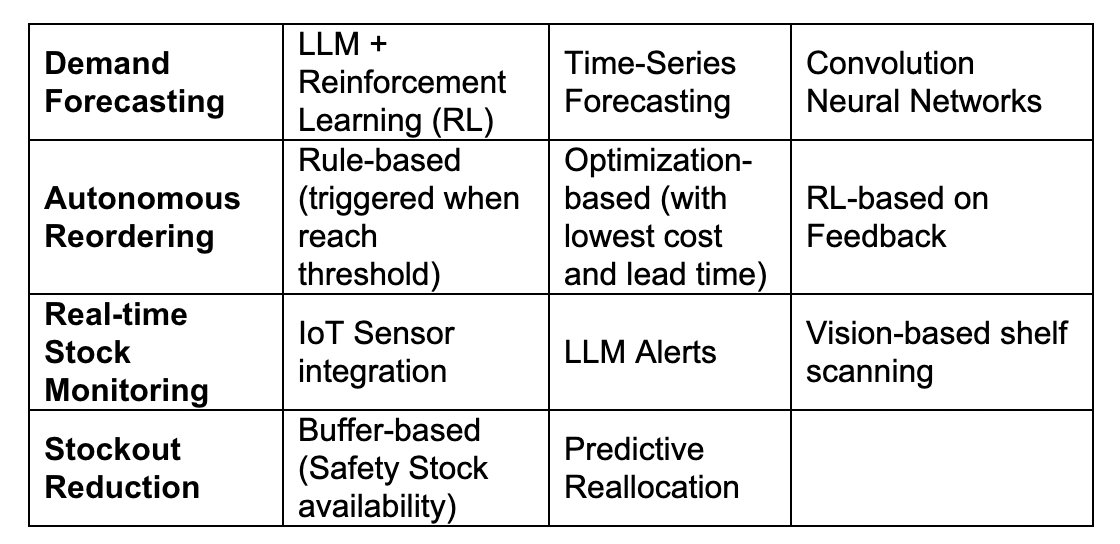

¶ 7. Technical Model: Morphological Matrix and Tradespace

The following are important variables in the technical system:

- Demand Volatility (DV) - degree of fluctuation in customer demand over time

- Supplier Lead Time Variability (SLTV) - inconsistency in delivery times from suppliers

- Model Complexity (MC) – depth of AI architecture (e.g., number of layers, reasoning modules)

- Token Budget (TB) - number of tokens allocated for processing each order

Mathematical Equations

FOM: Reliability

R = 1 - Error Rate = 1 - (Uncertainty/ System Capability)

Therefore, R = 1 − (DV⋅SLTV)/ (MC⋅TB)

FOM: Prediction Accuracy

MAPE = Sum of errors from multiple error channels/ Gain in performance

MAPE= (DV+SLTV)/ MC⋅log(TB+1)

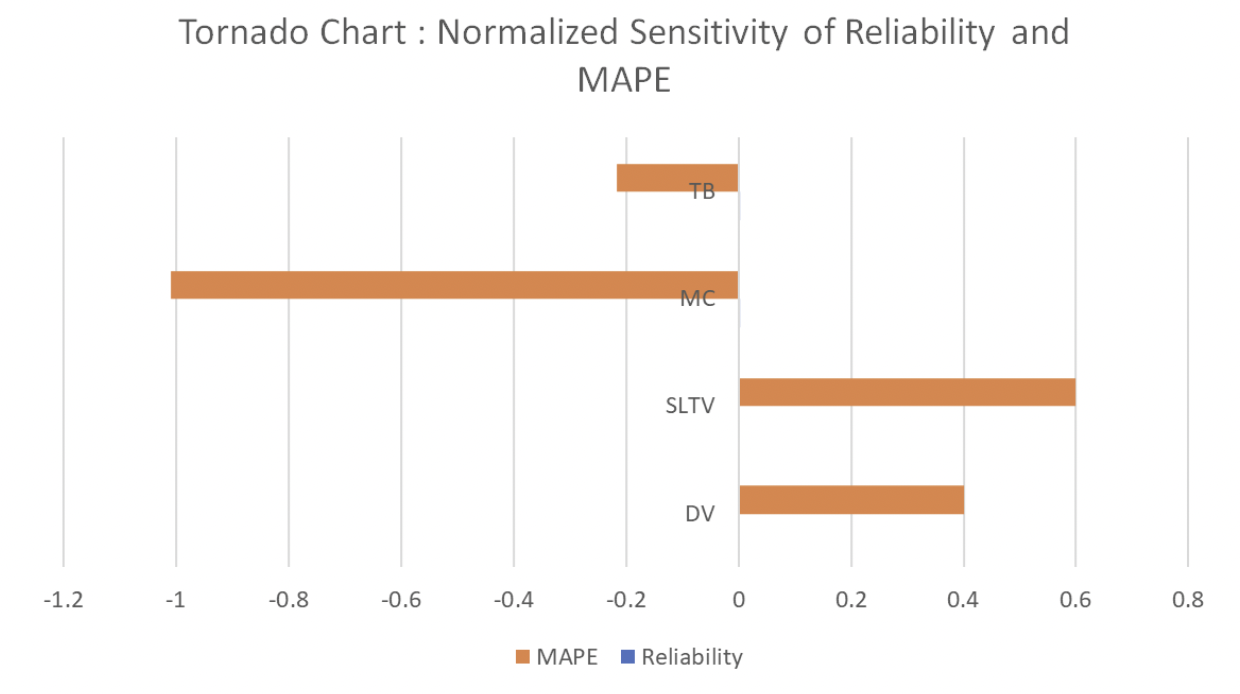

Sensitivity Analysis

The morphological matrix below shows the decisions available for the technical system:

To explore the trade space, the team conducted a sensitivity analysis on all available parameters for prediction accuracy (MAPE) and reliability.

Prediction Accuracy (MAPE) is most sensitive to model depth (MC), demand volatility (DV), and supplier lead time variability (SLTV). Token budget (TB) helps nominally.

Reliability was equally sensitive to all four variables.

¶ 8. Financial Model: Technology Value (𝛥NPV)

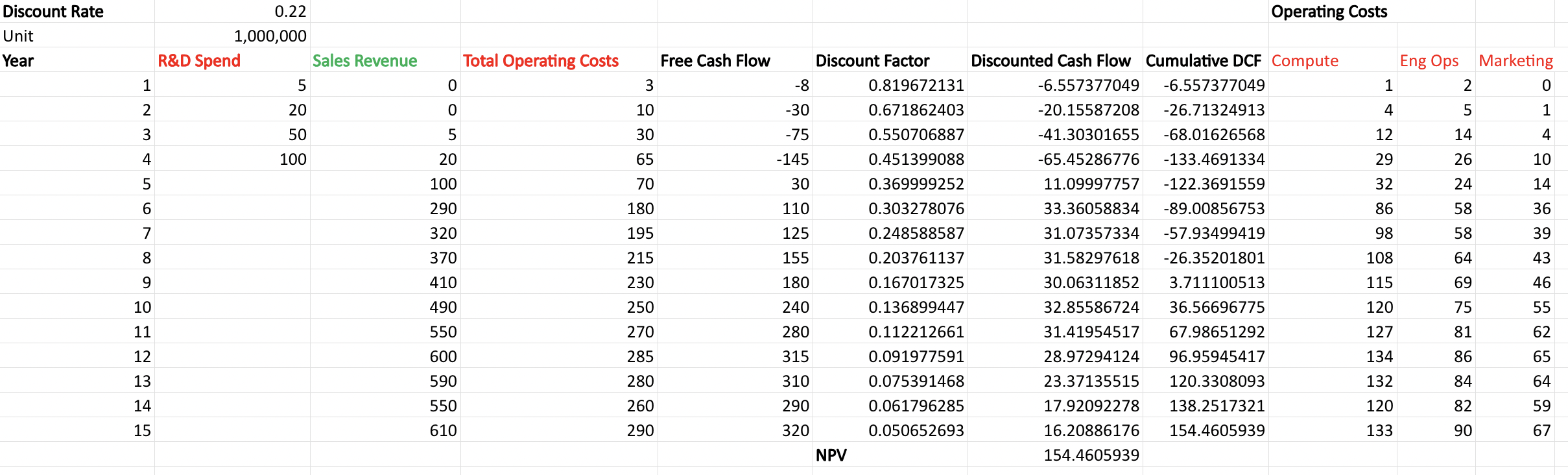

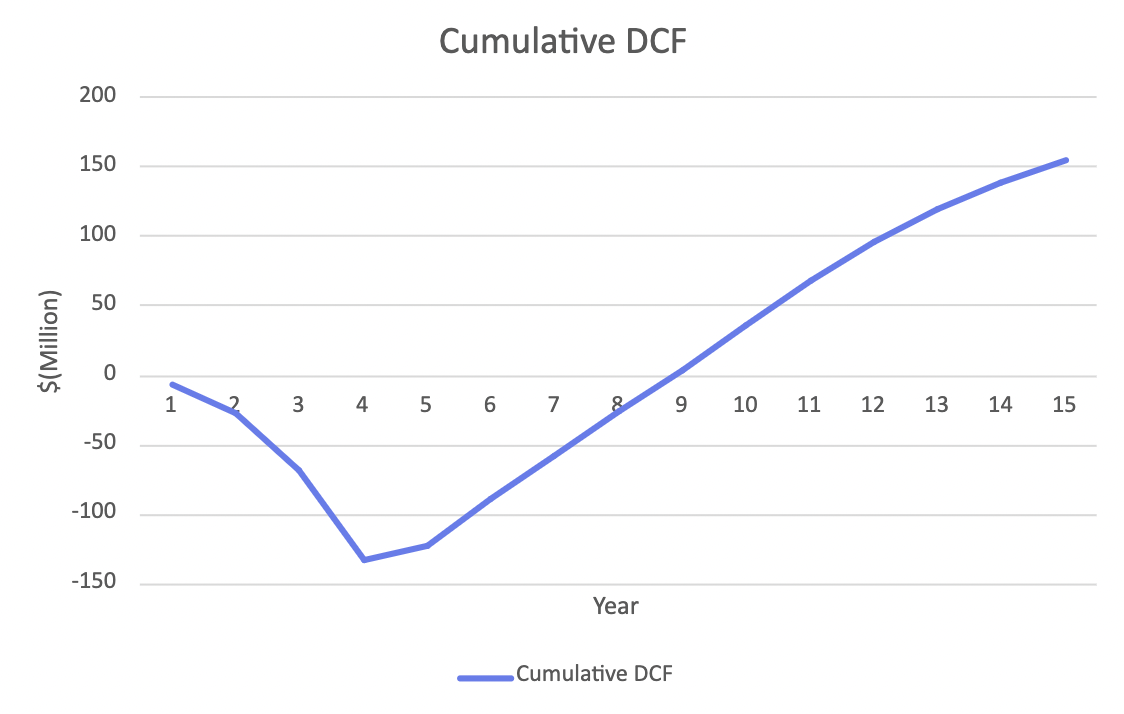

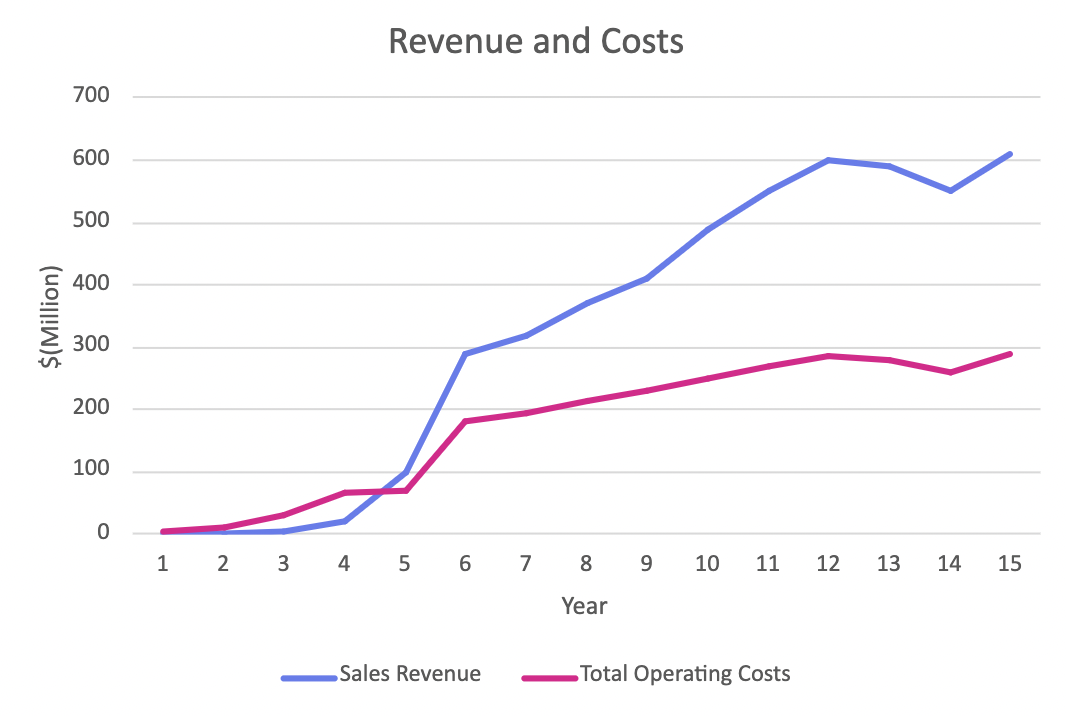

This model estimates cash flows for an AI agent for inventory management product. This NPV analysis assumes a discount rate consistent with other AI agent companies and uses a 15-year revenue trajectory modelled after Manhattan Associates, an inventory-management software firm. R&D spending reflects typical AI-agent startup behaviour, with heavy investment in the early build phase and tapering as the company scales. Operating costs were structured to mirror realistic shifts across the company’s lifecycle: in Years 1-2 (pre-revenue), the business incurs meaningful infrastructure and engineering operations costs with virtually no marketing spend; in Years 3-4 (pilot phase), revenue begins to appear but operating expenses grow faster as the company supports early customers and stabilizes integrations; in Years 5-8 (scaling phase), operating costs rise significantly due to increased compute usage and integration work, reflecting customer and SKU volume growth; and in Years 9-15 (mature growth), operating costs continue increasing but with improving efficiency, while marketing ramps as the company expands its go-to-market motion. Based on these assumptions, the resulting Net Present Value (NPV) is approximately $154.46 million.

¶ 9. List of R&D Projects and Prototypes

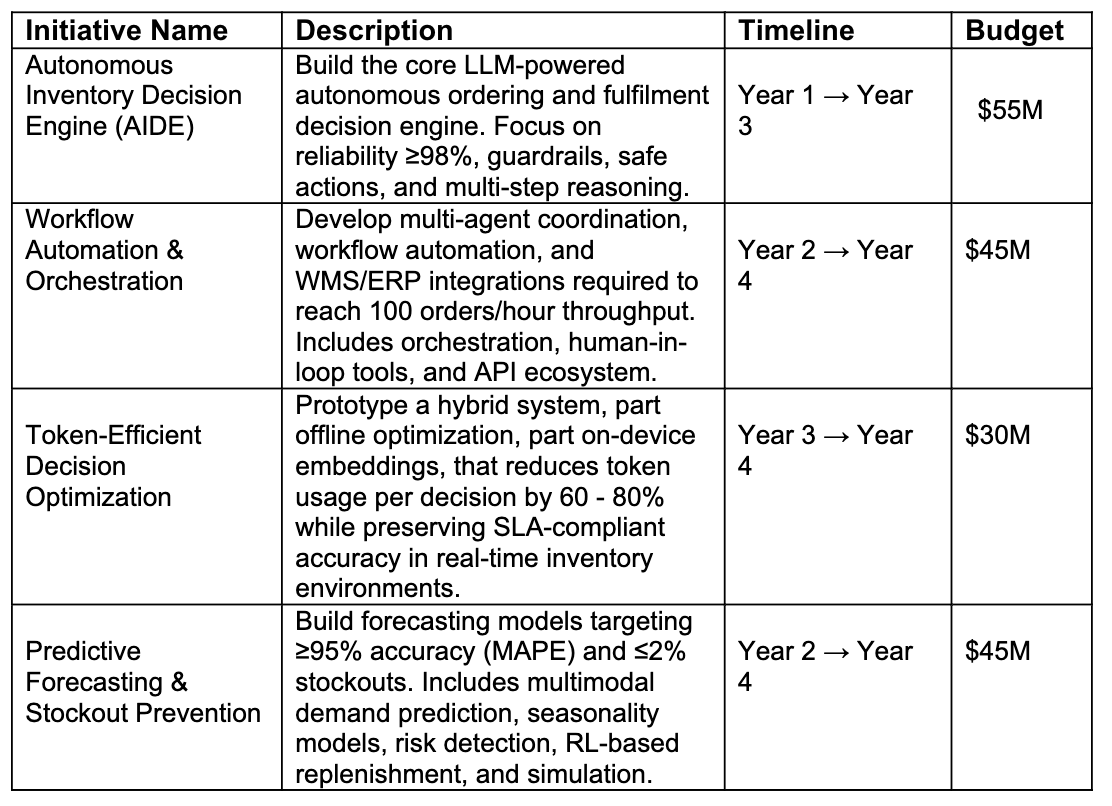

We used strategic drivers, R&D budget, and timeline available to propose the following R&D initiatives:

¶ 10. Key Publications, Presentations and Patents

¶ 10.1 Publications & Presentations

[1] N. Singh and D. Adhikari, “AI in inventory management: Applications, challenges, and opportunities,” International Journal for Research in Applied Science and Engineering Technology, 2023. [Online]. Available: https://www.researchgate.net/publication/AI_in_inventory_management_Applications_Challenges_and_Opportunities

- This paper is relevant because it outlines how AI technologies—including intelligent decision-making systems—can automate and optimize core inventory processes. It establishes the conceptual foundation for AI-driven agents that manage forecasting, ordering, and stock control autonomously.

[2] C. D. Roberts, A. S. Alatrany, and M. Alsaadi, “Artificial intelligence and its role in optimizing inventory management: A simulation study,” in Proceedings of the International Conference on Development in eSystems Engineering (DeSE), 2024. [Online]. Available: https://ieeexplore.ieee.org

- This study directly models agent-based AI systems in a simulated inventory environment, demonstrating how autonomous agents can adapt to supply and demand fluctuations. It provides practical evidence that agentic approaches outperform static inventory models in responsiveness and efficiency.

[3] D. Preil and M. Krapp, “Artificial intelligence-based inventory management: A Monte Carlo tree search approach,” Annals of Operations Research, 2022. [Online]. Available: https://link.springer.com/article/10.1007/s10479-022-04925-3

- This work contributes algorithmic insight by applying Monte Carlo Tree Search (MCTS), a decision-making framework well-suited for AI agents navigating complex, uncertain environments. It shows how agent-like optimization methods can enhance inventory planning and dynamic replenishment decisions.

¶ 10.2 Patents

US20240256598A1-“Generative AI and agentic AI systems and methods for product data, inventory, and pricing”

- The patent is highly relevant to AI Agents for Inventory Management because the invention describes a system that can generate, test, and refine predictive analytics models in semi- or unsupervised modes, enabling continuous learning and adaptation, which are capabilities essential for AI agents executing inventory control. It also outlines the use of AI agents that can subscribe to real-time product and inventory data, allowing for autonomous forecasting, optimization, and economic decision-making. Its combination of generative AI for hypothesis creation and agentic AI for action and response directly parallels the vision of deploying self-governing digital agents in supply chain operations.

¶ 11. Technology Strategy Statement

By 2028, our technology strategy for AI agents in inventory management is focused on building a highly reliable, efficient, and autonomous decision engine that can operate at scale across complex supply chains. By 2028, human operators should supervise exceptions rather than micromanage routine inventory processes, with agentic AI handling most of the planning, executing, and adjusting operational tasks in real time.

By 2040, our goal is to evolve these systems into fully autonomous supply networks that optimize end-to-end flows across sourcing, warehousing, transportation, and fulfilment. We would create self-healing logistics ecosystems capable of dynamic reallocation, predictive rerouting, supplier negotiation, and situation-aware recovery during global disruptions. These agents will operate as collaborative multi-agent systems, coordinating across organizations through secure protocols and shared data layers. Instead of simply managing stock, AI will continuously optimize working capital, carbon footprint, resilience scores, and delivery experience across the entire network. Ultimately, 2040 systems will behave as autonomous operations partners, not just tools.

To enable this future, we will invest in four R&D initiatives:

- Autonomous Inventory Decision Engine (AIDE): the core reasoning, simulation, and safe-action engine.

- Workflow Automation & Throughput Scaling Platform: multi-agent coordination and automated ordering to achieve high throughput.

- Token-Efficient Decision Optimization Program: compute-efficient architectures that minimize costs as usage scales.

- Predictive Forecasting & Stockout Prevention Engine: advanced demand models ensuring accuracy, low volatility, and ≤2% stockout rates.

Together, these investments position us to lead the shift from reactive operational tools to proactive, self-managing supply networks.