Difference between revisions of "Autonomy in the Corn Production System"

| Line 4: | Line 4: | ||

=Technology Roadmap Sections and Deliverables= | =Technology Roadmap Sections and Deliverables= | ||

* '''2ACP | * '''2ACP – Autonomous Machines in the Corn Production System''' | ||

Today’s farms are tasked with producing for a growing population with limited growth in key resources. Heiko Rischer et. al. estimated projection of 60% higher global food requirements by 2050 with only a 2% expected increase in agricultural land (1). This emphasizes the need for increased productivity per acre in today’s farming practices. We plan to explore key enabling technologies related to this need. Our intent is to look at the broad context of autonomous system benefits to the processes of agronomic decision making, data collection for decision making, and in-field execution of the selected farming practices. While today’s farms are heavily dominated by productivity goals, the value autonomous machines present is to increase output by managing plant level outcomes while also reducing inputs in the form of labor, crop inputs, and capital. We plan to generate a technology roadmap focused on autonomous in-field process execution that targets figures of merit related to field management resolution and operational costs. | |||

(1)Heiko Rischer, Géza R Szilvay, Kirsi-Marja Oksman-Caldentey, Cellular agriculture — industrial biotechnology for food and materials, Current Opinion in Biotechnology, Volume 61, 2020, Pages 128-134, | |||

==Roadmap Overview== | ==Roadmap Overview== | ||

| Line 15: | Line 17: | ||

The basic function of most agricultural machines is to manipulate soil, remove, transport, add commodity from the field, or assess crop or soil health. Agricultural Autonomous Machines may be exhibited in the form of aerial or ground vehicles. The focus of this roadmap will be on ground vehicles. These vehicles are typically constructed from steel or aluminum, carry on-board energy storage and crop commodities, are mounted on wheeled or track configurations, and powered by ICE (Internal Combustion Engines). Given the portability and energy density of diesel fuel, the diesel engine dominates power generation in agriculture vehicles today. Recent improvements in electrification and batteries have made this technology more appealing in lower power agriculture applications. | |||

The demands of each job step (Tilling, Planting, Nurturing, Protecting, Harvesting, Hauling) drive different operational capabilities to do the work and as such drive different implements to engage the soil or crop. For example, tilling requires greater tractive effort than planting and as such will require greater power and weight per unit of working width. The versatility of the tractor, with its defined implement interface and high configurability, have made it the vehicle of choice for the tilling, planting, and hauling in-field job steps, whereas spraying field access and harvesting material handling requirements have driven unique machine forms. | |||

Given that corn is planted in rows, the spacing between the row constrains the vehicle design. Additionally, environmental factors such as soil moisture and temperature, govern field access and timing of field operations. | |||

==Design Structure Matrix (DSM) Allocation== | ==Design Structure Matrix (DSM) Allocation== | ||

Revision as of 15:26, 11 October 2021

Page Under Development

Technology Roadmap Sections and Deliverables

- 2ACP – Autonomous Machines in the Corn Production System

Today’s farms are tasked with producing for a growing population with limited growth in key resources. Heiko Rischer et. al. estimated projection of 60% higher global food requirements by 2050 with only a 2% expected increase in agricultural land (1). This emphasizes the need for increased productivity per acre in today’s farming practices. We plan to explore key enabling technologies related to this need. Our intent is to look at the broad context of autonomous system benefits to the processes of agronomic decision making, data collection for decision making, and in-field execution of the selected farming practices. While today’s farms are heavily dominated by productivity goals, the value autonomous machines present is to increase output by managing plant level outcomes while also reducing inputs in the form of labor, crop inputs, and capital. We plan to generate a technology roadmap focused on autonomous in-field process execution that targets figures of merit related to field management resolution and operational costs.

(1)Heiko Rischer, Géza R Szilvay, Kirsi-Marja Oksman-Caldentey, Cellular agriculture — industrial biotechnology for food and materials, Current Opinion in Biotechnology, Volume 61, 2020, Pages 128-134,

Roadmap Overview

The working principle and architecture of solar-electric aircraft is depicted in the below.

The basic function of most agricultural machines is to manipulate soil, remove, transport, add commodity from the field, or assess crop or soil health. Agricultural Autonomous Machines may be exhibited in the form of aerial or ground vehicles. The focus of this roadmap will be on ground vehicles. These vehicles are typically constructed from steel or aluminum, carry on-board energy storage and crop commodities, are mounted on wheeled or track configurations, and powered by ICE (Internal Combustion Engines). Given the portability and energy density of diesel fuel, the diesel engine dominates power generation in agriculture vehicles today. Recent improvements in electrification and batteries have made this technology more appealing in lower power agriculture applications.

The demands of each job step (Tilling, Planting, Nurturing, Protecting, Harvesting, Hauling) drive different operational capabilities to do the work and as such drive different implements to engage the soil or crop. For example, tilling requires greater tractive effort than planting and as such will require greater power and weight per unit of working width. The versatility of the tractor, with its defined implement interface and high configurability, have made it the vehicle of choice for the tilling, planting, and hauling in-field job steps, whereas spraying field access and harvesting material handling requirements have driven unique machine forms.

Given that corn is planted in rows, the spacing between the row constrains the vehicle design. Additionally, environmental factors such as soil moisture and temperature, govern field access and timing of field operations.

Design Structure Matrix (DSM) Allocation

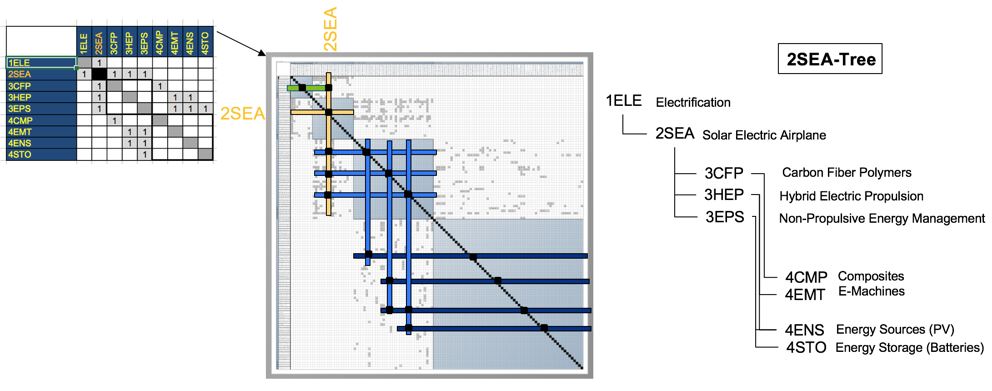

The 2-SEA tree that we can extract from the DSM above shows us that the Solar-Electric Aircraft (2SEA) is part of a larger company-wide initiative on electrification of flight (1ELE), and that it requires the following key enabling technologies at the subsystem level: 3CFP Carbon Fiber Polymers, 3HEP Hybrid Electric Propulsion and 3EPS Non-Propulsive Energy Management (e.g. this includes the management of the charge-discharge cycle of the batteries during the day-night cycle). In turn these require enabling technologies at level 4, the technology component level: 4CMP components made from CFRP (spars, wing box, fairings …), 4EMT electric machines (motors and generators), 4ENS energy sources (such as thin film photovoltaics bonded to flight surfaces) and 4STO (energy storage in the form of lithium-type batteries).

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2SEA roadmap in the figure below. This diagram captures the main object of the roadmap (Solar-Electric Aircraft), its various instances including main competitors, its decomposition into subsystems (wing, battery, e-motor …), its characterization by Figures of Merit (FOMs) as well as the main processes (Flying, Recharging).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.