Difference between revisions of "Variable Emissivity Materials For Spacecraft"

| (76 intermediate revisions by 2 users not shown) | |||

| Line 9: | Line 9: | ||

Thermochromic variable emissivity materials (VEMs) can be used for a wide range of applications, from spacecraft radiators to windows used on Earth. For this technology roadmap, the use of VEMs for spacecraft radiators will be the focus. | Thermochromic variable emissivity materials (VEMs) can be used for a wide range of applications, from spacecraft radiators to windows used on Earth. For this technology roadmap, the use of VEMs for spacecraft radiators will be the focus. | ||

==Roadmap Overview== | ==1. Roadmap Overview== | ||

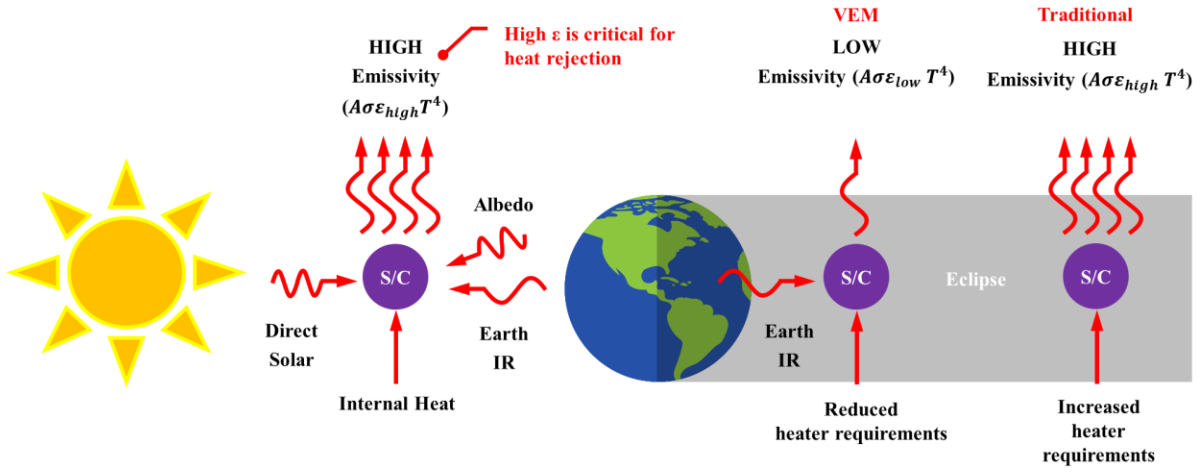

The only way that orbiting spacecraft can reject heat is through radiation. Because of this, the thermo-optical properties of spacecraft radiators are important. The thermo-optical properties of radiators, such as emissivity, determine how much heat is radiated away. | The only way that orbiting spacecraft can reject heat is through radiation. Because of this, the thermo-optical properties of spacecraft radiators are important. The thermo-optical properties of radiators, such as emissivity, determine how much heat is radiated away. | ||

| Line 27: | Line 27: | ||

[[File:howVEMsAffectSpacecraft.png|center]] | [[File:howVEMsAffectSpacecraft.png|center]] | ||

<div style="text-align: center;"> | <div style="text-align: center;"> | ||

Figure 1: Diagram of how VEMs affect spacecraft, from [1] | Figure 1: Diagram of how VEMs affect spacecraft, from [1] | ||

| Line 34: | Line 33: | ||

This roadmap will explore how thermochromic VEMs have evolved, their Figures of Merit, and what is expected in the future. | This roadmap will explore how thermochromic VEMs have evolved, their Figures of Merit, and what is expected in the future. | ||

==Design Structure Matrix (DSM) Allocation== | ==2. Design Structure Matrix (DSM) Allocation== | ||

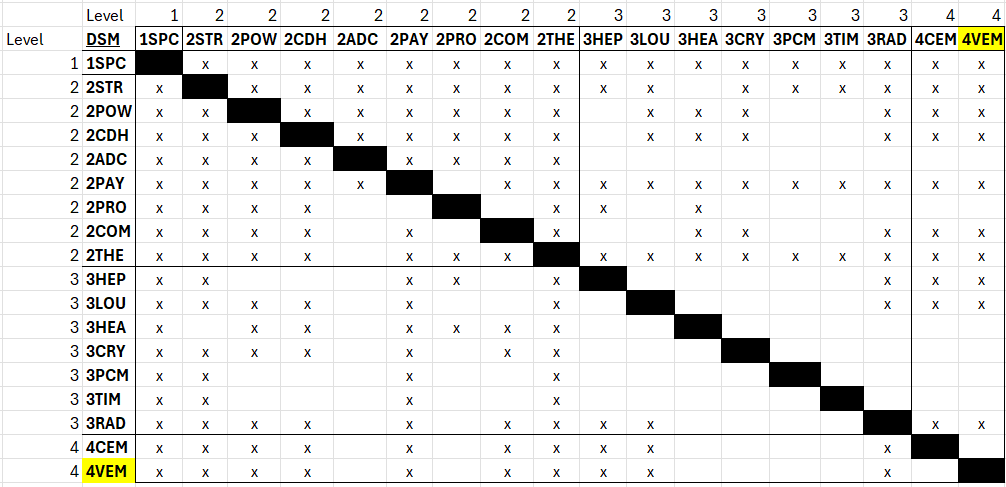

Figure 2 below shows the interactions between various technologies and the 4VEM variable emissivity technology. The x's in the matrix signify interaction. | Figure 2 below shows the interactions between various technologies and the 4VEM variable emissivity technology. The x's in the matrix signify interaction. | ||

[[File:DSMmatrixVEMsActuallyCorrect.png|center]] | [[File:DSMmatrixVEMsActuallyCorrect.png|center]] | ||

<div style="text-align: center;"> | <div style="text-align: center;"> | ||

Figure 2: DSM Matrix | Figure 2: DSM Matrix | ||

| Line 60: | Line 58: | ||

* 3HEP Heat Pipes | * 3HEP Heat Pipes | ||

* 3LOU Louvers | * 3LOU Louvers | ||

* 3HEA Heaters | |||

* 3CRY Cryocoolers | * 3CRY Cryocoolers | ||

* 3PCM Phase-change materials | * 3PCM Phase-change materials | ||

| Line 69: | Line 68: | ||

* 4VEM Variable emissivity materials used for radiators. | * 4VEM Variable emissivity materials used for radiators. | ||

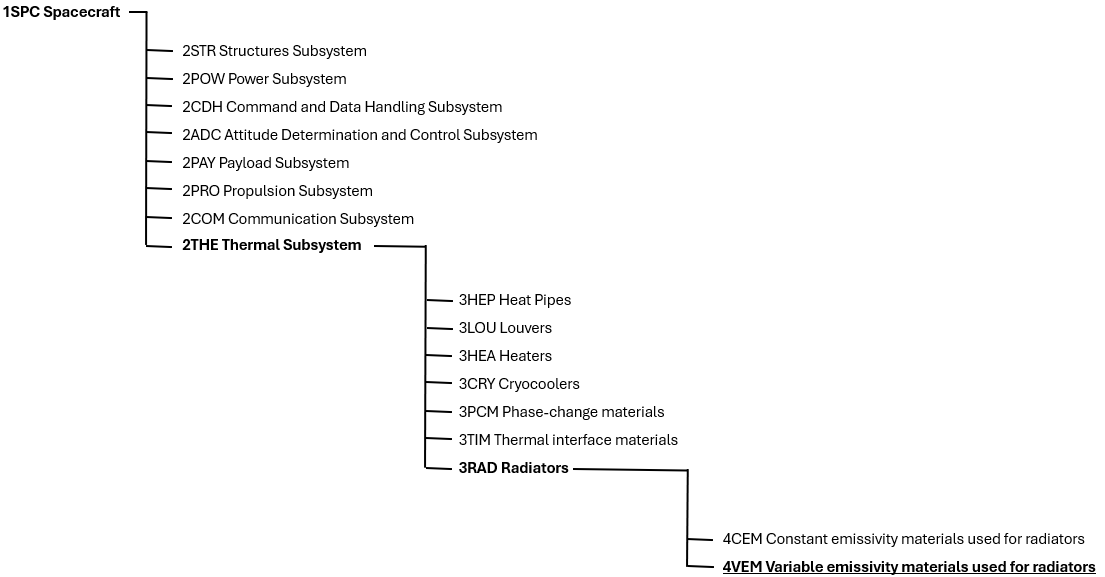

So, VEMs are a small part of the whole spacecraft technology. | So, VEMs are a small part of the whole spacecraft technology. Figure 3 below shows where the 4VEM technology is inside a tree. | ||

[[File:DSMtreeVEMs.png|center]] | |||

<div style="text-align: center;"> | |||

Figure 3: 4VEM Technology Tree Placement | |||

</div> | |||

== 3. Roadmap Model using OPM == | |||

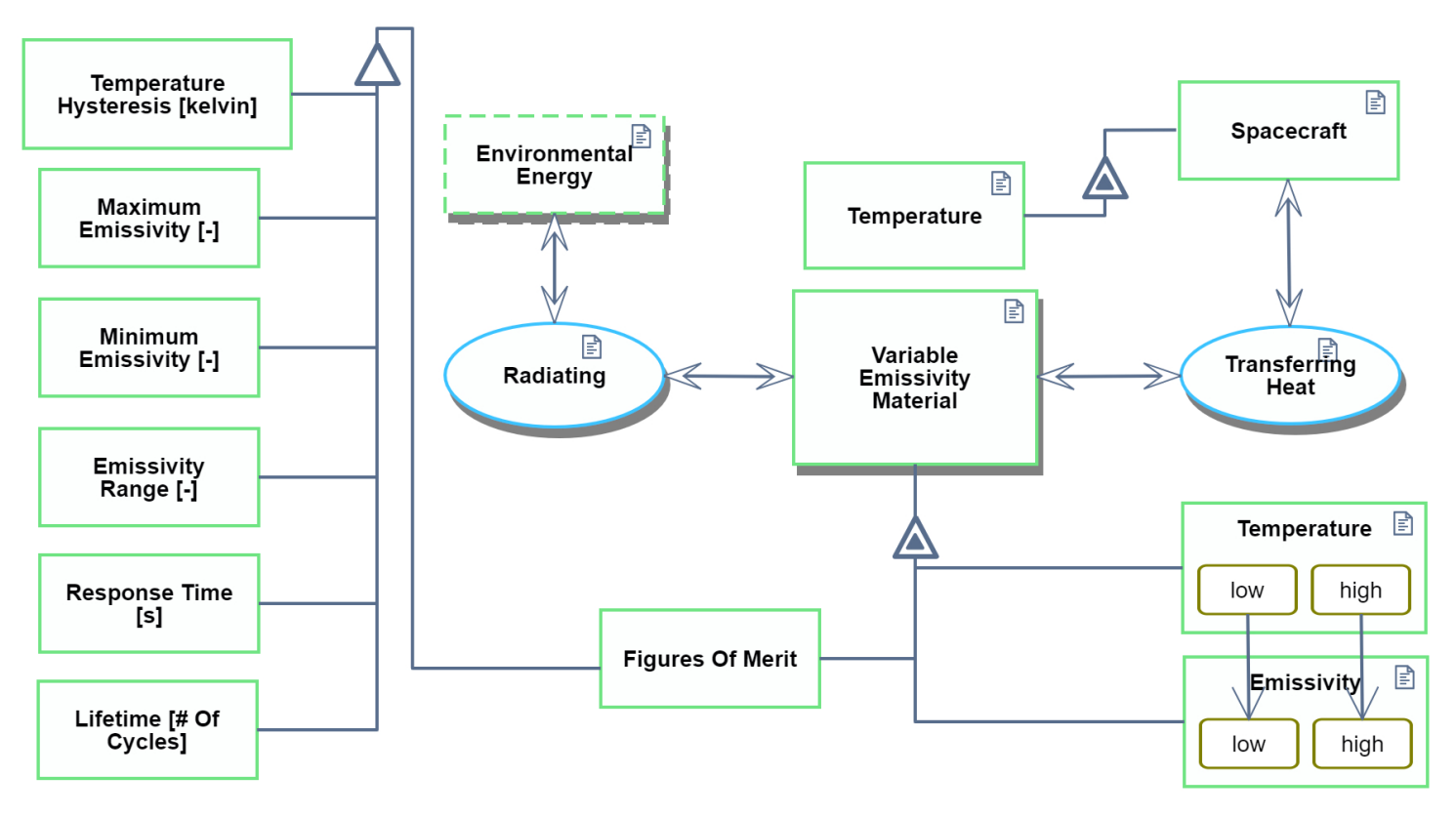

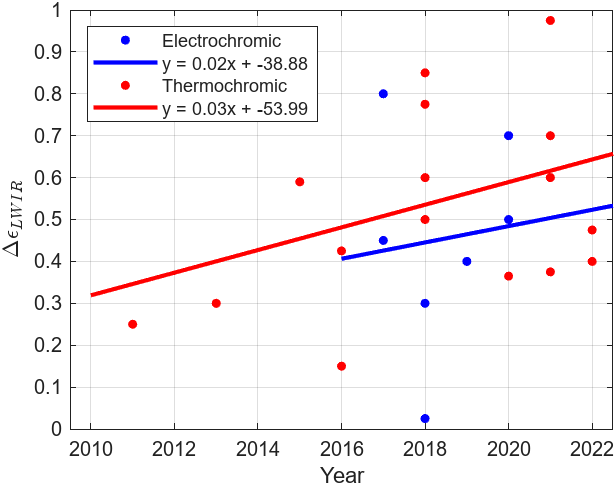

The Object-Process Diagram (OPD) and Object-Process Language (OPL) represented in Figure 4 and Figure 5, respectively, were generated by OPCloud. This model describes the processes and Figures of Merit (FOM) involved with passive spacecraft VEMs, as well as their object interactions. It highlights the thermochromic VEMs discussed in this roadmap, which require no electrical energy to operate. | |||

[[File:VEMOPM.png|center]] | |||

<div style="text-align: center;"> | |||

Figure 4: VEM OPD | |||

</div> | |||

[[File:VEMOPL.png|center]] | |||

<div style="text-align: center;"> | |||

Figure 5: VEM OPL | |||

</div> | |||

== 4. Figures of Merit (FOM) == | |||

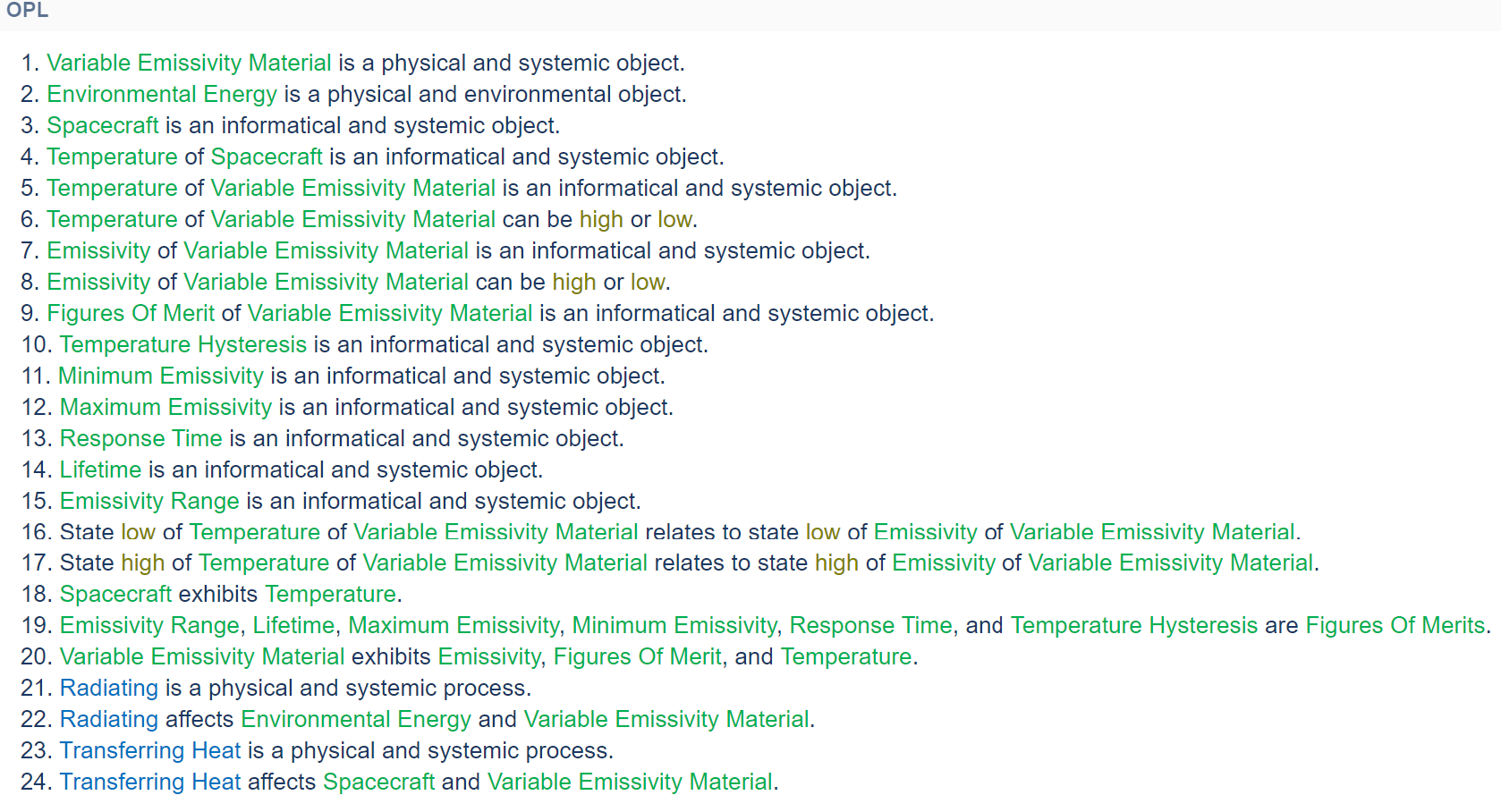

There are several Figures of Merit (FOMs) that describe VEMs. In order to describe the FOMs, an emissivity vs. temperature graph of several VEMs made from vanadium dioxide doped with tungsten will be shown in Figure 6, which is from [1]. | |||

[[File:EmissivityVersusTemperatureVEMs.png|center]] | |||

<div style="text-align: center;"> | |||

Figure 6: Emissivity versus Temperature for Some VEMs, from [1] | |||

</div> | |||

There are four types of VEMs shown in Figure 6; each VEM is made from vanadium dioxide doped with different percentages of tungsten. The first VEM is doped with 3.5% tungsten (the MPB W(3.5%) VEM), the second VEM is doped with 2.5% tungsten, the third VEM is doped with 1.5% tungsten, and the last VEM is doped with 0% tungsten. | |||

For each type of VEM, there is an up curve and a down curve. The up curve corresponds to the emissivity profile when the material is being heated up, and the down curve corresponds to the emissivity profile when the material is being cooled down. The logistic fit curve fits the data to a logistic equation, and the midpoint line is in between the up and down curves. | |||

Because there is a difference in the emissivity vs. temperature curves for when the material is being heated up and when the material is being cooled down, there is hysteresis. One FOM of VEMs is seeing how much hysteresis there is in the material. The less hysteresis, the better because it is easier and quicker to model VEMs with no hysteresis. | |||

One way to calculate the amount of hysteresis is to determine at what temperature the material is when emissivity is at its midpoint and compare that temperature between the heating curve and the cooling curve. So, for the MPB W(0%) down curve, the midpoint temperature <html><la-tex>T_{down}^\ast</la-tex> </html> is around 55 degrees Celsius; for the MPB W(0%) up curve, the midpoint temperature <html><la-tex>T_{up}^\ast</la-tex> </html> is around 80 degrees Celsius. So, the difference between <html><la-tex>T_{up}^\ast</la-tex> </html> and <html><la-tex>T_{down}^\ast</la-tex> </html> is a FOM, which will be called <html><la-tex>\Delta T_{hys}</la-tex> </html>. | |||

<div style="text-align: center;"> | |||

<html> | |||

<la-tex>∆T_{hys}=T_{up}^*-T_{down}^*</la-tex> | |||

</html> | |||

</div> | |||

For the MPB W(0%) curve, | |||

<div style="text-align: center;"> | |||

<html> | |||

<la-tex>∆T_{hys}=80-55 \; degrees \; C = 25 \; degrees \; C</la-tex> | |||

</html> | |||

</div> | |||

The lower <html><la-tex>\Delta T_{hys}</la-tex> </html> is, the less hysteresis. An increase in tungsten doping decreases hysteresis and <html><la-tex>\Delta T_{hys}</la-tex> </html> as shown in Figure 6. The nominal value of <html><la-tex>\Delta T_{hys}</la-tex> </html> is 0 degrees Celsius. | |||

There is also the minimum emissivity <html><la-tex>\varepsilon_L</la-tex> </html> and maximum emissivity <html><la-tex>\varepsilon_H</la-tex> </html> of a VEM. The minimum emissivity corresponds to when the material is relatively cold, and the maximum emissivity corresponds to when the material is relatively hot. The theoretical limit for minimum emissivity is an emissivity of 0, and the theoretical limit for maximum emissivity is an emissivity of 1. Engineers and scientists have generally been trying to make the minimum emissivity as close to 0 as possible and the maximum emissivity as close to 1 as possible. | |||

So, two FOMs are the minimum emissivity <html><la-tex>\varepsilon_L</la-tex> </html> and maximum emissivity <html><la-tex>\varepsilon_H</la-tex></html> of a VEM. For the MPB W(0%) midpoint curve, <html><la-tex>\varepsilon_L</la-tex> </html> is around 0.32, and <html><la-tex>\varepsilon_H</la-tex> </html> is around 0.8. | |||

Another FOM engineers and scientists have been using in analyzing VEM technology is the difference between the minimum emissivity <html><la-tex>\varepsilon_L</la-tex></html> and the maximum emissivity <html><la-tex>\varepsilon_H</la-tex> </html> of a VEM; this FOM, which is the tunability of the material, will be called <html><la-tex>\Delta\varepsilon</la-tex></html>. Engineers and scientists have been trying to maximize <html><la-tex>\Delta\epsilon</la-tex> </html> and trying to get <html><la-tex>\Delta\varepsilon</la-tex> </html> as close to 1 as possible; the nominal value for <html><la-tex>\Delta\varepsilon</la-tex> </html> is 1. | |||

<div style="text-align: center;"> | |||

<html> | |||

<la-tex>\Delta\varepsilon=\varepsilon_H-\varepsilon_L</la-tex> | |||

</html> | |||

</div> | |||

So, for the MPB W(0%) midpoint curve, with an <html><la-tex>\varepsilon_L</la-tex> </html> of around 0.32 and an <html><la-tex>\varepsilon_H</la-tex> </html> of around 0.8, | |||

<div style="text-align: center;"> | |||

<html> | |||

<la-tex>\Delta\varepsilon=0.8-0.32=0.48</la-tex> | |||

</html> | |||

</div> | |||

The closer <html><la-tex>\varepsilon_L</la-tex> </html>, <html><la-tex>\varepsilon_H</la-tex> </html>, and <html><la-tex>\Delta\varepsilon</la-tex> </html> are to their nominal values, the easier it should be for spacecraft to passively regulate their temperature. | |||

The below table presents the FOM that can be used to evaluate various VEMs. | |||

{| class="wikitable" | |||

|- | |||

! Figure of Merit !! Units !! Description | |||

|- | |||

| Temperature Hysteresis (<html><la-tex>\Delta T_{hys}</la-tex></html>)|| [K] || This describes how large hysteresis is for the VEM, and it is a difference of temperatures. The smaller the quantity, the better. The nominal value is 0 Kelvin (or 0 degrees Celsius). | |||

|- | |||

| Minimum Emissivity (<html><la-tex>\varepsilon_L</la-tex></html>) || [-] || This is the minimum emissivity of a VEM. The nominal value is 0. | |||

|- | |||

| Maximum Emissivity (<html><la-tex>\varepsilon_H</la-tex></html>) || [-] || This is the maximum emissivity of a VEM. The nominal value is 1. | |||

|- | |||

| Emissivity Range (<html><la-tex>\Delta\varepsilon</la-tex></html>) || [-] || This is the difference between the maximum and minimum emissivities of VEMs. The nominal value is 1. | |||

|- | |||

| Lifetime (<html><la-tex>n</la-tex></html>) || [Cycles] || This is the number of emissivity state switches the material can undergo before failure. The higher this value, the better the VEM. | |||

|- | |||

| Response Time (<html><la-tex>t</la-tex></html>) || [s] || This is the amount of time it takes for the device to switch between different emissivity states. The lower the response time, the better the thermal control. | |||

|} | |||

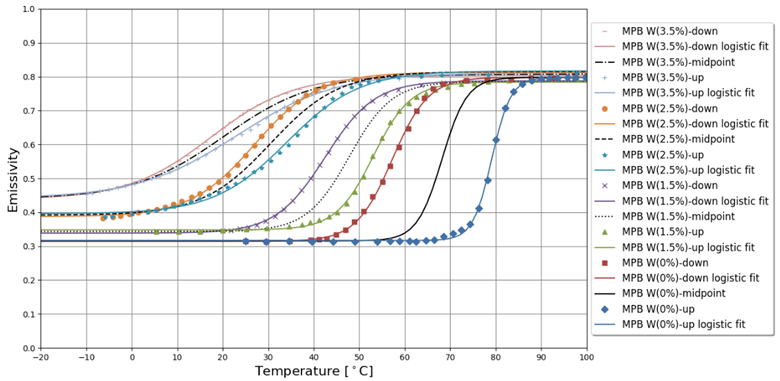

Figure 7 displays a diverse spread of variability in emissivity ranges for active and passive types of modern VEMs over time using data from [2] and [3], which also include the specific VEM technologies plotted. The distribution of the emissivity ranges is a reminder that emissivity range may not necessarily be the most important figure of merit for a specific VEM application, hence why there is not a clear upward trend in the data over time. Although the data is very disperse, linear regression models were applied, and they show an improvement for electrochromic and thermochromic VEMs of 0.02/year and 0.03/year, respectively. Due to physics principles, the theoretical emissivity range for a given material is 1, with the maximum emissivity being 1 and the minimum being 0. This cannot exceed 1 due to the law of conservation of energy. That it, an object cannot emit more than 100% of its energy. In terms of application to passive spacecraft thermal control, thermochromic VEMs are at the incubation stage of the technology lifecycle due to only one VEM technology, Thermal Control Tiles designed by MPB Communications, being sent to space [4][5]. However, there are initiatives for other thermochromic VEMs to be sent to space in the near future by the Air Force Research Laboratory [6]. | |||

[[File:VEMEmissivityRange.png|center]] | |||

<div style="text-align: center;"> | |||

Figure 7: Modern VEM Emissivity Ranges with Data Adapted from [2] and [3] | |||

</div> | |||

==5. Alignment with Company Strategic Drivers== | |||

Below is a table that has company strategic drivers, how they align with the roadmap, and targets for the company. | |||

{| class="wikitable" | |||

|- | |||

! Number !! Strategic Driver !! Alignment and Targets | |||

|- | |||

| 1 || To develop a || df | |||

|- | |||

| 2 || To develop dust-mitigated variable emissivity radiators for spacecraft on the moon. Lunar dust greatly affects spacecraft radiators on the moon [7], so by incorporating dust mitigation technology to the company's variable emissivity materials, the market can expand to lunar spacecraft more easily.|| The target would be to develop a variable emissivity material that easily repels lunar dust. This driver is '''not''' currently aligned with the roadmap because the FOMs that are explored in this roadmap are not about how VEMs repel lunar dust. | |||

|} | |||

One of NASA's main civil space technology shortfalls is surviving the lunar night [8], and having dust-mitigated VEMs will help spacecraft on the moon survive the night by decreasing heater power required. So, the company would like to eventually expand to create lunar dust-mitigated variable emissivity materials, but it will not be the main focus of the company currently; strategic driver 2 is not a requirement of this roadmap. | |||

==6. Positioning of Company versus Competition== | |||

==7. Technical Model== | |||

==8. Financial Model== | |||

==9. Portfolio of R&D Projects and Prototypes== | |||

==10. Key Publications and Patents== | |||

Below are descriptions of key publications and patents related to thermochromic radiators used for spacecraft. | |||

=== Publications === | |||

There have been several papers related to thermochromic spacecraft radiators. Below is a list of two important papers. | |||

*'''Title:''' VO2-based smart coatings with improved emittance-switching properties for an energy-efficient near room-temperature thermal control of spacecrafts | |||

**'''Authors:''' A. Hendaoui, N. Émond, S. Dorval, M. Chaker, and E. Haddad | |||

**'''Year:''' 2013 | |||

**'''Journal:''' Solar Energy Materials and Solar Cells, volume 117, pages 494-498 | |||

**'''DOI:''' https://doi.org/10.1016/j.solmat.2013.07.023 | |||

**'''Summary of Paper:''' Vanadium dioxide thin-film radiators were improved for spacecraft thermal control by adding a silicon-oxide layer and by doping with tungsten, which increased the material’s tunability (<html><la-tex>\Delta\varepsilon</la-tex></html>), increased the maximum emissivity (<html><la-tex>\varepsilon_H</la-tex></html>), lowered the transition temperature of the material, and decreased hysteresis. | |||

**'''Relevance of Paper:''' This paper improved several Figures of Merit of thermochromic vanadium dioxide radiators. | |||

*'''Title:''' VO2-based switchable radiator for spacecraft thermal control | |||

**'''Authors:''' Heungsoo Kim, Kwok Cheung, Raymond C. Y. Auyeung, Donald E. Wilson, Kristin M. Charipar, Alberto Piqué, and Nicholas A. Charipar | |||

**'''Year:''' 2019 | |||

**'''Journal:''' Nature Scientific Reports, 9, article number 11329 | |||

**'''DOI:''' https://doi.org/10.1038/s41598-019-47572-z | |||

**'''Summary of Paper:''' Calorimetric and optical measurements of vanadium dioxide thin film materials were taken to characterize their use case in spacecraft. Theoretical and experimental radiative properties are presented. | |||

**'''Relevance of Paper:''' Unlike many papers that were published before, this paper provided calorimetric measurements of vanadium dioxide thin film materials. Calorimetric measurements are more suited for calculating total radiative heat transfer than optical measurements. | |||

=== Patents === | |||

Because metamaterial thermochromic radiators is not a technology that has been widely used in spacecraft, there are relatively few patents related to it being used on spacecraft. However, there are decades worth of patents describing how to prepare thin film coatings, electrochromic radiators, and similar areas that are related to thermochromic spacecraft radiators. Below is a list describing two important US patents. | |||

* '''Title:''' THERMAL CONTROL COATINGS | |||

**'''Patent Number:''' US 7.691,435 B2 | |||

**'''Date of Patent:''' Apr. 6, 2010 | |||

**'''Inventors:''' John G. Keller, Robert M. Moy, Jane R. Felland | |||

**'''Assignee:''' The Boeing Company | |||

**'''Classifications:''' C23C28/042, C23C28/322, C23C28/34, C23C28/3455, C23C28/42 | |||

**'''Description of Invention:''' A multi-layer thermal control coating for spacecraft that may have thermochromic layers of silicon and vanadium dioxide in addition to having solar rejection layers made from zinc sulfide and magnesium fluoride. | |||

**'''Relevance of Invention:''' It describes another way of incorporating vanadium dioxide thermochromic material into spacecraft radiators. | |||

* '''Title:''' VARIABLE EMITTANCE THERMOCHROMIC MATERIAL AND SATELLITE SYSTEM | |||

**'''Patent Number:''' US 7,761,053 B2 | |||

**'''Date of Patent:''' Jul. 20, 2010 | |||

**'''Inventors:''' Roman V. Kruzelecky, Emile Haddad, Brian Wong, Wes R. Jamroz | |||

**'''Assignee:''' MPB Communications Inc. | |||

**'''Classifications:''' C09K9/00, Y10T428/24413, Y10T428/2462, Y10T428/24851, Y10T428/24893, Y10T428/24909, Y10T428/31504, Y10T428/31678 | |||

**'''Description of Invention:''' Multiple variations of a thermochromic variable emissivity material used for spacecraft radiators, some of which have vanadium dioxide as the transition metal. These materials are used for communications satellites. | |||

**'''Relevance of Invention:''' MBP Communications Inc. flew their thermochromic smart radiator device on a Canadian small satellite in the 2020's [4][5]. | |||

==11. Technology Strategy Statement== | |||

==Sources== | ==Sources== | ||

[1] I. Foster, "Variable Emissivity Materials for Thermal Radiators: Introduction to Characterizing Thermochromic Infrared Surfaces in Space," in AIAA SciTech 2024 Forum, 2024. https://arc-aiaa-org.libproxy.mit.edu/doi/abs/10.2514/6.2024-1295 | [1] I. Foster, "Variable Emissivity Materials for Thermal Radiators: Introduction to Characterizing Thermochromic Infrared Surfaces in Space," in AIAA SciTech 2024 Forum, 2024. https://arc-aiaa-org.libproxy.mit.edu/doi/abs/10.2514/6.2024-1295 | ||

[2] https://arc.aiaa.org/doi/10.2514/1.T6555 | |||

[3] https://doi.org/10.1016/j.xcrp.2022.101198 | |||

[4] https://umstarlab.ca/index.php/past-projects/ | |||

[5] https://ttu-ir.tdl.org/items/4b815052-4a4a-4031-9624-48605cae9c89 | |||

[6] https://afresearchlab.com/technology/space-power-beaming/ | |||

[7] https://ntrs.nasa.gov/citations/20220018746 | |||

[8] https://www.nasa.gov/wp-content/uploads/2024/07/civil-space-shortfall-ranking-july-2024.pdf?emrc=67223caeba458 | |||

Revision as of 18:52, 30 October 2024

Technology Roadmap Sections and Deliverables

- 4VEM - Variable Emissivity Materials for Spacecraft

Thermochromic variable emissivity materials (VEMs) can be used for a wide range of applications, from spacecraft radiators to windows used on Earth. For this technology roadmap, the use of VEMs for spacecraft radiators will be the focus.

1. Roadmap Overview

The only way that orbiting spacecraft can reject heat is through radiation. Because of this, the thermo-optical properties of spacecraft radiators are important. The thermo-optical properties of radiators, such as emissivity, determine how much heat is radiated away.

There is a way to calculate how much heat is radiated from a surface, and it is shown in the equation below. Q is heat being radiated away from a surface, A is the area of the radiating surface, σ is the Stefan-Boltzmann constant, ε is the emissivity of the surface material, and T is the temperature of the surface.

The emissivity of a material is directly proportional to the heat radiated away. So, when a material has high emissivity, more heat is radiated away. Most materials have a constant emissivity, but there are some materials whose emissivity can change based on environmental conditions or whether they are powered. These materials are called variable emissivity materials (VEMs).

There are active (electrochromic) and passive (thermochromic) VEMs. Electrochromic VEMs require power input to change emissivity, unlike thermochromic VEMs which change their emissivity based on their temperature. The technology of thermochromic VEMs whose emissivity is lower at low temperatures and higher at high temperatures is expected to be widely used in radiators for spacecraft, because compared to constant-emissivity radiators, it reduces spacecraft heater power requirements and temperature swings, all without power or human input. Figure 1 shows how a thermochromic VEM can help spacecraft more efficiently manage their temperature.

Figure 1: Diagram of how VEMs affect spacecraft, from [1]

This roadmap will explore how thermochromic VEMs have evolved, their Figures of Merit, and what is expected in the future.

2. Design Structure Matrix (DSM) Allocation

Figure 2 below shows the interactions between various technologies and the 4VEM variable emissivity technology. The x's in the matrix signify interaction.

Figure 2: DSM Matrix

VEMs are part of a larger technology tree, with the 1st level being the technology of a general spacecraft:

- 1SPC Spacecraft

The 1SPC Spacecraft technology has a variety of subsystem technologies; all of the subsystems of a spacecraft interact with each other and make the spacecraft work, and they make up the second level:

- 2STR Structures Subsystem

- 2POW Power Subsystem

- 2CDH Command and Data Handling Subsystem

- 2ADC Attitude Determination and Control Subsystem

- 2PAY Payload Subsystem

- 2PRO Propulsion Subsystem

- 2COM Communication Subsystem

- 2THE Thermal Subsystem.

VEMs are part of the 2THE thermal subsystem of a spacecraft. There are many technologies that are used for spacecraft thermal subsystems, and they are in the 3rd level:

- 3HEP Heat Pipes

- 3LOU Louvers

- 3HEA Heaters

- 3CRY Cryocoolers

- 3PCM Phase-change materials

- 3TIM Thermal interface materials

- 3RAD Radiators

VEMs are used in the 3RAD Radiators technology. The 3RAD technology can be split into two groups as well, which comprise the 4th level:

- 4CEM Constant emissivity materials used for radiators

- 4VEM Variable emissivity materials used for radiators.

So, VEMs are a small part of the whole spacecraft technology. Figure 3 below shows where the 4VEM technology is inside a tree.

Figure 3: 4VEM Technology Tree Placement

3. Roadmap Model using OPM

The Object-Process Diagram (OPD) and Object-Process Language (OPL) represented in Figure 4 and Figure 5, respectively, were generated by OPCloud. This model describes the processes and Figures of Merit (FOM) involved with passive spacecraft VEMs, as well as their object interactions. It highlights the thermochromic VEMs discussed in this roadmap, which require no electrical energy to operate.

Figure 4: VEM OPD

Figure 5: VEM OPL

4. Figures of Merit (FOM)

There are several Figures of Merit (FOMs) that describe VEMs. In order to describe the FOMs, an emissivity vs. temperature graph of several VEMs made from vanadium dioxide doped with tungsten will be shown in Figure 6, which is from [1].

Figure 6: Emissivity versus Temperature for Some VEMs, from [1]

There are four types of VEMs shown in Figure 6; each VEM is made from vanadium dioxide doped with different percentages of tungsten. The first VEM is doped with 3.5% tungsten (the MPB W(3.5%) VEM), the second VEM is doped with 2.5% tungsten, the third VEM is doped with 1.5% tungsten, and the last VEM is doped with 0% tungsten.

For each type of VEM, there is an up curve and a down curve. The up curve corresponds to the emissivity profile when the material is being heated up, and the down curve corresponds to the emissivity profile when the material is being cooled down. The logistic fit curve fits the data to a logistic equation, and the midpoint line is in between the up and down curves.

Because there is a difference in the emissivity vs. temperature curves for when the material is being heated up and when the material is being cooled down, there is hysteresis. One FOM of VEMs is seeing how much hysteresis there is in the material. The less hysteresis, the better because it is easier and quicker to model VEMs with no hysteresis.

One way to calculate the amount of hysteresis is to determine at what temperature the material is when emissivity is at its midpoint and compare that temperature between the heating curve and the cooling curve. So, for the MPB W(0%) down curve, the midpoint temperature

For the MPB W(0%) curve,

The lower

There is also the minimum emissivity

So, two FOMs are the minimum emissivity

Another FOM engineers and scientists have been using in analyzing VEM technology is the difference between the minimum emissivity

So, for the MPB W(0%) midpoint curve, with an

The closer

The below table presents the FOM that can be used to evaluate various VEMs.

| Figure of Merit | Units | Description |

|---|---|---|

| Temperature Hysteresis ( |

[K] | This describes how large hysteresis is for the VEM, and it is a difference of temperatures. The smaller the quantity, the better. The nominal value is 0 Kelvin (or 0 degrees Celsius). |

| Minimum Emissivity ( |

[-] | This is the minimum emissivity of a VEM. The nominal value is 0. |

| Maximum Emissivity ( |

[-] | This is the maximum emissivity of a VEM. The nominal value is 1. |

| Emissivity Range ( |

[-] | This is the difference between the maximum and minimum emissivities of VEMs. The nominal value is 1. |

| Lifetime ( |

[Cycles] | This is the number of emissivity state switches the material can undergo before failure. The higher this value, the better the VEM. |

| Response Time ( |

[s] | This is the amount of time it takes for the device to switch between different emissivity states. The lower the response time, the better the thermal control. |

Figure 7 displays a diverse spread of variability in emissivity ranges for active and passive types of modern VEMs over time using data from [2] and [3], which also include the specific VEM technologies plotted. The distribution of the emissivity ranges is a reminder that emissivity range may not necessarily be the most important figure of merit for a specific VEM application, hence why there is not a clear upward trend in the data over time. Although the data is very disperse, linear regression models were applied, and they show an improvement for electrochromic and thermochromic VEMs of 0.02/year and 0.03/year, respectively. Due to physics principles, the theoretical emissivity range for a given material is 1, with the maximum emissivity being 1 and the minimum being 0. This cannot exceed 1 due to the law of conservation of energy. That it, an object cannot emit more than 100% of its energy. In terms of application to passive spacecraft thermal control, thermochromic VEMs are at the incubation stage of the technology lifecycle due to only one VEM technology, Thermal Control Tiles designed by MPB Communications, being sent to space [4][5]. However, there are initiatives for other thermochromic VEMs to be sent to space in the near future by the Air Force Research Laboratory [6].

Figure 7: Modern VEM Emissivity Ranges with Data Adapted from [2] and [3]

5. Alignment with Company Strategic Drivers

Below is a table that has company strategic drivers, how they align with the roadmap, and targets for the company.

| Number | Strategic Driver | Alignment and Targets |

|---|---|---|

| 1 | To develop a | df |

| 2 | To develop dust-mitigated variable emissivity radiators for spacecraft on the moon. Lunar dust greatly affects spacecraft radiators on the moon [7], so by incorporating dust mitigation technology to the company's variable emissivity materials, the market can expand to lunar spacecraft more easily. | The target would be to develop a variable emissivity material that easily repels lunar dust. This driver is not currently aligned with the roadmap because the FOMs that are explored in this roadmap are not about how VEMs repel lunar dust. |

One of NASA's main civil space technology shortfalls is surviving the lunar night [8], and having dust-mitigated VEMs will help spacecraft on the moon survive the night by decreasing heater power required. So, the company would like to eventually expand to create lunar dust-mitigated variable emissivity materials, but it will not be the main focus of the company currently; strategic driver 2 is not a requirement of this roadmap.

6. Positioning of Company versus Competition

7. Technical Model

8. Financial Model

9. Portfolio of R&D Projects and Prototypes

10. Key Publications and Patents

Below are descriptions of key publications and patents related to thermochromic radiators used for spacecraft.

Publications

There have been several papers related to thermochromic spacecraft radiators. Below is a list of two important papers.

- Title: VO2-based smart coatings with improved emittance-switching properties for an energy-efficient near room-temperature thermal control of spacecrafts

- Authors: A. Hendaoui, N. Émond, S. Dorval, M. Chaker, and E. Haddad

- Year: 2013

- Journal: Solar Energy Materials and Solar Cells, volume 117, pages 494-498

- DOI: https://doi.org/10.1016/j.solmat.2013.07.023

- Summary of Paper: Vanadium dioxide thin-film radiators were improved for spacecraft thermal control by adding a silicon-oxide layer and by doping with tungsten, which increased the material’s tunability (

\Delta\varepsilon ), increased the maximum emissivity (\varepsilon_H ), lowered the transition temperature of the material, and decreased hysteresis. - Relevance of Paper: This paper improved several Figures of Merit of thermochromic vanadium dioxide radiators.

- Title: VO2-based switchable radiator for spacecraft thermal control

- Authors: Heungsoo Kim, Kwok Cheung, Raymond C. Y. Auyeung, Donald E. Wilson, Kristin M. Charipar, Alberto Piqué, and Nicholas A. Charipar

- Year: 2019

- Journal: Nature Scientific Reports, 9, article number 11329

- DOI: https://doi.org/10.1038/s41598-019-47572-z

- Summary of Paper: Calorimetric and optical measurements of vanadium dioxide thin film materials were taken to characterize their use case in spacecraft. Theoretical and experimental radiative properties are presented.

- Relevance of Paper: Unlike many papers that were published before, this paper provided calorimetric measurements of vanadium dioxide thin film materials. Calorimetric measurements are more suited for calculating total radiative heat transfer than optical measurements.

Patents

Because metamaterial thermochromic radiators is not a technology that has been widely used in spacecraft, there are relatively few patents related to it being used on spacecraft. However, there are decades worth of patents describing how to prepare thin film coatings, electrochromic radiators, and similar areas that are related to thermochromic spacecraft radiators. Below is a list describing two important US patents.

- Title: THERMAL CONTROL COATINGS

- Patent Number: US 7.691,435 B2

- Date of Patent: Apr. 6, 2010

- Inventors: John G. Keller, Robert M. Moy, Jane R. Felland

- Assignee: The Boeing Company

- Classifications: C23C28/042, C23C28/322, C23C28/34, C23C28/3455, C23C28/42

- Description of Invention: A multi-layer thermal control coating for spacecraft that may have thermochromic layers of silicon and vanadium dioxide in addition to having solar rejection layers made from zinc sulfide and magnesium fluoride.

- Relevance of Invention: It describes another way of incorporating vanadium dioxide thermochromic material into spacecraft radiators.

- Title: VARIABLE EMITTANCE THERMOCHROMIC MATERIAL AND SATELLITE SYSTEM

- Patent Number: US 7,761,053 B2

- Date of Patent: Jul. 20, 2010

- Inventors: Roman V. Kruzelecky, Emile Haddad, Brian Wong, Wes R. Jamroz

- Assignee: MPB Communications Inc.

- Classifications: C09K9/00, Y10T428/24413, Y10T428/2462, Y10T428/24851, Y10T428/24893, Y10T428/24909, Y10T428/31504, Y10T428/31678

- Description of Invention: Multiple variations of a thermochromic variable emissivity material used for spacecraft radiators, some of which have vanadium dioxide as the transition metal. These materials are used for communications satellites.

- Relevance of Invention: MBP Communications Inc. flew their thermochromic smart radiator device on a Canadian small satellite in the 2020's [4][5].

11. Technology Strategy Statement

Sources

[1] I. Foster, "Variable Emissivity Materials for Thermal Radiators: Introduction to Characterizing Thermochromic Infrared Surfaces in Space," in AIAA SciTech 2024 Forum, 2024. https://arc-aiaa-org.libproxy.mit.edu/doi/abs/10.2514/6.2024-1295

[2] https://arc.aiaa.org/doi/10.2514/1.T6555

[3] https://doi.org/10.1016/j.xcrp.2022.101198

[4] https://umstarlab.ca/index.php/past-projects/

[5] https://ttu-ir.tdl.org/items/4b815052-4a4a-4031-9624-48605cae9c89

[6] https://afresearchlab.com/technology/space-power-beaming/