Difference between revisions of "Ballistic Vests"

| (236 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Technology Roadmap Sections and Deliverables= | =Technology Roadmap Sections and Deliverables= | ||

https://www.youtube.com/watch?v=IwBLL7Z3OvU&t=34s (Start at 1:57 and End at 2:19) | |||

The selected technology that Team 6 will be spending the remainder of the semester on developing a technology road map is ballistic vest technology (specifically for military and law enforcement applications). | The selected technology that Team 6 will be spending the remainder of the semester on developing a technology road map is ballistic vest technology (specifically for military and law enforcement applications). | ||

| Line 7: | Line 7: | ||

This indicates that we are dealing with a “level 2” roadmap at the product level. | This indicates that we are dealing with a “level 2” roadmap at the product level. | ||

==Roadmap Overview== | ==1.1 Roadmap Overview== | ||

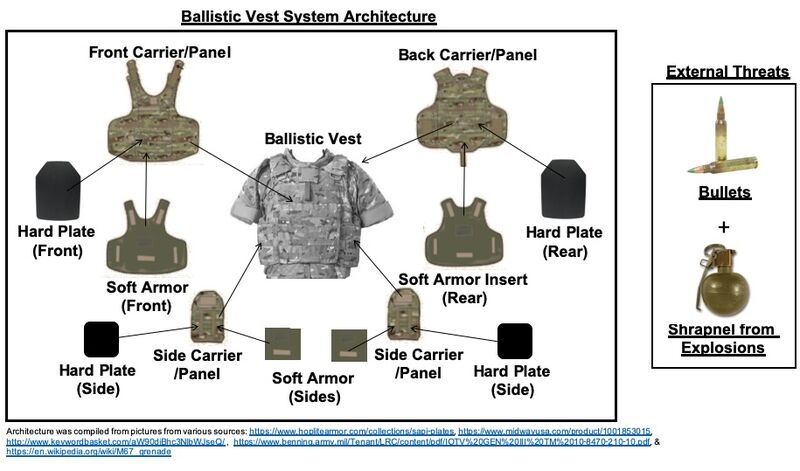

The working principle and architecture of Ballistic Vests is depicted in the below. | The working principle and architecture of Ballistic Vests is depicted in the below diagram. | ||

[[File:TM6S2.jpg]] | [[File:TM6S2.jpg|800px]] | ||

A ballistic vest works by absorbing the kinetic energy from a high-speed projectile (bullet or shrapnel from an explosion) at the point of impact over a wide area. The ballistic vest is meant to spread the kinetic energy by displacing it across the ballistic vest materials in a process called material deformation. The deformation occurs in two-fold, deformation of the ballistic vest materials as the bullet absorbs the kinetic energy and deformation of the bullet itself, called mushrooming. The remainder of the energy is consumed as heat. | A ballistic vest works by absorbing the kinetic energy from a high-speed projectile (bullet or shrapnel from an explosion) at the point of impact over a wide area. The ballistic vest is meant to spread the kinetic energy by displacing it across the ballistic vest materials in a process called material deformation. The deformation occurs in two-fold, deformation of the ballistic vest materials as the bullet absorbs the kinetic energy and deformation of the bullet itself, called mushrooming. The remainder of the energy is consumed as heat. | ||

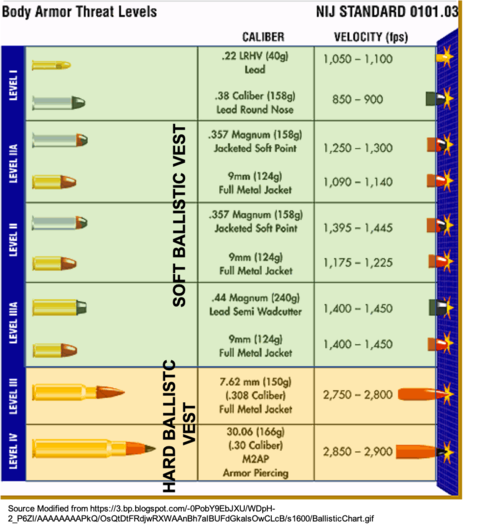

This technology is a lifesaving technology to aid military personnel and law enforcement during their daily activities. A ballistic vest is typically worn on an individual’s chest and is meant to be replaced after it has taken an impact (from high speed projectile or mishandling of vest e.g. dropped) or date of manufacturing has expired. There are six levels of protection (Type I, Type IIA, Type II, Type | This technology is a lifesaving technology to aid military personnel and law enforcement during their daily activities. A ballistic vest is typically worn on an individual’s chest and is meant to be replaced after it has taken an impact (from high speed projectile or mishandling of vest e.g. dropped) or date of manufacturing has expired. There are six levels of protection; Type I, Type IIA, Type II, Type IIIA, Type III, and Type IV (See below chart for the six threat levels of protection. Soft ballistic vests are made of soft armor and consist of Type I, Type IIA, Type II, and Type IIIA which primarily protect against handgun rounds. Whereas, hard ballistic vests are made of hard amor and consist of Type III and Type IV which primarily protect against rifle rounds. The history of personal armor dates back to 500 BC when chain mail/coat mail was used as a form of individual protection from slashing blows by an edged weapon (e.g. swords). Modern day individual body armor is meant to protect from high speed projectiles. New fibers were discovered in the 1960’s for the possibility to make resistant vests and DuPont developed Kevlar ballistic fabric in the 1970s. | ||

[[File:Threat Levels.png|500px]] | |||

==1.2 Design Structure Matrix (DSM) Allocation== | |||

[[File:DSMBV.png|800px]] | |||

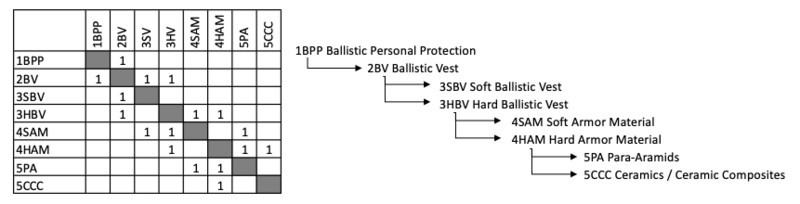

==Roadmap Model using OPM== | The 2-BV tree that we can extract from the DSM above shows us that the Soft Vest (2BV) is part of a larger initiative on Ballistic Personal Protection (1BPP) and that it requires the following key enabling technologies at the subsystem level: 4SAM Soft Armor Material, 4HAM Hard Armor Material and 5PA Para-Aarmids and 5CCC Ceramics / Ceramic Composites. | ||

==1.3 Roadmap Model using OPM== | |||

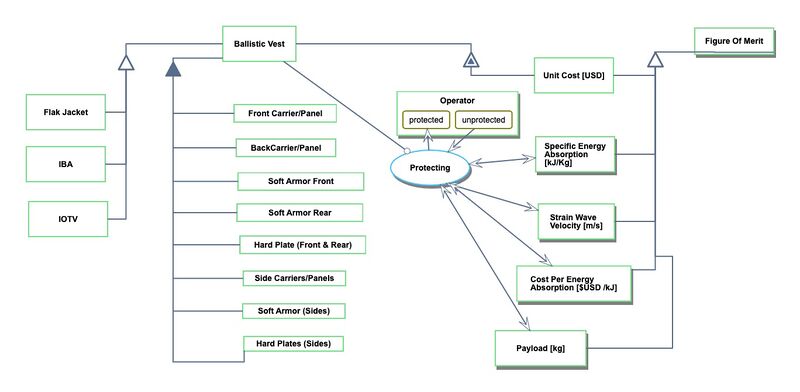

We provide an Object-Process-Diagram (OPD) of the 2BV roadmap in the figure below. This diagram captures the main object of the roadmap (Ballistic Vest), its various instances including common ballistic vest products, its decomposition into components (front carrier/panel, rear carrier/panel, side carrier/panel, soft armor (front & rear), hard plate (front, back, & sides, etc.), its characterization by Figures of Merit (FOMs) as well as the main processes (Protecting with two states protected and unprotected). | We provide an Object-Process-Diagram (OPD) of the 2BV roadmap in the figure below. This diagram captures the main object of the roadmap (Ballistic Vest), its various instances including common ballistic vest products, its decomposition into components (front carrier/panel, rear carrier/panel, side carrier/panel, soft armor (front & rear), hard plate (front, back, & sides, etc.), its characterization by Figures of Merit (FOMs) as well as the main processes (Protecting with two states protected and unprotected). | ||

[[File:TM6S3OPM.JPG]] | [[File:TM6S3OPM.JPG|800px]] | ||

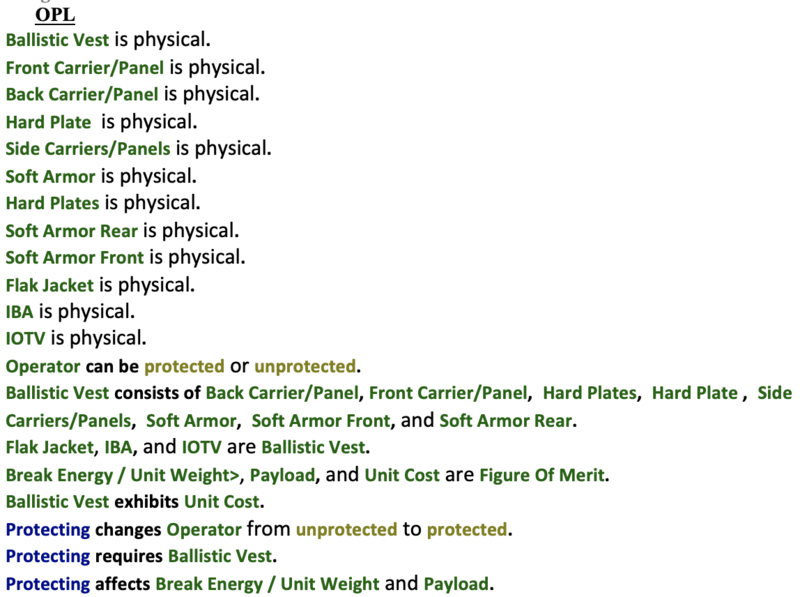

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language. | An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language. | ||

[[File:TM6S3.2.png]] | [[File:TM6S3.2.png|800px]] | ||

==1.4 Figures of Merit== | |||

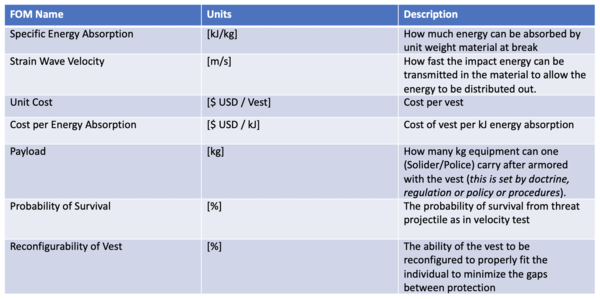

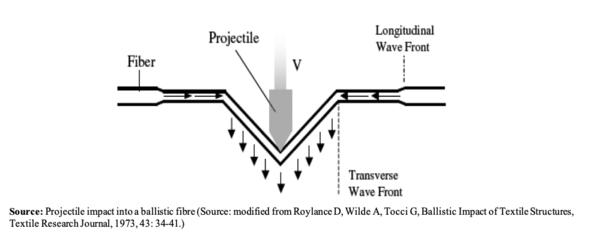

The table below shows a list of FOMs by which ballistic vest can be assessed. | |||

[[File:BV3UPDATE.png|600px]] | |||

[[File:Gov Equations BV.png|800px]] | |||

'''Background:''' | |||

Male Vs. Female: The majority of body armor on the current market is primarily designed for males but there are some companies producing body armor for females. In recent years, the U.S. Army revised the 5th generation of improved outer tactical vest to be specifically designed for females. They addressed the following seven issues; 1) Length, 2) Side plates too large/long/wide/better location, 3) Too big in upper chest/ shoulder, 4) Adjustability in the shoulder, 5) Inability to seat a weapon/ too much bulk in upper body, 6) Issues with collar/yoke/too much bulk, and 7)Donning and doffing difficult. | |||

The | |||

Cost: Typically the higher the level of the protection, the higher the cost. The typical cost of a ballistic vest is declining for old technology due to efficiencies in process manufacturing and the cost of the latest technology integrated into the ballistic vest is on the incline. The typical cost of soft ballistic vests are in the range from $120 to $400 for Level I to Level IIA and $400 to $1200 for Level IIIA to Level IV. | |||

[[File:Projectile.png|600px]] | |||

== | ==1.5 Alignment with Company Strategic Drivers== | ||

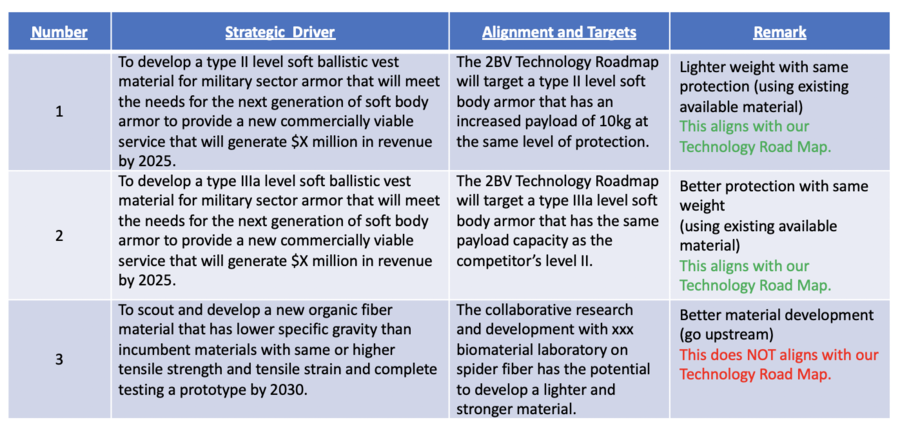

The | The table below shows our companies strategic drivers and alignment of 2BV technology with roadmap. | ||

[[File: | [[File:SD 2.png|900px]] | ||

The | The two strategic drivers (1 and 2) show that the company views the next generation of soft body armor as a potential new business product that will generate $X revenue by 2027 and $X revenue by 2028 respectively. Strategic Driver 1 of a Type IIIA soft ballistic vest has the alignment and targets of 4 more kilograms of payload than current model. The companies new Type IIIA payload will be greater than competitors Type IIIA, thus increased value in payload compared to competitors’ same type product). Strategic Driver 2 of a Type III level soft ballistic vest has the alignment and targets of new Type III payload will be the same as the competitors Type IIIA payload, but with an increased value in protection level. Strategic driver 3 is a more aggressive driver that aligns with the 2BV technology roadmap with a lead developer strategy to have the most advanced material with higher protection and lighter integrated into soft body armor. | ||

The strategic driver 3 looks very interesting and may enable us to have a technological breakthrough in raw material, but is not well aligned with our roadmap. Our roadmap is focused on vest technology and products, while the strategic driver 3 will need us to go to upstream for raw material development and manufacturing. | |||

==1.6 Positioning of Company vs. Competition== | |||

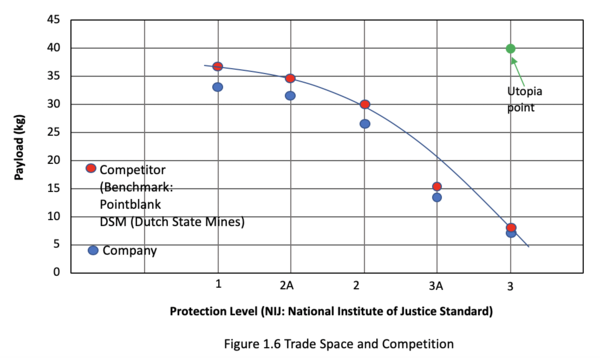

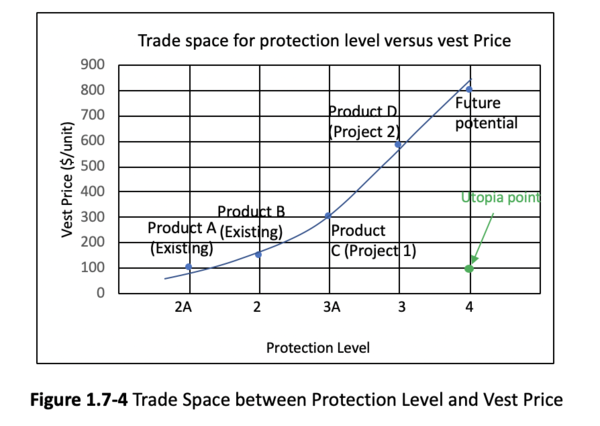

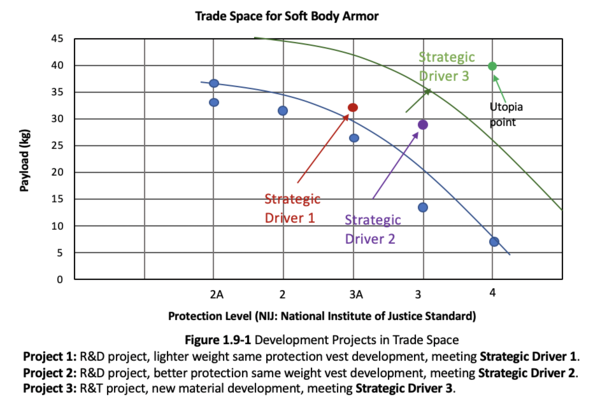

The | The tradespace below shows the position of our Company to the Competitors for various soft body armor protection models. Utopia is marked with a green dot (spider silk). The competitor (red circles) is currently on the Pareto Front (denoted in below curve line) and our company (blue circles) is slightly off of the Pareto Front. In order to gain market share and provide added value to the customer, we need to push the pareto curve with our road map driven by our three strategic drivers and alignment of targets. | ||

[[File:Company.png|600px]] | |||

==1.7 Technical Model== | |||

In order to assess the feasibility of technical (and financial) targets at the level of the 2BV roadmap it is necessary to develop a technical model. The purpose of such a model is to explore the design tradespace and establish what are the active constraints in the system. The first step can be to establish a morphological matrix that shows the main technology selection alternatives that exist at the first level of decomposition, see the figure below. | |||

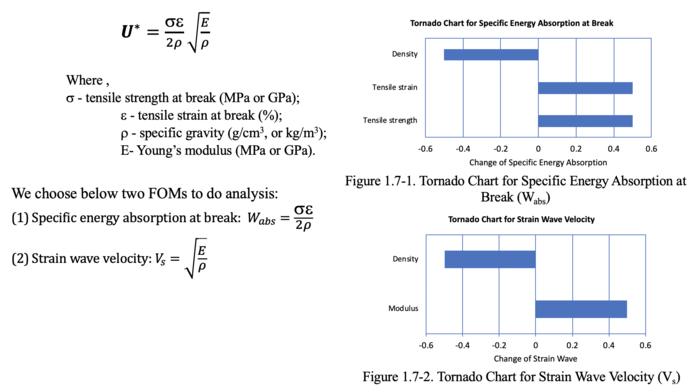

Our technical model of the ballistic vest is the dimensionless composite ballistic performance index U* developed by Cunniff as in Section 1.4. This composite index is: | |||

[[File:SBV Equations.png|700px]] | |||

Interestingly, every unit change of these 3 parameters get same unit of change of the first FOM, but increase in strength and strain increases Wabs and increase in specific gravity decreases Wabs. | |||

Again, one unit of change in Young’s modulus and one unit of change in specific gravity lead to same unit of change in strain wave velocity, but increasing modulus increases Vs, and increasing specific gravity decreases Vs. | |||

Therefore Figure 1.7-1 illustrates that every unit change in strength, strain or specific gravity will change the Wabs (Specific Energy Absorption) by 0.5 unit, respectively. This is a very significant change. | |||

One can see that in Figure 1.7-2, 1 unit increase in modulus increases 0.5 unit of strain wave velocity, and 1 unit decrease in specific gravity increases 0.5 unit of strain wave velocity. These are significant effects than those in the specific energy absorption. | |||

We can choose different design variables based on these, | |||

Table 1.7-1 summarizes the morphological matrix for a soft body armor (optionally with hard plates). | |||

[[File:BV Table 4.png]] | |||

[[File:Morph New.png|650px]] | |||

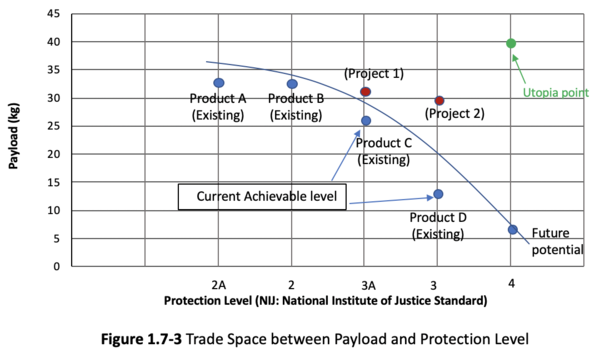

From Table 1.7-3, one can see that with increasing protection level, the payload is decreasing. A simple trade space is that one needs to choose trade off between the protection level and payload. If the customer needs more protection on body, then they have to choose to carry less equipment or ammunition, and vice versa. | |||

[[File:BV4UPDATE.png|600px]] | |||

'''Patent | (Note: the body armor weight is estimated from literature data, not the real product performance data which are difficult to access. These data include soft body armor made of different materials.). | ||

When | |||

[[File:Tradespace Pricev2.png|600px]] | |||

==1.8 Financial Model== | |||

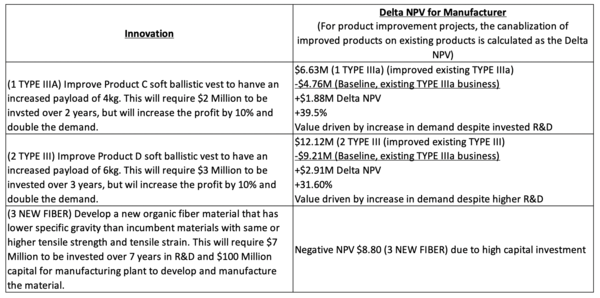

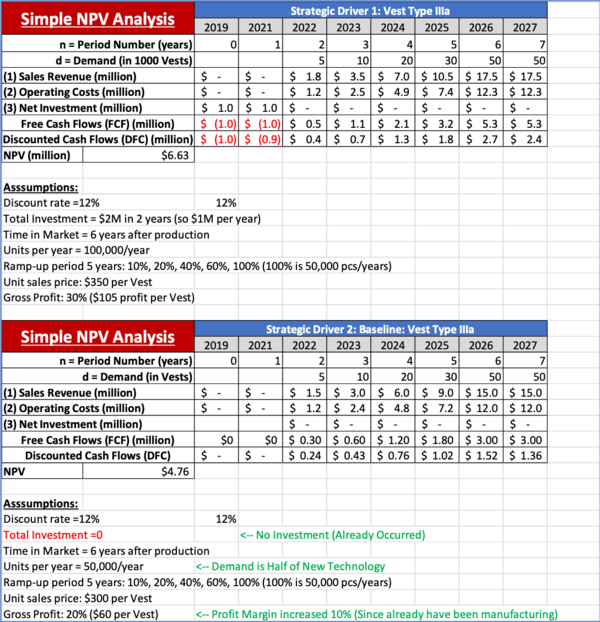

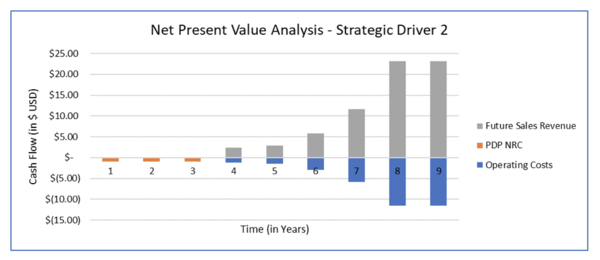

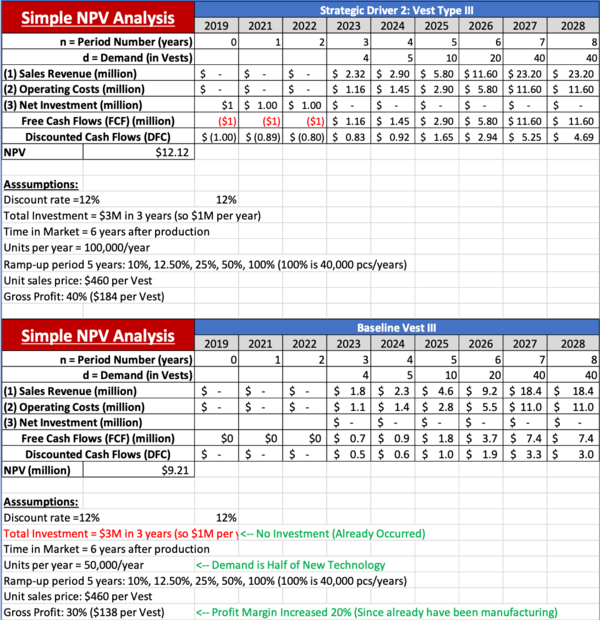

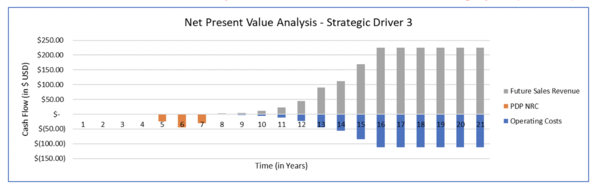

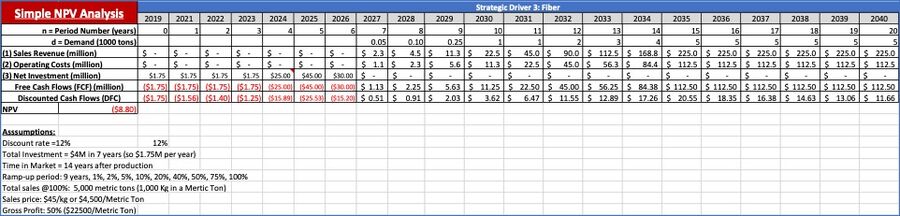

A static NPV Analysis was conducted for all three strategic drivers of the 2BV roadmap and the below table is the summary findings from the analysis. A time horizon of 6 years after R&D was utilized for Strategic Drivers 1 and 2, and 14 years after R&D was utilized for Strategic Driver 3. A discount rate of 12% was utilized for all three strategic drivers. | |||

[[File:I Table v3.png|600px]] | |||

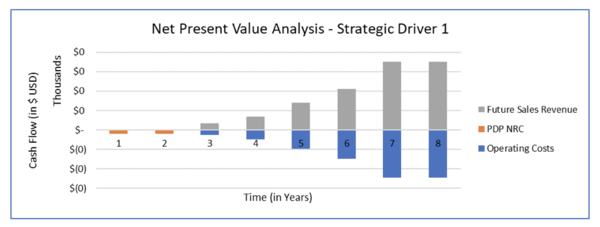

Strategic Driver 1 static NPV Analysis Graph and the excel portion of New and Baseline NPV below: | |||

[[File:SD1G.png|600px]] | |||

[[File:NPV1A.png|600px]] | |||

Strategic Driver 2 static NPV Analysis Graph and the excel portion of New and Baseline NPV below: | |||

[[File:SD2G.png|600px]] | |||

[[File:NPV2A.png|600px]] | |||

Strategic Driver 3 static NPV Analysis Graph and the excel portion of New and Baseline NPV below: | |||

[[File:SD3G.png|600px]] | |||

[[File:NPV3A.jpg|900px]] | |||

==1.9 List of R&T Projects and Prototypes== | |||

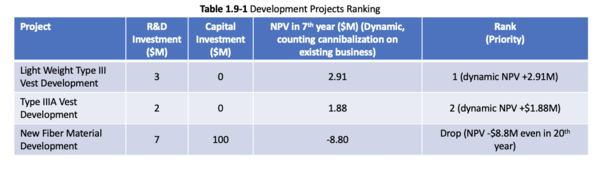

In order to select and prioritize R&D (R&T) projects we recommend using the technical and financial models developed as part of the roadmap to rank-order projects based on an objective set of criteria and analysis. | |||

[[File:TRO.png|600px]] | |||

[[File:Table 1.9v2.png|600px]] | |||

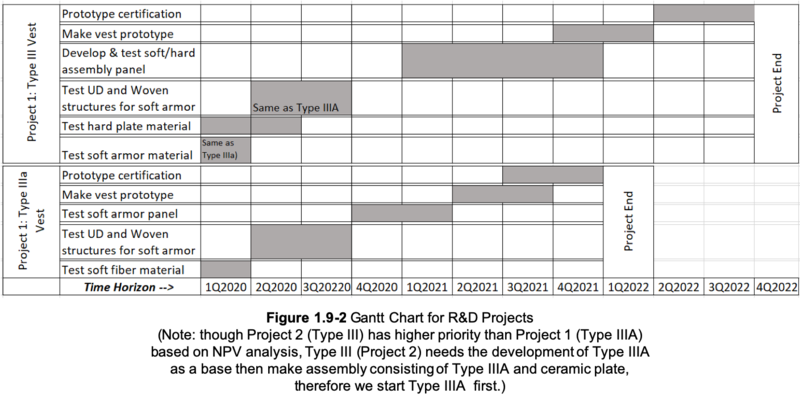

[[File:GV3.png|800px]] | |||

==1.10 Key Publications, Presentations and Patents== | |||

A thorough literature review of key publications, presentations, and patents was conducted for our technology of choice, ballistic vest material used in soft body armor. | |||

The analysis focused on two particular areas: | |||

'''Area 1:''' what materials can improve soft body armor’s ballistic performance? And getting a material, what structure of the body armor would maximize the material properties? | |||

'''Area 2:''' what material properties governs the ballistic performance? | |||

Based on these patents and publication analysis, we draw conclusions as summarized as follows, | |||

Soft materials development have came to a bottle neck. It has not made breakthrough for more than 30 years. It is a proof that it is a very challenging task. In combination with our NPV analysis, it is wise for us to drop the new material development. | |||

The recent research and development focus is on how to optimize the textile structure by using existing available materials. This is what we will be trying to do with our Type IIIA and Type III vest development projects. | |||

There is no accurate technology to predict the ballistic performance though there is are governing functions that guide the direction. The ballistic performance still heavily rely on testing and validation. | |||

'''Detailed Patent Analysis''' | |||

When dealing with materials, it is necessary to analyze both the material and the process. In the soft body armor material history, two patents have been remarkably important. | |||

'''Patent 1:''' Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957. | '''Patent 1:''' Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957. | ||

==Technology Strategy Statement== | '''Patent 2:''' Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972. | ||

The first patent, US3,006,899 disclosed how to make an aromatic amide polymer which is known later as Kevlar®. Before this patent, the strongest synthetic material is nylon fiber which is polymerized with aliphatic units. DuPont attempted to use aromatic units to replace the aliphatic units in nylon to improve its physical properties such as strength and thermal resistance. They were able to synthesize a wholly aromatic amide polymer as disclosed in this patent filed in 1957 and granted in 1961. | |||

'''Patent 3:''' Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974. | |||

Soon after the successful development of Kevlar® fiber (with the patent disclosure in 1974), a ballistic vest patent was filed in 1974 by using aramid (aramid is aromatic amide polymer) fiber. The independent claim (claim 1) in this patent is: | |||

A ballistic vest comprising: at least one member formed of a plurality of layers of alternately placed woven fabric sheets of (1) ballistic nylon fiber and (2) aramid fiber, said member being sewn so as to prevent substantial relative movement between said layers; and means for securing said member to the torso of a person. | |||

'''Patent 4:''' Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp. | |||

'''Patent 5:''' Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. | |||

When a material breakthrough is achieved, it is hard to make next breakthrough in a short time. Most of the work is to optimized the use of the newly developed material. Soft body armor (ballistic vest) is an article with a structure. Most of the work has been focused on how to optimize the structure of the vest made of the newly developed material. | |||

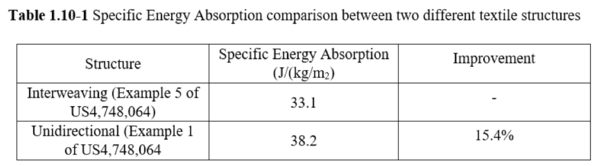

Traditionally the textile soft body armor was made by interweaving. In this Allied Corp (later Honeywell) disclosed a non-woven structure that has improved ballistic performance by aligning fiber unidirectionally. The interweaving was removed from the structure. This structure is claimed in the dependent claim 4: | |||

Claim 4: An article as recited in claim 1 where in said network of fibers comprises a sheet-like fiber array in which said fibers are arranged substantially parallel to one another along a common fiber direction. This innovation structure improved the ballistic performance as opposed to the traditional interwoven structure. The results are extracted from the patent and compared in Table 1.10-1. | |||

[[File:Table23.png|600px]] | |||

The improvement is 15.4% by simply changing the structure. This improvement seems not large, but it is indeed significant enough to make difference. Imagine if one soldier wears a vest of 10 lbs weight, and 15.4% reduction in weight is 1.5lbs. If this 1.5lbs are freed and he could carry 1.5lbs more ammunition, that can make a huge difference in time of needs. | |||

'''Detailed Key Publications Analysis''' | |||

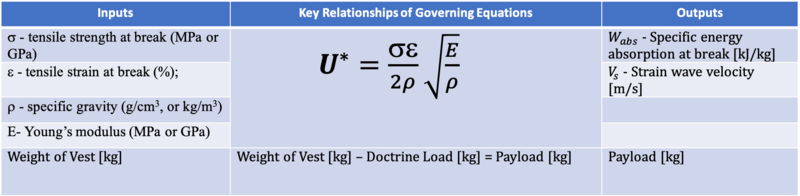

'''Paper 1:''' Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41. | |||

In this paper, Roylance et al described how the impact energy dissipated through longitudinal wave front and transverse wave front. They compared the ballistic performance of different fabrics made of fibers with different properties. And found that the fiber properties (the tensile properties) did not have correlation with the fabric ballistic performance. This indicates that the fiber properties are at least not the only governing factor for the ballistic performance. | |||

'''Paper 2:''' Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310. | |||

Since the invention of Kevlar® aramid fiber, people had been wondering what are the governing materials properties that contribute to the ballistic performance. It was believed that the material strength is the most critical property to ballistic performance. But carbon fiber has much higher strength than Kevlar® aramid fiber, it does not exhibit good ballistic performance. Then it is also believed that the most critical property is the total amount of energy at break which can be obtained on a tensile machine. However, nylon fiber has higher energy at break in tensile testing, but it does not have good ballistic performance. The paper also compares the mechanical properties of carbon fiber, Kevlar® aramid fiber and nylon fiber. | |||

'''Paper 3:''' Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949. | |||

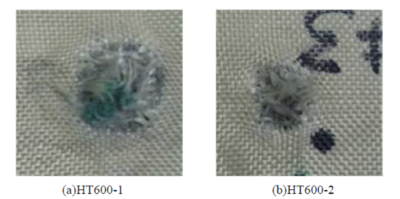

In this paper, two different structure of aramid fabrics were compared. Both structures have very similar weight, but one (HT 600-1) has higher crimp ratio (the fiber is less straight) than the other (HT 600-2). | |||

(a) A bottom view of the crushed bullets retrieved from HT600 fabrics | |||

(b) Perforated regions of two HT-600 fabrics impacted by the projectile. | |||

[[File:Fig26.png|400px]] | |||

Ballistic testing performance of HT600 fabrics (Source: Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949.) | |||

The testing results suggested that higher crimp in fabric leads to poorer ballistic performance. This indication supports the claim in the patent 4 mentioned above where the fiber is perfectly straight without any interweaving. | |||

'''Consolidated Reference Summary:''' | |||

'''Breakthrough Ballistic Material Patent (Kevlar):''' | |||

Patent 1: Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957. | |||

'''Process Patent (Spinning of Polymer into Useable Fiber):''' | |||

Patent 2: Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972. | |||

'''Ballistic Vest Patent:''' | |||

Patent 3: Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974. | |||

'''Ballistic Vest Composite Patent:''' | |||

Patent 4: Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp. (Allied later merged with Honeywell) | |||

'''Ballistic Vest Non-Weavon Patent:''' | |||

Patent 5: Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. (Allied-Signal later merged with Honeywell) | |||

'''Fabrics/Textile Structure:''' | |||

Paper 1: Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41. | |||

Paper 2: Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310. | |||

Paper 3: Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949. | |||

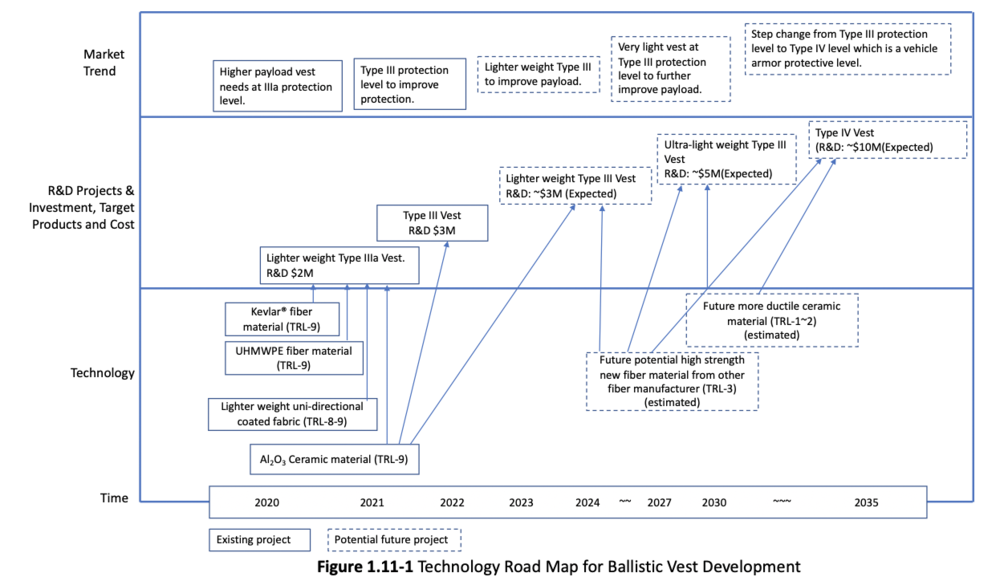

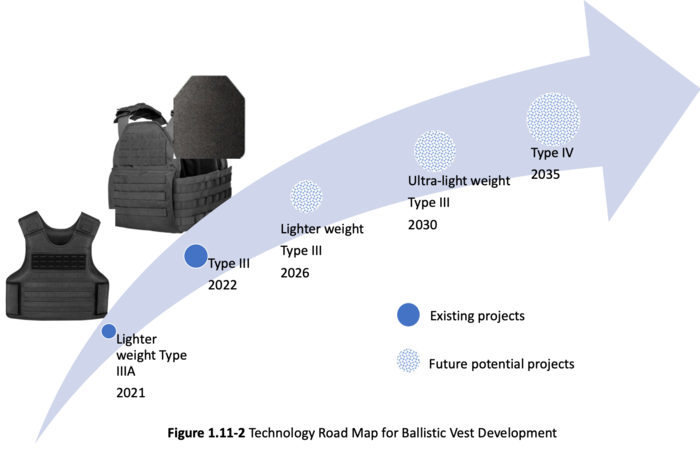

==1.11 Technology Strategy Statement== | |||

We will focus on our core capability to leverage the best available materials in the market to research and develop protective vests of lighter weight with same protection and of better protection at same weight. We will not pursue new materials development which is not within our core capability. | |||

By end of 2021, we shall develop a light weight Type IIIA vest product that offers better mobility to the wearers by investing $2M in R&D. | |||

By end of 2022, we shall develop a Type III vest product that has same or similar weight to Type IIIA vest that offers better protection to the wearers while not sacrificing the mobility by investing $3M in R&D. | |||

'''''Our vision is to develop and produce the best protective vest products to protect those who protect our lives.''''' | |||

[[File:TRCM.png|1000px]] | |||

[[File:Swosh.png|700px]] | |||

==1.12 References== | |||

1. https://en.wikipedia.org/wiki/Lorica_segmentata | |||

2. https://pdfs.semanticscholar.org/2222/bf336a754957728e6b02afbe83f7844d4eda.pdf | |||

3. http://www.medievalwarfare.info/armour.htm | |||

4. https://owlcation.com/stem/What-is-the-Strongest-Metal-The-Hardest-Metals-Known-to-Man | |||

5.https://en.wikipedia.org/wiki/Improved_Outer_Tactical_Vest | |||

6. https://en.wikipedia.org/wiki/Stephanie_Kwolek). | |||

7. http://www.dupont.co.uk/content/dam/dupont/products-and-services/fabrics-fibers-and-nonwovens/fibers/documents/Technical%20Guide%20for%20Kevlar%C2%AE%20in%20Mechanical%20Rubber%20Goods.pdf | |||

8. https://www.dupont.com/products-and-services/fabrics-fibers-nonwovens/fibers/press-releases/iacp-survivors-club-honoree.html | |||

9. https://digital.hagley.org/2014249_20140819_Blades | |||

10. Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957. | |||

11. Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972. | |||

12. Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974. | |||

13. Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp. (Allied later merged with Honeywell) | |||

14. Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. (Allied-Signal later merged with Honeywell) | |||

15. Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41. | |||

16. Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310. | |||

17.Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949. | |||

Latest revision as of 12:13, 7 December 2019

Technology Roadmap Sections and Deliverables

https://www.youtube.com/watch?v=IwBLL7Z3OvU&t=34s (Start at 1:57 and End at 2:19) The selected technology that Team 6 will be spending the remainder of the semester on developing a technology road map is ballistic vest technology (specifically for military and law enforcement applications).

Clear and unique identifier:

- 2BV - Ballistic Vests

This indicates that we are dealing with a “level 2” roadmap at the product level.

1.1 Roadmap Overview

The working principle and architecture of Ballistic Vests is depicted in the below diagram.

A ballistic vest works by absorbing the kinetic energy from a high-speed projectile (bullet or shrapnel from an explosion) at the point of impact over a wide area. The ballistic vest is meant to spread the kinetic energy by displacing it across the ballistic vest materials in a process called material deformation. The deformation occurs in two-fold, deformation of the ballistic vest materials as the bullet absorbs the kinetic energy and deformation of the bullet itself, called mushrooming. The remainder of the energy is consumed as heat.

This technology is a lifesaving technology to aid military personnel and law enforcement during their daily activities. A ballistic vest is typically worn on an individual’s chest and is meant to be replaced after it has taken an impact (from high speed projectile or mishandling of vest e.g. dropped) or date of manufacturing has expired. There are six levels of protection; Type I, Type IIA, Type II, Type IIIA, Type III, and Type IV (See below chart for the six threat levels of protection. Soft ballistic vests are made of soft armor and consist of Type I, Type IIA, Type II, and Type IIIA which primarily protect against handgun rounds. Whereas, hard ballistic vests are made of hard amor and consist of Type III and Type IV which primarily protect against rifle rounds. The history of personal armor dates back to 500 BC when chain mail/coat mail was used as a form of individual protection from slashing blows by an edged weapon (e.g. swords). Modern day individual body armor is meant to protect from high speed projectiles. New fibers were discovered in the 1960’s for the possibility to make resistant vests and DuPont developed Kevlar ballistic fabric in the 1970s.

1.2 Design Structure Matrix (DSM) Allocation

The 2-BV tree that we can extract from the DSM above shows us that the Soft Vest (2BV) is part of a larger initiative on Ballistic Personal Protection (1BPP) and that it requires the following key enabling technologies at the subsystem level: 4SAM Soft Armor Material, 4HAM Hard Armor Material and 5PA Para-Aarmids and 5CCC Ceramics / Ceramic Composites.

1.3 Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2BV roadmap in the figure below. This diagram captures the main object of the roadmap (Ballistic Vest), its various instances including common ballistic vest products, its decomposition into components (front carrier/panel, rear carrier/panel, side carrier/panel, soft armor (front & rear), hard plate (front, back, & sides, etc.), its characterization by Figures of Merit (FOMs) as well as the main processes (Protecting with two states protected and unprotected).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.

1.4 Figures of Merit

The table below shows a list of FOMs by which ballistic vest can be assessed.

Background:

Male Vs. Female: The majority of body armor on the current market is primarily designed for males but there are some companies producing body armor for females. In recent years, the U.S. Army revised the 5th generation of improved outer tactical vest to be specifically designed for females. They addressed the following seven issues; 1) Length, 2) Side plates too large/long/wide/better location, 3) Too big in upper chest/ shoulder, 4) Adjustability in the shoulder, 5) Inability to seat a weapon/ too much bulk in upper body, 6) Issues with collar/yoke/too much bulk, and 7)Donning and doffing difficult.

Cost: Typically the higher the level of the protection, the higher the cost. The typical cost of a ballistic vest is declining for old technology due to efficiencies in process manufacturing and the cost of the latest technology integrated into the ballistic vest is on the incline. The typical cost of soft ballistic vests are in the range from $120 to $400 for Level I to Level IIA and $400 to $1200 for Level IIIA to Level IV.

1.5 Alignment with Company Strategic Drivers

The table below shows our companies strategic drivers and alignment of 2BV technology with roadmap.

The two strategic drivers (1 and 2) show that the company views the next generation of soft body armor as a potential new business product that will generate $X revenue by 2027 and $X revenue by 2028 respectively. Strategic Driver 1 of a Type IIIA soft ballistic vest has the alignment and targets of 4 more kilograms of payload than current model. The companies new Type IIIA payload will be greater than competitors Type IIIA, thus increased value in payload compared to competitors’ same type product). Strategic Driver 2 of a Type III level soft ballistic vest has the alignment and targets of new Type III payload will be the same as the competitors Type IIIA payload, but with an increased value in protection level. Strategic driver 3 is a more aggressive driver that aligns with the 2BV technology roadmap with a lead developer strategy to have the most advanced material with higher protection and lighter integrated into soft body armor.

The strategic driver 3 looks very interesting and may enable us to have a technological breakthrough in raw material, but is not well aligned with our roadmap. Our roadmap is focused on vest technology and products, while the strategic driver 3 will need us to go to upstream for raw material development and manufacturing.

1.6 Positioning of Company vs. Competition

The tradespace below shows the position of our Company to the Competitors for various soft body armor protection models. Utopia is marked with a green dot (spider silk). The competitor (red circles) is currently on the Pareto Front (denoted in below curve line) and our company (blue circles) is slightly off of the Pareto Front. In order to gain market share and provide added value to the customer, we need to push the pareto curve with our road map driven by our three strategic drivers and alignment of targets.

1.7 Technical Model

In order to assess the feasibility of technical (and financial) targets at the level of the 2BV roadmap it is necessary to develop a technical model. The purpose of such a model is to explore the design tradespace and establish what are the active constraints in the system. The first step can be to establish a morphological matrix that shows the main technology selection alternatives that exist at the first level of decomposition, see the figure below.

Our technical model of the ballistic vest is the dimensionless composite ballistic performance index U* developed by Cunniff as in Section 1.4. This composite index is:

Interestingly, every unit change of these 3 parameters get same unit of change of the first FOM, but increase in strength and strain increases Wabs and increase in specific gravity decreases Wabs.

Again, one unit of change in Young’s modulus and one unit of change in specific gravity lead to same unit of change in strain wave velocity, but increasing modulus increases Vs, and increasing specific gravity decreases Vs.

Therefore Figure 1.7-1 illustrates that every unit change in strength, strain or specific gravity will change the Wabs (Specific Energy Absorption) by 0.5 unit, respectively. This is a very significant change.

One can see that in Figure 1.7-2, 1 unit increase in modulus increases 0.5 unit of strain wave velocity, and 1 unit decrease in specific gravity increases 0.5 unit of strain wave velocity. These are significant effects than those in the specific energy absorption. We can choose different design variables based on these,

Table 1.7-1 summarizes the morphological matrix for a soft body armor (optionally with hard plates).

From Table 1.7-3, one can see that with increasing protection level, the payload is decreasing. A simple trade space is that one needs to choose trade off between the protection level and payload. If the customer needs more protection on body, then they have to choose to carry less equipment or ammunition, and vice versa.

(Note: the body armor weight is estimated from literature data, not the real product performance data which are difficult to access. These data include soft body armor made of different materials.).

1.8 Financial Model

A static NPV Analysis was conducted for all three strategic drivers of the 2BV roadmap and the below table is the summary findings from the analysis. A time horizon of 6 years after R&D was utilized for Strategic Drivers 1 and 2, and 14 years after R&D was utilized for Strategic Driver 3. A discount rate of 12% was utilized for all three strategic drivers.

Strategic Driver 1 static NPV Analysis Graph and the excel portion of New and Baseline NPV below:

Strategic Driver 2 static NPV Analysis Graph and the excel portion of New and Baseline NPV below:

Strategic Driver 3 static NPV Analysis Graph and the excel portion of New and Baseline NPV below:

1.9 List of R&T Projects and Prototypes

In order to select and prioritize R&D (R&T) projects we recommend using the technical and financial models developed as part of the roadmap to rank-order projects based on an objective set of criteria and analysis.

1.10 Key Publications, Presentations and Patents

A thorough literature review of key publications, presentations, and patents was conducted for our technology of choice, ballistic vest material used in soft body armor.

The analysis focused on two particular areas:

Area 1: what materials can improve soft body armor’s ballistic performance? And getting a material, what structure of the body armor would maximize the material properties?

Area 2: what material properties governs the ballistic performance?

Based on these patents and publication analysis, we draw conclusions as summarized as follows, Soft materials development have came to a bottle neck. It has not made breakthrough for more than 30 years. It is a proof that it is a very challenging task. In combination with our NPV analysis, it is wise for us to drop the new material development. The recent research and development focus is on how to optimize the textile structure by using existing available materials. This is what we will be trying to do with our Type IIIA and Type III vest development projects. There is no accurate technology to predict the ballistic performance though there is are governing functions that guide the direction. The ballistic performance still heavily rely on testing and validation.

Detailed Patent Analysis When dealing with materials, it is necessary to analyze both the material and the process. In the soft body armor material history, two patents have been remarkably important.

Patent 1: Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957.

Patent 2: Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972. The first patent, US3,006,899 disclosed how to make an aromatic amide polymer which is known later as Kevlar®. Before this patent, the strongest synthetic material is nylon fiber which is polymerized with aliphatic units. DuPont attempted to use aromatic units to replace the aliphatic units in nylon to improve its physical properties such as strength and thermal resistance. They were able to synthesize a wholly aromatic amide polymer as disclosed in this patent filed in 1957 and granted in 1961.

Patent 3: Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974. Soon after the successful development of Kevlar® fiber (with the patent disclosure in 1974), a ballistic vest patent was filed in 1974 by using aramid (aramid is aromatic amide polymer) fiber. The independent claim (claim 1) in this patent is:

A ballistic vest comprising: at least one member formed of a plurality of layers of alternately placed woven fabric sheets of (1) ballistic nylon fiber and (2) aramid fiber, said member being sewn so as to prevent substantial relative movement between said layers; and means for securing said member to the torso of a person.

Patent 4: Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp.

Patent 5: Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. When a material breakthrough is achieved, it is hard to make next breakthrough in a short time. Most of the work is to optimized the use of the newly developed material. Soft body armor (ballistic vest) is an article with a structure. Most of the work has been focused on how to optimize the structure of the vest made of the newly developed material. Traditionally the textile soft body armor was made by interweaving. In this Allied Corp (later Honeywell) disclosed a non-woven structure that has improved ballistic performance by aligning fiber unidirectionally. The interweaving was removed from the structure. This structure is claimed in the dependent claim 4:

Claim 4: An article as recited in claim 1 where in said network of fibers comprises a sheet-like fiber array in which said fibers are arranged substantially parallel to one another along a common fiber direction. This innovation structure improved the ballistic performance as opposed to the traditional interwoven structure. The results are extracted from the patent and compared in Table 1.10-1.

The improvement is 15.4% by simply changing the structure. This improvement seems not large, but it is indeed significant enough to make difference. Imagine if one soldier wears a vest of 10 lbs weight, and 15.4% reduction in weight is 1.5lbs. If this 1.5lbs are freed and he could carry 1.5lbs more ammunition, that can make a huge difference in time of needs.

Detailed Key Publications Analysis

Paper 1: Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41. In this paper, Roylance et al described how the impact energy dissipated through longitudinal wave front and transverse wave front. They compared the ballistic performance of different fabrics made of fibers with different properties. And found that the fiber properties (the tensile properties) did not have correlation with the fabric ballistic performance. This indicates that the fiber properties are at least not the only governing factor for the ballistic performance.

Paper 2: Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310. Since the invention of Kevlar® aramid fiber, people had been wondering what are the governing materials properties that contribute to the ballistic performance. It was believed that the material strength is the most critical property to ballistic performance. But carbon fiber has much higher strength than Kevlar® aramid fiber, it does not exhibit good ballistic performance. Then it is also believed that the most critical property is the total amount of energy at break which can be obtained on a tensile machine. However, nylon fiber has higher energy at break in tensile testing, but it does not have good ballistic performance. The paper also compares the mechanical properties of carbon fiber, Kevlar® aramid fiber and nylon fiber.

Paper 3: Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949.

In this paper, two different structure of aramid fabrics were compared. Both structures have very similar weight, but one (HT 600-1) has higher crimp ratio (the fiber is less straight) than the other (HT 600-2).

(a) A bottom view of the crushed bullets retrieved from HT600 fabrics

(b) Perforated regions of two HT-600 fabrics impacted by the projectile.

Ballistic testing performance of HT600 fabrics (Source: Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949.) The testing results suggested that higher crimp in fabric leads to poorer ballistic performance. This indication supports the claim in the patent 4 mentioned above where the fiber is perfectly straight without any interweaving.

Consolidated Reference Summary:

Breakthrough Ballistic Material Patent (Kevlar):

Patent 1: Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957.

Process Patent (Spinning of Polymer into Useable Fiber):

Patent 2: Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972.

Ballistic Vest Patent:

Patent 3: Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974.

Ballistic Vest Composite Patent:

Patent 4: Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp. (Allied later merged with Honeywell)

Ballistic Vest Non-Weavon Patent:

Patent 5: Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. (Allied-Signal later merged with Honeywell)

Fabrics/Textile Structure:

Paper 1: Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41.

Paper 2: Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310.

Paper 3: Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949.

1.11 Technology Strategy Statement

We will focus on our core capability to leverage the best available materials in the market to research and develop protective vests of lighter weight with same protection and of better protection at same weight. We will not pursue new materials development which is not within our core capability.

By end of 2021, we shall develop a light weight Type IIIA vest product that offers better mobility to the wearers by investing $2M in R&D.

By end of 2022, we shall develop a Type III vest product that has same or similar weight to Type IIIA vest that offers better protection to the wearers while not sacrificing the mobility by investing $3M in R&D.

Our vision is to develop and produce the best protective vest products to protect those who protect our lives.

1.12 References

1. https://en.wikipedia.org/wiki/Lorica_segmentata

2. https://pdfs.semanticscholar.org/2222/bf336a754957728e6b02afbe83f7844d4eda.pdf

3. http://www.medievalwarfare.info/armour.htm

4. https://owlcation.com/stem/What-is-the-Strongest-Metal-The-Hardest-Metals-Known-to-Man

5.https://en.wikipedia.org/wiki/Improved_Outer_Tactical_Vest

6. https://en.wikipedia.org/wiki/Stephanie_Kwolek).

9. https://digital.hagley.org/2014249_20140819_Blades

10. Hill HW Jr, Kwolek SL, Morgan PW. Polyamides from reaction of aromatic diacid halide dissolved in cyclic nonaromatic oxygenated organic solvent and an aromatic diamine, US3,006,899, DuPont, 1957.

11. Blades H. Dry jet wet spinning process, US3,767,756, DuPont, 1972.

12. Leach J, Fash WG, Ballistic Vest, Burlington Industries, US3,891,996, 1974.

13. Harpell GA, Paelley I, Kavesh S, Prevorsek DC. Ballistic-resistance composite article, US4,748,064, 1985, Allied Corp. (Allied later merged with Honeywell)

14. Harpell GA, Prevorsek DC, Li HL, Flexible multi-layered armor, US5,175,040, 1991. Allied-Signal. (Allied-Signal later merged with Honeywell)

15. Roylance D, Wilde A, Tocci G, Ballistic Impact of Textile Structures, Textile Research Journal, 1973, 43: 34-41.

16. Cunniff, PM, Dimensionless parameters for optimization of textile-based body armor systems. In: Proceedings of the 18th International Symposium on Ballistics, San Antonio, Texas, 15-19 Nov 1999. Pp 1303-1310.

17.Lim JS, Lee BH, Lee CB, Han IS, Effect of the weaving density of aramid fabrics on their resistance to ballistic impacts, Engineering, 2012, 4, 944-949.