Difference between revisions of "Energy Storage via Battery"

(Created page with "=Technology Roadmap Sections and Deliverables= The first point is that each technology roadmap should have a clear and unique identifier: * '''2SEA - Solar Electric Aircraft...") |

|||

| Line 11: | Line 11: | ||

[[File:Section 1.JPG]] | [[File:Section 1.JPG]] | ||

An electrical battery can store and use energy by chemical reaction. It is composed of an anode (-), a cathode (+), the electrolyte, and separator. The chemical reaction is a redox reaction caused by an electrical difference between the anode and the cathode. That is, electrons are expelled from the anode to the cathode via an external circuit and metal ion in the electrolyte receives the electrons on the cathode. This redox reaction lasts until | An electrical battery can store and use energy by chemical reaction. It is composed of an anode (-), a cathode (+), the electrolyte, and separator. The chemical reaction is a redox reaction caused by an electrical difference between the anode and the cathode. That is, electrons are expelled from the anode to the cathode via an external circuit and metal ion in the electrolyte receives the electrons on the cathode. This redox reaction lasts until electrical equilibrium. Although the primary battery is designed to be used once and discarded, the secondary battery can be recharged with electricity and reused. First secondary batteries based on Ni/Cd and Pd-acid were produced around 1900. After that, Ni/Zn battery which showed higher specific density appeared in the 1950s. In 1990, Lithium-ion battery (LIB) which is a major rechargeable battery today was released. The capabilities of LIB such as specific density, volumetric density, and cycle durability have improved more and more by developing new materials and the energy price is going down. These trends contribute to the growing availability of Electric vehicles. | ||

==Design Structure Matrix (DSM) Allocation== | ==Design Structure Matrix (DSM) Allocation== | ||

Revision as of 03:34, 6 October 2019

Technology Roadmap Sections and Deliverables

The first point is that each technology roadmap should have a clear and unique identifier:

- 2SEA - Solar Electric Aircraft

This indicates that we are dealing with a “level 2” roadmap at the product level (see Fig. 8-5), where “level 1” would indicate a market level roadmap and “level 3” or “level 4” would indicate an individual technology roadmap.

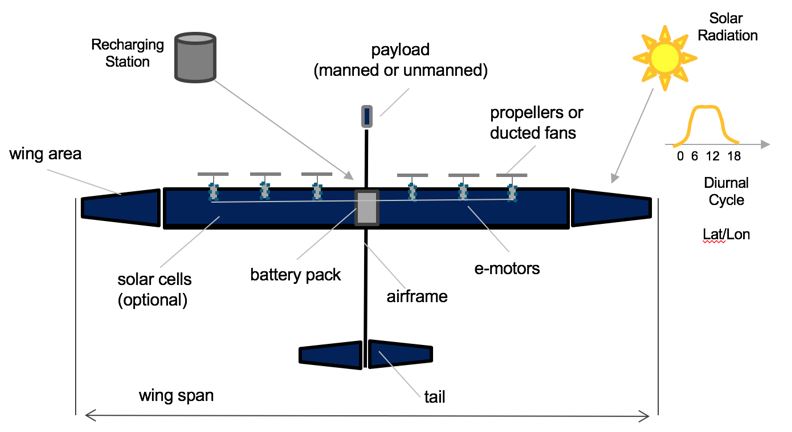

Roadmap Overview

The working principle and architecture of an electrical battery are depicted in the below.

An electrical battery can store and use energy by chemical reaction. It is composed of an anode (-), a cathode (+), the electrolyte, and separator. The chemical reaction is a redox reaction caused by an electrical difference between the anode and the cathode. That is, electrons are expelled from the anode to the cathode via an external circuit and metal ion in the electrolyte receives the electrons on the cathode. This redox reaction lasts until electrical equilibrium. Although the primary battery is designed to be used once and discarded, the secondary battery can be recharged with electricity and reused. First secondary batteries based on Ni/Cd and Pd-acid were produced around 1900. After that, Ni/Zn battery which showed higher specific density appeared in the 1950s. In 1990, Lithium-ion battery (LIB) which is a major rechargeable battery today was released. The capabilities of LIB such as specific density, volumetric density, and cycle durability have improved more and more by developing new materials and the energy price is going down. These trends contribute to the growing availability of Electric vehicles.

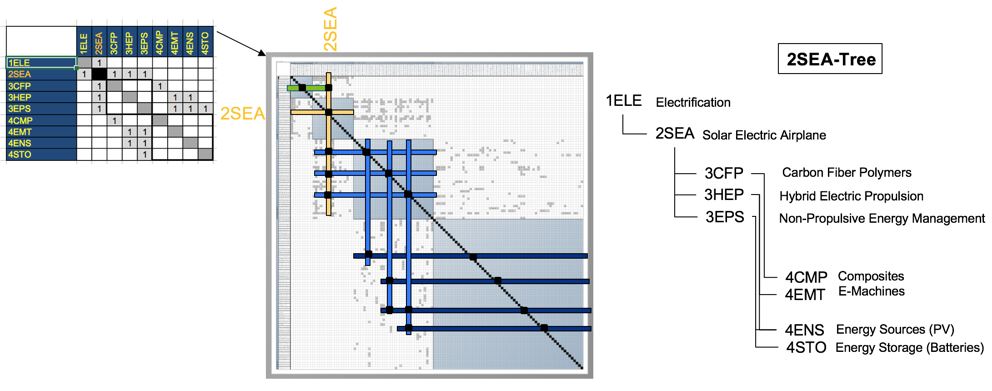

Design Structure Matrix (DSM) Allocation

The 2-SEA tree that we can extract from the DSM above shows us that the Solar-Electric Aircraft (2SEA) is part of a larger company-wide initiative on electrification of flight (1ELE), and that it requires the following key enabling technologies at the subsystem level: 3CFP Carbon Fiber Polymers, 3HEP Hybrid Electric Propulsion and 3EPS Non-Propulsive Energy Management (e.g. this includes the management of the charge-discharge cycle of the batteries during the day-night cycle). In turn these require enabling technologies at level 4, the technology component level: 4CMP components made from CFRP (spars, wing box, fairings …), 4EMT electric machines (motors and generators), 4ENS energy sources (such as thin film photovoltaics bonded to flight surfaces) and 4STO (energy storage in the form of lithium-type batteries).

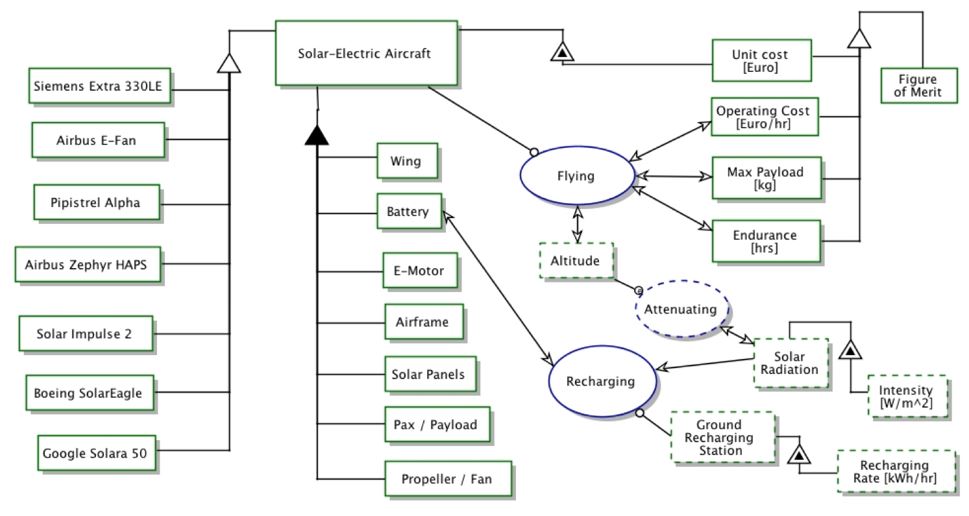

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2SEA roadmap in the figure below. This diagram captures the main object of the roadmap (Solar-Electric Aircraft), its various instances including main competitors, its decomposition into subsystems (wing, battery, e-motor …), its characterization by Figures of Merit (FOMs) as well as the main processes (Flying, Recharging).

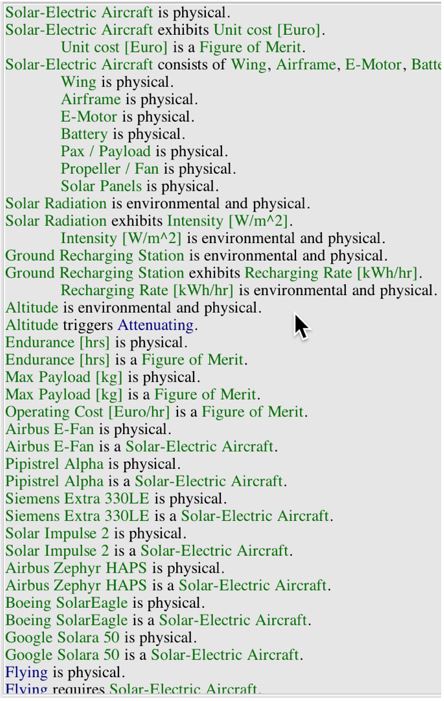

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.

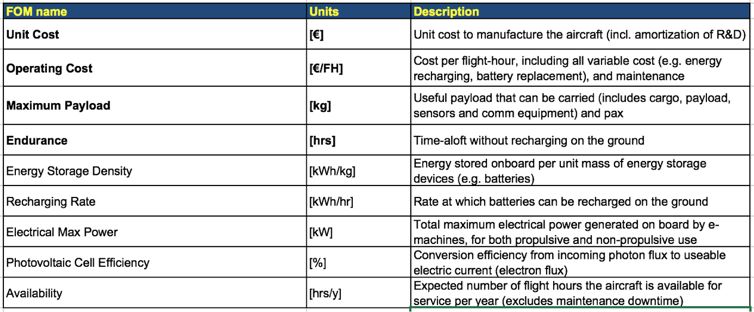

Figures of Merit

The table below show a list of FOMs by which solar electric aircraft can be assessed. The first four (shown in bold) are used to assess the aircraft itself. They are very similar to the FOMs that are used to compare traditional aircraft which are propelled by fossil fuels, the big difference being that 2SEA is essentially emissions free during flight operations. The other rows represent subordinated FOMs which impact the performance and cost of solar electric aircraft but are provided as outputs (primary FOMs) from lower level roadmaps at level 3 or level 4, see the DSM above.

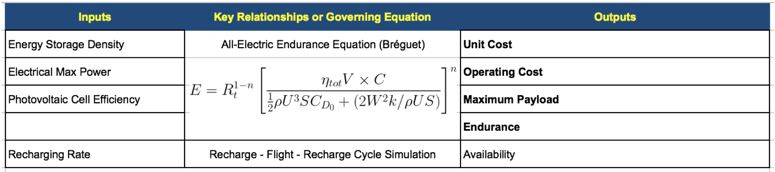

Besides defining what the FOMs are, this section of the roadmap should also contain the FOM trends over time dFOM/dt as well as some of the key governing equations that underpin the technology. These governing equations can be derived from physics (or chemistry, biology ..) or they can be empirically derived from a multivariate regression model. The table below shows an example of a key governing equation governing (solar-) electric aircraft.