Difference between revisions of "Optical Payload for Space Situational Awareness in Geosynchronous Orbit"

| Line 17: | Line 17: | ||

[[File:Surveillance_network_pillars.png|450px]] | [[File:Surveillance_network_pillars.png|450px]] | ||

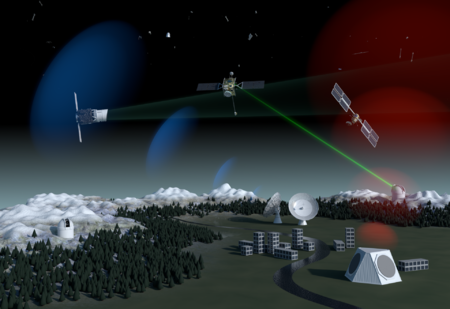

'' | ''Artist's impression of various SSA systems comprising a full SSA architecture.''<ref>Paranthaman, M. P. “Lithium extraction from geothermal brine solution.” Webinar presented by the U.S. Department of Energy Oak Ridge National Laboratory.” 2018. Available at: https://iastate.app.box.com/v/cmi-webinar-november-2018</ref> | ||

[[File:Research tasks.jpg|450px]] | [[File:Research tasks.jpg|450px]] | ||

==Design Structure Matrix (DSM) Allocation== | ==Design Structure Matrix (DSM) Allocation== | ||

Revision as of 17:28, 1 October 2020

Technology Roadmap Sections and Deliverables

This is a technology roadmap for:

- 3HSSA - Space Situational Awareness for the Hungarian Space Office

Roadmap Overview

Our technology roadmap concept—a low-cost space situational awareness sensor that could be integrated into a geostationary (GEO) satellite bus—was motivated by one particular research question: How can an emerging space actor contribute to space situational awareness in the geosynchronous region by launching just one satellite to GEO?

Space situational awareness (SSA)—detecting, identifying, and tracking resident space objects (RSOs) as they orbit the Earth—requires observing many RSOs, using the measurements deduced from those observations to determine the orbit of each object, and then using those determined orbits to identify objects again in the future, while further improving their orbital parameters. Comprehensive SSA results in knowing where all RSOs of some minimum size are at a given time and where they’re going, which results in a reasonably accurate assessment of the likelihood of collision between two RSOs. The collision of two satellites typically results in catastrophic damage to both RSOs involved and the creation of thousands of pieces of space debris, uniformly unfavorable results for all space actors in the orbital regime in which the collision occurred.

SSA systems generate RSO observations using a variety of sensors: including ground- and space-based optical telescopes and radar systems. SSA in GEO, specifically, has historically been pursued using optical, ground-based telescopes, as part of broader systems maintained by the space actors that have contributed the most number of RSOs to the near-Earth space environment: the United States and Russia. Since SSA is critical to maintaining a sustainable GEO environment, improving SSA in GEO is the interest of all space actors, even those in their earliest stages.

A relatively nascent space actor—one in the early stages of planning its first GEO launch—may not find it feasible to develop a new ground-based optical telescope to contribute to global space situational awareness. They could, however, contribute excellent SSA observations for the sliver of the GEO belt that they intend to occupy with their satellite upon successful launch. The new space actor could plan to add a small, optical sensor to its GEO satellite designed to monitor the satellite’s vicinity during its operational lifetime and report its observations either to the public or an international space object catalog.

Artist's impression of various SSA systems comprising a full SSA architecture.<ref>Paranthaman, M. P. “Lithium extraction from geothermal brine solution.” Webinar presented by the U.S. Department of Energy Oak Ridge National Laboratory.” 2018. Available at: https://iastate.app.box.com/v/cmi-webinar-november-2018</ref>

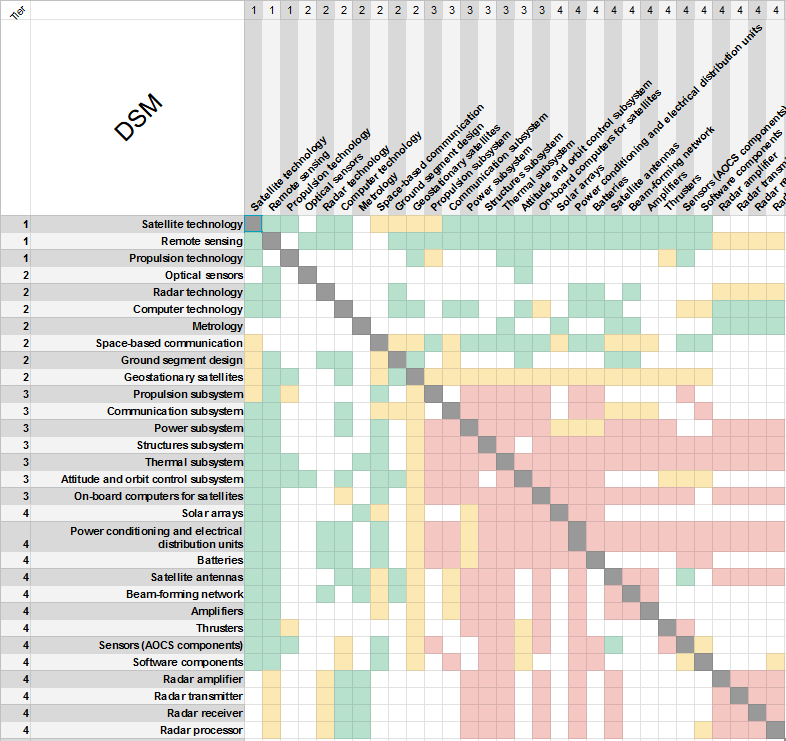

Design Structure Matrix (DSM) Allocation

The detailed DSM shows connections between the various technologies comprising the radar-based SSA (marked with green), as well as hierarchical relationships between technologies and objects (yellow), and physical relationships between components or subsystems (red).

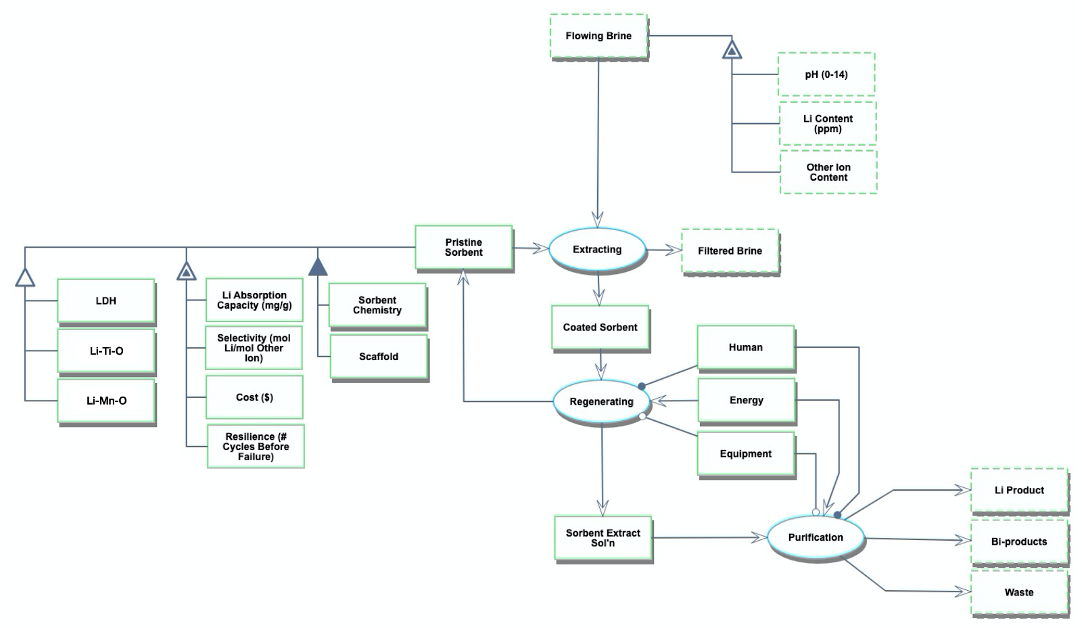

Roadmap Model using OPM

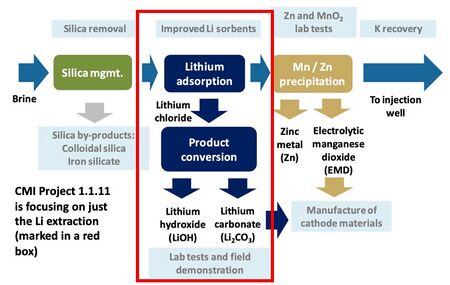

The Object-Process-Diagram (OPD) of the 4AIE roadmap is shown in the figure below. This diagram captures the main object of the roadmap (sorbent), its various instances including Lithium Manganese Oxides (Li-Mn-O), Lithium Titanium Oxides (Li-Ti-O), Lithium Aluminum Layered Double Hydroxide (LDH) Chloride; and its characterization by Figures of Merit (FOMs).

Figures of Merit

| FOM Name | Unit | Description |

|---|---|---|

| Adsorption capacity | [mg/g] |

|

| Selectivity | [dmnl] |

|

| Lithium Production Cost | [$/kg] |

|

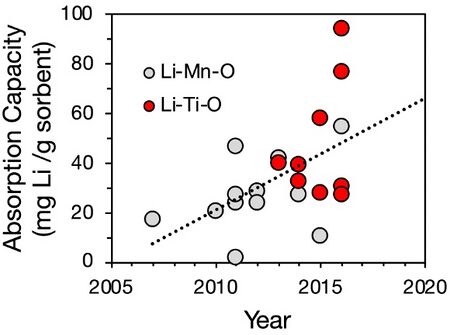

We gathered reported data from 21 peer-reviewed publications within the Li brine extraction literature to generate a plot of sorption capacity. Note that we provide data for only 2 of the 3 sorbents identified in our roadmap OPM (Li-Mn-O and Li-Ti-O), as there are few reports of sorbent capacity for lithium aluminum layered double hydroxide chloride (LDH) sorbent.

Adsorption capacities of major sorbents.<ref>Li, L., Deshmane, V. G., Paranthaman, M. P., Bhave, R., Moyer, B. A., & Harrison, S. (2018). Lithium recovery from aqueous resources and batteries: A brief review. Johnson Matthey Technology Review, 62(2), 161–176.</ref>

References

<references />