Difference between revisions of "Autonomous Underwater Vehicle"

| Line 7: | Line 7: | ||

The offshore platforms are the oil and gas production facilities that are located offshore. In the past, oil and gas were generally produced on the ground. However, as the number of fossil fuel-rich sites that were accessible from the ground has been limited, offshore oil and gas development has been important. In 2016, there were more than 3,000 offshore oil and gas production facilities in the world, and it is estimated that the number of facilities will increase.<ref>International Energy Agency (IEA), Offshore Energy Outlook (2018), https://webstore.iea.org/download/direct/1034</ref><br> | The offshore platforms are the oil and gas production facilities that are located offshore. In the past, oil and gas were generally produced on the ground. However, as the number of fossil fuel-rich sites that were accessible from the ground has been limited, offshore oil and gas development has been important. In 2016, there were more than 3,000 offshore oil and gas production facilities in the world, and it is estimated that the number of facilities will increase.<ref>International Energy Agency (IEA), Offshore Energy Outlook (2018), https://webstore.iea.org/download/direct/1034</ref><br> | ||

The offshore platform has a lot of subsea structures such as pipelines, so the inspection and maintenance of these structures is a very important issue. However, some platforms are installed in water depths of more than hundreds of meters, so it is impossible for humans to dive and inspect these structures. In order to overcome this problem, Remotely Operated Vehicles (ROVs) are widely used. ROVs are unmanned vehicles that are connected to the mothership by a wire and can be manipulated by operators who are boarding in the mothership. In addition, ROVs can get power through the wire, so they can be operated for a long time. However, ROVs have many problems such as motion limitation caused by the wire. On the other hand, the Autonomous Underwater Vehicles (AUVs) don't have wires, so the operation flexibility is the great advantage of AUVs.<br> | The offshore platform has a lot of subsea structures such as pipelines, so the inspection and maintenance of these structures is a very important issue. However, some platforms are installed in water depths of more than hundreds of meters, so it is impossible for humans to dive and inspect these structures. In order to overcome this problem, Remotely Operated Vehicles (ROVs) are widely used. ROVs are unmanned vehicles that are connected to the mothership by a wire and can be manipulated by operators who are boarding in the mothership. In addition, ROVs can get power through the wire, so they can be operated for a long time. However, ROVs have many problems such as motion limitation caused by the wire. On the other hand, the Autonomous Underwater Vehicles (AUVs) don't have wires, so the operation flexibility is the great advantage of AUVs.<br><br> | ||

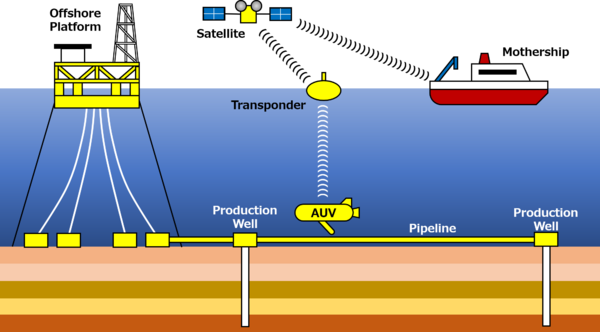

The overview of the AUVs operation in the offshore platform is as below. The AUVs inspect the subsea structures such as pipelines automatically and they can communicate with the operators in the mothership through the transponders and satellites. | The overview of the AUVs operation in the offshore platform is as below. The AUVs inspect the subsea structures such as pipelines automatically and they can communicate with the operators in the mothership through the transponders and satellites. | ||

[[File:AUV inspection.png|600px |frameless|]]<br><br> | [[File:AUV inspection.png|600px|frameless|]]<br><br> | ||

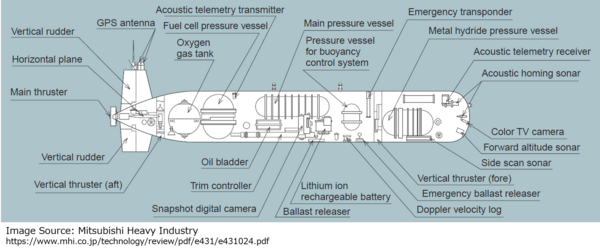

The general arrangement of AUV's mechanical components is as below. Typical AUVs look like a submarine, and they have thrusters and power sources that are necessary to move in the water. In addition, there are some sensors and communication systems such as sonar, camera, and acoustic telemetry system, and they are very important to move underwater automatically and inspect the subsea structures. | The general arrangement of AUV's mechanical components is as below. Typical AUVs look like a submarine, and they have thrusters and power sources that are necessary to move in the water. In addition, there are some sensors and communication systems such as sonar, camera, and acoustic telemetry system, and they are very important to move underwater automatically and inspect the subsea structures. | ||

[[File:Urashima.png|600px |frameless|]] | [[File:Urashima.png|600px|frameless|]] | ||

==Design Structure Matrix (DSM) Allocation== | ==Design Structure Matrix (DSM) Allocation== | ||

Revision as of 11:04, 25 November 2020

Technology Roadmap Sections and Deliverables

The unique identifier of this technology roadmap is:

- 2AUVOPI - Autonomous Underwater Vehicle for Offshore Platform Inspection

This indicates that we are dealing with a “level 2” roadmap at the product or system level, where “level 1” would indicate a market level roadmap and “level 3” or “level 4” would indicate an individual technology roadmap.

Roadmap Overview

The offshore platforms are the oil and gas production facilities that are located offshore. In the past, oil and gas were generally produced on the ground. However, as the number of fossil fuel-rich sites that were accessible from the ground has been limited, offshore oil and gas development has been important. In 2016, there were more than 3,000 offshore oil and gas production facilities in the world, and it is estimated that the number of facilities will increase.<ref>International Energy Agency (IEA), Offshore Energy Outlook (2018), https://webstore.iea.org/download/direct/1034</ref>

The offshore platform has a lot of subsea structures such as pipelines, so the inspection and maintenance of these structures is a very important issue. However, some platforms are installed in water depths of more than hundreds of meters, so it is impossible for humans to dive and inspect these structures. In order to overcome this problem, Remotely Operated Vehicles (ROVs) are widely used. ROVs are unmanned vehicles that are connected to the mothership by a wire and can be manipulated by operators who are boarding in the mothership. In addition, ROVs can get power through the wire, so they can be operated for a long time. However, ROVs have many problems such as motion limitation caused by the wire. On the other hand, the Autonomous Underwater Vehicles (AUVs) don't have wires, so the operation flexibility is the great advantage of AUVs.

The overview of the AUVs operation in the offshore platform is as below. The AUVs inspect the subsea structures such as pipelines automatically and they can communicate with the operators in the mothership through the transponders and satellites.

The general arrangement of AUV's mechanical components is as below. Typical AUVs look like a submarine, and they have thrusters and power sources that are necessary to move in the water. In addition, there are some sensors and communication systems such as sonar, camera, and acoustic telemetry system, and they are very important to move underwater automatically and inspect the subsea structures.

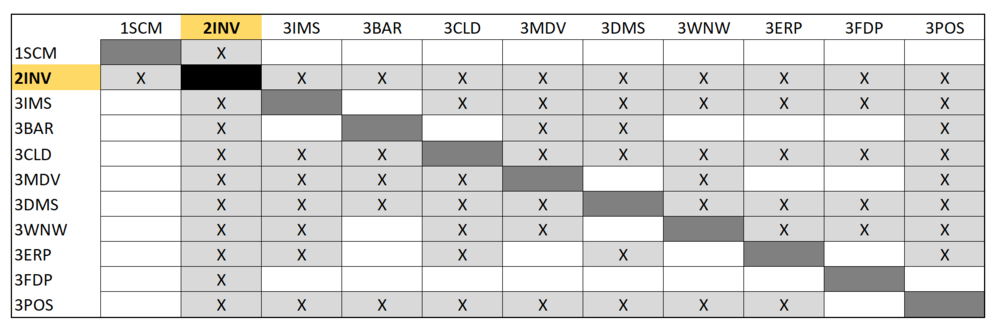

Design Structure Matrix (DSM) Allocation

Roadmap Model using OPM

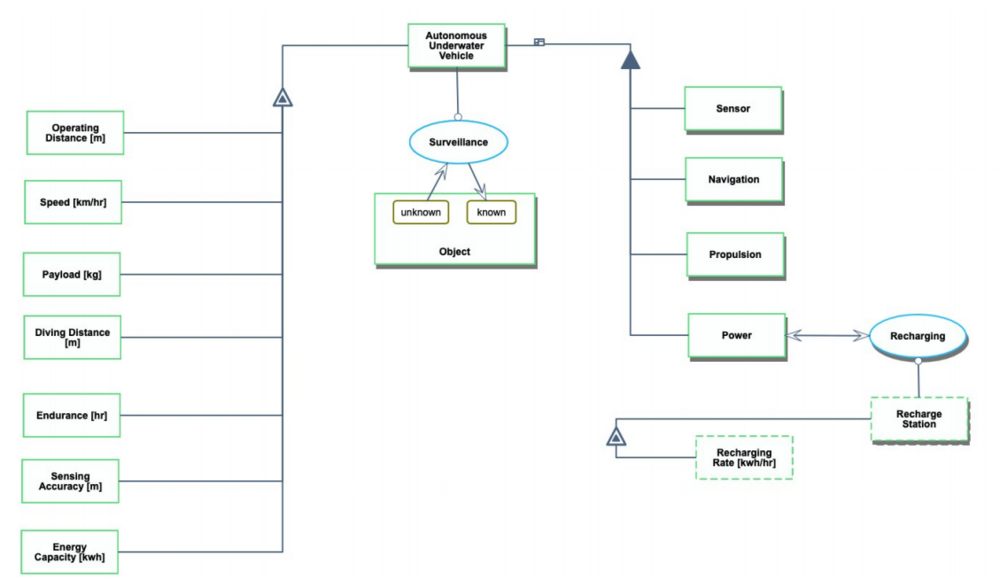

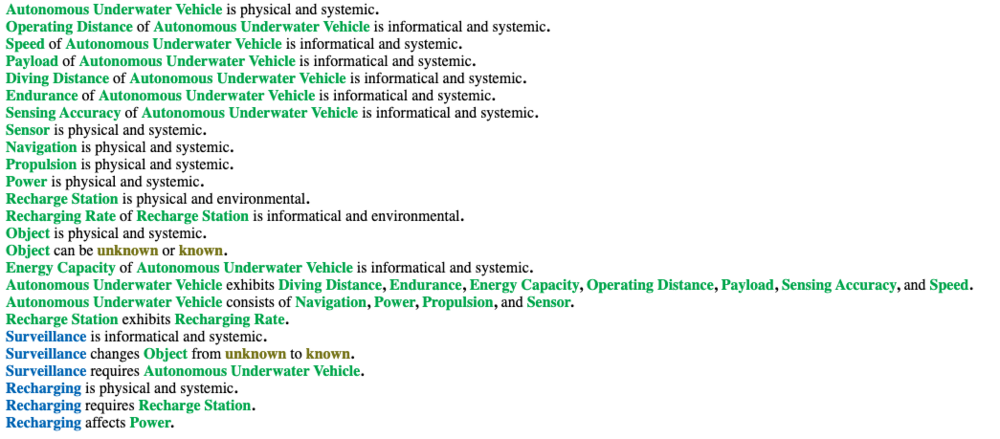

This diagram captures the main object of the roadmap (Autonomous Underwater Vehicle), its various instances including its decomposition into subsystems (Sensors, Navigation, propulsion, Battery, etc…), its characterization by Figures of Merit (FOMs) as well as the main processes (Surveying, Recharging, etc).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.

Figures of Merit (FOMs)

The table below shows a list of FOMs by which autonomous underwater vehicle can be assessed.

| FOM name | Units | Description |

|---|---|---|

| Operating Distance | km | Distance that can be traveled in an operation |

| Speed | km/h | Cruising speed in the water |

| Payload | kg | Useful payload that can be carried |

| Diving Depth | m | Depth that can be reached |

| Endurance | h | Hours that can be operated |

Alignment with Company Strategic Drivers

| # | Strategic Objective | Alignment and Targets |

|---|---|---|

| 1 | To develop batteries for AUVs that can last longer | This will enable the AUVs to dive for a longer duration of time without coming back to the docking station. This will also increase the range to which AUVs can go in one charge. |

| 2 | Better docking system for AUVs | Dockers are used to charge the battery and transfer information from AUVs. But current dockers are prone to error. So a better docking station will make the system more reliable. |

| 3 | Better sensing system for AUVs | One of the typical sensing technologies of the marine vehicle is SONAR. A more accurate SONAR system will help the AUVs to detect any defects in the pipes accurately. |

Positioning of Company vs. Competition

source: https://www.mdpi.com/2076-3417/10/4/1256/pdf

Technical Model

Among many technical components of AUV, the sensor and power source are key components in order to use in the inspection field of the offshore oil & gas production facility, so we focused on these components.

Sensor

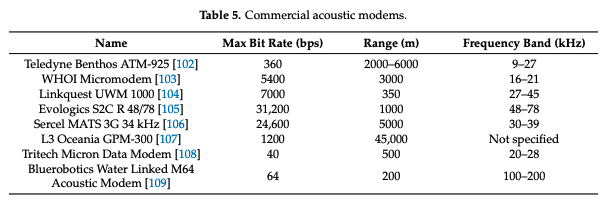

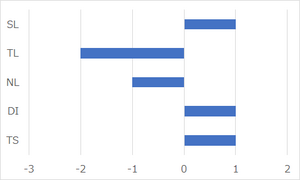

The key FOM of sonar is the “Detection Threshold (DT)”, and the technical equation of DT is as below.

Below is the normalized tornado chart that shows the sensitivity of each parameter to DT.

As this chart shows, TL is the most sensitive parameter. However, it is impossible to change TL and NL because these parameters are determined by the composition and depth of seawater. In addition, TS depends on the character of the inspection target, so we can’t also change this parameter. If we increase SL, DT will be improved, but it needs more energy in order to increase SL. This method may not be effective for AUV because the energy capacity of AUV is limited. On the other hand, DI can be improved by changing the directivity of the receiver, and this improvement would have minimal impact on other components of AUV, so this approach may be effective to improve DT.

Power Source

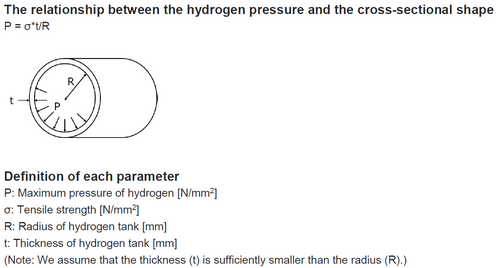

One of the expected power sources of AUV is a fuel cell. If we want to increase the energy capacity of a fuel cell, it is necessary to increase the amount of hydrogen storage. However, the space capacity of AUV is limited, so increasing the pressure of the stored hydrogen, rather than making the dimension of the hydrogen tank larger, would be effective. The relationship between the hydrogen pressure and the tank dimension is below.

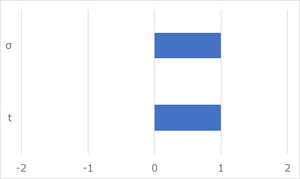

If we can’t change the overall dimension of the hydrogen tank because of the AUV's size limitation, the variables that can be changed are “σ” and “t” in order to increase the hydrogen capacity. Below is the normalized tornado chart that shows the sensitivity of “σ” and “t” to the maximum hydrogen pressure.

As this chart shows, “σ” and “t” have the same sensitivity for maximum hydrogen pressure. However, if we increase “t”, this directly leads to increasing the hydrogen tank weight. In order to avoid weight increase, it is effective to increase“σ”by changing the material of the hydrogen tank.

Key Publications and Patents

In the inspection of Oil & Gas offshore platforms, AUV moves slowly near the facilities such as pipelines on the seabed, and AUV checks the facilities by using nondestructive inspection methods. The key factors of inspection AUVs are "navigation”, “energy supply", "safety”, and “inspection method", so we select the related key publication and patent as below.

Publications

- Yoshiki Sato, Toshihiro Maki, Kotohiro Masuda, Takumi Matsuda, and Takashi Sakamaki, "Autonomous Docking of Hovering Type AUV to Seafloor Charging Station based on acoustic and visual sensing", IEEE Underwater Technology, 2017

Executive Summary: This report is about the automatic navigation and docking technology that use the acoustic signal and visible LED light. In addition, the author also reports the result of wireless charging to AUVs during docking.

Patents

- Byrd, et al. (2019) "Underwater vehicle for inspection of a subsea structure in a body of water and related method", United States Patent 10370074

Executive Summary: The invented AUV has a body like a torpedo and this AUV can sail safely at a certain distance from the pipelines. In addition, this AUV has 2 sensors on the upper and lower side of its body, and these sensors enable us to detect problems such as corrosion in the pipelines nondestructively.

List of R&D Projects

Summary

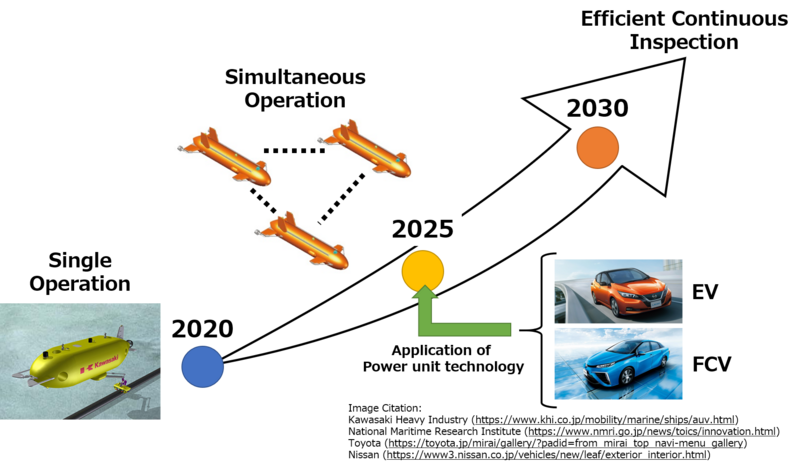

Our goal is the establishment of an AUV system for continuous inspection of oil and gas offshore platforms. This will be able to contribute to providing efficient inspections and making platforms safe.

However, because the energy capacity of each AUV is limited, it is necessary to put the multiple AUVs into the mission by turns.

In order to achieve a seamless inspection, it is important to communicate between each AUV and take over the mission smoothly, so the establishment of communication technology between AUVs is an important R&T topic.

In addition, the longer the hours an AUV can operate per one mission, the more cost-effective it becomes because we can reduce the number of AUVs that are necessary to be deployed for replacement.

Therefore, we think that the extension of AUV's operating hours is also an important R&T issue.

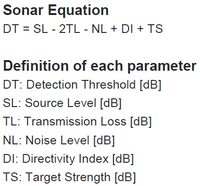

Communication technology between AUVs

Currently, AUVs for oil and gas platform inspection are in practical use, but they are operating independently.<ref>Kawasaki Heavy Industries, Autonomous Underwater Vehicle (AUV) “SPICE”, http://www.khisubsea.co.uk/autonomous-underwater-vehicle/</ref>

If we want to operate several AUVs simultaneously, acoustic multiplexing technology is necessary as a communication method, and this technology has recently been matured.<ref>JAMSTEC, Next-generation technology for ocean resources exploration, https://www.jamstec.go.jp/sip/en/pdf/brochure.pdf</ref>

Based on this situation, our first goal is the integration of acoustic multiplexing technology with AUVs for oil and gas platform inspection.

We plan to take five years for this challenge.

Extension of AUV's operating hours

The extension of AUV's operating hours will be achieved by the development of battery technology or fuel cell technology.

These technologies require a lot of resources, so it is difficult to build everything up from scratch. Fortunately, the technology competition between battery and fuel cell has been progressing in the automobile field, so we will be able to apply the result of R&T of the automotive.

In our analysis, we think that both Li-ion battery and fuel cell are promising energy source for AUV at present.

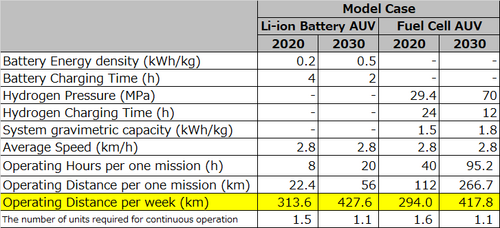

Based on the battery-powered and fuel-cell-powered AUVs that were built so far, we made model cases in 2020 and 2030 as follows.

<ref>Kawasaki Heavy Industries, https://www.khi.co.jp/stories/articles/vol99/</ref>

<ref>Toshio Maeda et al, Fuel Cell AUV "URASHIMA", Mitsubishi Heavy Industries, Ltd. Technical Review Vol.43 No.1(Jan.2006), https://www.mhi.co.jp/technology/review/pdf/e431/e431024.pdf</ref>

<ref>NEDO, Rechargeable Battery Technology Development Roadmap 2013, https://www.nedo.go.jp/content/100535728.pdf</ref>

<ref>Reinhardt Wagner, Battery Fuel Gauges: Accurately Measuring Charge Level (2006)</ref>

<ref>DOE, Target Explanation Document: Onboard Hydrogen Storage for Light-Duty Fuel Cell Vehicles (2017), https://www.energy.gov/sites/prod/files/2017/05/f34/fcto_targets_onboard_hydro_storage_explanation.pdf</ref>

At present, the performance of battery and fuel cell are in competition (Battery (313.6(km/week)) VS Fuel Cell (294.0(km/week))). In addition, the performance improvement expected in 2030 is also in competition (Battery (427.6(km/week)) VS Fuel Cell (417.8(km/week))). Therefore, we think that narrowing down power unit candidates to either battery or fuel cell is not a good idea at this time.

However, these predictions are just model cases, so the situation may change significantly depending on future technological developments.

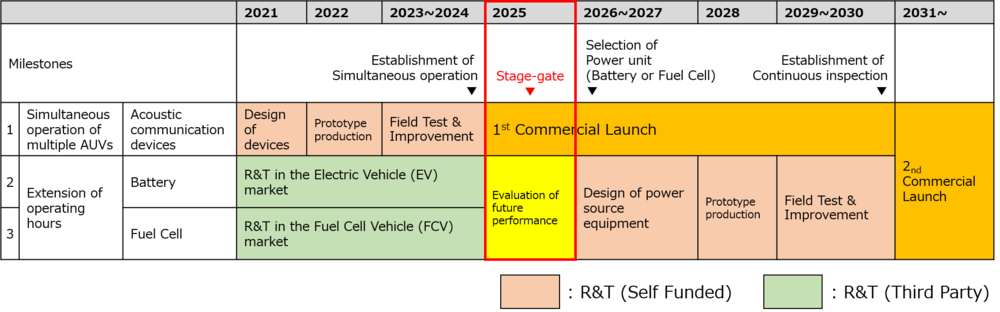

Therefore, we plan to keep following up on the development trends of power unit until 2025, decide which technology is suitable for our AUV in 2025, and install the power unit in 2030.

R&T schedule

The overall R&T schedule is as below. We set a stage-gate in 2025 and are going to decide whether we should expand our project or not.

Financial Model

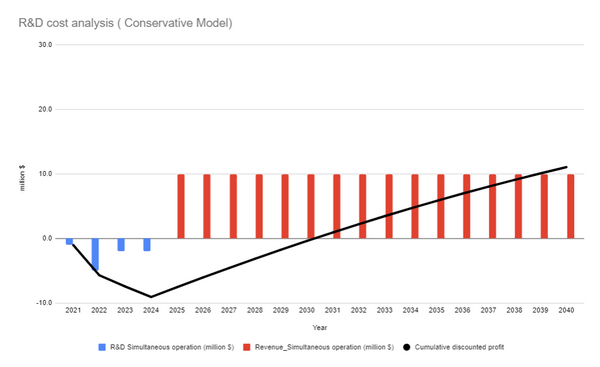

Based on the above R&T schedule, we analyzed the financial feasibility of our project.

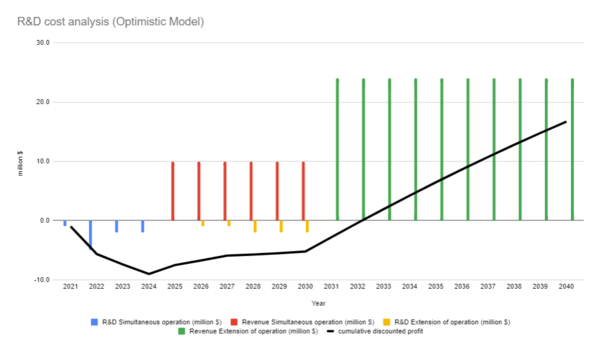

Our strategy has two stages. In the first stage, we conduct R&T of acoustic communication technology and start selling AUVs with this technology in 2025.

In the second stage, we conduct R&T of battery or fuel cell technology and start selling AUVs with new power units in 2031.

Based on the evaluation results about the power unit scheduled in 2025, we will be able to choose between the following two models.

1) Conservative model: We don't invest in the R&T of the power unit, and we continue to sell only AUVs with acoustic communication technology. In this case, the operation hours of this AUV remain short, so the unit price will be low and the number of sales will be small (1 million$/unit, 10 unit/year) because of the low competitiveness.

2) Optimistic model: We decide to invest in the R&T of the power unit, and we will start to sell the AUVs with new power units in 2031. In this case, the operation hours of this new AUV will be long, so the unit price and the number of sales will increase (1.2 million$/unit, 20 unit/year) based on the high competitiveness.

Based on the similar projects of AUV's communication technology, we estimated that the R&T cost of acoustic communication technology is 10 million $. This cost covers the design, 2 prototype AUVs production, field test, and improvement. The manufacturing cost of 2 prototype AUVs will be the most expensive (5 million $). In addition, we estimated that the R&T cost of the power unit is 8 million $. We plan to divert the prototype AUVs for acoustic communication technology to the R&T of the power unit, and this will lead to cost-saving of R&T. In both models, we expect a learning effect on productivity. We assume that the initial profit margin is 20%, and the profit margin improves by 1% each year. Furthermore, we assume that the discount rate is 7% that is general in the R&D project, and calculate the Net Present Value (NPV) by 2040. Based on these assumptions, we analyzed the financial forecast as follows.

Financial forecast of conservative model

Financial forecast of optimistic model

As these results show, even if we choose the conservative model, the NPV is positive (11.1 million $). This means that the conservative model is profitable. However, the optimistic model is more profitable (NPV: 16.7 million $), so it can be mentioned that the stage-gate related to the power unit scheduled in 2025 is very important for our project because this will determine whether we can maximize profits or not.

Technology Strategy Statement

As we mentioned above, our goal is the establishment of an AUV system for efficient continuous inspection of oil and gas offshore platforms in 2030. In order to achieve this goal, we will invest in two R&T projects. The first is the integration of acoustic multiplexing technology with AUVs, and we plan to succeed in the coordinated simultaneous operation of multiple AUVs until 2025. The second project is the extension of AUV's operating hours. Our strategy is to apply the technology of the automobile industry to AUVs, so we plan to assess the development trends of the automobile power unit in 2025 and integrate the selected technology into the AUVs in 2030. This will enable us to maximize the operating hours and minimize the number of AUVs which are necessary to the continuous inspection mission.

References

<references />