Difference between revisions of "Selective Laser Sintering"

| (10 intermediate revisions by the same user not shown) | |||

| Line 9: | Line 9: | ||

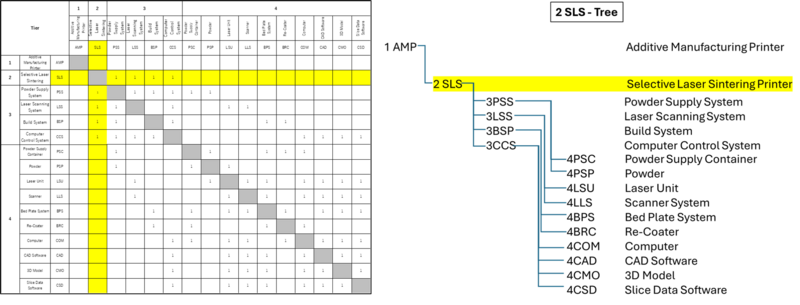

==Design Structure Matrix (DSM) Allocation== | ==Design Structure Matrix (DSM) Allocation== | ||

[[File: | [[File:DSM SLS.png|800x800px|frameless|center]] | ||

==Roadmap Model using OPM== | ==Roadmap Model using OPM== | ||

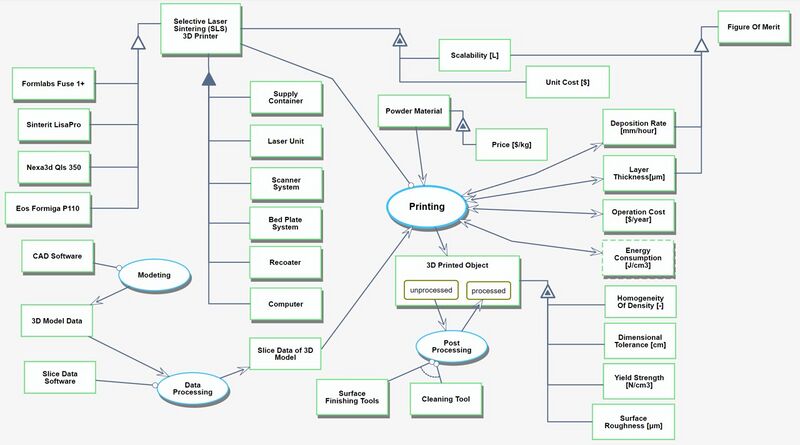

We provide an Object-Process-Diagram (OPD) | We provide an Object-Process-Diagram (OPD) of the 2SLS roadmap in the figure below (Fig.4-1). This diagram captures the main object of the roadmap (SLS 3D printing), its various instances that are famous in the industry, its decomposition into subsystems (laser unit, supply container, bed plate system …), its characterization by Figures of Merit (FOMs) as well as the main 3D printing processes (modeling, printing, post-processing). | ||

[[File: | [[File:OPD SLS.jpg|800x800px|frameless|center]] | ||

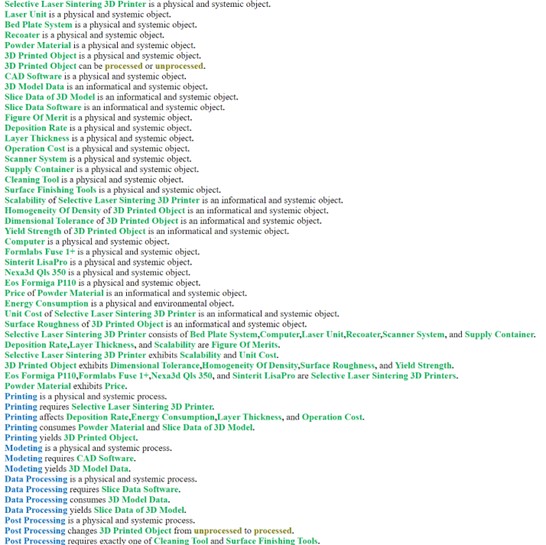

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below | An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. | ||

[[File: | [[File:OPL SLS.jpg]] | ||

==Figures of Merit== | ==Figures of Merit== | ||

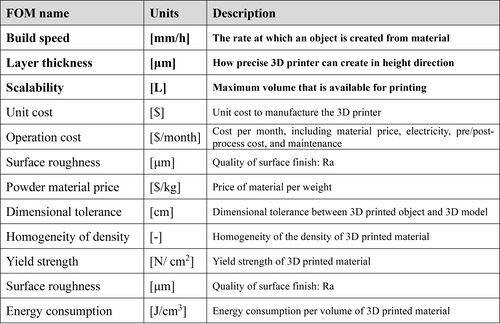

The | The below shows a list of FOMs by which SLS 3D printing can be assessed. Since we focus on applying this technology to industry, cost, time, and precision are critical factors. | ||

[[File: | [[File:FOM SLS.jpg|500x500px|frameless|center]] | ||

Latest revision as of 05:29, 10 October 2024

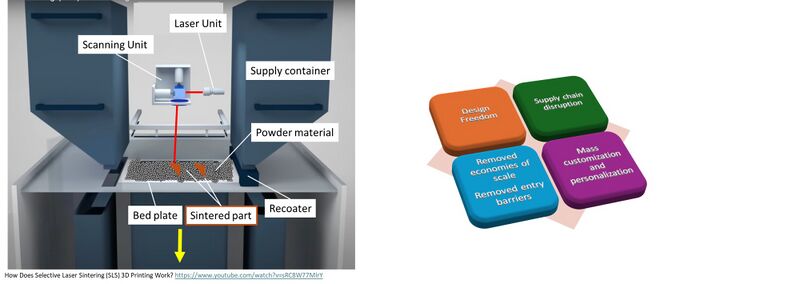

Roadmap Overview

3D printing, or additive manufacturing, is a disruptive innovation transforming traditional manufacturing. Unlike subtractive methods, which remove material from a large block, 3D printing builds parts layer by layer, creating intricate designs previously impossible to manufacture. This technology has significantly reduced the time and complexity involved in assembly, allowing parts to be made on demand without sourcing from distant suppliers. By streamlining the prototyping process, 3D printing accelerates innovation and lowers costs, enhancing customer satisfaction and reducing product development waste. This technology has also changed cost structures in manufacturing by eliminating the need for large-scale, non-recurring investments in molds, tools, and setups. Industries such as aerospace, automotive, and healthcare have benefited from 3D printing's ability to produce lightweight, complex designs, like Pratt & Whitney's Geared Turbo Fan engine components and GE's 3D-printed fuel nozzles. With its potential to minimize waste and support sustainability, 3D printing continues to disrupt supply chains and enable mass customization across various sectors.

Design Structure Matrix (DSM) Allocation

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2SLS roadmap in the figure below (Fig.4-1). This diagram captures the main object of the roadmap (SLS 3D printing), its various instances that are famous in the industry, its decomposition into subsystems (laser unit, supply container, bed plate system …), its characterization by Figures of Merit (FOMs) as well as the main 3D printing processes (modeling, printing, post-processing).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below.

Figures of Merit

The below shows a list of FOMs by which SLS 3D printing can be assessed. Since we focus on applying this technology to industry, cost, time, and precision are critical factors.