Difference between revisions of "Inventory Management System"

| Line 49: | Line 49: | ||

[[File:FoM_Table_1.png|700px|frameless|left]] | [[File:FoM_Table_1.png|700px|frameless|left]] | ||

<br /> | |||

==== Examples of FOM performance ==== | ==== Examples of FOM performance ==== | ||

Revision as of 17:12, 12 October 2023

Technology Roadmap

Roadmap Overview

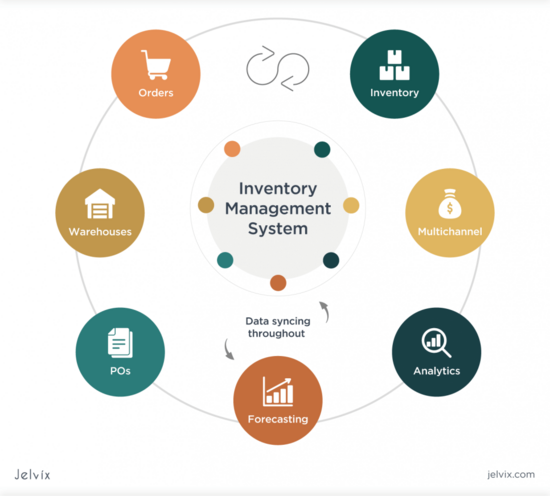

Inventory management system is a critical component of business operations' supply chain management that ensures efficient flows of materials and products from vendors to customers.

Key Goals of the SCM – inventory management system are:

- Providing timely, complete, and accurate inventory levels to managements

- Minimizing carrying costs while ensuring product availability.

- Reducing stockouts and overstock situations.

- Enhancing supply chain visibility and responsiveness.

- Streamlining operations and reducing inefficiencies.

- Lowering costs while maintaining service levels.

- Meeting customer demand accurately and on time.

- Adapting to changes in demand, supply, and market conditions.

Effective management systems provide the right products at the right time and place to meet growing customer demand. It is a critical aspect of modern business operations and plays a crucial role in achieving profitability and customer satisfaction.

*image-source - https://jelvix.com/blog/automated-inventory-management-system

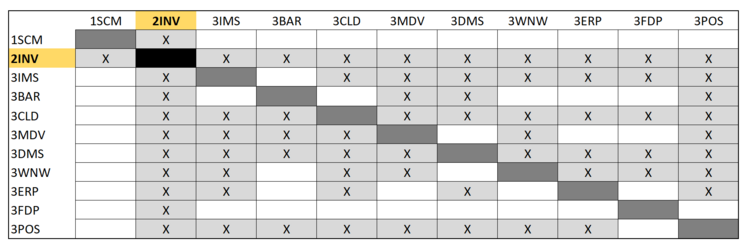

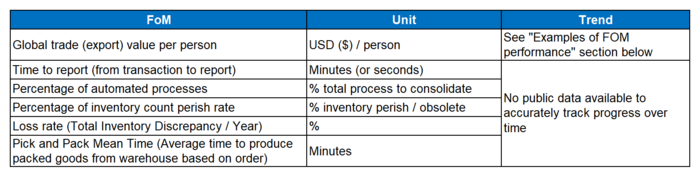

Design Structure Matrix (DSM) Allocation

DSM of the Inventory Management System:

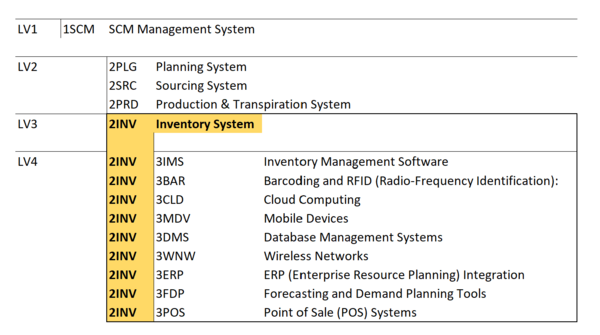

The tree structure of the Inventory Management System.

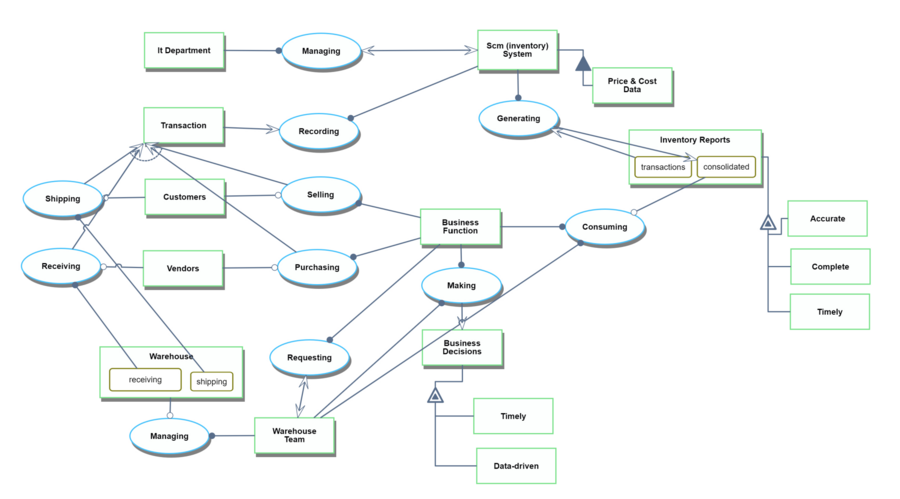

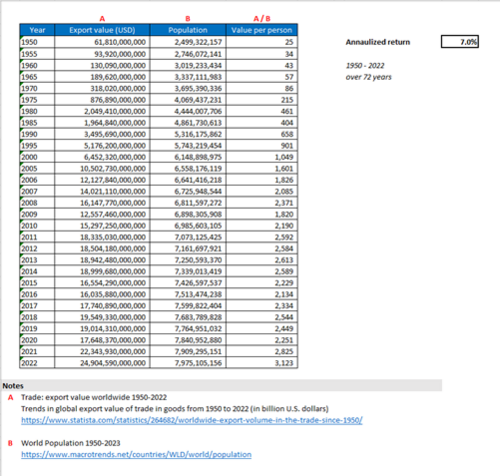

Object Process Model (OPM)

This OPM represents the Inventory Management System:

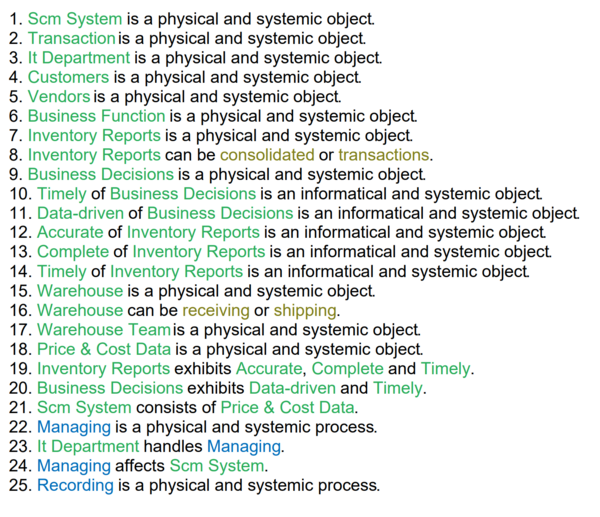

Figures of Merit (FoM)

The table below show a list of FOMs by which can assess an Inventory Management System technology:

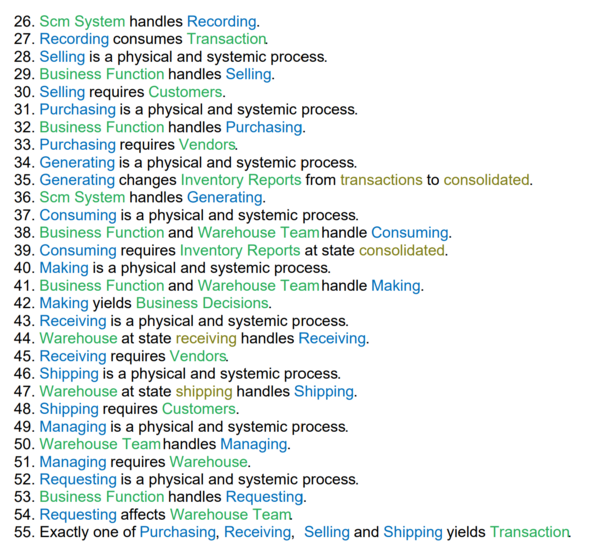

Examples of FOM performance

Over the last 52 years, inventory management system was improved by about 7% annualized growth based on the FoM trend indicated below: