Difference between revisions of "Superconducting Cable"

| Line 88: | Line 88: | ||

Our review of patents and academic papers aims to facilitate the pragmatic implementation of superconducting cables. We identify the three technological domains as follows: | Our review of patents and academic papers aims to facilitate the pragmatic implementation of superconducting cables. We identify the three technological domains as follows: | ||

*1. | '''*1. Enhancing Critical Current Density in High Magnetic Fields'''<br /> | ||

==Technology Strategy Statement== | ==Technology Strategy Statement== | ||

Revision as of 13:22, 27 October 2023

Technology Roadmap Sections and Deliverables

- 3SC - Superconducting Cable

Roadmap Overview

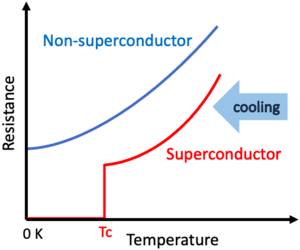

The feature of the superconductivity phenomenon, the basis of this roadmap technology (3SC - Superconducting Cable), is an unusual property of certain substances, including metals, alloys, and ceramics, in which electrical resistance drops to zero when the temperature is reduced below a critical temperature (Tc), as shown in the Right-sided graph. In contrast, in the case of the other normal materials, electrical resistance decreases as the temperature is lowered but does not disappear completely.

The roadmap technology is the superconducting cable, which is the cable incorporated by some material that can show superconducting phenomenon (i.e., superconductors or superconducting material) to be designed for conducting electricity with zero resistance. (It is classified under the "Transporting Process (2)" and the "Energy (E)" categories in 5x5 matrix.) The technology is pivotal for mitigating energy losses inherent to electrical resistance, which is crucial for efficiency and operational cost reduction, especially in the context of long-distance power transmission.

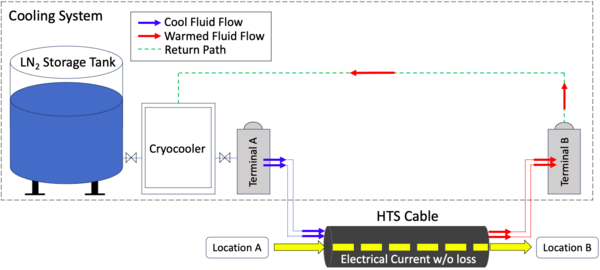

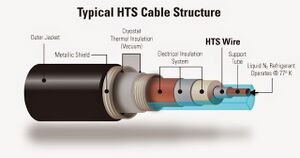

In general, there are three types of superconductors: low temperature superconductors, high temperature superconductors and room temperature superconductors. The Right-sided figure shows the typical depiction of high temperature superconducting cable, incorporating high temperature superconducting materials, which is designed to conduct electricity with zero resistance by using liquid nitrogen to cool the superconductors up to certain enough temperature(e.g., to 77k) and activate the superconductivity phenomenon. Compared with the traditional low temperature superconducting materials, which necessitate even lower temperatures, typically requiring liquid helium, high temperature superconducting cable can perform the superconductive state with relatively higher temperatures inside the cable. It means that the high temperature superconducting cable is advantageous regarding the cooling costs and the availability of coolants.

The system concept of the high temperature superconducting cable (including a cooling system) transporting electrical current without loss is as follows. Typically, High Temperature Superconducting (HTS) wires, consisting of superconducting materials, are placed in a pipe (cryostat thermal insulation) with a vacuum, which thermally isolates the superconductor from the remaining environment. Inside the pipe is the liquid nitrogen flow path. The technology requires special cable joints and specific cable termination for extreme temperature differences and a permanent cooling system for keeping the cryostat. Note: If room temperature superconductors that operate at atmospheric pressure are discovered in the future, the need for a cooling system can be eliminated. That is one of the ultimate technologies; however, they are still in the basic research stage.

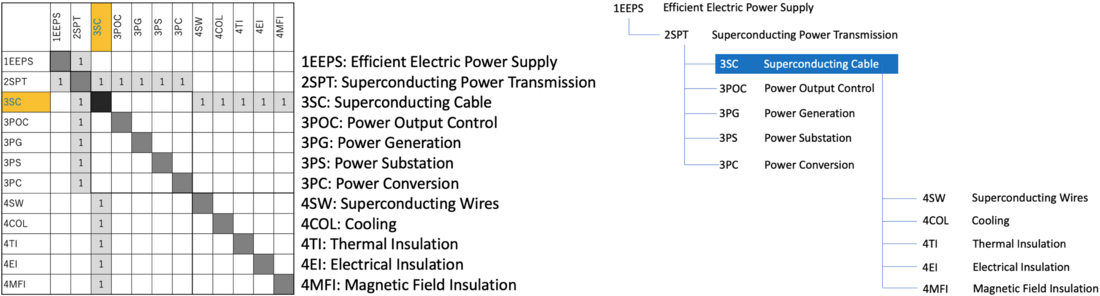

Design Structure Matrix (DSM) Allocation

The 3SC-tree that we can extract from the DSM above shows us that the Superconducting Cable (3SC) is part of a larger system initiative on Superconducting Power Transmission (2SPT), and Superconducting Power Transmission is also part of a larger initiative on achieving Efficient Electric Power Supply (1EEPS).

As subsystem level of the Superconducting Power Transmission, other than Superconducting Cable, the following are required: Power Output Control (3POC), Power Generation (3PG), Power Substation (3PS) and Power Conversion (3PC).

Superconducting Cable requires the following key enabling technologies at the component level: Superconducting Wires (4SW), Cooling (4COL), Thermal Insulation (4TI), Electrical Insultation (4EI) and Magnet Field Insulation (4MFI). These five are the most common technology components to apply the phenomenon of superconductivity to the power transmission cable.

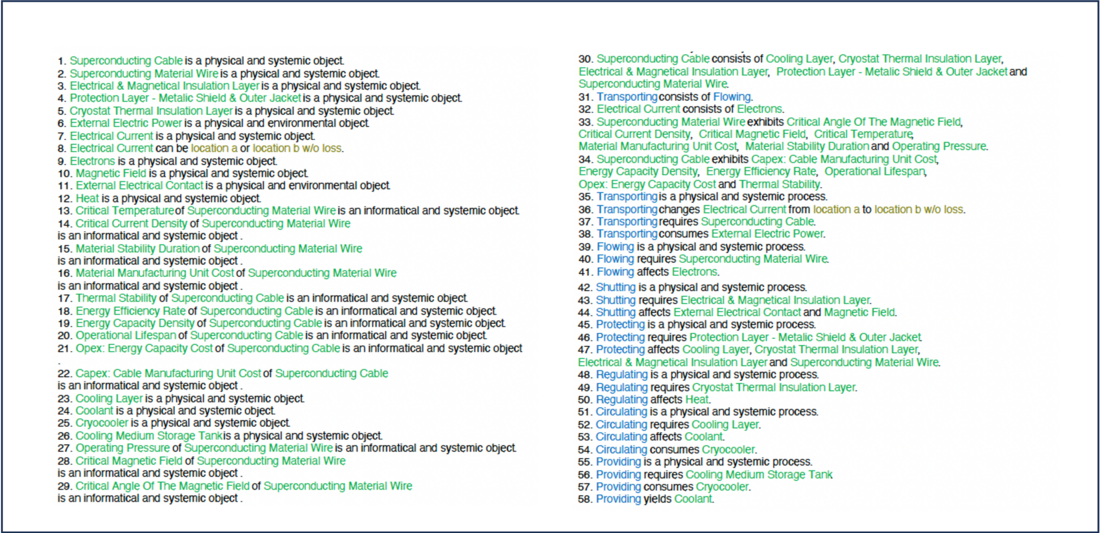

Roadmap Model using OPM

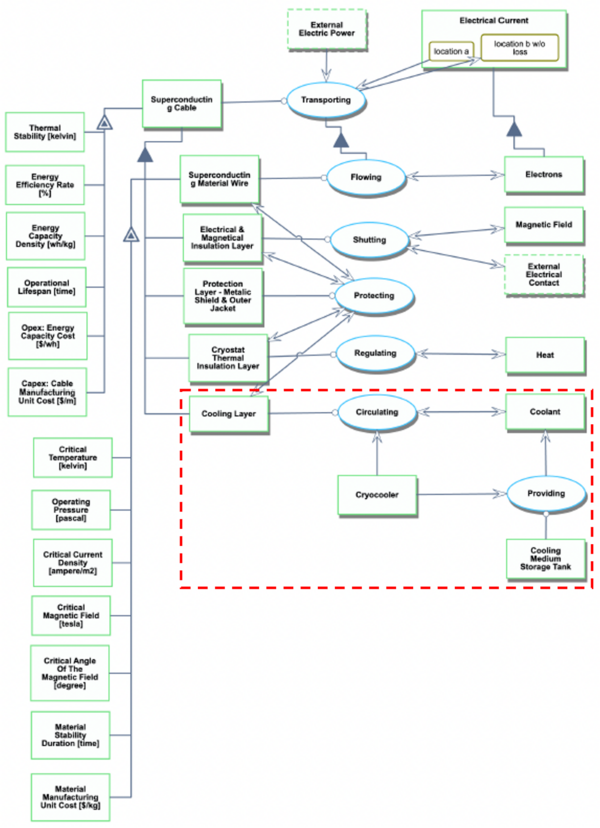

We provide an Object-Process-Diagram (OPD) of the 3SC roadmap in the figure below. This diagram captures the main object of the roadmap (Superconducting Cable), including subsystem decompositions such as superconducting material wire and cooling system, and characterizes the Figures of Merits (FOMs) as well as the main processes (transporting) and state changes (electrical current from location A to location B without loss). Note that for room-temperature superconducting cables, the area enclosed by the red dashed-line square can be deleted from the OPD because it does not require the cooling medium.

An Object-Process Language (OPL) of the roadmap scope, which corresponds with the above OPD, is shown as follows:

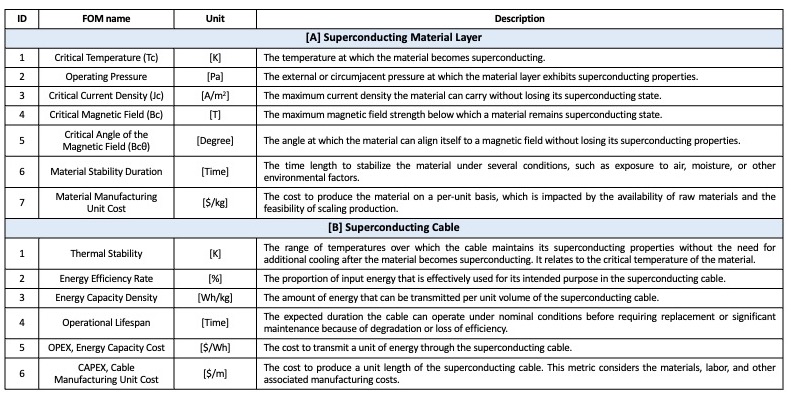

Figures of Merit

The table below shows a list of FOMs by which superconducting cable can be assessed. The FOMs are divided into two groups, compatible with the OPD. Group A shows the FOMs for the superconducting material layer, and Group B shows the FOMs for the superconducting cable, the technology itself we have chosen. To quantify how well a technology performs and how valuable the technology is for the users, it is indispensable to focus on the superconducting material layer, which is critical at the lower level of the system, as well as the cable.

The important FOM trends over time dFOM/dt as well as some of the key governing equations that underpin the technology are summarized as follows:

Critical Temperature and operating pressure

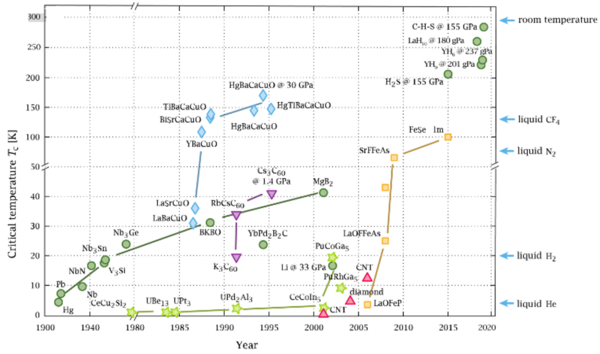

The critical temperature (Tc), the most prominent FOM, has evolved by following some stepping and rising trends. The journey of superconductors began with their discovery in 1911 by Heike Kamerlingh Onnes. Since then, the quest to elevate the critical temperature (Tc) has been relentless. Initially, the focus was on iron-based superconductors, represented by green dots in the following figure (It represents the historical trends of the critical temperature).

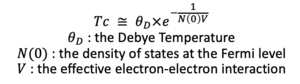

The then governing equation in superconductivity was assumed by BCS theory, a fundamental one based on the following equation:

A monumental shift occurred in 1986 with the emergence of high-temperature superconductors like LaBaCuO, symbolized by blue diamonds, which was beyond the BCS theory and its governing equation. While Nb-based superconductors had a Tc of 20-30K, the high-temperature variant YBCO soared beyond 100K, surpassing even the liquid nitrogen temperature (77K). This achievement held immense practical implications. The subsequent years saw the discovery of superconductors nearing room temperature, though their real-world application is constrained by the need for extremely high pressures, often exceeding 100GPa (i.e., The operating pressure is another FOM of the technology). At present, the critical temperature is found through simulations and experiments, not yet elucidated the governing equations. To summarize the trends, the critical temperature has risen by 280 Kelvin for 110 years since 1911, which means that the rate of critical temperature increase is 2.5 Kelvin per year.

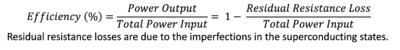

Energy Efficiency Rate

The Energy Efficiency Rate follows the governing equation shown in Right, which means a higher rate indicates minimal energy losses during transmission. For superconducting cables, the efficiency should ideally be close to 100%, indicating nearly zero energy loss during transmission. While over the years, there has been a consistent effort to improve their performance by following the trends of decreasing loss, especially against challenges such as short circuit faults, the present efficiency is around 95% at best. The rate has improved by 20% for 70 years, which means that the increase in the energy efficiency rate is about 0.3% per year(Calculated based on the source: https://www.tepco.co.jp/corporateinfo/illustrated/electricity-supply/transmission-distribution-loss-j.html).

Alignment with Company Strategic Drivers

TBD

Positioning of Company vs. Competition

TBD

Technical Model

TBD

Financial Model

TBD

List of R&D Projects and Prototypes

TBD

Key Publications, Presentations and Patents

Our review of patents and academic papers aims to facilitate the pragmatic implementation of superconducting cables. We identify the three technological domains as follows:

*1. Enhancing Critical Current Density in High Magnetic Fields

Technology Strategy Statement

TBD

References

TBD