Difference between revisions of "Autonomous Mobile Robots for Enhancing Warehouse Logistics"

| Line 8: | Line 8: | ||

=Roadmap Model using OPM= | =Roadmap Model using OPM= | ||

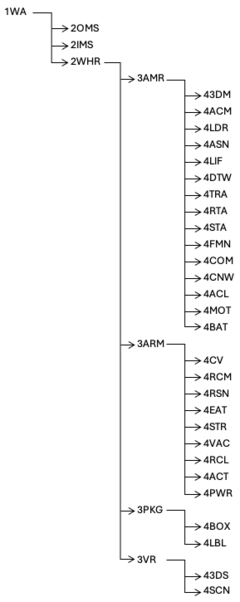

The OPM for Warehouse Automation and the role of Autonomous Mobile Robots is shown below. | |||

[[File:3AMR_OPM_v02.jpeg|1200px]] | [[File:3AMR_OPM_v02.jpeg|1200px]] | ||

Revision as of 22:46, 9 October 2024

Roadmap Overview

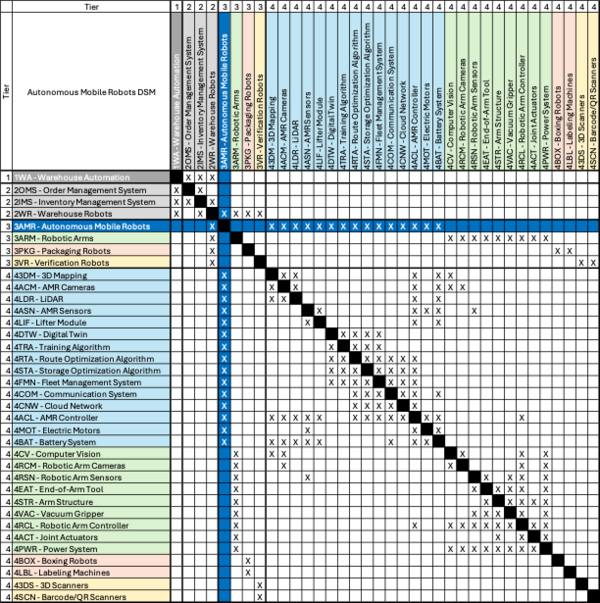

Design Structure Matrix (DSM) Allocation

We present here the DSM allocation of Autonomous Mobile Robots and its tree. The company-wide initiative of Warehouse Automation is supported by the Order Management System, the Inventory Management System, and Warehouse Robots. Warehouse Robots can be classified into Autonomous Mobile Robots, Robotic Arms, Packaging Robots, and Verification Robots. We focus on the Autonomous Mobile Robot for this roadmap, which is enabled by level 4 technologies in light blue, such as 3D Mapping, Digital Twin, and the Route Optimation Algorithm. The DSM shows coupling between technologies; for example, the development of the Lifter Module is dependent on the performance of Sensors, Controller, and Battery System.

Roadmap Model using OPM

The OPM for Warehouse Automation and the role of Autonomous Mobile Robots is shown below.

Figures of Merit (FOM)

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Payload Capacity | [kg] | Total weight the AMR can carry (including items and shelves) |

| Speed | [m/s] | Average speed of the AMR while carrying shelves inside the warehouse |

| Volume | [m^3] | Volume of AMR (width x length x height) |

| Continuous Operation Time | [hrs] | Total time the AMR can operate in one full charge |

| Picking Rate | [units / hr] | Number of units the AMR can assist the picker to pick per hour |

| Failure Rate | [times/ hr] | Number of times the AMR fails per hour |

| Learning Time | [hrs] | Total time it takes to train the AMR to operate in a warehouse |