Difference between revisions of "On Demand Spare Manufacturing"

Jump to navigation

Jump to search

| Line 32: | Line 32: | ||

| Material Waste || Excess material utilized in the production process || % | | Material Waste || Excess material utilized in the production process || % | ||

|- | |- | ||

| Defect Rate || The fraction of parts that are not suitable for use || % | | Defect Rate || The fraction of parts produced that are not suitable for use || % | ||

|} | |} | ||

Revision as of 04:45, 10 October 2024

Overview

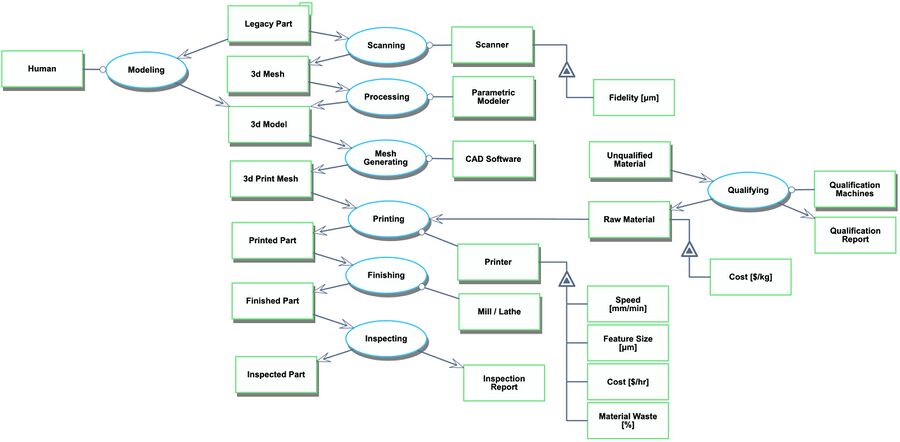

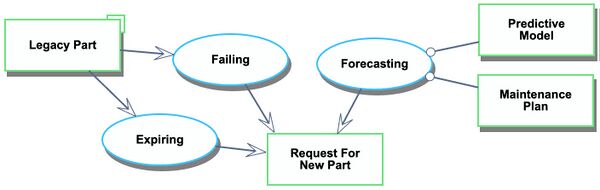

On Demand Spare Manufacturing is the manufacturing of spare parts as-needed as opposed to a traditional stockpiling approach. It leverages digital manufacturing technologies such as additive manufacturing, 3D scanning, optimization algorithms, and supply chain logistics. On Demand Spare Manufacturing requires identifying the need for a spare, transporting materials for manufacturing, scanning, processing, mesh generating, manufacturing the spare part, finishing, inspecting, transporting the spare part to the system, and installing the replacement part.

Design Structure Matrix

Roadmap Model using Object-Process-Methodology (OPM)

Figures of Merit

| FOM | Description | Unit |

|---|---|---|

| Turn-Around-Time | Time from need identified to need met | hr |

| Cost | Total replacement part cost | $ |

| Feature Size | The smallest detail that can be reproduced | μm |

| Lifespan | Replacement part lifespan | year |

| Material Cost | Raw material cost | $/kg |

| Production Cost | Aggregate cost of labor, machine time, etc... | $/hr |

| Material Waste | Excess material utilized in the production process | % |

| Defect Rate | The fraction of parts produced that are not suitable for use | % |