Difference between revisions of "Digital Twin Technology"

| Line 116: | Line 116: | ||

[[File:5.3.2.jpg|800px|none]] | [[File:5.3.2.jpg|800px|none]] | ||

[[File:5.3.3.jpg|800px|none]] | [[File:5.3.3.jpg|800px|none]] | ||

[[File:5.3.4.jpg|800px|none]] | |||

[[File:5.3.5.jpg|800px|none]] | |||

[[File:5.3.6.jpg|800px|none]] | |||

[[File:5.3.7.jpg|800px|none]] | |||

[[File:5.3.8.jpg|800px|none]] | |||

[[File:5.3.9.jpg|800px|none]] | |||

[[File:5.3.10.jpg|800px|none]] | |||

[[File:5.3.11.jpg|800px|none]] | |||

[[File:5.3.12.jpg|800px|none]] | |||

[[File:5.3.13.jpg|800px|none]] | |||

[[File:5.3.14.jpg|800px|none]] | |||

[[File:5.3.15.jpg|800px|none]] | |||

[[File:5.3.16.jpg|800px|none]] | |||

[[File:5.3.17.jpg|800px|none]] | |||

[[File:5.3.18.jpg|800px|none]] | |||

[[File:5.3.19.jpg|800px|none]] | |||

</div> | </div> | ||

Revision as of 07:00, 5 November 2024

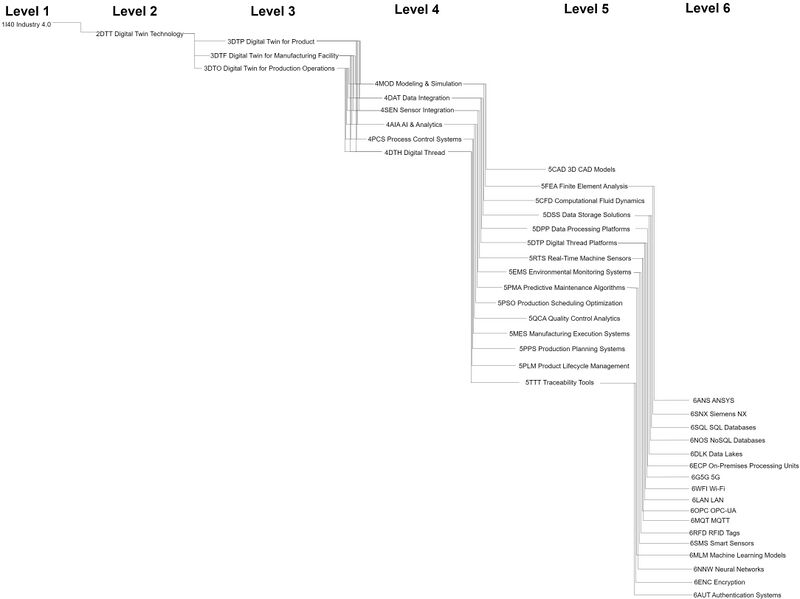

Technology Roadmap Sections and Deliverables

Our technology roadmap identifier is shown as:

- 2DTT - Digital Twin Technology

This identifier represents a Level 2 technology roadmap focused on product-level aspects of Digital Twin Technology. The roadmap is segmented into various tiers, with each level becoming more granular and specific as it progresses.

Level 1 (Market Level):

- It focuses on the broader market context for Embraer to revolutionize its manufacturing facilities, primarily focusing on Industry 4.0.

- The market demands, and technological trends that drive the need for Digital Twin solutions are addressed here.

Level 2 (Product/Technology Level):

- This is the product or overarching technology level, dealing with the general 2DTT Digital Twin Technology and its strategic significance to industry needs.

- Level 2 encompasses the overall architecture and essential components of Digital Twin, such as Physical Technology Integration and Smart Industry Platforms.

Level 3 (System/Facility Level):

- The roadmap breaks down into system-level components where the Digital Twin is implemented across specific systems or facilities.

- Key areas covered include technology implementation in product, facility, and operations. Level 3 covers end-to-end integration and system-level optimization.

Level 4 (Subsystem Level):

- At this level, the subsystems and digital enablers are detailed, such as Modeling & Simulation, Sensor Integration, CAD Data Integration, AI & Analytics, Process Control Systems, and Digital Threads.

- Level 4 subsystems are pivotal in effectively deploying Digital Twins across different environments.

Level 5 (Component Level):

- The roadmap moves to specific components like Edge Units, Real-Time Monitoring Sensors, Data Storage Structures, Predictive Maintenance Algorithms, and Quality Control Analysis.

- Level 5 components ensure the robust performance of digital twin models by continuously feeding real-time data and predictive insights into the system.

Level 6 (Technology or Tool Level):

- Finally, at the most granular level, individual technologies or tools such as AI/ML Models, Encryption Mechanisms, Authentication Systems, and Digital Twins Interoperability Tools are addressed.

- Level 6 elements ensure that the Digital Twin systems are secure, scalable, and integrated with other enterprise systems.

Technology Overview

Implementing a digital twin in Embraer’s aircraft manufacturing facility is an essential step towards realizing Industry 4.0, characterized as the Embraer 4.0 strategy by 2030. The field of Digital Engineering defines Digital Twin as a virtual representation of physical assets, processes, systems, or products that serve as a real-time representation throughout the system development lifecycle. The Aircraft Manufacturing Facility’s Digital Twin is a seamless integration of Data Handling, System Integration, Modeling, Simulation, and Digital Thread Implementation.

As per Embraer's Digital Twin strategy, defined by the Industry 4.0 Vertical Team, it primarily addresses three critical challenges:

- a) Infrastructure

- b) Business Processes

- c) Digital Thread

In addition, the successful realization of Digital Twin also encompasses:

- i) Establishing robust system integration

- ii) Optimizing data storage

- iii) Processing capacities

- iv) Evaluating ROI

- v) Managing transformative changes

The Digital Twin Strategy is intended not to be realized in a vacuum but well integrated with other ongoing Digital/AI Transformation efforts. This includes 'Generative AI models which will play an essential role in enabling Digital Twins to simulate and optimize manufacturing processes, adapt to unforeseen scenarios, and generate innovative solutions.

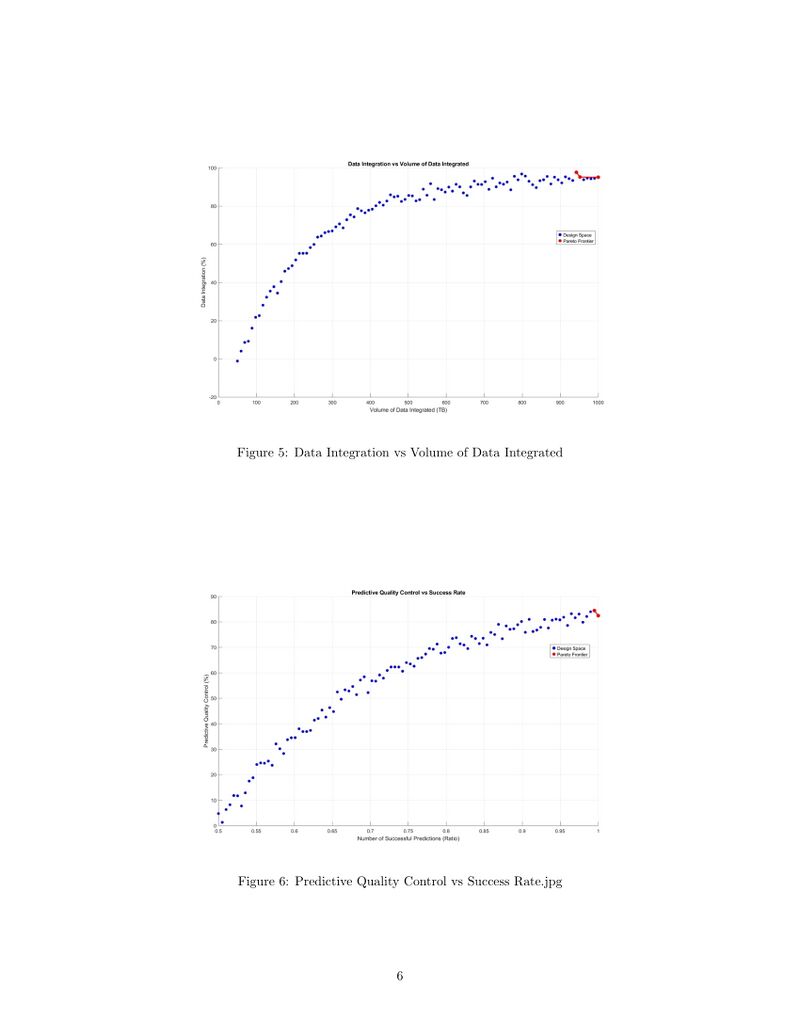

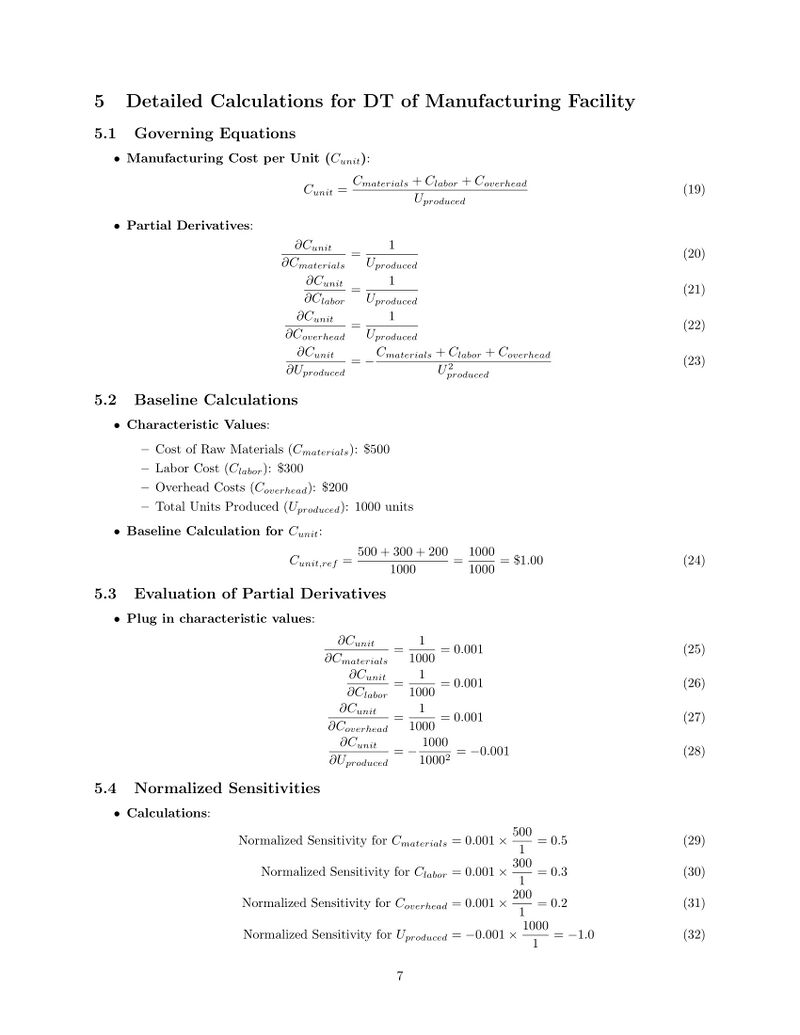

The diagram Progress of Digital Twin Technology from 1943 to 2024 illustrates how Digital Twin has evolved over the years regarding its capability to integrate available data for specific complex systems. Historical events have been used as Data points to illustrate the critical milestones in Ditial Twin, incorporating technologies such as Neural Networks, Computer Aided Engineering (CAE), Computer-Aided Design (CAD), and Cognitive Learning capabilities. The evolution graph uses Data Integration Equation to track the progression of capability development of Digital Twin, with each historical milestone appearing to mark an increase in data integration.

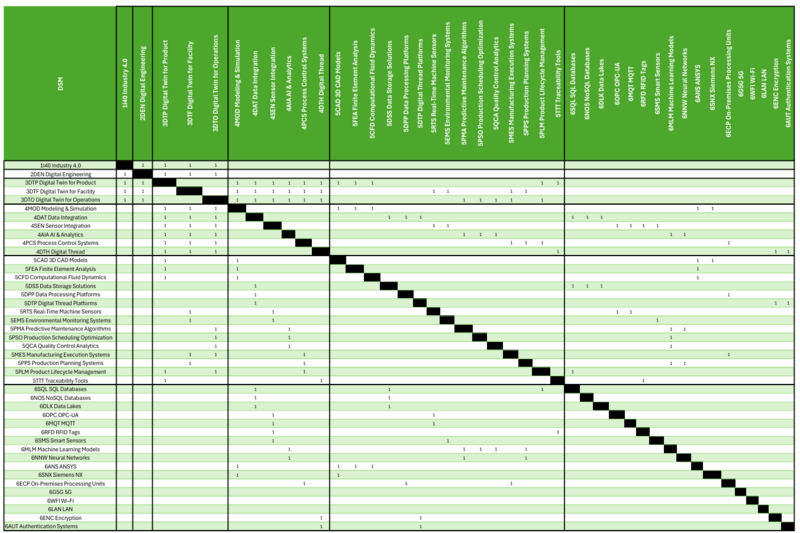

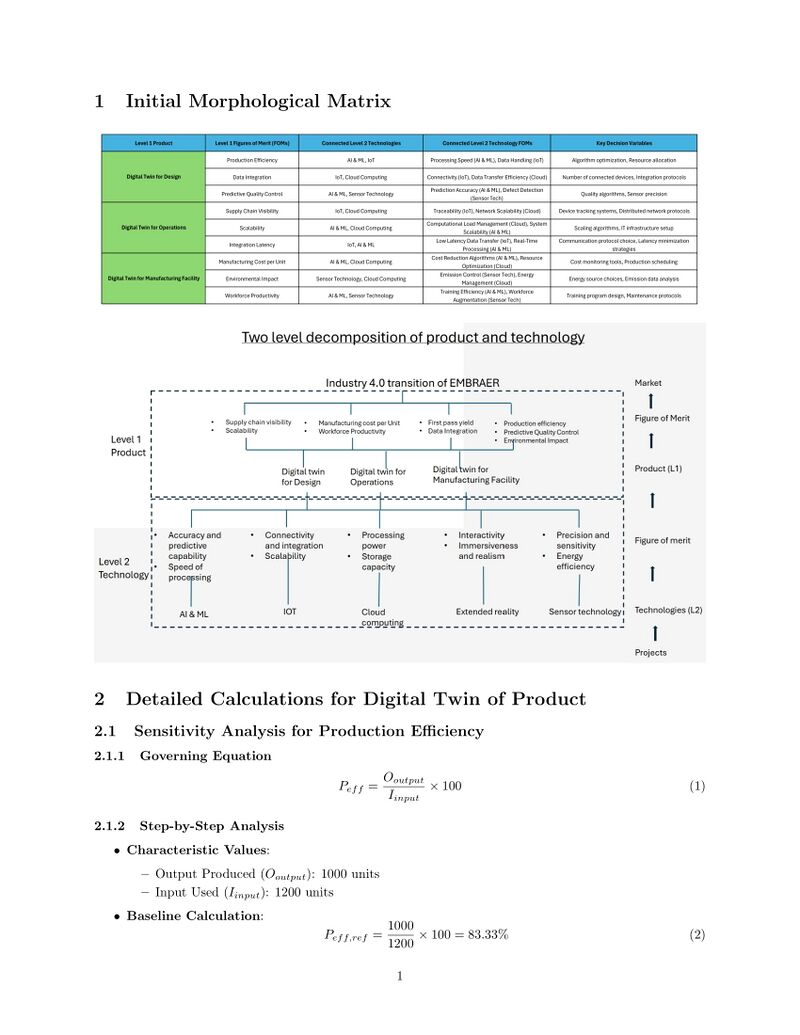

Design Structure Matrix (DSM) Allocation

The above 2DTT Digital Twin Technology decomposition and Design Structure Matrix (DSM) visualize the complex layers of technology integration essential for next-generation systems. Starting at 1I40 Industry 4.0, the framework trickles down through key enablers like 2DEN Digital Engineering and 3DTF Digital Twin for Facilities, connecting all the way to component-level technologies such as 4MOD Modeling & Simulation, 4SEN Sensor Integration, and 5PMA Predictive Maintenance Algorithms. These lower-level elements at levels 4 and 5 don't operate in silos, and their interdependencies within the DSM reveal a dynamic, real-time interplay that facilitates continuous system optimization. By illustrating the interaction between subsystems like 4PCS Process Control Systems and 5DPP Data Processing Platforms, the matrix demonstrates how each layer contributes to the holistic advancement of digital twins—from high-level frameworks to operational intelligence. As data integration reaches new heights, the DSM paves the way for intelligent, adaptive systems that drive scalability, efficiency, and innovation, establishing the Digital Twin as the linchpin of future industrial transformation.

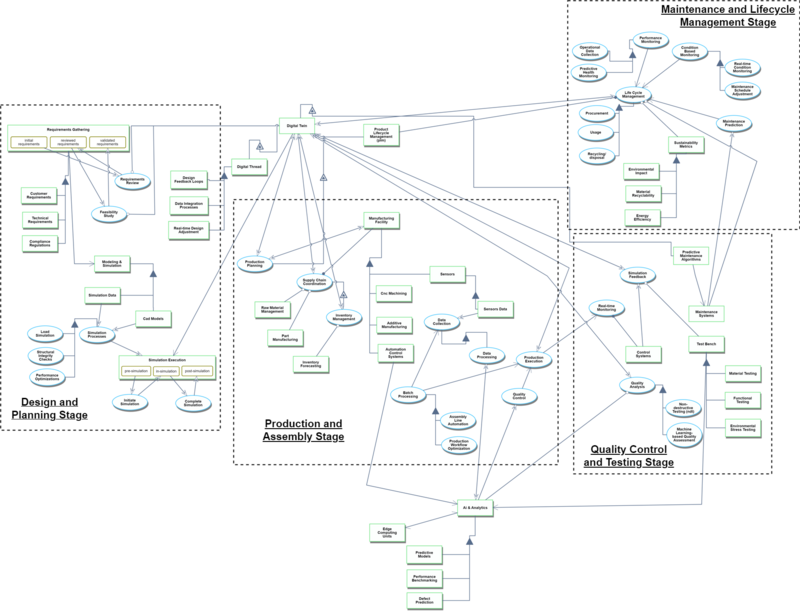

Roadmap of Digital Twin Technology OPM

The Digital Twin roadmap outlines a comprehensive flow across multiple lifecycle stages, incorporating the design and planning, production and assembly, quality control and testing, and maintenance and lifecycle management stages. At the core is the Digital Twin, which integrates data from sensors and real-time monitoring systems to simulate, optimize, and adjust virtual models of aircraft products, manufacturing facilities, and operational systems. Through the Digital Thread, a continuous feedback loop is maintained, connecting the aircraft's design, production, and operational performance. The roadmap includes processes such as Data Collection, Simulation Execution, Predictive Maintenance, Quality Control, and Lifecycle Monitoring, ensuring that the digital and physical realms are synchronized for efficient production, real-time operational adjustments, and sustainable lifecycle management. Advanced AI Analytics and Predictive Algorithms enhance the system's ability to monitor and predict outcomes, while interdependencies between the Supply Chain, Manufacturing Process, and Product Design are continuously optimized for enhanced productivity, scalability, and environmental sustainability. This approach ensures a seamless integration of all stages, enabling precise decision-making and high operational efficiency.

Roadmap Images

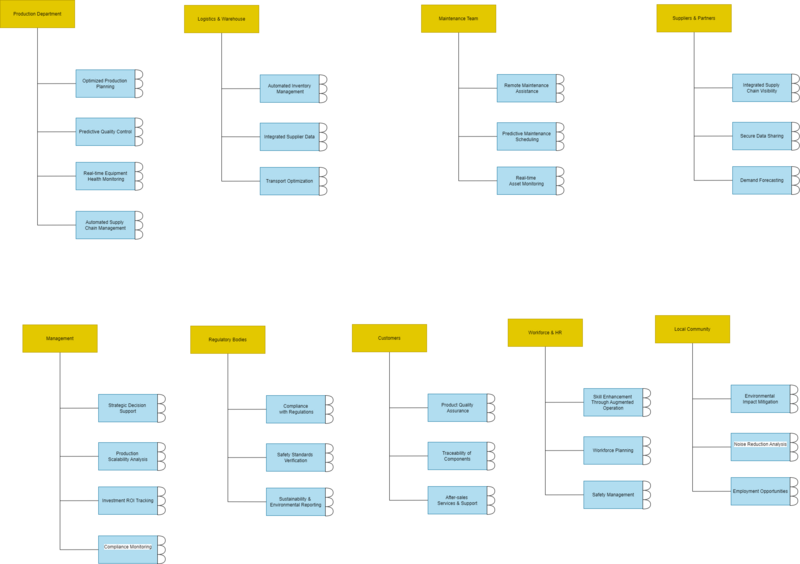

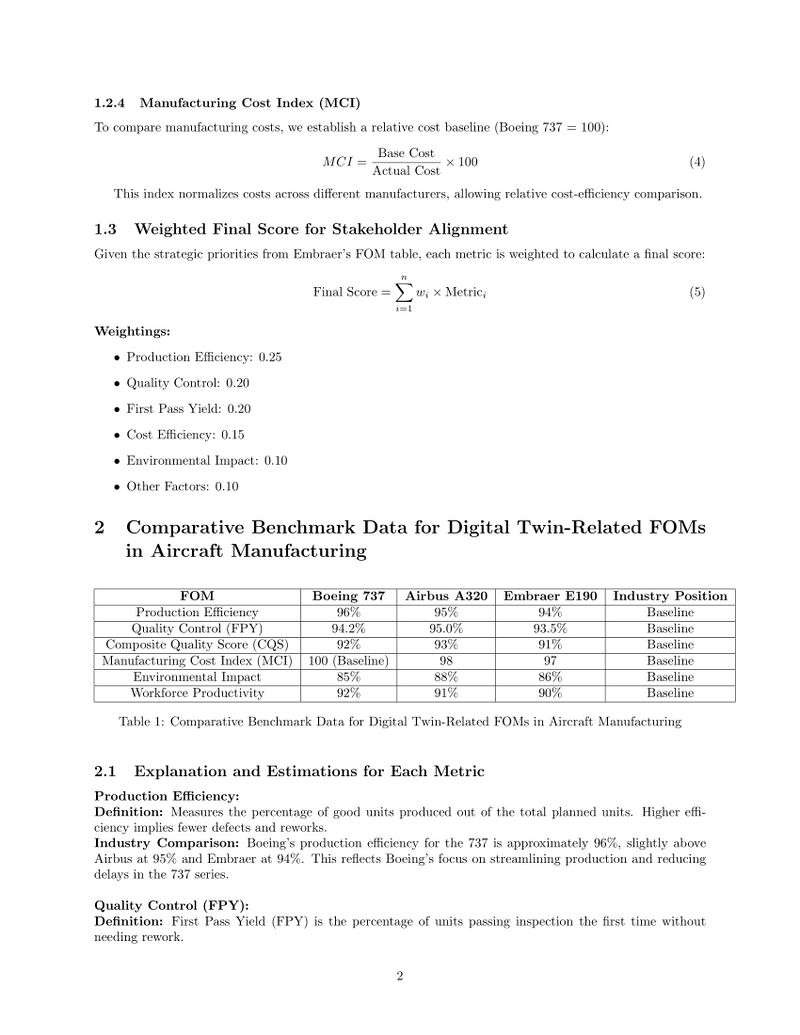

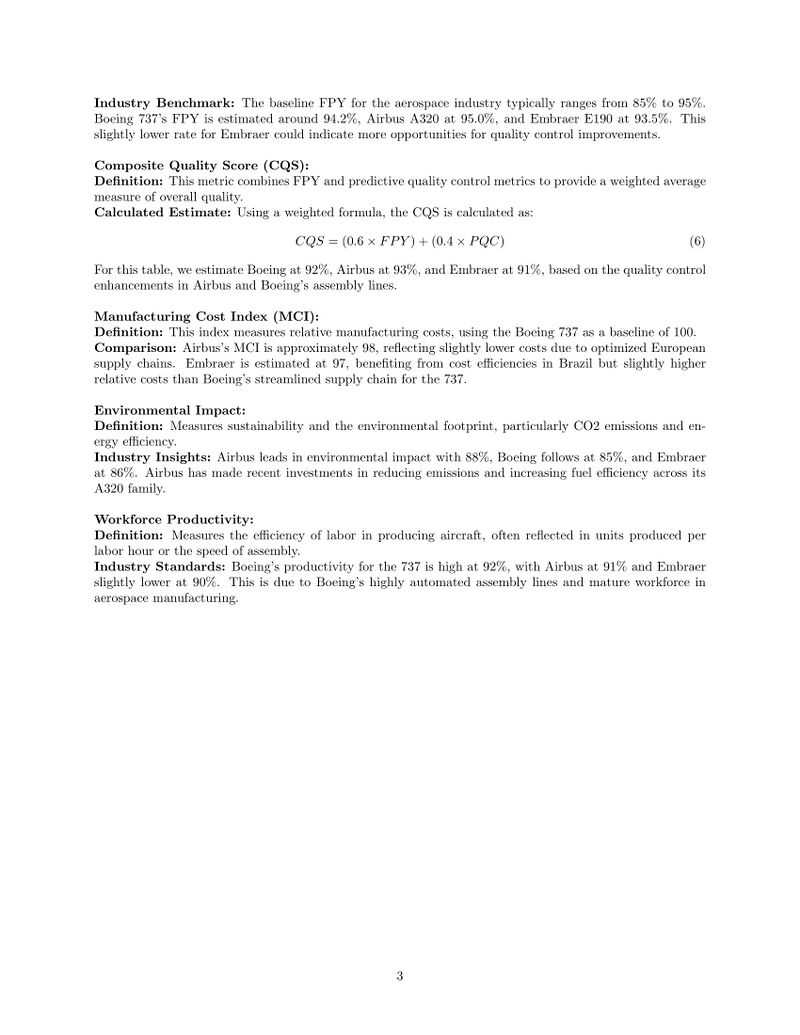

Figure of Merit (FOM) Section

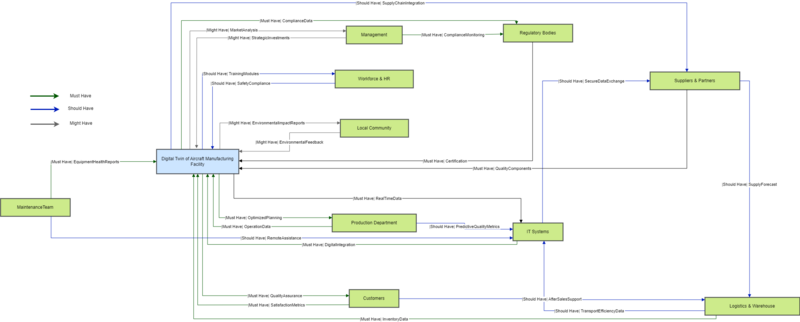

We began by identifying key stakeholders who have a direct or indirect impact on the Digital Twin system, as well as those who rely on its performance. This included departments such as production, logistics, IT systems, management, regulatory bodies, customers, and the workforce. For each stakeholder, we conducted a thorough needs analysis to determine their core requirements. For instance, the production department required high efficiency and cost control, while the workforce and HR emphasized safety and productivity improvements. This stakeholder mapping helped us clarify both the fundamental and aspirational goals of each group, ensuring that the Digital Twin technology aligns with their expectations.

To further refine our understanding, we conducted a Stakeholder Value Network (SVN) analysis. In this phase, we mapped out relationships between stakeholders and defined the critical goals (Must Have), important requirements (Should Have), and aspirational excellence (Might Have). For example, Must Have included critical components like equipment health reports for the maintenance team and supply chain visibility for logistics. Should Have requirements focused on optimization goals such as predictive quality metrics and secure data exchange between suppliers. Might Have items were considered performance enhancements, such as advanced environmental feedback and long-term investment insights for management. This analysis provided a structured approach to prioritizing stakeholder needs in line with both operational and strategic objectives.

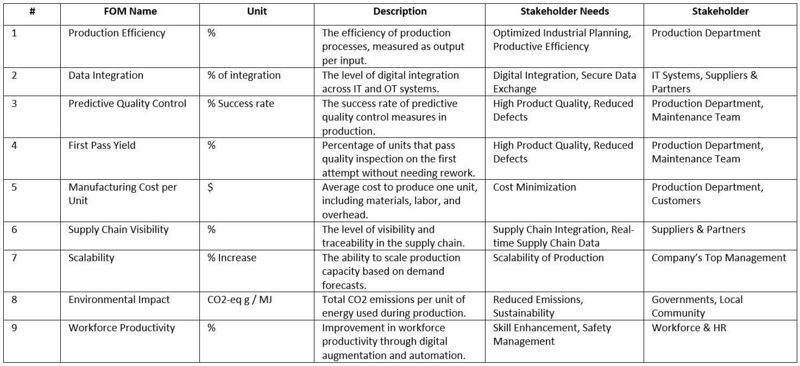

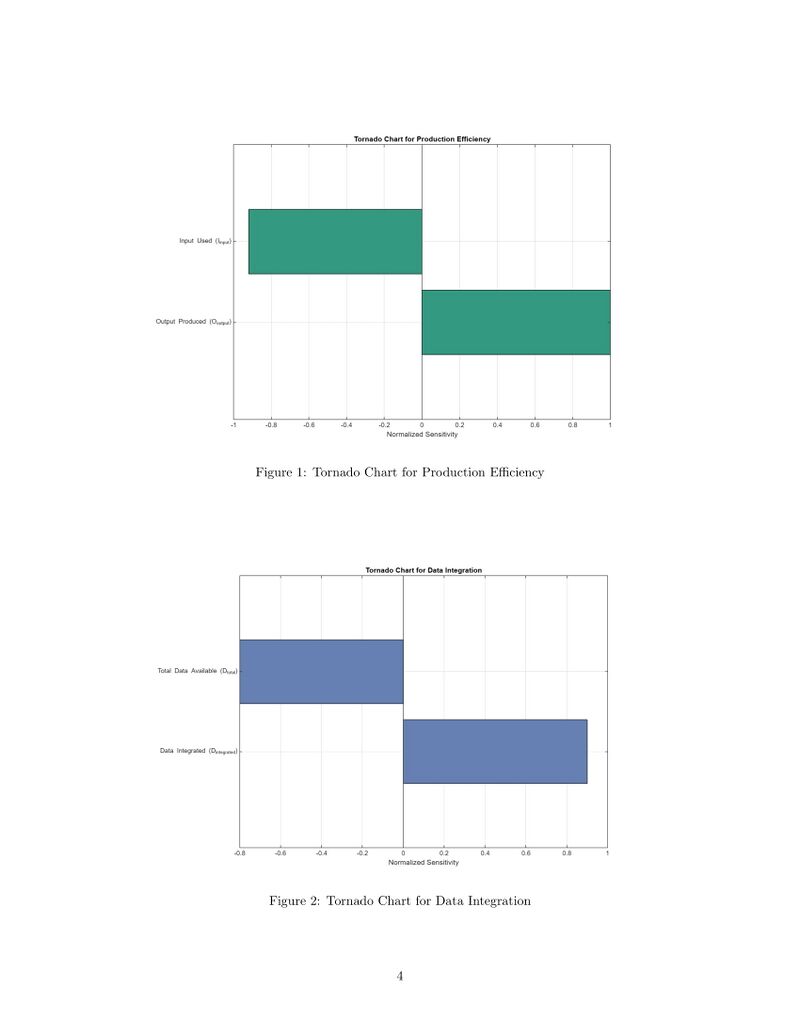

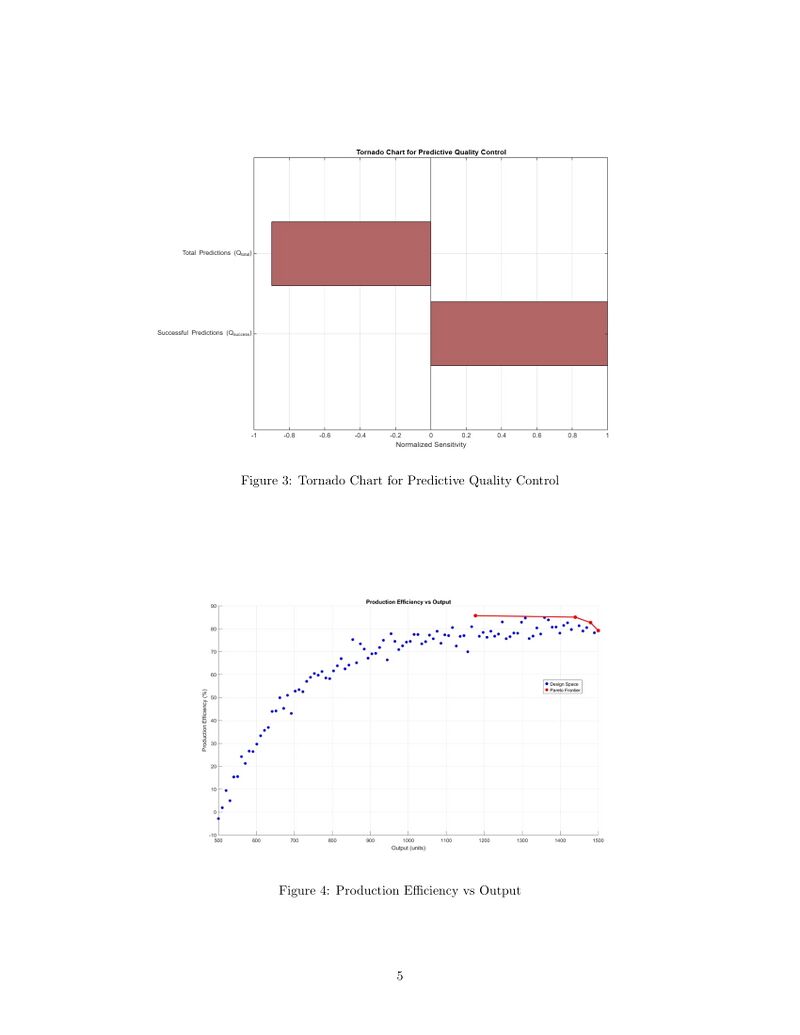

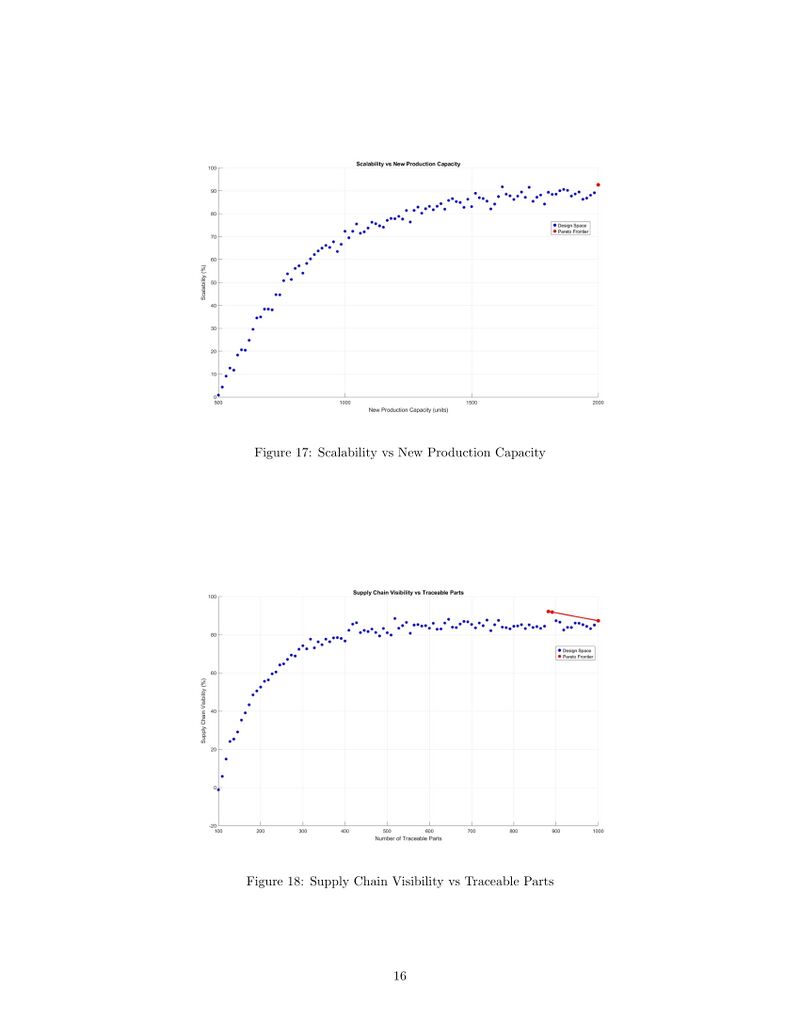

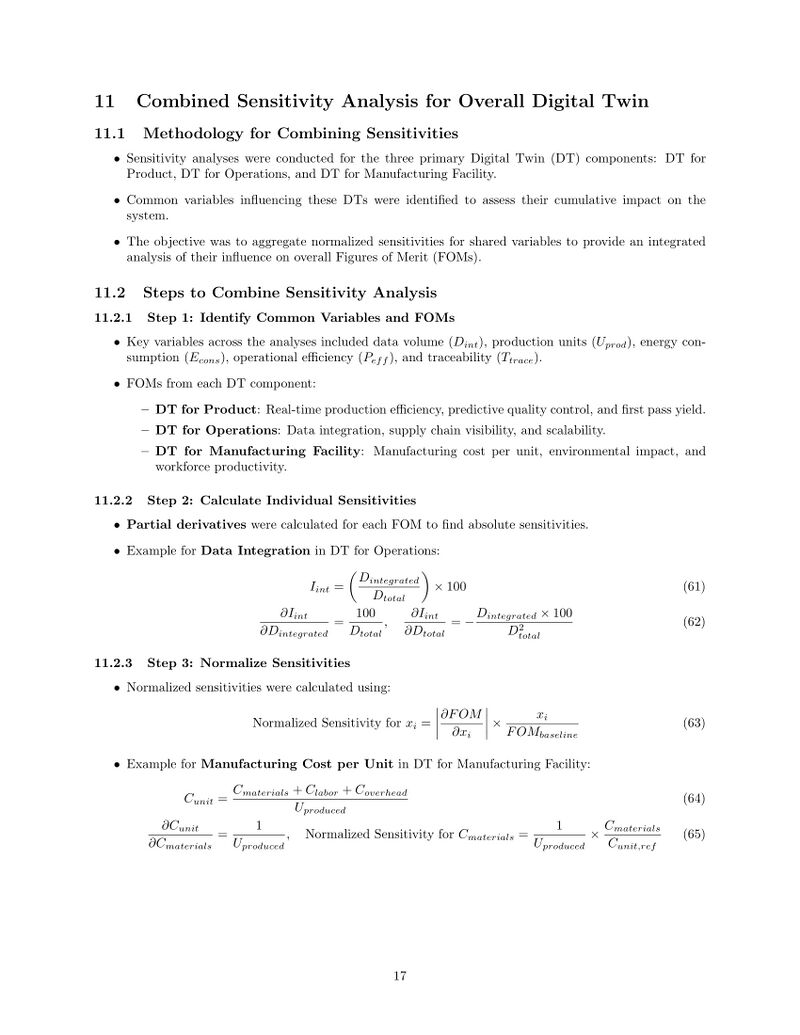

Using the stakeholder needs and goals derived from the SVN analysis, we developed a set of Figures of Merit (FOMs) to address these requirements quantitatively. Each FOM was designed to evaluate the performance of the system in a way that directly aligns with the needs of the stakeholders. For example, Production Efficiency was created to measure how well the manufacturing process optimizes output per input, directly addressing the production department's need for cost-effective operations. Similarly, Supply Chain Visibility measured how well the system tracks parts and inventory throughout the production process, aligning with logistics and warehouse goals. These FOMs ensured that every stakeholder's critical needs were measurable and improvable within the Digital Twin framework.

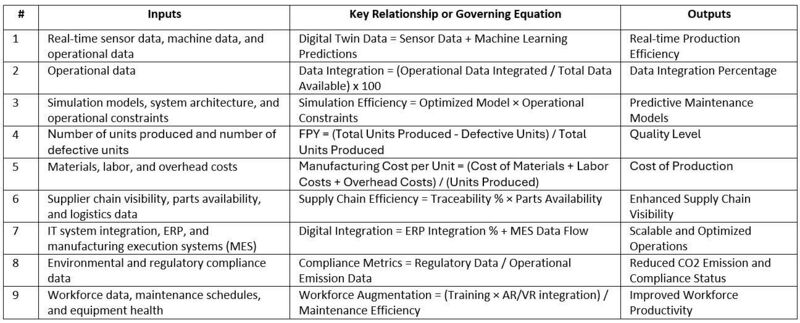

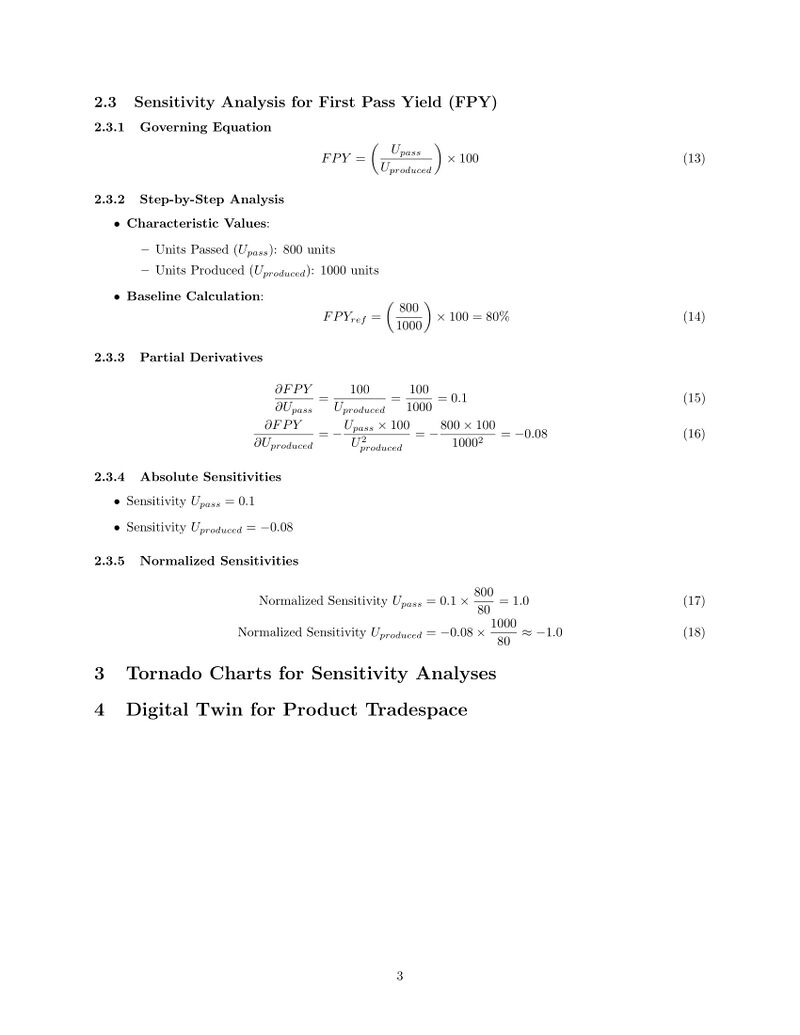

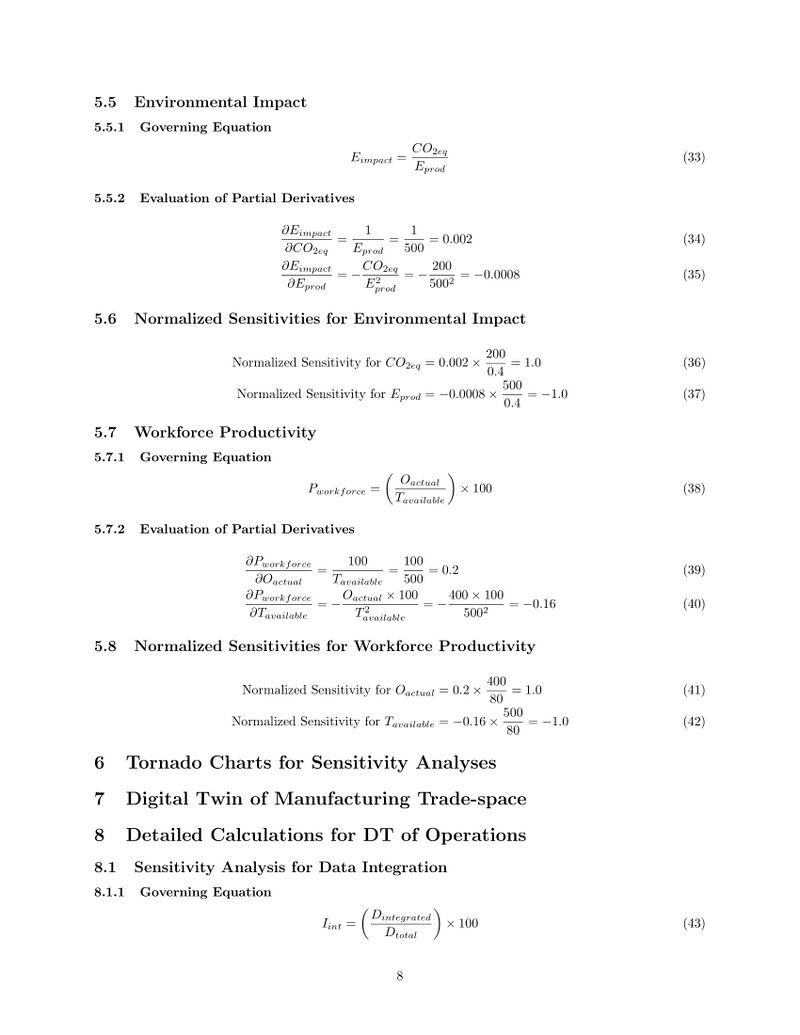

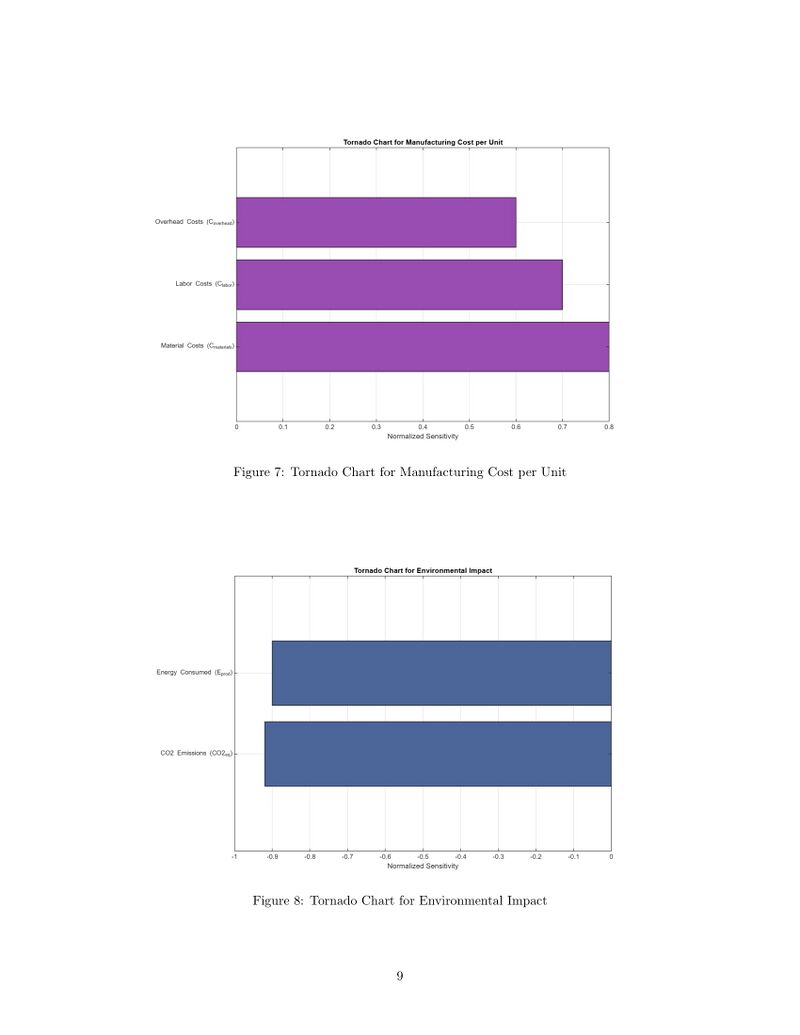

After defining the FOMs, we focused on developing the key governing equations that could quantify each metric. These equations helped us translate stakeholder needs into mathematical formulas that could be tracked and optimized in the Digital Twin system. For example, Production Efficiency was calculated using real-time sensor data, machine learning predictions, and operational output data. First Pass Yield (FPY) was derived from the total number of units produced versus defective units, reflecting quality control measures. Each governing equation ensured that our FOMs were not only measurable but also provided actionable insights into system performance, enabling continuous optimization and alignment with stakeholder needs.

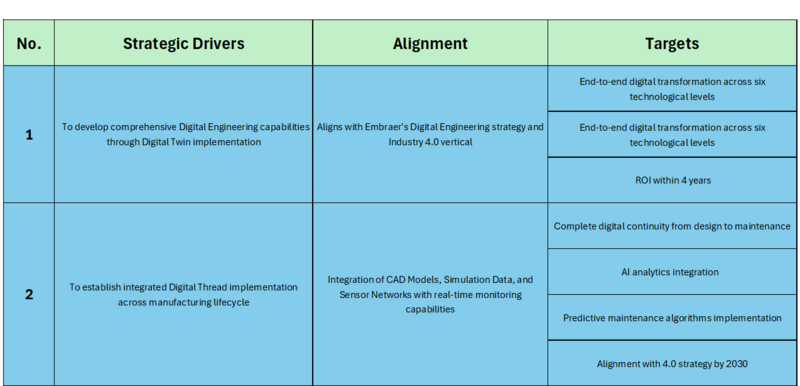

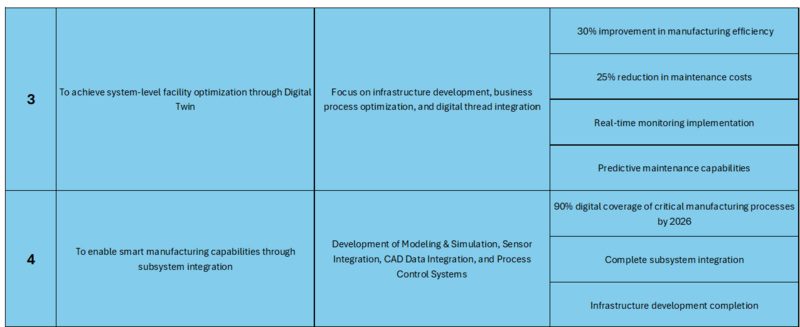

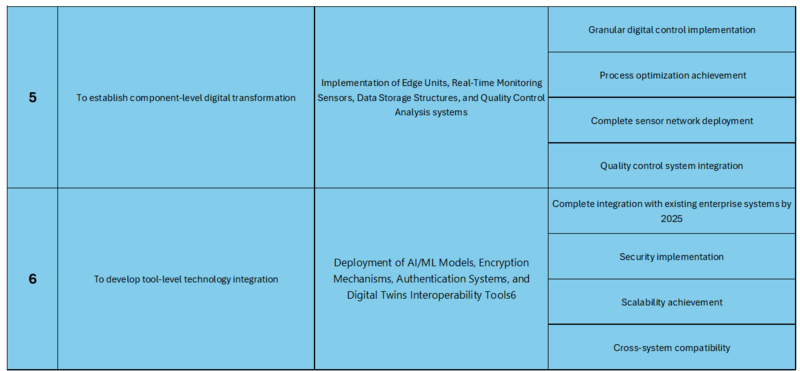

Alignment with Company Strategic Driver

The table illustrates the strategic alignment of Embraer's Digital Twin implementation with key objectives. The first strategic driver focuses on developing Digital Engineering capabilities, aligning with Embraer’s Digital Engineering strategy and Industry 4.0 goals. The targets include achieving end-to-end digital transformation across six technological levels and realizing ROI within four years. The second driver emphasizes the establishment of an integrated Digital Thread across the manufacturing lifecycle, aligning through CAD models, simulation data, and real-time monitoring capabilities. This driver aims to achieve digital continuity from design to maintenance, AI analytics integration, and predictive maintenance by 2030. The third driver targets system-level optimization through infrastructure enhancement and business process improvements, aiming for a 30% efficiency increase, 25% cost reduction in maintenance, and real-time monitoring. The fourth driver supports smart manufacturing through subsystem integration, targeting 90% digital coverage of critical processes by 2026. The fifth driver focuses on component-level digital transformation, aiming for granular digital control, process optimization, and complete sensor network deployment. Lastly, the sixth driver aims to integrate AI/ML models, encryption, and interoperability tools at the tool level, targeting enterprise-wide integration, security, scalability, and cross-system compatibility by 2025.

Positioning of Company vs. Competition