Difference between revisions of "Large Ultra Lightweight Monolithic Mirros for Space Missions"

| Line 28: | Line 28: | ||

A significant amount of developments developmentswas carried outoutforultra lightweight mirrors. Ball Aerospace demonstrated Beryllium mirrors with an aerial density as low as 9.8 kg/m m2. However , this was for a diameter 0.5m and without guaranteeing sufficient stiffness in order to survive the launch, similar as for the JWST where the mirrors have to be re designed with a final aerial density of 28 kg/m m2, while whilethe initial concept was aiming to achieve even below 15 kg/m m2. | A significant amount of developments developmentswas carried outoutforultra lightweight mirrors. Ball Aerospace demonstrated Beryllium mirrors with an aerial density as low as 9.8 kg/m m2. However , this was for a diameter 0.5m and without guaranteeing sufficient stiffness in order to survive the launch, similar as for the JWST where the mirrors have to be re designed with a final aerial density of 28 kg/m m2, while whilethe initial concept was aiming to achieve even below 15 kg/m m2. | ||

[[File:JWST1.jpg]] | [[File:JWST1.jpg]] | ||

Revision as of 19:36, 7 October 2023

Technology Roadmap Sections and Deliverables

This is a technology roadmap for:

- 3LULMMFSM - Large Ultra-Lightweight Monolithic Mirros for Space Missions

Large-Ultra Lightweight Monolithic Mirrors (LULMM) also enabling segmented designs for space missions - Mirrors are enabling technology for space based telescopes. Primary mirror size and quality is directly traceable to telescope performance. Every engineering advancement in space mirror technology has resulted in improved earth observation and science performance. Future large scale optical instruments for Earth Observation and Science missions will require very large primary mirrors with extreme light weighting. There has been significant technical evolution realized over the last years. However, the current level of light weighting is reaching the limit of classical techniques and decreasing optical performances due to side efforts, causing mission concepts with active correction capabilities which could be simplified by using alternative techniques for lighter and stiffer primary mirrors. The weight can be drastically reduced with designs based on a thin optical face sheets, which are attached to a stiff and lightweight support structures (e.g. honeycomb…).

Ultra precision mirrors are setting the space telescope design. Rare are the components whose design lies at such optimal crossroads between 3 major engineering fields (optical, thermal and mechanical), all the while challenging manufacturing and integration capacities in these same fields. The recent spotlight on JWST’s magnificently gigantic golden primary mirror, and the incredible pictures it helps create, has brought mirror design to the forefront of the public eye as well as the engineer’s, yet the subtle and skillful art and efforts which underlie a truly successful mirror design are not always obvious. This roadmap addresses previous, current and future needs of space mirror technologies.

Roadmap Overview

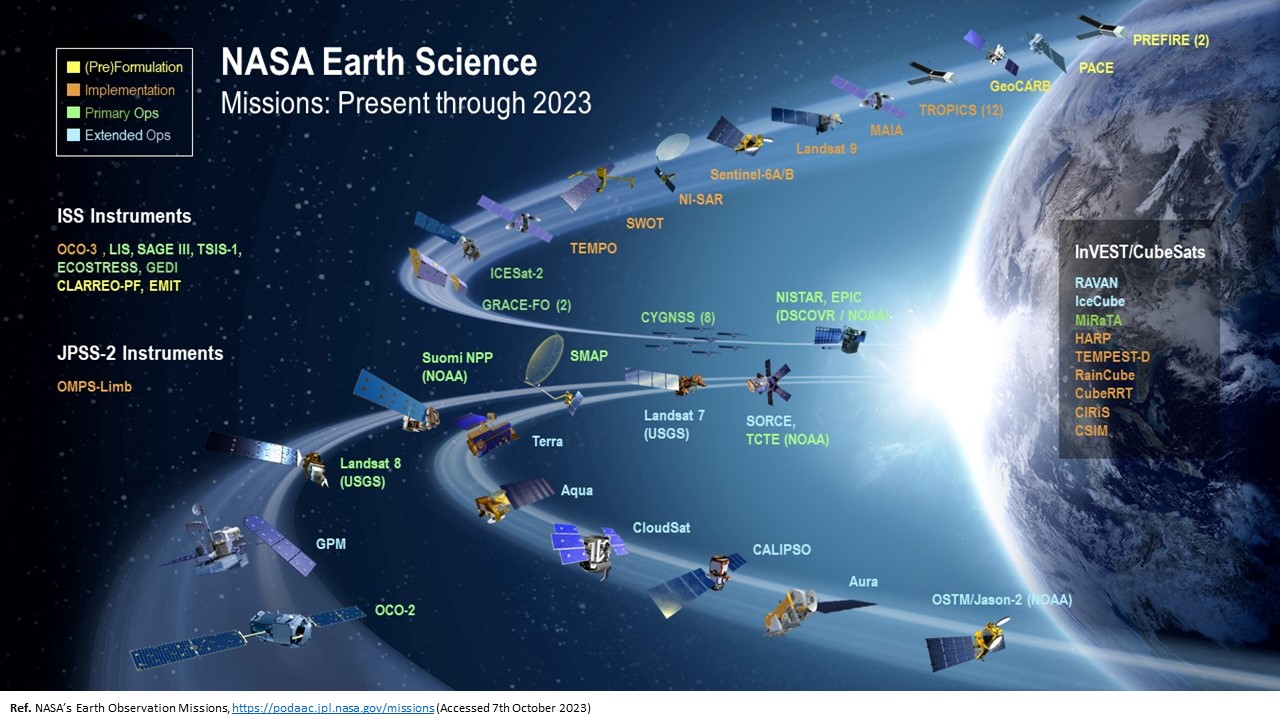

Images show the Science and Earth Observation programs from the European Space Agency (ESA) and National Aeronautics and Space Administration NASA), indicating the needs for space mirror technologies.

Some critical elements enabling the LULMM considers:

- large aperture, lowr-areal denisty and ultra-high stiff mirror substrates

- support structure

- mid/high-spatial frequency figure error

- segment-to-segment gap phasing

- mirror segment edges

- modeling and validation

Figure is showing the 5x5 Technology Matrix [Ref.1] with the position of 3LULMMFSM.

A significant amount of developments developmentswas carried outoutforultra lightweight mirrors. Ball Aerospace demonstrated Beryllium mirrors with an aerial density as low as 9.8 kg/m m2. However , this was for a diameter 0.5m and without guaranteeing sufficient stiffness in order to survive the launch, similar as for the JWST where the mirrors have to be re designed with a final aerial density of 28 kg/m m2, while whilethe initial concept was aiming to achieve even below 15 kg/m m2.