Difference between revisions of "Battery Electric Vehicle Platforms"

| Line 86: | Line 86: | ||

TBD | TBD | ||

[[File:BEV Vehicles.png| | [[File:BEV Vehicles.png|1300px|center]] | ||

{| class="wikitable sortable" style="margin-left: auto; margin-right: auto; border: none;" | {| class="wikitable sortable" style="margin-left: auto; margin-right: auto; border: none;" | ||

Revision as of 20:47, 23 October 2023

Technology Roadmap Sections and Deliverables

- 2BEV - Battery Electric Vehicle Platforms

The Battery Electric Vehicle (BEV) platform, a level 2 roadmap, represents the critical product/system of the Battery Electric Platform that is integrated within a broader electrified vehicle. The level 1 system above the BEV is the electrified vehicle market segment, which includes other types of electrified vehicles (e.g., FCEV's, PHEV's, etc.) as well as the other vital systems that comprise electrified vehicles (e.g., steer-by-wire systems). Level 3 roadmaps represent critical subsystems within a BEV platform-based electrified vehicle, and level 4 roadmaps would indicate an individual component technology roadmap.

Roadmap Overview

Electrified vehicles (PHEV, BEV, FCV, etc.) are vehicles that utilize electric power (from a variety of different sources, such as batteries or fuel cells) to power an electric motor-based propulsion system. Electrified vehicles are an increasingly popular alternative to traditional gas-powered vehicles that generate propulsion through internal combustion engines. Electrified vehicles are one part of a broader ecosystem of solutions being used to combat the evolving problem/challenge of climate change. Electric vehicles help to solve this problem by providing humanity with an alternate mode of transportation that does not produce harmful greenhouse gas emissions.

This roadmap will focus specifically on the battery electric vehicle (BEV) platform. BEV platforms are becoming increasingly popular as consumers seek different options within the electric vehicle market, and manufacturers look for ways to meet this customer demand through the use of modular architectures that multiple different vehicle variants may be built upon. Modular architectures / platforms for battery electric vehicles are typically comprised of a battery pack, on board charging module, integrated power electronics, drive units, and a chassis will a wheel base. Multiple different vehicle bodies and accompanying features may then be built upon these platforms. Below are two examples BEV platforms being produced today (one by Tesla Motors, and one by General Motors).

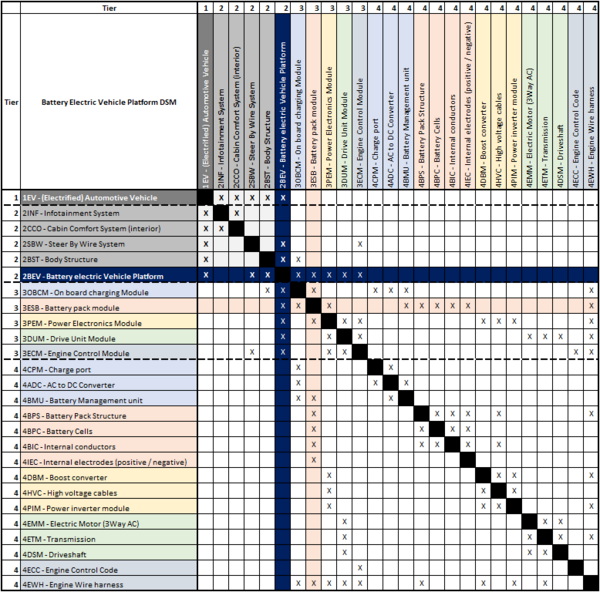

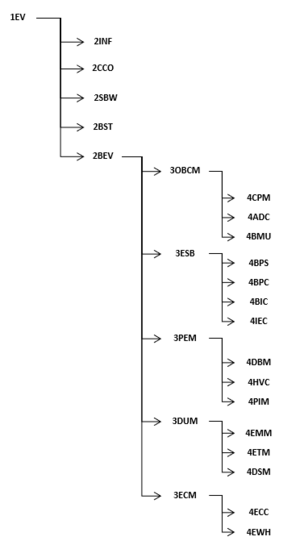

Design Structure Matrix (DSM) Allocation

Our technology of interest, battery electric vehicle platforms, is identified in the DSM below with dark blue highlighting at level 2 (2BEV). Additionally, we also show a tree structure that decomposes into the systems, and subsystems that comprise our level 2 technology. The DSM shows how these critical systems and subsystems interact to comprise the battery electric vehicle platform. For example, we see that a critical subsystem is the level 3 battery pack module, which is color-coded to indicate that it has its own, existing technology roadmap (3ESB - Energy_Storage_via_Battery). The battery pack module (or Energy Storage Battery) is comprised of the battery cells, pack structure, and other subsystems. The battery cells break down into their individual components (anode, cathode, etc.) that generate electrons to conduct electricity. However, we also see the interdependency between the battery pack structure and the high voltage cables, which in turn have a connection to the power inverter module. All this is to say that the interconnected nature of subsystems within a BEV platform critically come together to create the emergence exhibited by a battery electric vehicle.

Roadmap Model using OPM

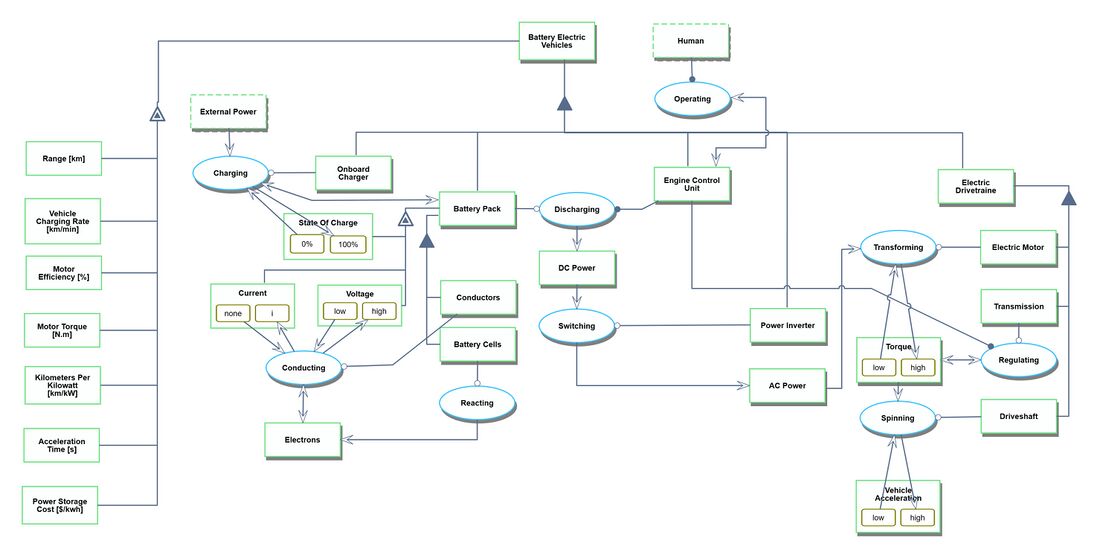

We provide an Object-Process-Diagram (OPD) of the Battery Electric Vehicle (BEV) Platform in the figure below. This diagrams captures the main object of the technology (Battery Electric Vehicle), the value-generating processes and different instruments associated with their characterization by Figures of Merit (FoM).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given in OPL_Battery_Electric_Vehicle. It reflects the same content as the previous figure, but in a formal natural language.

Figures of Merit

The table below summarizes the figures of merit used to evaluate battery electric vehicle platform technologies. Some of these figures of merit, such as range and acceleration, are very similar to the figures of merit used to evaluate traditional automotive vehicle. Other figures of merit, such as power storage cost and charge rate, are critical to evaluating the battery pack technology employed within the battery electric vehicle as well as the battery electric vehicle platform itself. Finally, FOM's such as carbon dioxide emissions and kilometers per kilowatt are very specific FOM's to battery electric vehicle platform technologies in totality.

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Range | [km] | The number of miles the vehicle can travel on a single full charge |

| Acceleration time | [s] | Time to accelerate to from 0 to 100 kmh (km per hour) |

| Motor Torque | [N.m] | Torque produced by the electric vehicle motor |

| Motor Efficiency | [%] | Percentage of energy discharged from the battery pack that is converted to mechanical energy |

| Kilometers per kilowatt | [km / kw] | The average distance the vehicle travels based upon the amount of energy used |

| Vehicle charge rate | [km/min] | The rate at which vehicle range (in km) is added to the BEV platform during charging |

| Power Storage Cost | [$/kWh] | Total cost of power storage within a BEV platform (at the battery pack level) in dollars per kilowatt |

| Carbon Dioxide Emissions | [g/km] | The total amount of carbon dioxide emissions generated by the vehicle platform per mile driven |

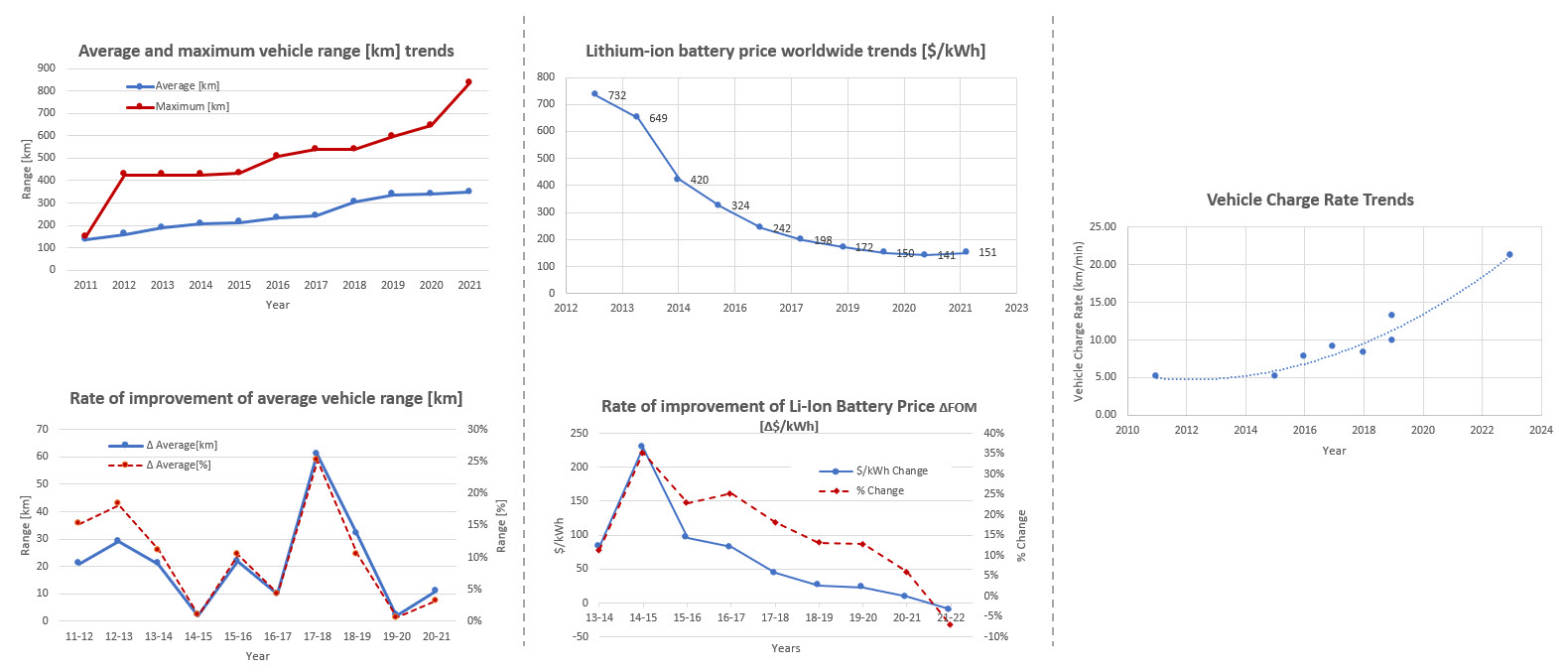

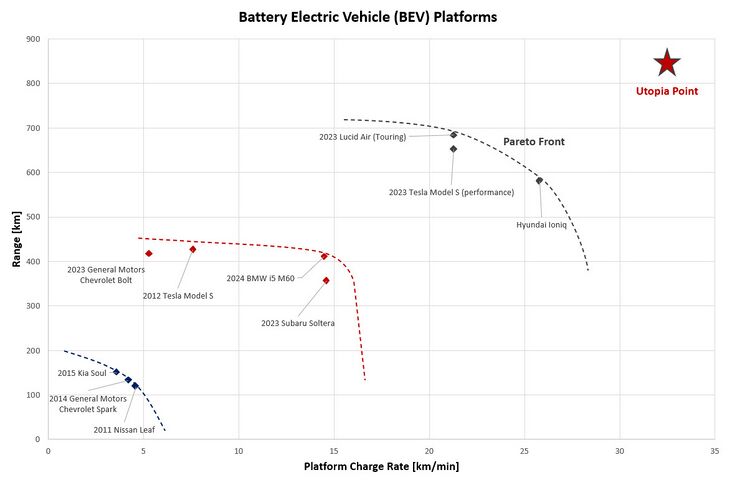

Below are some trends related to the figures of merit listed above. The charts show that the range of battery vehicles has been steadily increasing over the past decade, all while battery prices have rapidly declined. Both of these factors have contributed to increasing adoption of battery electric vehicle platforms, as the cost and performance of these systems continue to rise. Finally, charging trends are improving substantially, as new technology around superchargers enters the market (on both the BEV platform and charging station sides of the interface).

In addition to the figures of merit shown above, some of the key governing equations for battery electric vehicles are shown below.

| Input | Key Relationship or Governing Equation | Output |

|---|---|---|

|

ηm = P_out / P_in | ηm : motor efficiency (expressed as a %) |

|

T = (V_ac* I_ac * p_f ) / ((2π* N_rpm )/60) | T = motor torque |

Alignment with Company Strategic Drivers

TBD

Positioning of Company vs. Competition

TBD

| Manufacturer | Model | Model Year | Range [km] | Battery Size [kwh] | Acceleration Time [s] | Vehicle Charge Rate [km/min] | Max Torque [N.m] | Electric Drive Configuration |

|---|---|---|---|---|---|---|---|---|

| General Motors | Chevrolet Bolt | 2023 | 416 | 65 | 6.5 | 5.3 | 360 | Single Electric Motor (FWD) |

| Tesla | Model S (performance) | 2023 | 652 | 100 | 2.4 | 21.3 | 967 | Dual Electric Motors |

| Lucid | Air (Touring) | 2023 | 684 | 94 | 3.4 | 21.3 | 1200 | Dual Electric Motors |

| BMW | i5 M60 | 2024 | 411 | 84 | 3.7 | 14.5 | 795 | Dual Electric Motors |

| Subaru | Soltera | 2023 | 357 | 73 | 6.5 | 14.6 | 338 | Dual Electric Motors |

| Nissan | Leaf | 2011 | 118 | 24 | 9.9 | 4.6 | 280 | Single Electric Motor (FWD) |

| Kia | Soul | 2015 | 150 | 30.5 | 11.2 | 3.6 | 285 | Single Electric Motor (FWD) |

| Tesla | Model S | 2012 | 426.5 | 85 | 5.4 | 7.6 | 440 | Single Electric Motor (RWD) |

| General Motors | Chevrolet Spark | 2014 | 132 | 21.3 | 7.9 | 4.2 | 542 | Single Electric Motor (FWD) |

| Hyundai | IONIQ | 2023 | 581 | 77 | 5.1 | 25.8 | 350 | Dual Electric Motors |

Technical Model

TBD

Financial Model

TBD

List of R&D Projects and Prototypes

TBD

Key Publications, Presentations and Patents

The following are a representative set of patents that have contributed to the overall development of Battery Electric Vehicle Platforms. Battery electric vehicle platforms fall under the umbrella CPC code of B60L - "Propulsion of electrically propelled vehicles". Many of the patents describing advances in subcomponent technology, control algorithms, etc. can be found beneath even more detailed CPC codes such as B60L 50/60 ("Electric propulsion with power supplied within the vehicle using power supplied by batteries), B60L 50/51 ("electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells characterized by AC-motors”), and B60L 15/20 ("methods for controlling the traction motor speed of electrically-propelled vehicles").

High Power Low Voltage Electrified Powertrain

- US Patent: 9484852 B2

- Assignee: FCA US LLC

- Inventors: Timmons, Adam, Anand Sathyan, and Marian Mirowski

- Year:2016

- Description: This patent represents a way in which 4 low voltage battery modules could be used to power an electric motor by providing 4 distinct DC voltages to a power inverter that then switches the DC power to AC power to drive an electric motor of 4 or more phases. This represents one potential approach to how a BEV platform could be configured.

Electrified Powertrain With Maximum Performance Mode Control Strategy Using Extended Inverter Limit

- US Patent: 2022/1069237

- Assignee: GM Global Technology Operations LLC

- Inventors: Hu, Yiran, Gagas Brent, Kee Kim, James Creehan, and Brian Welchko

- Year:2022

- Description: This patent describes the concept of electrified powertrain maximum performance mode control strategy using extended inverter limit.

System and Method of Controlling Power Distribution From Charging Source to Electric Vehicle

- US Patent: 2021/0031643 A1

- Assignee: GM Global Technology Operations LLC

- Inventors: Wang, Yue-Yun, J Brooks, Jun-Mo Kang, and Donald Grimm

- Year:2021

- Description: This patent describes the concept of controlling power distribution from a charging source to electric vehicle, including how the state of charge of the battery is controlled during the charging process.

In addition to the many patents published on concepts that comprise battery electric vehicle platforms, many articles have also been published to describe BEV's, their market progression, and example architectures. Some early examples of articles that reviewed the BEV technology readiness and BEV technology progress are below:

- Andwari, Amin, Apostolos Pesiridis, Srithar Rajoo, Ricardo Martinez-Botas, and Vahid Esfahanian. “A Review of Battery Electric Vehicle Technology and Readiness Levels.” Renewable and Sustainable Energy Reviews 78 (2017): 414–30.

- Sun, Xiaoli, Zhengguo Li, Xiaolin Wang, and Chengjiang Li. “Technology Development of Electric Vehicles: A Review.” Energies 13, no. 1 (2019): 90.

Technology Strategy Statement

TBD

References

[1] Szczesny, Joseph. “GM Targeting Bigger Share of Bev Market, CEO Barra Says.” WardsAuto, June 16, 2022. https://www.wardsauto.com/industry-news/gm-targeting-bigger-share-bev-market-ceo-barra-says.

[2] Seabaugh, Christian. “Beyond Plaid: A Quad-Motor Tesla Model S Is Possible.” MotorTrend, June 18, 2021. https://www.motortrend.com/news/tesla-model-s-quad-motor-report/.

[3] Ritchie, Hannah. “The End of Range Anxiety: How Has the Range of Electric Cars Changed over Time?” Sustainability by numbers, February 27, 2023. https://www.sustainabilitybynumbers.com/p/electric-car-range.

[4] 2023 Bloomberg Finance L.P. (2022, December 6). Lithium-ion battery pack prices rise for first time to an average of $151/kwh. BloombergNEF. https://about.bnef.com/blog/lithium-ion-battery-pack-prices-rise-for-first-time-to-an average-of-151-kwh/

[5] Cai, Wenlong, Yu-Xing Yao, Gao-Long Zhu, Chong Yan, Li-Li Jiang, Chuanxin He, Jia-Qi Huang, and Qiang Zhang. “A Review on Energy Chemistry of Fast-Charging Anodes.” Chemical Society Reviews 49, no. 12 (June 2020): 3806–33. https://doi.org/10.1039/c9cs00728h.