Difference between revisions of "Sustainable Aviation Fuel"

| Line 66: | Line 66: | ||

==Key Publications, Presentations and Patents== | ==Key Publications, Presentations and Patents== | ||

A thorough survey of literature available in the public domain has been perused to gauge the current progression of various available SAF technologies [[#References|[1]]]. Published in | A thorough survey of literature available in the public domain has been perused to gauge the current progression of various available SAF technologies [[#References|[1]]]. Published in 2019, the survey details and highlights the theory and the multiple pathways behind key SAF technologies[[#References|[1]]]. Figure P1 is presented below to illustrate the extensive search results of research publications related to SAF since 1960. | ||

[[File:keypublications.png|650px|]]<br> | [[File:keypublications.png|650px|]]<br> | ||

Revision as of 03:42, 6 November 2023

Technology Roadmap Sections and Deliverables

Our technology roadmap identifier is shown as:

- 2SAF - Sustainable Aviation Fuel

This indicates that we are dealing with a “level 2” roadmap at the product level, where “level 1” would indicate a market level roadmap and “level 3” or “level 4” would indicate an individual technology roadmap.

Roadmap Overview

Sustainable aviation fuel (SAF) is a strong candidate to deal with global warming in the context of aviation, using low carbon footprint resources such as biomass, waste oil, CO2, and water. SAF has a good compatibility with the present aircraft. SAF has similar characteristics to the current jet fuel and can be mixed with it, so the architecture of aircraft does not need to change. On the other hand, another strong alternative for low carbon footprint fuel is hydrogen, which needs the rearchitecting of the aircraft because of its small density and temperature, affecting the vehicle size. The following figure coming from FAA shows SAF is the key toward the ambitious goal of "net zero CO2 emissions" in aviation.

For producing SAF, there are several pathways depending on feedstock and the way of conversion from feedstock to SAF. However, each pathway has advantages and disadvantages such as cost, scalability, and technological readiness. This roadmap tries to identify the impactful technologies on the feasibility of SAF, and show their development plan.

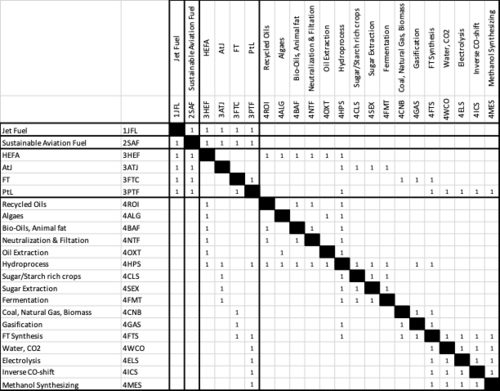

Design Structure Matrix (DSM) Allocation

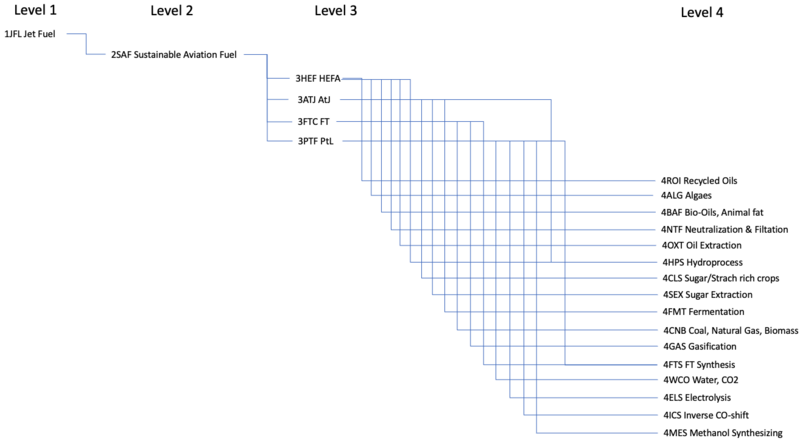

The above 2SAF tree shows the relationship between other technologies related to the SAF. Specifically, the enabling technologies to SAF, by key feedstocks and processes, are considered. The enabling of SAF with the use of existing feedstocks are indicated with the connection of 2SAF to 3HEF, 3ATJ, 3FTC, 3PTL, 4BAF, 4CLS, 4CNB, and 4WCO. The enabling of SAF through various processes are shown through 2SAF connections to 4ROI, 4NTF, 4HPS, 4SEX, 4FNT, 4GAS, 4FTS, 4ELS, 4ICS, and 4MES. The connections of SAF to Level 3 and 4 technologies are shown in the DSM. In the following section, further details on the SAF production architecture is presented using Object-Process-Model (OPM).

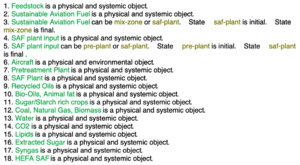

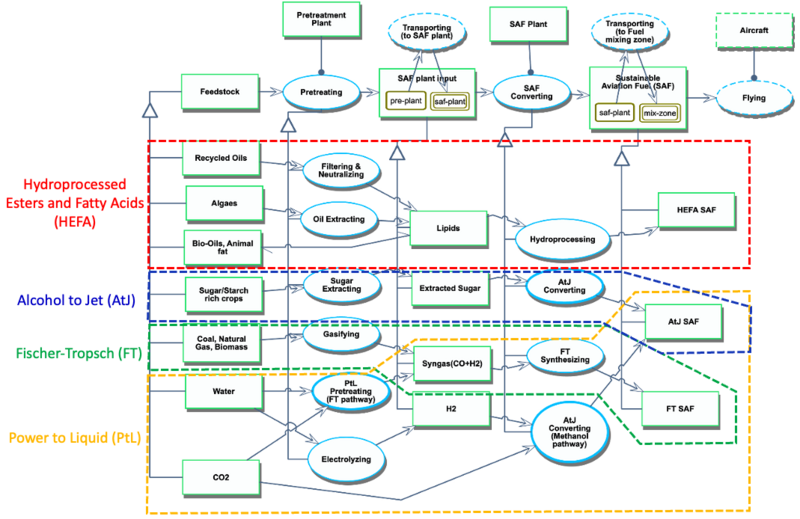

Roadmap Model using OPM

The Object-Process-Model (OPM) of the 2SAF - Sustainable Aviation Fuel roadmap is presented in the figure with the Object-Process-Language (OPL) below. This diagram shows the processes (Pretreating, and SAF Converting) for producing SAF with the representative pathways with different types of feedstocks. We include four different representative SAF producing categories: 1) Hydroprocessed Esters and Fatty Acids (HEFA) with recycled oils, bio-oils, and animal fat, 2) Alcohol-to-Jet (AtJ) with cellulose, 3) Fischer-Tropsch (FT) with coal, natural gas, and biomass, and 4) Power-to-Liquid (PtL) with water and CO2.

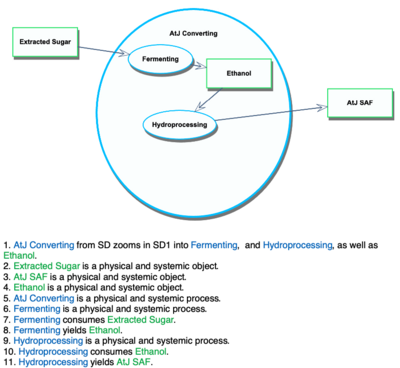

Three functional zoom-up views of the OPM are shown in the following figures.

PtL Pretreating (FT pathway)

AtJ Converting

AtJ Converting(Methanol pathway)

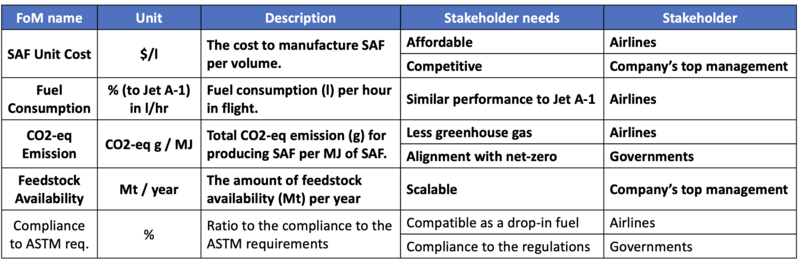

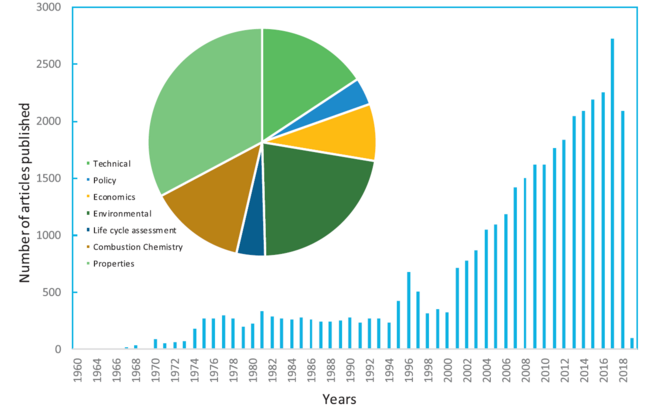

Figures of Merit

The table below shows a list of FOMs by which sustainable aviation fuel can be assessed. The first three (shown in bold) are identified as main FoMs for sustainable aviation fuel with the following reasons: 1)One of the biggest disadvantages of SAF is its cost. 2) Currently, SAF blend ratio to the current jet fuel is up to 50%, and this blend ratio needs to be improved for net zero CO2 emission. 3) CO2 emission when producing SAF also needs to be assessed to fairly evaluate the net CO2 emission. The other five FoMs are used for analyzing the trade-off of the technology choice of SAF production.

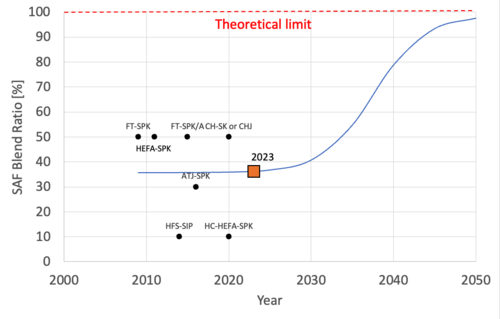

The figure below shows an expected SAF blending ratio improvement with seven approved technologies by ASTM. For predicting the improvement rate, the logistics (growth) function is used to fit the seven approved technologies, assuming the net-zero CO2 emission by 2050.(See [Bergero2023 for net-zero CO2 emission in detail.) Since the expected line does not start to rise up in 2023 we evaluate that SAF is still in "incubation" phase.

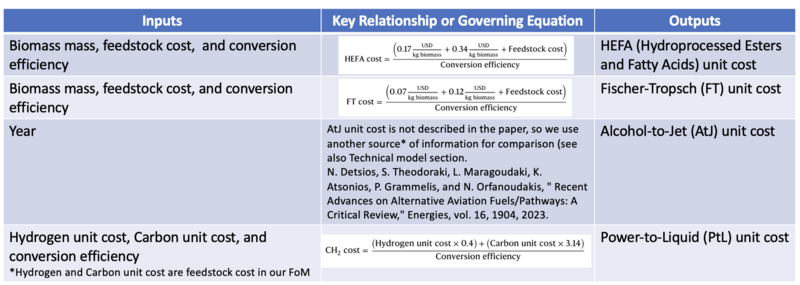

As mentioned in the selection of FoMs, the cost is a key to assess SAF. Here, we summarize the governing equations given in the literature[[Bergero2023]]. The right figure is an example of the SAF cost with a)Power-to-Liquid (PtL) , c)Hydroprocessed Esters and Fatty Acids (HEFA), and e)Fischer-Tropsch (FT) [Bergero2023]. As pointed with the black arrows, the SAF and current jet fuel costs place at up-right and upper-middle to bottom-left, respectively, where the utopia point is bottom-left. Thus, the direction of technology advancement of SAF with these figures goes from up-right to bottom-left, as shown in the red arrows.

Alignment with Company Strategic Drivers

Our “company” is a SAF producer specializing in high-conversion Power to Liquid (PtL) type that is looking to enable net-zero CO2 emissions in aviation fuel. Specifically, our company is targeting a 30% total market share of the SAF market, with plans on enabling airline operations with SAF by 2035. The details of the strategic driver, alignments, and targets are as presented below:

Positioning of Company vs. Competition

Technical Model

Key Publications, Presentations and Patents

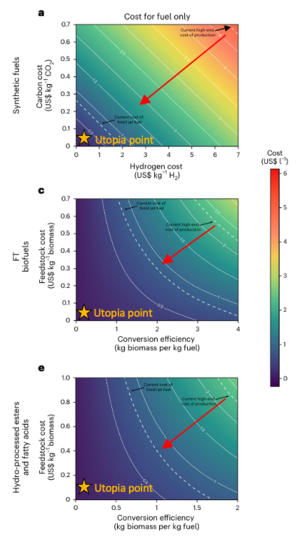

A thorough survey of literature available in the public domain has been perused to gauge the current progression of various available SAF technologies [1]. Published in 2019, the survey details and highlights the theory and the multiple pathways behind key SAF technologies[1]. Figure P1 is presented below to illustrate the extensive search results of research publications related to SAF since 1960.

Figure P1. Web of Science data ( > 1960) of bio-aviation fuel publications, with bio-aviation (jet) fuel as main index, and ‘technical, policy, economics, environmental, LCA, combustion chemistry and properties as sub-indices [1]

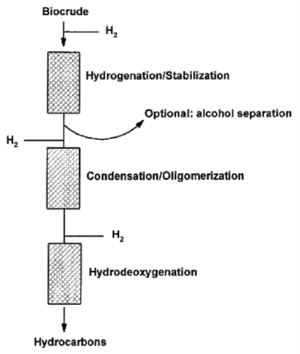

One key enabling patent for the production of SAF that closely tracks the findings of the extensive literature survey from Figure P1 was granted in Jan 14, 2014 in the United States as Patent No. US 8,629,310 B2 [2]. Granted to associates from the Phillips 66 Company regarding “Transportation Fuels from Biomass Oxygenates", the patent describe a process through which “biocrude” or “oxygenate feedstocks derived from biomass” are converted into hydrocarbons through condensation/oligomerization and hydrodeoxygenation processes [2]. The key figure describing the patent processes are shown below in Figure P2:

Figure P2. US 8,629,310 B2 Patent Process Highlight[2]

This patent is especially relevant to the SAF technology because it presents one of the key pathways for aviation fuels to be produced from non-fossil sources. Numerous research papers that have been published describing the “oxygenic precursors from carbohydrates” conversion into SAF, and many are outlined in [1]. While the patent provides only a summary and does not detail the entire process through which the hydrocarbons are generated, it is nonetheless useful to see that it leverages methods that have been published regarding pathways that have enabled the “production of bio-aviation fuel and precursors through an improved fatty acid and biosynthetic pathway” [1] while also touching upon elements of pathways that enable the “production of bio-aviation fuel and precursors through the alcohol biosynthetic pathway” [1] as an option. Further analysis of the “fatty acid pathways” are cited in [1], among which [3] and [4] are especially relevant for understanding the microbial production of alkanes, which is a key enabler for the technology behind the patent.

References

[1] M. Wang, R. Dewil, K. Maniatis, J. Wheeldon, T. Tan, J. Baeyens and Y. Fang, "Biomass-derived aviation fuels: Challenges and perspective," Progress in Energy and Combustion Science, vol. 74, pp. 31-49, 2019.

[2] E. Lotero, K. Fjare, T. Shi, S. Pansare and Y. Bao, "Transportation Fuels from Biomass Oxygenates". USA Patent US 8,629,310 B2, 14 January 2014.

[3] A. Schirmer, M. A. Rude, X. Li and S. B. Del Cardayre, "Microbial biosynthesis of alkanes," Science, vol. 329, no. 5991, pp. 559-562, 2010.

[4] Y. J. Choi and S. Y. Lee, "Microbial production of short-chain alkanes," Nature, vol. 502, no. 7472, pp. 571-574, 2013.