Difference between revisions of "Space Resource Generation"

| Line 91: | Line 91: | ||

Because many space resource generation proposals require interplanetary travel to the Moon and Mars, at the market-level these technologies are in the initial proof-of-concept phase. The only demonstration of such a technology off-world is MOXIE (Mars OXygen ISRU Experiment) which produced oxygen aboard the perseverance rover [1]. But we have been using oxygen generation technologies in space on the ISS which can be modeled over time, though it is important to note that this technology is more advanced compared to other space resource generation systems. Additionally, there are currently very few adopters of this technology (because there are very few space stations), so there isn’t a lot of data. | Because many space resource generation proposals require interplanetary travel to the Moon and Mars, at the market-level these technologies are in the initial proof-of-concept phase. The only demonstration of such a technology off-world is MOXIE (Mars OXygen ISRU Experiment) which produced oxygen aboard the perseverance rover [1]. But we have been using oxygen generation technologies in space on the ISS which can be modeled over time, though it is important to note that this technology is more advanced compared to other space resource generation systems. Additionally, there are currently very few adopters of this technology (because there are very few space stations), so there isn’t a lot of data. | ||

Increasing the Launch-adjusted atom economy FOM first became desirable due to the continuous operation of space stations like Mir and the ISS and the expensive cost of launch to supply life-support consumables. The first example is burning alkali chlorate “candles,” a form of solid oxide fuel generation [3]: 60% of what is launched and used creates usable oxygen, so this leads to an atom economy of around 30%. Introducing water electrolysis to the ISS improved the atom economy, because 89% of what is launched is used as oxygen [4]. But because water is also a demand on the crew and this consumes water, it still has to be launched and results in an atom economy of 42%. An atom economy of 47% is achieved with a Sabatier reactor recovering some of the water and reducing the required launch mass, but still does not reach full conversion of CO2, and produces Methane which is currently vented [4]. A series bosch reactor, projected to reach maturity by around 2035, has a theoretical SAE limit of 73%, and paired with a carbon utilization technology could increase more [5]. Plotting the hypothetical maturation date, we see this may be the beginnings of stagnation, because where beyond full oxygen recovery there may be less desire to improve this FOM. The theoretical limit is 100%. In terms of oxygen generation and recovery technologies, it appears to be somewhere between rapid progress and slowing down (shown in the linear trend line) in improving how well we recycle launched oxygen-containing materials into space, approximately equal to about 1.11% improvement in LaAE per year using a linear regression. | |||

[[File:dFOMdt.png]] | [[File:dFOMdt.png]] | ||

The specific energy input required per kg of product has also increased over time, with the updated technologies and additions of reactors in series, but in the case of space station operations where energy can be renewably generated by solar panels, this has been favorable to minimize the launch mass. Interestingly, the decrease in specific energy input for MOXIE offers new value to stakeholders who are not concerned with full oxygen recovery, but instead want an efficient conversion process to scale up production. | |||

[[File:dFOMdt2.png]] | |||

Revision as of 17:50, 10 October 2024

Roadmap Creators: | Lanie McKinney

Technology Roadmap Sections and Deliverables

This technology roadmap has the unique identifier:

1SRG - Space Resource Generation

The number 1 denotes that this is a Level 1 technology roadmap at the market level. In reference to our technology, Level 1 encompasses all conversion technologies used in space, Level 2 describes the product level, for example oxygen generation. Level 3, the system level, could reference a solid oxide electrolysis system for oxygen production and Level 4, the subsystem level could represent the material used for the electrode stack.

Roadmap Overview

Space Resource Generation refers to the thermal or chemical conversion processes to generate resources in space environments which relax launch requirements, and subsequently enable a range of exploration and commercial activities in space. NASA's Artemis program plans to head back to the Moon this decade in a phased approach to build up lunar activity, including a commercial presence, to serve as a proving ground for human missions to Mars. The space industry is set to be valued at ~1.8 trillion USD by 2035, with increasing access to space enabled through the reduction of launch costs. The need for space resource generation technologies is driven by increasingly longer stays off-world at destinations of increasing distance from Earth, where technologies that recycle utilize available resources can make these missions safer, more Earth-independent, and even enable cost-savings.

Space resource technologies can be used for life-support among numerous human space stations, propellant generation, metal extraction and production, radiation shielding, landing pad production, etc. Space resource generation includes both “in-situ resource utilization” (ISRU) and resource recycling technologies, because these two categories of technologies share similar operating principles and should be compared using the same Figures of Merit (FOMs) to elucidate the different value in different mission profiles.

Design Structure Matrix (DSM) Allocation

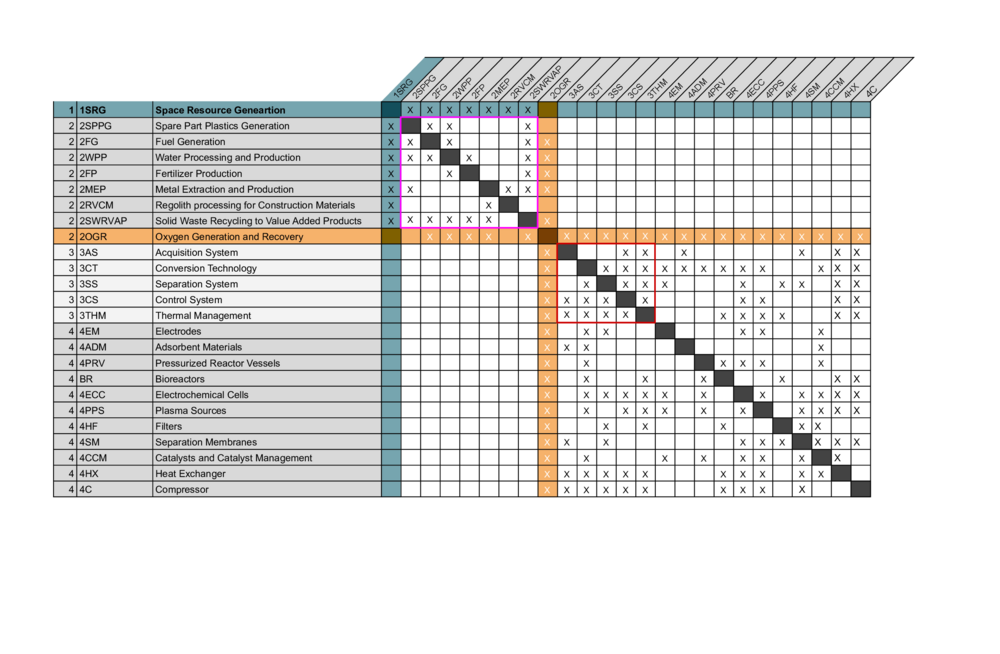

The market level DSM for Space Resource Generation demonstrates that there is a high level of interdependency between different chemical conversion processes and their target/waste products, highlighted in Green for level 2. For example, oxygen generation can be used for both life-support and rocket propellant, and can be obtained from regolith, water, atmospheric constituents (Mars, space habitats), and as a byproduct of the recycling products and metal extraction. At the system level of oxygen generation, the focus of FOM modeling below, key enabling technologies are the acquisition system (3AS), conversion technology (3CT), separation system (3SS), control system (3CS), and thermal management system (3THM). At level 4, the enabling technologies include 4EM electrodes, 4ADM adsorbent materials, 4PRV pressurized reactor vessels, 4BR bioreactors, 4ECC electrochemical cells, 4PPS plasma sources, 4HF filters, 4SM Separation Membranes, 4CCM catalysts and catalyst management, 4HX heat exchangers, and 4C compressors. Different combinations of level 4 elements may lead to novel performance.

Roadmap Model using OPM

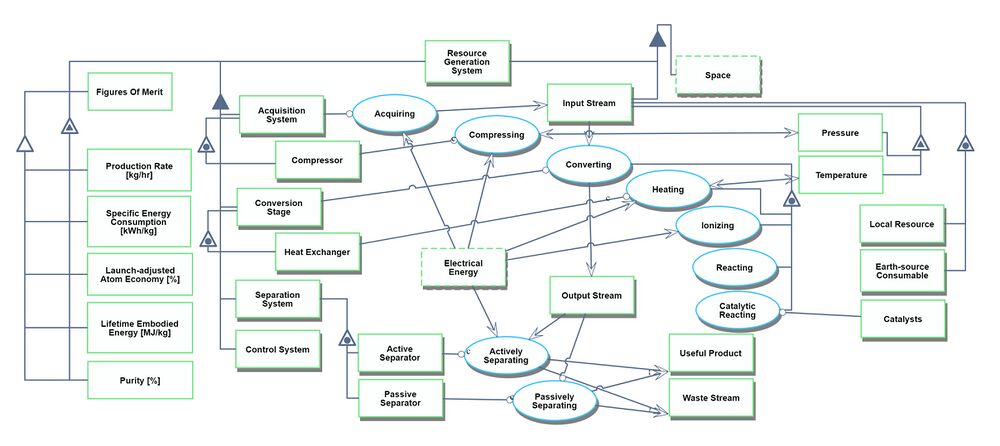

We provide an Object-Process-Diagram (OPD) of the 1SRG roadmap in the figure below. This diagram captures the main product of the roadmap (Space Resource Generation Systems), and decomposes the possible common subsystems of level 2 technologies into their level 3 systems (acquisition, conversion, separation stages, control system), its characterization by Figures of Merit (FOMs) as well as the main processes (of Acquiring, Converting, Separating) through a myriad of possible routes.

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.

Figures of Merit

The table below show a list of FOMs that can be used to assess Space Resource Generation Technologies.

| Figure of Merit | Unit | Description |

|---|---|---|

| Production Rate | kg/hr | the rate of generating a target product |

| Lifetime Embodied Energy | MJ/kg | the thermodynamic sum of past, present and future work required to create, operate, maintain and decommission a system per kg of product produced |

| Specific Energy Consumption | kWh/kg | total energy required to produce a kg of product |

| Purity | % | percentage of the target product in separated product stream |

| Launch-adjusted Atom Economy | % | ratio of mass of useful product generated to the total mass of reactants and launched mass needed |

Production Rate

At it's simplest, a space resource generation technology must meet a demand for a product, described as a production rate. Production rates can be constrained by the performance of the technology itself or also by the available inputs, as space is a resource constrained environment.

Lifetime Embodied Energy

This FOM is defined as “...the thermodynamic sum of past, present and future work required to create, operate, maintain and decommission a system, including appropriate shares of indirect contributions from upstream systems as well as from other systems in a system-of-systems [2].” This metric has been shown to reproduce results from Equivalent System Mass analyses, the industry standard for trading advanced life support systems, while decoupling from launch mass (which is becoming an outdated cost proxy). While similar in units to SEC, this FOM captures value (as a proxy for cost) across a whole architecture or lifetime. This is an extremely relevant metric to the space industry for determining what the real cost of developing infrastructure and operating a space resource generation technology over longer time periods to identify promising business use cases.

Specific Energy Consumption

This FOM describes the energy required of a chemical conversion process per kg of value-added output produced. It is an energy efficiency metric which can allow comparison between different technologies which may use different chemical pathways. With production rate, these FOM’s can be multiplied to imply a power requirement.

Purity

This FOM describes how pure the useful product stream is after separation of the output stream, which is an evaluation of conversion and separation performance.

Launch-adjusted Atom Economy

This is a measure of a conversion technology's sustainability, or its ability to minimize waste streams through recycling available resources. It is launch-adjusted so as to reward better recycling and penalize when resources must be launched to refuel. This metric is relevant for comparing conversion architectures that may involve different chemical pathways which make better use of launched materials and/or not require launched materials at all, and may produce less waste or unusable products. This also aligns with NASA’s space sustainability goals and may support long duration missions where local resources are unavailable or a particular resource is scarce.

LaAE = (product mass [kg/mol] ) / (launch + reactant mass [kg/mol])

Note

These Figures of Merit are more general than other FOMs used to describe particular technologies, because other metrics will have different fundamental limits which depend heavily on the technology. For example, faradaic efficiency describes how efficiently an electrolytic cell performs compared to theoretical limits, but this would not be a fair comparison to a reported first law efficiency (energy out/energy in) of a thermal conversion process. These FOMs were chosen to compare different space resource generation technologies at the market level.

Governing Equations

All conversion processes must conserve matter, which is why the available resources constrain the products that can be made. Broadly speaking, all conversion processes require some energy. The first law of thermodynamics ensures that energy is conserved within a system ΔU=Q−W, where ΔU is the change in internal energy of the system, Q is the heat added to the system, and W is the work done on the system. The second Law introduces the concept of entropy (S) and sets limits on the efficiency of conversion processes. The entropy change in a system is: ΔS= Q/T, where T is the temperature at which heat is transferred. All conversion processes can be described by these laws, and fundamental limits on each depend on the mechanism by which the conversion is occurring. It depends on if it is a chemical reaction, or purely a thermal process involving a change of state, or something else.

Time Evolution of Figures of Merit

Because many space resource generation proposals require interplanetary travel to the Moon and Mars, at the market-level these technologies are in the initial proof-of-concept phase. The only demonstration of such a technology off-world is MOXIE (Mars OXygen ISRU Experiment) which produced oxygen aboard the perseverance rover [1]. But we have been using oxygen generation technologies in space on the ISS which can be modeled over time, though it is important to note that this technology is more advanced compared to other space resource generation systems. Additionally, there are currently very few adopters of this technology (because there are very few space stations), so there isn’t a lot of data.

Increasing the Launch-adjusted atom economy FOM first became desirable due to the continuous operation of space stations like Mir and the ISS and the expensive cost of launch to supply life-support consumables. The first example is burning alkali chlorate “candles,” a form of solid oxide fuel generation [3]: 60% of what is launched and used creates usable oxygen, so this leads to an atom economy of around 30%. Introducing water electrolysis to the ISS improved the atom economy, because 89% of what is launched is used as oxygen [4]. But because water is also a demand on the crew and this consumes water, it still has to be launched and results in an atom economy of 42%. An atom economy of 47% is achieved with a Sabatier reactor recovering some of the water and reducing the required launch mass, but still does not reach full conversion of CO2, and produces Methane which is currently vented [4]. A series bosch reactor, projected to reach maturity by around 2035, has a theoretical SAE limit of 73%, and paired with a carbon utilization technology could increase more [5]. Plotting the hypothetical maturation date, we see this may be the beginnings of stagnation, because where beyond full oxygen recovery there may be less desire to improve this FOM. The theoretical limit is 100%. In terms of oxygen generation and recovery technologies, it appears to be somewhere between rapid progress and slowing down (shown in the linear trend line) in improving how well we recycle launched oxygen-containing materials into space, approximately equal to about 1.11% improvement in LaAE per year using a linear regression.

The specific energy input required per kg of product has also increased over time, with the updated technologies and additions of reactors in series, but in the case of space station operations where energy can be renewably generated by solar panels, this has been favorable to minimize the launch mass. Interestingly, the decrease in specific energy input for MOXIE offers new value to stakeholders who are not concerned with full oxygen recovery, but instead want an efficient conversion process to scale up production.