Difference between revisions of "Small Launch Vehicles"

| Line 34: | Line 34: | ||

In general, small launcher companies aim for very high launch rates (weekly instead of monthly), high scheduling flexibility (months instead of years), and low launch costs thanks to significant economies of scale enabled by mass production. Some also leverage uncommon launch strategies (balloons, planes, catapults), but here we only include into our scope actual orbital launchers with launching pads on earth or on sea. | In general, small launcher companies aim for very high launch rates (weekly instead of monthly), high scheduling flexibility (months instead of years), and low launch costs thanks to significant economies of scale enabled by mass production. Some also leverage uncommon launch strategies (balloons, planes, catapults), but here we only include into our scope actual orbital launchers with launching pads on earth or on sea. | ||

Using a simple linear regression model, we can find a decreasing cost of $-2930.4\$/kg/year$. | Using a simple linear regression model, we can find a decreasing cost of $-2930.4\$/kg/year$. | ||

Revision as of 16:43, 1 October 2020

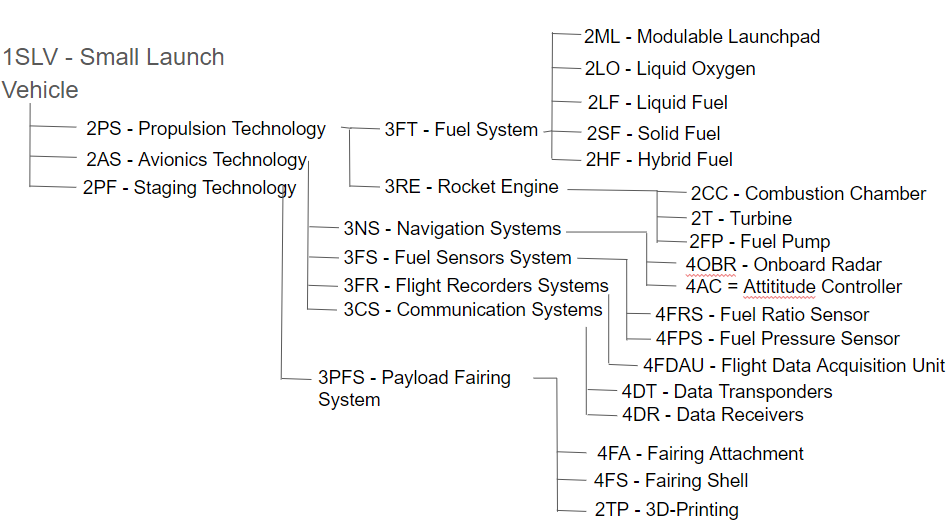

Technology Roadmap Sections and Deliverables

- 1SLV - Small Launch Vehicles

Roadmap Overview

Small launch vehicles (also called "Small launchers" or "Small-lift launch vehicles") are a category of orbital launchers capable of carrying a payload of maximum 2000kg* to LEO (Low Earth Orbit). Half a century ago, many families of launch vehicles have started as small launchers, as prototypes, and led to today's large landscape of heavy launch vehicles (Ariane V, Falcon 9, Soyuz, Delta IV...). Today, the growing market of small satellites (below 500kg) - including, notably, LEO constellations projects and cubesats - pushes towards dedicated small launchers. This trend started in the 90s and considerably accelerated in the 2010s with the development of a broad ecosystem of small launchers startups.

Design Structure Matrix (DSM) Allocation

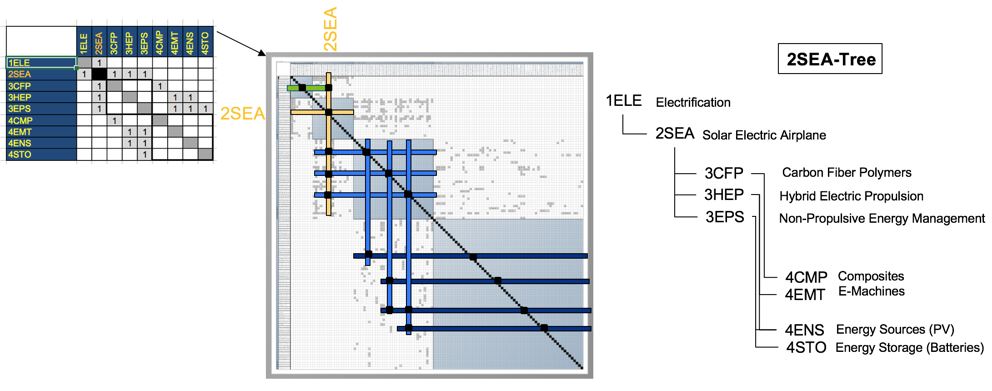

The 2-SEA tree that we can extract from the DSM above shows us that the Solar-Electric Aircraft (2SEA) is part of a larger company-wide initiative on electrification of flight (1ELE), and that it requires the following key enabling technologies at the subsystem level: 3CFP Carbon Fiber Polymers, 3HEP Hybrid Electric Propulsion and 3EPS Non-Propulsive Energy Management (e.g. this includes the management of the charge-discharge cycle of the batteries during the day-night cycle). In turn these require enabling technologies at level 4, the technology component level: 4CMP components made from CFRP (spars, wing box, fairings …), 4EMT electric machines (motors and generators), 4ENS energy sources (such as thin film photovoltaics bonded to flight surfaces) and 4STO (energy storage in the form of lithium-type batteries).

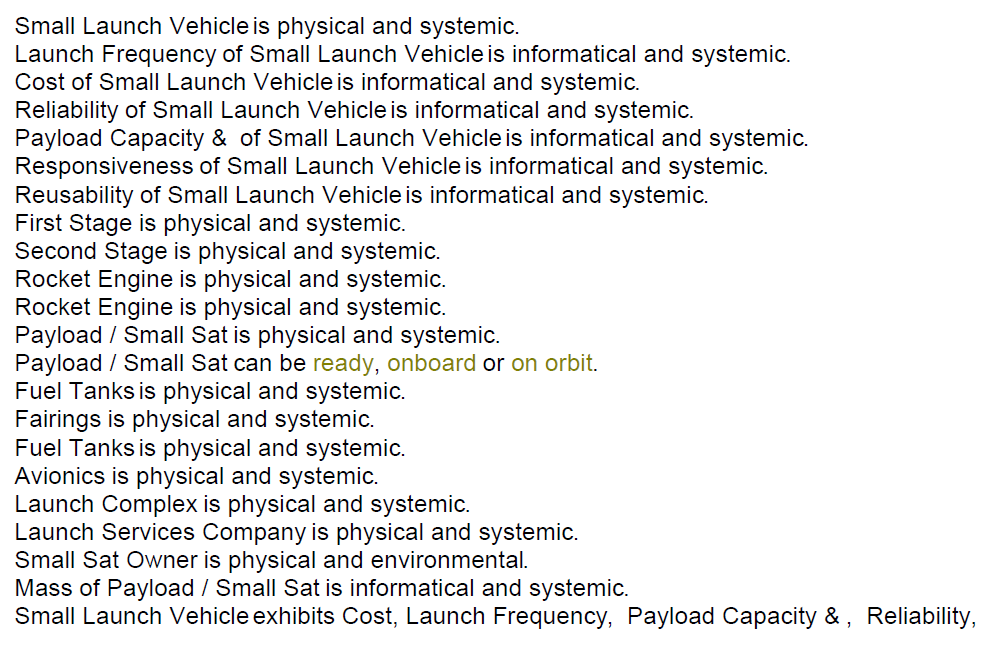

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2SEA roadmap in the figure below. This diagram captures the main object of the roadmap (Solar-Electric Aircraft), its various instances including main competitors, its decomposition into subsystems (wing, battery, e-motor …), its characterization by Figures of Merit (FOMs) as well as the main processes (Flying, Recharging).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.

Figures of Merit

Figures of Merit (FoM) used to evaluate small launchers are very similar to the FoMs of conventional launch vehicles, but they have redefined the priorities among these. Typical FoMs for small launchers are: Launch Frequency [launch/month], Reliability [$\%$ of successful launches], Payload mass capacity [kg of payload to LEO], Total cost [$\$$], Cost per kg [$\$ /kg$ of payload to LEO], Reusability [Number of reuse cycles], Scheduling flexibility (sometimes called Responsiveness, duration between the launch window and the notification of its flight parameters - orbit, latitude, date...) [weeks or months or years]

In general, small launcher companies aim for very high launch rates (weekly instead of monthly), high scheduling flexibility (months instead of years), and low launch costs thanks to significant economies of scale enabled by mass production. Some also leverage uncommon launch strategies (balloons, planes, catapults), but here we only include into our scope actual orbital launchers with launching pads on earth or on sea.

Using a simple linear regression model, we can find a decreasing cost of $-2930.4\$/kg/year$.

THe physics of launchers is governed by the Rocket Equation:

$$\Delta V = v_e \log(\frac{m_0}{m_f})$$

$\Delta V$ is the change of velocity available to the missile

$m_0$ is the initial wet mass

$m_f$ is the (final) dry mass

$v_e$ is the effective exhaust velocity