Geothermal Power Plant

Technology Roadmap

Roadmap Overview

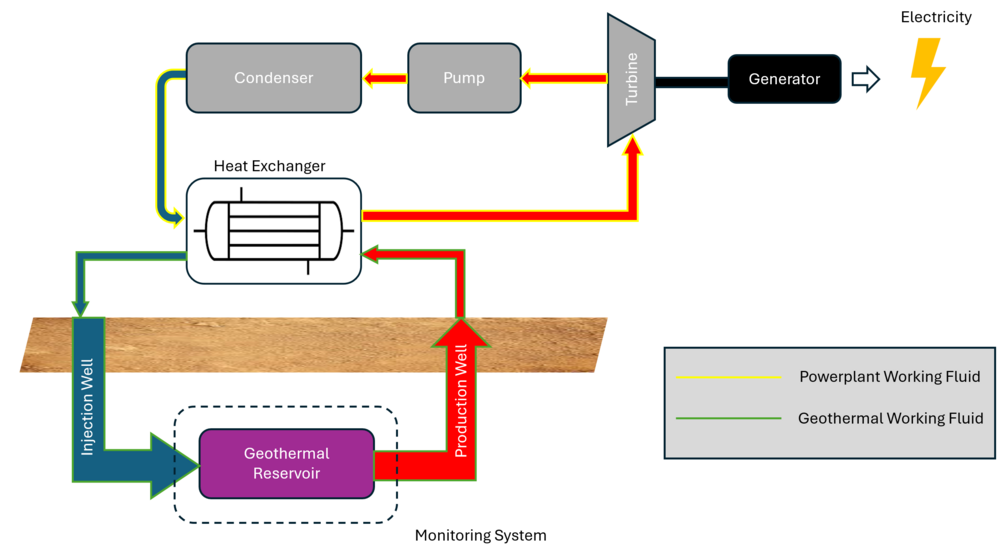

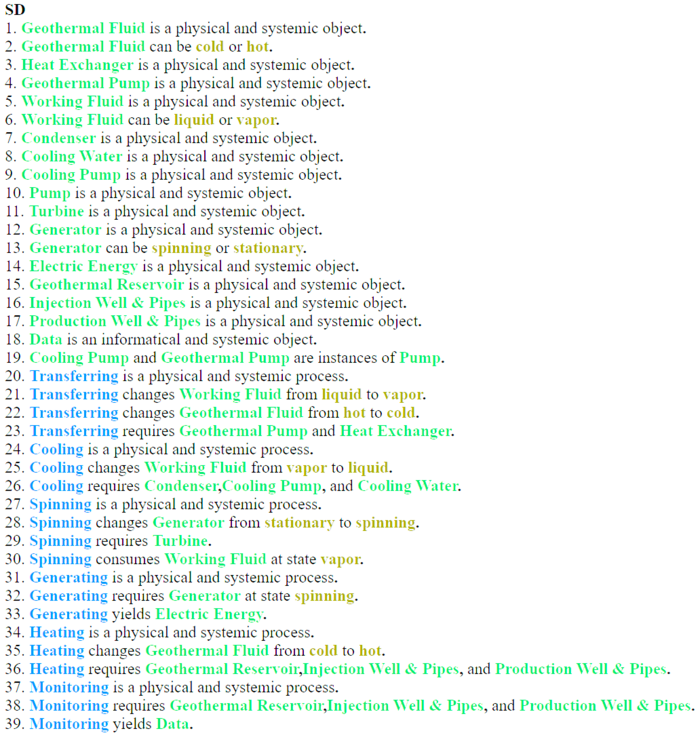

Technology Description: Geothermal power plants generate electricity by harnessing geothermal energy through a series of steps. First, geothermal fluid is heated by accessing the geothermal reservoir, either by injecting it directly into the reservoir (Enhanced Geothermal System) or using pipes that pass through the reservoir (Closed Loop). The heated fluid is then brought to the surface and passed through a heat exchanger, transferring its heat to a working fluid. This working fluid, now heated, drives a turbine, which powers a generator to produce electricity. Afterward, the working fluid is cooled and condensed back into a liquid form before being recirculated through the heat exchanger to repeat the process.

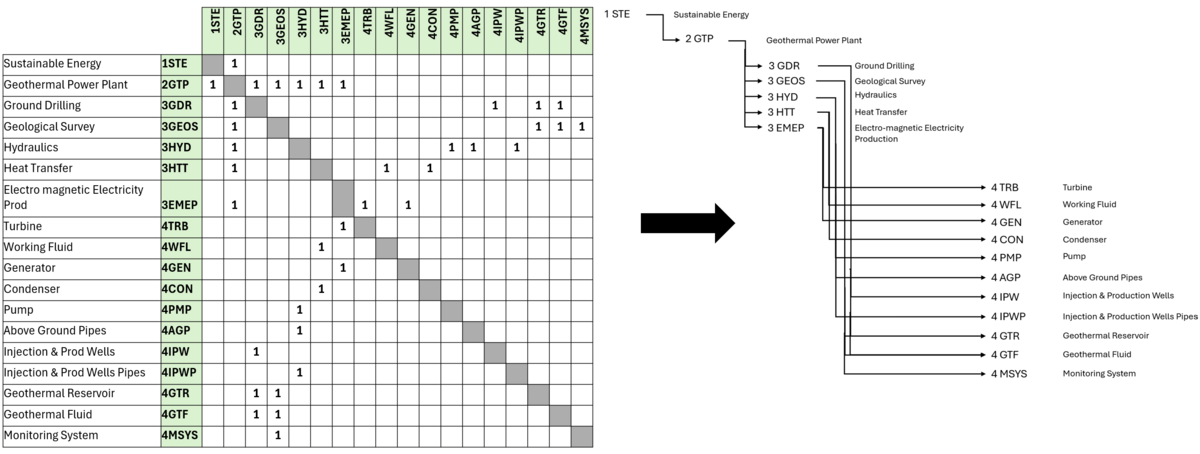

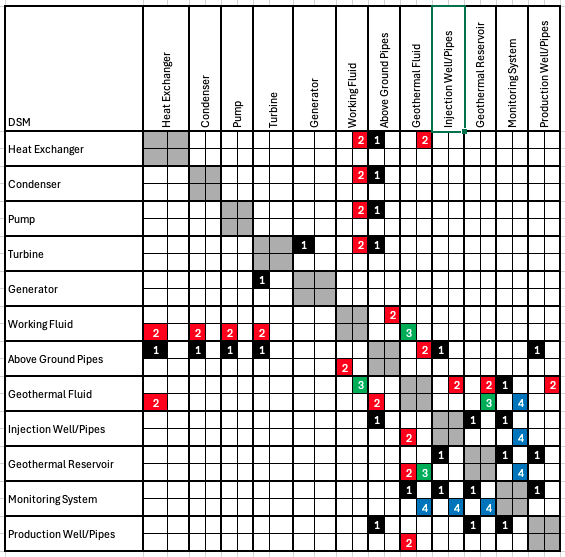

Design Structure Matrix (DSM) Allocation

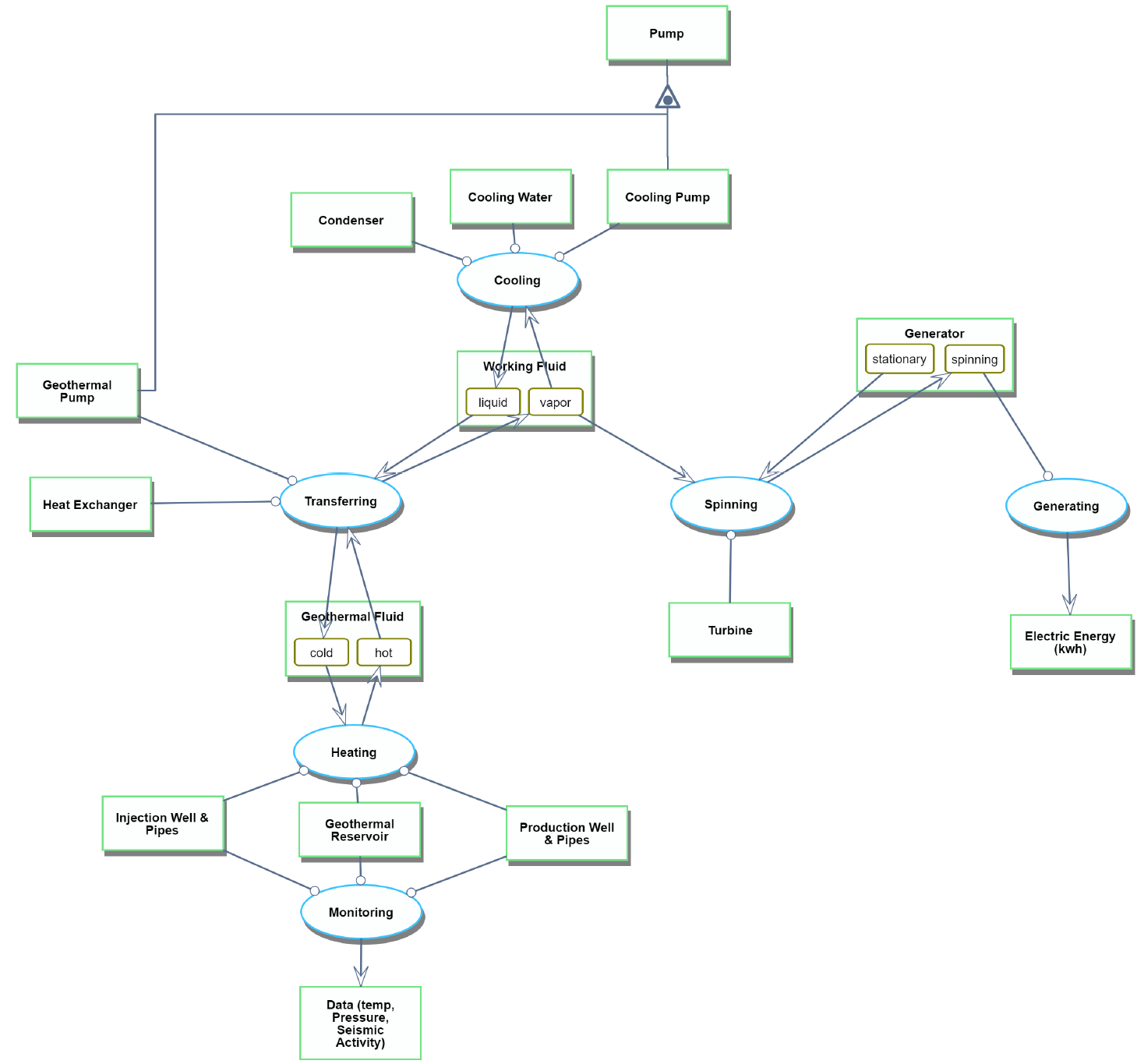

Roadmap Model using OPM

Figures of Merit

Alignment with Company Strategic Drivers

Positioning of Company vs. Competition

Technical Model

Financial Model

List of R&T Projects and Prototypes

Key Publications, Presentations, Patents

Publications:

The Sandia GeoVision Analysis report is widely cited as a reference for drilling considerations on all geothermal well development. This report provides a baseline for drilling costs given different borehole diameters and drilling directions. The drilling analysis includes bit design, environmental considerations, non-drilling activities, reservoir stimulation mechanisms and their associated costs, and hydraulic performance. These considerations are oriented on performance and cost, producing well cost curve scenarios for many drilling situations. This provides a significant resource in planning geothermal borehole development without requiring experience in the specific characteristics of the location or development. This report also includes maintenance and management practices to ensure enthalpy production remains within planned bounds. The combination of drilling costs tied to capital expenditure and maintenance and management costs provides a strong resource for estimating the overall costs needed for a levelized cost of electricity assessment.

T. S. Lowry et al., “GeoVision Analysis Supporting Task Force Report: Reservoir Maintenance and Development”