Small Launch Vehicles

Technology Roadmap Sections and Deliverables

- 1SLV - Small Launch Vehicles

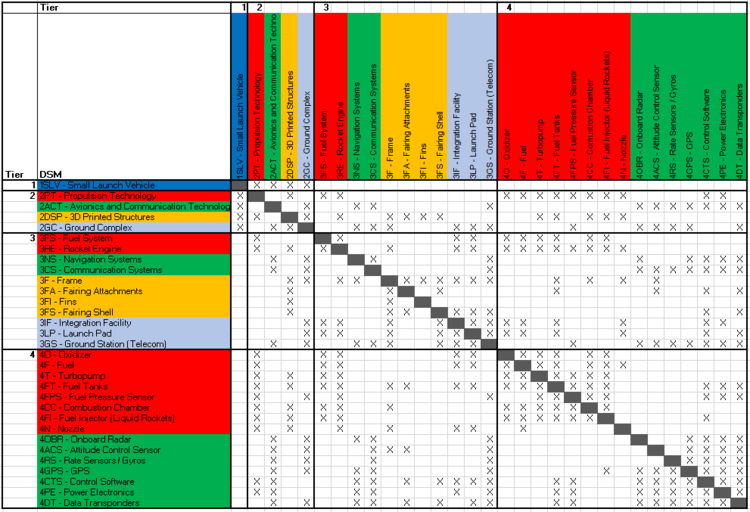

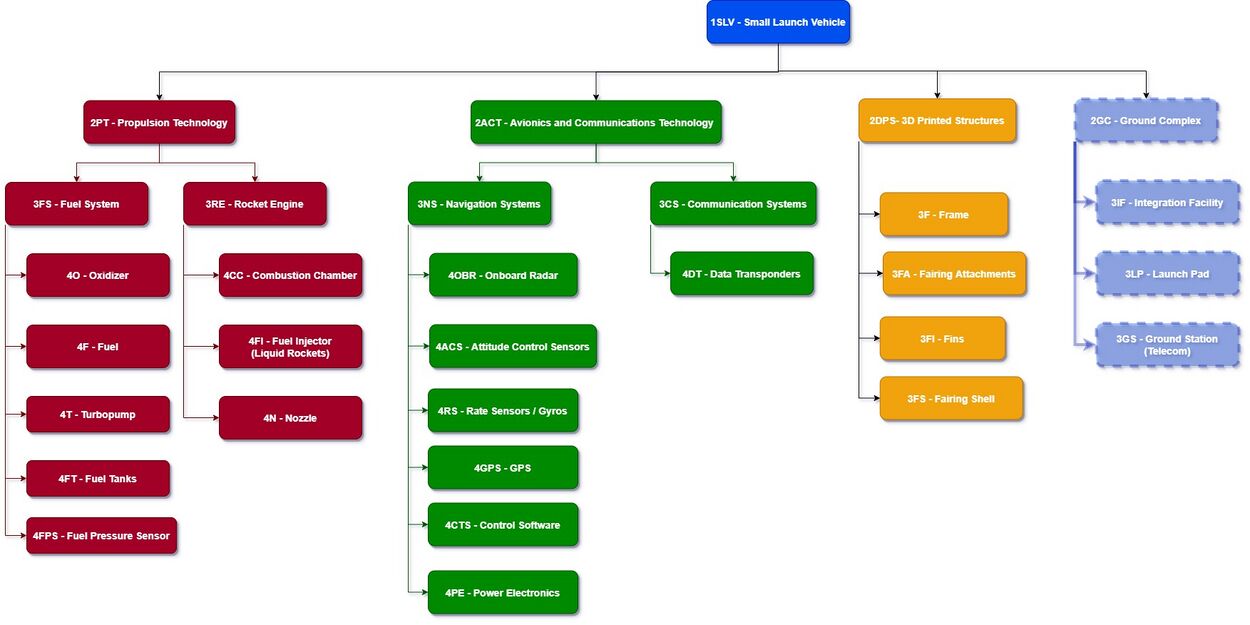

The small launch vehicle market, a level 1 roadmap, is a sub-sect of the launch vehicle / launch provider market. Level 2 roadmaps are the product level, level 3 roadmaps are at the subsystem level, and level 4 roadmaps are at the component level.

Roadmap Overview

Small launch vehicles (SLVs, also called "Small launchers" or "Small-lift launch vehicles") are a category of orbital launchers capable of carrying a payload of maximum 2000kg* to LEO (Low Earth Orbit). Half a century ago, many families of launch vehicles have started as small launchers, as prototypes, and have led to today's large landscape of heavy launch vehicles (Ariane V, Falcon 9, Soyuz, Delta IV...). Today, the growing market of small satellites (below 500kg) - including, notably, LEO constellations projects and cubesats - pushes towards dedicated small launchers. This trend started in the 1990s and considerably accelerated in the 2010s with the development of a broad ecosystem of SLV startups. In comparison to conventional (heavy) launch vehicles, SLVs have: a higher scheduling flexibility, a higher launch frequency, a much lower total cost but a higher cost per kg of payload.

*: Diverse definitions exist. Some define small launchers as limited to 1 ton instead of 2 tons, some also define a lower boundary of 500kg under which launchers are called 'micro-launchers'.

Design Structure Matrix (DSM) Allocation

The technology hierarchy demonstrates that such technologies as metal 3-D printing and modulable launchpads are supporting the development of small launchers. Initiatives and development plans for these technologies enhance small launchers by increasing their reusability, launch rate, scheduling flexibility, and reducing their cost per kilogram to launch payloads into orbit.

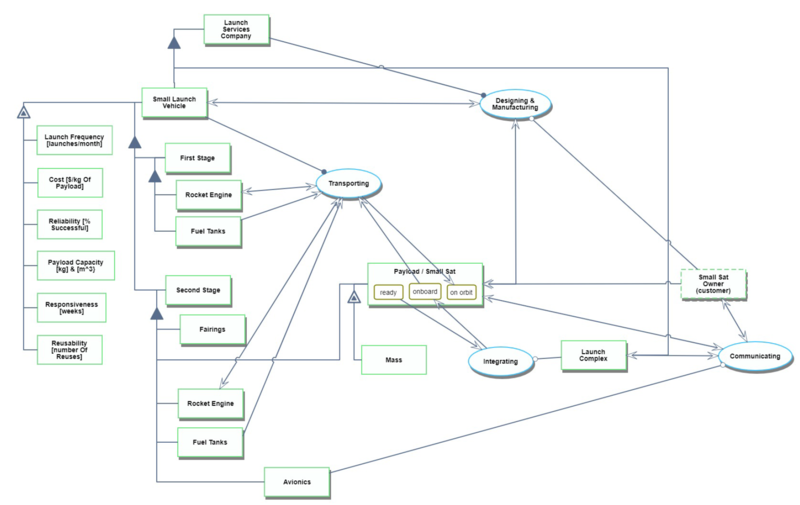

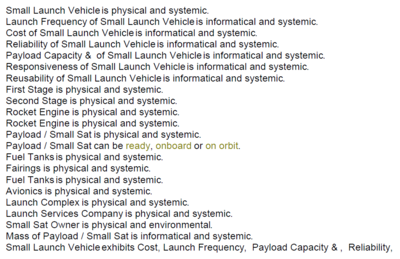

Roadmap Model using OPM

We provide below an Object-Process-Diagram (OPD) of the 1SLV roadmap. This diagram captures the main object of the roadmap, its decomposition into subsystems (engines, avionics, payload...), its characterization by Figures of Merit (FOMs) as well as the main processes and actors involved.

An Object-Process-Language (OPL) description of the technology is auto-generated and given below:

Figures of Merit

Figures of Merit (FoM) used to evaluate small launchers are very similar to the FoMs of conventional launch vehicles, but they have redefined the priorities among these. Typical FoMs for small launchers are:

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Launch Frequency | [launches/month] | The number of launches a launch vehicle can perform in a month |

| Reliability | [% of successful launches] | The percentage of launches out of total launches that are successful as determined by ability to meet end requirements of customers |

| Payload mass capacity | [kg of payload to 500km LEO] | The amount of payload in kilograms that can be launched to 500km Low Earth Orbit (LEO) with the launch vehicle. LEO is a large range and so this FOM standardizes the various launch vehicles by specifying 500km LEO |

| Total cost | [$] | The total cost of the launch to include fixed and variable costs |

| Cost per kg | [$/kg of payload to LEO] | The total cost of the launch divided by the amount of payload to 500km LEO |

| Reusability | [Number of reuse cycles] | The number of times a launch vehicle can be reused before a new one must be built |

| Scheduling flexibility | [weeks or months or years] | How quickly the launch vehicle can go from initial talks with customer to launch to LEO. (Sometimes called Responsiveness, it is the duration between the launch window and the notification of its flight parameters - orbit, latitude, date, etc.) |

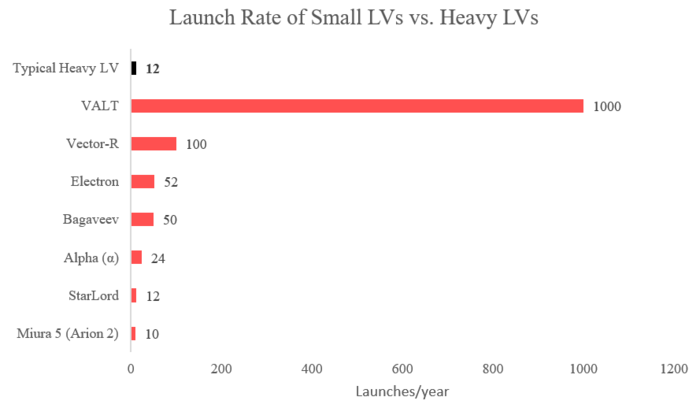

In general, small launcher companies aim for very high launch rates (weekly instead of monthly), high scheduling flexibility (months instead of years), and low launch costs thanks to significant economies of scale enabled by mass production. Some also leverage uncommon launch strategies (balloons, planes, catapults), but here we only include into our scope actual orbital launchers with launching pads on earth or on sea.

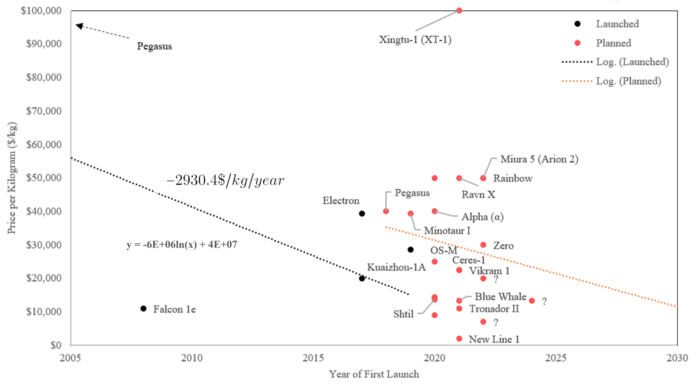

The following plots have been built using a database our team built and plan upgrade regularly throughout time. Main sources of information are SpaceFund.com, Newspace.im and small launcher companies' websites and user guides.

Using a simple linear regression model, we can find a decreasing cost of: $$-2930.4\$/kg/year$$ This means that costs for launch are project to decrease by $2930.40 per year. This is a rough estimate and data is still being collected to make this model more accurate as small launchers are relatively new and data is scarce.

The physics of launchers is governed by the Rocket Equation:

$$\Delta V = v_e \log(\frac{m_0}{m_f})$$

<math> \Delta V </math> is the change of velocity available to the missile

<math> m_0 </math> is the initial wet mass

<math> m_f </math> is the (final) dry mass

<math> v_e </math> is the effective exhaust velocity

Alignment of Strategic Drivers

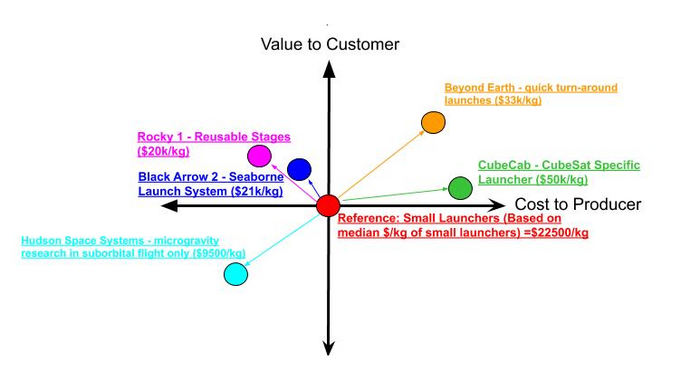

Positioning of Company versus Competition

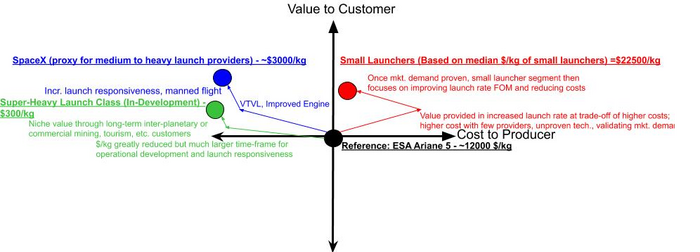

The first graph depicts the positioning of the small launcher market with respect to the medium, heavy, and super-heavy launch markets. Larger launchers, such as SpaceX's Falcon 9 rocket, are able to provider cheaper costs per kilogram with high reliability which explains their positioning as cheaper producers and improved value. Small launchers on the other hand cost more per kilogram than the other launchers but the overall launch cost is lower overall, the launch frequency is likely to be higher because customers do not need to wait for ride-sharing to be sorted out for payloads, and the reliability is supposedly similar although most are as un-proven as the conventional launchers.

The micro- and nano- launch markets are much smaller and unproven so therefore not shown. However, the value of those two markets would be more niche in providing smaller, more specified payloads and thus more expensive with respect to $/kg albeit it at the tradeoff of likely higher launch frequencies and lower overall costs.

The above graph depicts the positioning of a standard small launch company (based upon the average small launcher cost per kilogram (average frequency of launch is difficult to assume due to low available data but would be a better reference and indicator of value) based on the suggested FOM introduced by small launchers. As seen, various small launch vehicle providers are attempting to bring value through respectively unique means. Some are attempting to introduce reusable stages similar to SpaceX's Falcon 9 to small launchers, others are attempting to narrow in on the niche of cubesats, some are attempting to focus on seaborne launch which reduces the costs of aborting launch and clearing an area/waiting for weather, and so on. Although some competitors are increasing costs in order to accommodate more niche markets while others are pursuing more advanced, riskier technologies to reduce overall costs, all are attempting to differentiate their service from other competitors in order to extract value from their own niche and remain profitable in their own competitive space.

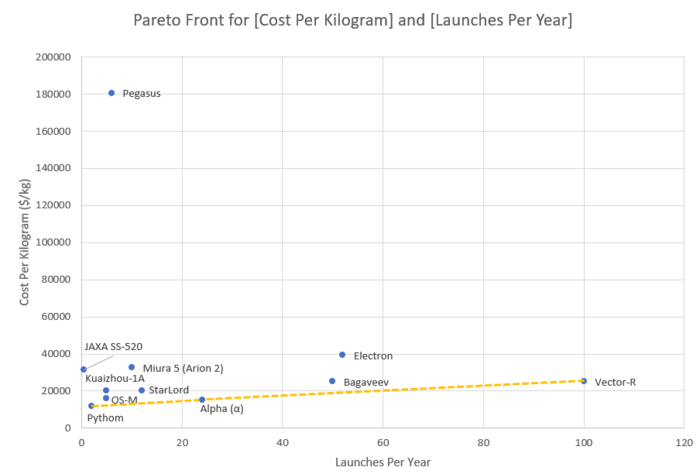

The pareto front below is not based on time but rather cost per kilogram and launches per year (also described as launch frequency/responsiveness). As seen, the Pythom, Alpha, and Vector-R launchers are pareto dominant whereas the other launchers are dominated alternatives. Of note, however, is that many, many launchers (150+) did not have data publicly available on both Figures of Merit and therefore were omitted from the data set. Furthermore, some launchers such as Pythom, are still in the developmental stages are projecting these launch costs and frequencies despite having never operationally proven these figures. Other launchers, some as the SS-520, Pegasus, and Kuaizhou-1A have been operationally proven with several successful launches. Currently, small launch companies are being reached out to manually in order to inquire about projections and more data is being continually added to the set as they respond. The current pareto optimal alternatives are expected to shift as more are added and the model can be improved by differentiating between pareto optimal launchers that are operational and those that are not yet launched. Finally, at $22,500, the reference company above would be pareto dominated by all other small launchers currently on the market. This means that the reference company should focus on both decreasing launch costs and increasing launch frequency.

Technical Model: Morphological Matrix and Tradespace

The *Responsiveness* of SLVs (Small Launch Vehicles) is by far the main differentiator of this market segment. Building such a model for responsiveness (which is based on organizational principles rather than physical principles) is complex and very little data is available at this granularity. For these reasons we decomposed this figure of merits into a sum of components on which we have actual data, or can do an educated guess with limited uncertainty in terms of factors at play and relative magnitudes. We used the SLV databases already mentioned in previous sections, manufacturers' websites, and for data only available for heavy launch vehicles, we scaled them.

For simplicity, we decide to use *lead time* as a proxy for Responsiveness: it is defined as the average duration between the order from the customer and the actual launch provided by the SLV services company. It assumes that a contract already exists between the two sides, but the chronometer starts when the actual orbit parameters, launch date and other specifications are communicated. Delays are very frequent, so we decompose responsiveness in the following way:

Responsiveness (days): $$R = \sum D_{\text{Launch Prep. Phases}} + \sum P_{\text{Delay Likelihood}} \cdot D_{\text{Delay}}$$ $$R = D_{1} + D_{2} + D_{3} + D_{4} + D_{5} + D_{6} + P_L D_{L-Delay} + P_S D_{S-Delay}$$

With (in Days):

S/C mating onto adapter: $$D_{1} = 3 \frac{m}{2000} $$ S/C mating into launcher: $$D_{2} = 5 \frac{m}{2000}$$ Fairing installation $$D_{3} = 1 $$ Launchpad preparation: $$D_{4} = 7 + 3 N + 2 S$$ S/C-Launcher Mission definition (trajectory, perf...): $$D_{5} = 15 - \frac{N}{2} - \frac{3}{2} S$$ Fuel system of main stage: $D_{6} = 2 $ for SRMs (solid rocket motors) ; $D_{6} = 6 $ for liquid rocket engines

Delays:

- Launcher

Likelihood: $$P_L= 0.3*\frac{m}{2000} + P_1 + P_2 $$ with <math> P_1 = 0.05 </math> if reused launcher (0 otherwise) and $P_2 = 0.1$ for liquid rocket engines (0 otherwise). $$D_{L-Delay} = 10$$

- Satellite/Spacecraft S/C

Likelihood: $$P_S= 0.05*\frac{m}{2000} $$ $$D_{L-Delay} = 20$$

Parameters: m payload mass capacity (mass of the spacecraft, S/C) 0<m<=2000kg N number of launchpad sites available (hypothesis: optimized spreading among the conventional inclination values used for LEO missions). 0<N<=8 S number of rocket stages 0<S<=3

“𝛿0” Disposable vs reused launcher main stage “𝛿1” Propellant type for main stage (solid vs liquid)

Comments: Phases that can be conducted in parallel of other “constraining” tasks (i.e. on the critical path of the supply chain) have been included in phases done in series. N is a variable that describes the ability of the company to launch from different sites at different inclinations, whether it is a fixed launchpad or a movable one (the more launchpad sites available, the easier the mission definition phase, the shorter the wait for an available site, but the less ready to go)

$$\Delta V = \text{Isp} \cdot g_0 \log (R)$$

$$ \frac{\partial \Delta V}{\partial \text{Isp}} = g_0 \log (R)$$

$$ \frac{\partial \Delta V}{\partial R} = \frac{\text{Isp} \cdot g_0 }{R}$$

$$ \frac{Isp_0}{\Delta V_0} g_0 \log (R_0) = 0.99$$

$$ \frac{R_0}{\Delta V_0} \frac{\text{Isp_0} \cdot g_0 }{R_0} = 0.43 $$

Key Publications and Patents

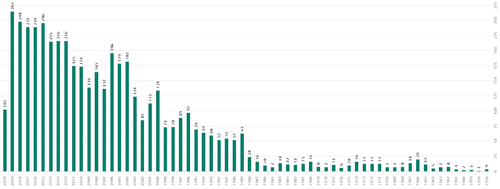

Number of publications per year about small launch vehicles (and equivalent denominations):

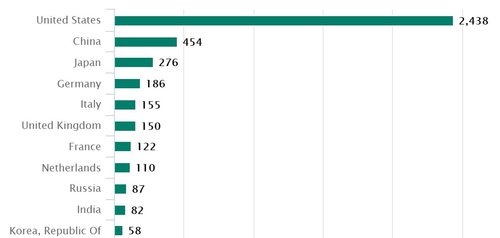

Most families of launch vehicles started as small launcher prototypes, as early as the 50s/60s, hence the few papers from that period. However, small launchers really became an attractive design in the 90s with the start of the miniaturization of satellites. There is a growing number of publications every year on the topic. If we conduct an analysis of author affiliations, we note that JPL (CA) is by far the most active on this topic, followed by the China Academy of Launch Vehicle Technology, and NASA. The countries of origin are the following:

We decided to focus on two papers about small launch vehicle technologies, highly cited and giving a good overview of current research areas. The first focuses on the use of small launchers for cubesat constellations’ deployment, the second one focuses on vibration isolation to protect payloads during launch from SLVs.

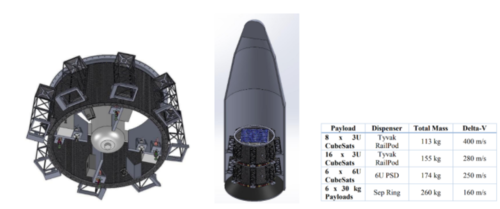

“Utilizing Small Launch Vehicles for Multiple Small Payload Missions” (2017)

Sending several cubesat payloads with different orbital parameters in a single launch is a challenge today because these often don’t have on-board propulsion systems and because small rockets don’t have 3rd/4th stages to precisely insert satellites one at a time. This paper presents a concept for a low-cost/low-mass “propulsive rideshare adapter” called SL-OMV that is able to remain on orbit for longer durations to distribute cubesats up to 6U to their respective LEO orbits. Both authors are employees of Moog, Inc (Aerospace and Defense company). Their solution may be particularly helpful for the deployment of cubesat constellations.

SL-OMV from below (left) and integrated under the fairings (right). SL-OMV Capacities.

“Multi-axis whole-spacecraft vibration isolation for small launch vehicles” (2001)

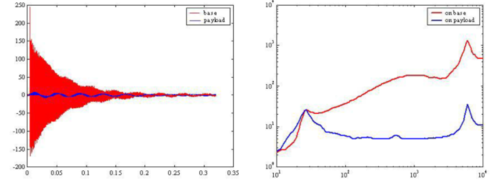

Vibration isolation systems are critical for launch vehicles to protect their sensitive payloads from vibrations resulting from the launch. Because of the mass and volume constraints on small launch vehicles, conventional isolation systems cannot be used. This is clearly a threat to the attraction of small launcher vehicles. This paper presents two passive vibration isolation systems to reduce dynamic launch loads. The first one protects against axial loads and has been used in three launches to date. The second one is a multi-axis device that performs the same functions and has been tested twice for space missions. They are both relatively simple to manufacture, passive, small, lightweight and reliable.

Additional attenuation provided by the second isolation device (accelerations/frequencies).

Patent analysis

We have found patents from small launch vehicle startups, aerospace companies and agencies about propulsion technologies, avionics, control software, launch pads and manufacturing methods. Most patents were filed during the past two decades. The first patent shows a way for SLV manufacturers to cut costs associated with high-quality avionics systems onboard launchers. The second one provides a mechanism to save mass and volume in the satellite deployment system for SLVs.

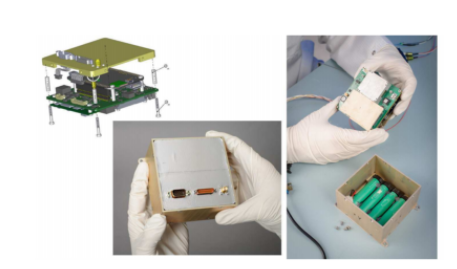

“Affordable vehicle avionics system”, 2020, NASA

Developed at NASA Ames research center, the AVA (Affordable Vehicle Avionics) is a low-cost, self contained GNC (Guidance, Navigation and Control) system made for nano- and micro-launchers. This system is qualified to survive the launch environment and leverages already existing commercial sensors and processors, to make it cost-effective (10% of the current cost of such systems). Its size is 100 mm x 120 mm x 69 mm with a mass of 0.84kg, it includes a tactical-grade MEMS inertial measurement unit that leverages a GPS receiver, inertial sensors and a magnetometer to reach precision levels suited for space navigation.

CAD model and pictures of the AVA (NASA website)

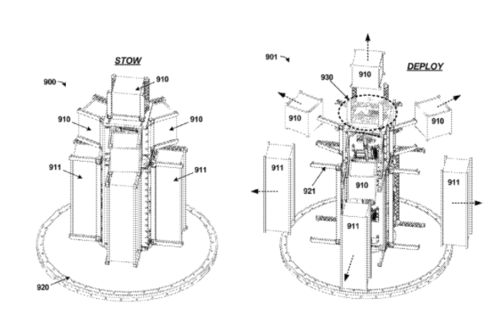

“Triggered satellite deployment mechanism”, 2016, Vector Launch Inc.

This patent presents an improved design for payload deployment systems. Weight and size are even more critical for small launch vehicles than for traditional launch vehicles, so this patent minimizes the size of the deployment mechanism. More precisely, it avoids having to enclose the satellite in a box structure. It instead uses pairs of “opposing hooks that slide over a set of small chassi rails” that stick out and are compliant with cubesat standards.

Satellite deployment mechanism