On Demand Spare Manufacturing

Roadmap Creators: Robaire Galliath, Alexa Rucks, Ahaana Sarup

Overview

On Demand Spare Manufacturing is the production of spare parts as needed, rather than maintaining a traditional inventory. This approach leverages digital manufacturing technologies such as additive manufacturing, 3D scanning, optimization algorithms, and supply chain logistics. The process involves identifying the need for a spare part, transporting materials for manufacturing, scanning the existing part, processing and generating a mesh, manufacturing the spare part, finishing, inspecting, transporting the spare part to the system, and installing the replacement part.

Technology Focus: Metallic 3D Printing

While many additive manufacturing technologies were initially developed for polymers and resins, they have modern applications in metallic additive manufacturing. At its core, additive manufacturing involves adding material layers repeatedly until a 2D or 3D object is formed. This roadmap will focus only on metallic applications and their relationship to managing spare part inventory within a target company’s supply chain. Unless clearly defined, we will use powder bed fusion as our default 3D printing technology. Main Categories of Metallic 3D Printing Technology

- Powder Bed Fusion (PBF): Includes technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These methods involve spreading a thin layer of metal powder over a build platform and selectively melting it with a laser or electron beam.

- Direct Energy Deposition (DED): Technologies such as Laser Engineering Net Shape (LENS) and Electron Beam Additive Manufacturing (EBAM) use focused thermal energy to melt materials as they are deposited.

- Binder Jetting: A binding agent is selectively deposited onto a powder bed, bonding the powder particles together. The part is then cured and sintered to achieve its final properties.

- Material Extrusion: Includes technologies like Metal Fused Filament Fabrication (FFF), where metal filaments are extruded through a heated nozzle and deposited layer by layer. The printed part is then sintered to remove the binder and fuse the metal particles.

- Sheet Lamination: Involves stacking and bonding sheets of metal, which are then cut to shape using a laser or another cutting tool. Ultrasonic Additive Manufacturing (UAM) is a common example.

Powder Bed Fusion Background

Powder bed fusion processes work by spreading a thin layer of metallic powder over a build plate that is subjected to energy from a laser and fused into a solid layer of material. The entire process takes place in an inert chamber, commonly argon gas, that enables the quick removal of produced gases. The process produces a better surface finish, higher resolutions, and lower rate of defects than other printing processes. The ability to control powder deposition, powder homogeneity, and the rate of gas flow off the part surface enable the higher resolution and lower defect rate.

There are a few key drawbacks to this printing technology. The size of the printed part is limited to the size of the base plate that will fit in the controlled environment. The material powder handling requires proper storage and high-quality control to maintain homogeneity in the powder. Certain metal chemistries, such as carbon steel, are more prone to oxidation due to the increased surface area of the metallic powders and therefore are not good candidates for PBF. In the field, this may mean having to consider alloying-up to a more expensive metal chemistry and additional engineering review before a part can be approved for printing.

Current State of Spare Part Manufacturing

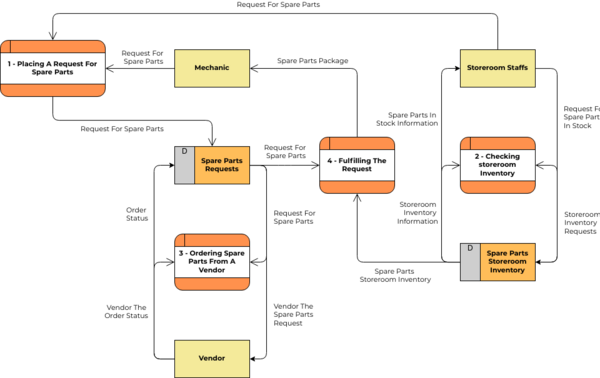

Traditionally, when a part breaks or is retired, the inventory is checked for spares. If no spares are available, drawings are created or found, sent out to suppliers, and quoted for replacement. This process can lead to procurement delays due to long lead times for OEMs to manufacture a part and time lost to redesign.

When evaluating a spare part inventory, there are many key decision points that need to be evaluated. Cost, speed of manufacturing, and technical requirements are common considerations when deciding between traditional or additive processes. Evaluating a spare part inventory involves several key steps to ensure efficiency and reliability. First, conduct a thorough inventory assessment to identify critical components that are prone to failure. Prioritize these essential parts based on their impact on operations. Next, evaluate the feasibility of using 3D printing for these parts, considering factors like material compatibility and cost savings. Create a digital inventory and develop accurate CAD models for the parts to be 3D printed. Select appropriate materials and printers that meet the mechanical and environmental requirements.

Integration of 3D Printing in Spare Part Manufacturing

3D printing fits into the current manufacturing landscape by offering several advantages:

- Customization: Ability to produce customized parts on demand without the need for expensive tooling.

- Reduced Lead Times: Faster production times compared to traditional manufacturing methods, especially for complex or low-volume parts.

- Inventory Reduction: Minimizes the need for large inventories, reducing storage costs and waste.

- Complex Geometries: Enables the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing.

Challenges and Future Prospects

Despite its advantages, metallic additive manufacturing faces challenges such as high initial costs, material limitations, and the need for post-processing. However, ongoing advancements in technology and materials are expected to address these issues, making 3D printing a more viable option for spare part manufacturing in the future. In summary, metallic additive manufacturing for spare parts represents a significant shift from traditional inventory-based approaches to a more flexible, on-demand production model. As technology continues to evolve, it is poised to play an increasingly important role in the manufacturing landscape.

Design Structure Matrix

The DSM below shows how an On Demand Spare Parting roadmap would relate to a company's roadmaps in other areas that enable on demand spare parting and its support activities.

Roadmap Model using Object-Process-Methodology (OPM)

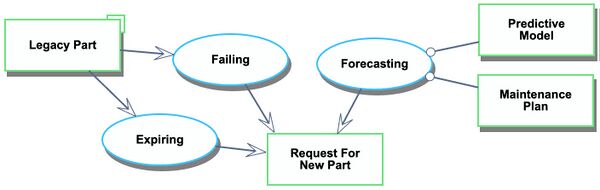

The graphic below depicts the different processes by which a need for a spare part is identified. Depending on different factors, such as the industry and risk tolerance, the need for a spare may arise differently. For example, a spare may be needed to replace a component during routinely scheduled maintenance as opposed to a spare that is required because a component failed. In the first case, the need for the spare can be anticipated ahead of time; in the second case, the need arises unexpectedly.

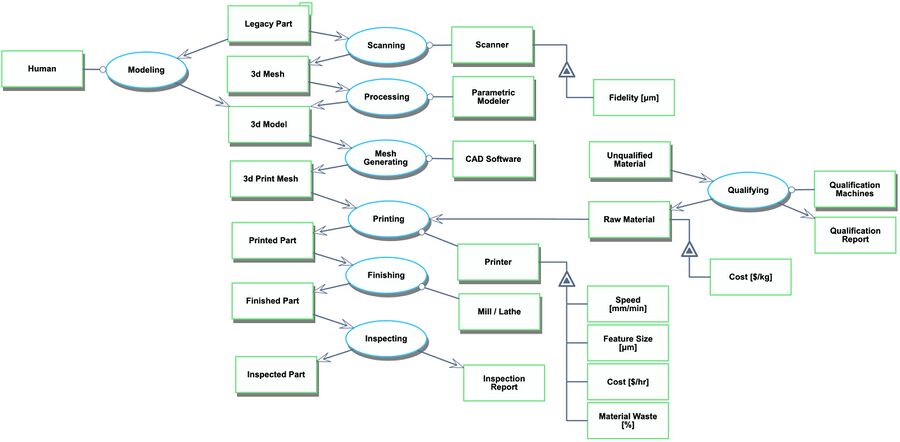

The graphic below depicts the primary objects and processes associated with On Demand Spare Manufacturing. In this model, humans are only identified when they are active participants in the process. Humans are not identified as actors if they are passive participants, such as an operator running a machine.

Figures of Merit

| FOM | Description | Unit | Trend |

|---|---|---|---|

| Turn-Around-Time | Time from need identified to need met | hr | decreasing |

| Cost | Total replacement part cost | $ | decreasing |

| Feature Size | The smallest detail that can be reproduced | μm | constant |

| Lifespan | Replacement part lifespan | year | constant |

| Material Cost | Raw material cost | $/kg | constant |

| Production Cost | Aggregate cost of labor, machine time, etc... | $/hr | decreasing |

| Material Waste | Excess material utilized in the production process | % | decreasing |

| Defect Rate | The fraction of parts produced that are not suitable for use | % | constant |

Strategic Drivers

A strategic driver is a key factor that influences the direction and success of a company’s strategy. These drivers help in setting priorities, making decisions, and allocating resources to achieve long-term goals. In the context of strategic spare part printing, the chosen figures of merit (FOM) serve as strategic drivers that guide the company’s efforts to improve quality and competitiveness.As we evaluated potential technical models for strategic spare part printing, many potential merit figures surfaced such as laser power, scanning speed, fulfillment time, or defect rate. We felt that we wanted to focus on higher level figures of merit that we can use to explore our tradespace and to allow for comparison across industry sectors (such as traditional manufacturing vs additive). We chose to investigate the overall process variance and error rate.

Process Variance: This strategic driver focuses on the variability inherent in the manufacturing process. It is the sum of the critical manufacturing steps for scanning It encompasses:

- Scanner Variance: Related to the inherent optical properties of the scanner.

- Processing Variance: Related to the modeling process and the inherent error in using 3D mesh to model a dimensional surface.

- Laser Variance: Related to the printing process and the natural noise that comes with laser deposition.

By targeting process variance, the company aims to reduce inconsistencies and improve the precision of the manufacturing process. Enhancing instrumentation and hardware as technology progresses is the primary method to improve this FOM.

Error Rate: This strategic driver addresses the frequency of errors occurring during the manufacturing process. It includes:

- Material Errors: Such as improper storage of feedstock powder leading to metal oxide formation.

- Processing Errors: Such as issues in tuning and editing 3D meshes.

- Environmental Errors: Such as improper control of printer bed temperature and humidity.

Minimizing the error rate involves upholding proper standards and rigorous monitoring during manufacturing. Addressing errors at the manufacturing level is significantly more cost-effective than fixing them in the field or with the customer. However, it is acknowledged that some level of defects is inevitable in this type of manufacturing.

Positioning vs Competition

The Defense Innovation Unit (DIU) operates with a higher appetite for risk, a willingness to try new things, and a larger budget compared to typical companies. For instance, DIU’s budget for fiscal year 2024 is nearly $1 billion, allocated to accelerate and initiate critical projects. This contrasts sharply with industries like refineries, which may have lower risk tolerance and a more urgent need for reliable parts during turnarounds. DIU’s strategic focus on innovation and rapid deployment of commercial technology to meet defense needs allows it to explore cutting-edge solutions that might be too risky or costly for traditional companies to pursue.

DIU’s risk appetite is evident in its approach to adopting and scaling new technologies. The unit is known for its willingness to invest in bleeding-edge technologies and capabilities that work within a Department of Defense (DoD) or intelligence community setting. This includes projects like AI-enabled tools to combat deepfakes and advanced cyber capabilities. DIU’s ability to take on higher risks is supported by its flexible budget and strategic mandate to close critical operational capability gaps with speed and scale. This risk tolerance enables DIU to push the boundaries of innovation, providing the U.S. military with advanced technological solutions that might not be feasible for more risk-averse organizations.

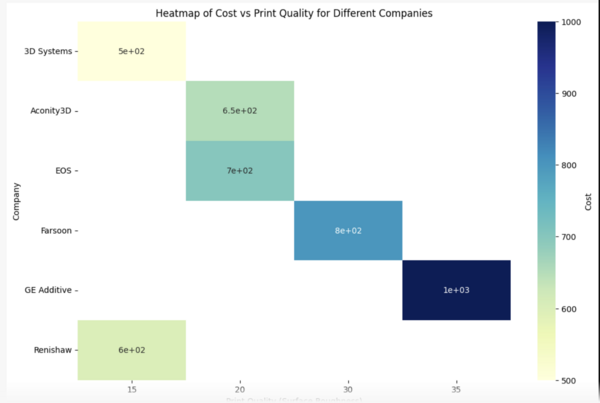

Due to the secretive nature of both the companies and the competitors, we utilized readily available information to price printing costs vs quality at well-known public companies. Please see the estimated cost heat map below to explore the additive manufacturing space. There will be a deep dive comparing traditional manufacturing to the players shown in the heat map below.

By focusing on minimizing process variance and error rates, DIU can position itself favorably against competitors. This strategic focus helps in demonstrating superior quality and reliability in its products, which is crucial for maintaining a competitive edge in the market.

Principal competitors in the field of spare manufacturing are traditional modeling methods coupled with traditional manufacturing methods and traditional modeling methods coupled with on demand manufacturing methods. Traditional modeling refers to the modeling of replacement components by a human in order to generate a CAD model for manufacturing. Our technology aims to minimize human involvement and cost by utilizing 3D scanning and automated processing techniques. Traditional manufacturing refers to typical "job shop" manufacturing for components, typically using a mix of manually operated machine tools or CNC machine tools depending on component complexity and quantity. On demand CNC is a variant of traditional manufacturing that utilizes highly automated CNC workflows to quickly manufacture components given a 3D model. This is an emerging market with companies such as Proto Labs providing quick turn-around manufacturing.

| FOM | Description | Unit | On Demand Spare Manufacturing | Traditional Modelling / CNC Manufacturing | Traditional Modelling w/ On Demand CNC |

|---|---|---|---|---|---|

| Turn-Around-Time | Time from need identified to need met | hr | 24 | ~300 | ~100 |

| Cost | Total replacement part cost | $ | Material Cost + Machine Time | Material Cost * 5 + Modeling Labor + Machine Time | Material Cost * 5 + Modeling Labor + Machine Time |

| Feature Size | The smallest detail that can be reproduced | µm | ~300 | ~100 | ~100 |

| Lifespan | Replacement part lifespan | year | 75% | 100% | 100% |

| Material Cost | Raw material cost | $/kg | Material Cost | Material Cost * 5 | Material Cost * 5 |

| Production Cost | Aggregate cost of labor, machine time, etc. | $/hr | Machine Time | Modeling Labor + Machine Time | Modeling Labor + Machine Time |

| Material Waste | Excess material utilized in the production process | % | 5% | 70% | 70% |

| Defect Rate | The fraction of parts produced that are not suitable for use | % | 3% | 1% | 1% |

Technical Model: Morphological Matrix and Tradespace

A Morphological Matrix is a tool used in engineering and design to explore all possible solutions to a complex problem by breaking it down into its fundamental components and systematically varying each component. This method helps in identifying innovative combinations and configurations that might not be immediately obvious.

Tradespace analysis, on the other hand, involves evaluating different design alternatives based on multiple criteria, such as cost, performance, and risk. By mapping out these alternatives in a tradespace, decision-makers can visualize the trade-offs and make informed choices about which design best meets their objectives. Together, these tools are essential for optimizing design processes and achieving balanced, effective solutions.

Below is a Morphological Matrix and Trade Space analysis for On Demand Spare Manufacturing based on the technical model developed.

| Decision Variable | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Scanning Variance | 0.03 mm1 | 0.04 mm | 0.05 mm2 | 0.06 mm3 | 0.1 mm4 | 0.2 mm5 |

| Processing Variance | 0.02 mm6 | 0.03 mm | 0.04 mm | 0.05 mm7 | 0.1 mm8 | 0.5 mm9 |

| Laser Variance | 0.02 mm10 | 0.035 mm12 | 0.04 mm11 | 0.05 mm14 | 0.1 mm13 | 0.2 mm |

| Material Storage Defect Rate | 1% | 3% 15 | 5%17 | 7%16 | 9% | 11% |

| Printing Defect Rate | 1%10 | 3%11,12 | 5%14 | 7%13 | 9% | 11% |

| Environmental Defect Rate | 1%18 | 3%19 | 5%20 | 7%21 | 9% | 11% |

| Algorithm Time Complexity | O(n) | O(n^2) | O(nlogn) | O(logn) |

The numbers notated in superscript in the table correspond to the numbers in the list below of different companies and products in the technology space. Values noted as estimated are best estimates based on internet research and personal experience as official numbers could not be found. All defect rates are estimated as we companies were not reporting on defect rates of their products.

- Creaform (HandySCAN 3D SILVER Series)

- Revopoint (POP 2)

- Hexagon AB (Absolute Arm with RS6)

- Artec 3D (Artec Eva)

- Trimble (X12)

- 3D Systems (Geomagic Design X) [estimated]

- CNR-ISTI (Meshlab) [estimated]

- Autodesk (Autodesk ReCap) [estimated]

- Agisoft (Agisoft Metashape) [estimated]

- Formlabs (Form 4)

- Anycubic (Photon M5s)

- Elegoo (Mars 3 Pro)

- Creality (Ender 3 V2)

- Qidi Tech (X-Plus 3)

- Metal Powders [estimated]

- Polymer Filaments [estimated]

- Ceramic and Composite Powders [estimated]

- Low Humidity, Sealed [estimated]

- Low Humidity, Open Air [estimated]

- High Humidity, Sealed [estimated]

- High Humidity, Open Air [estimated]

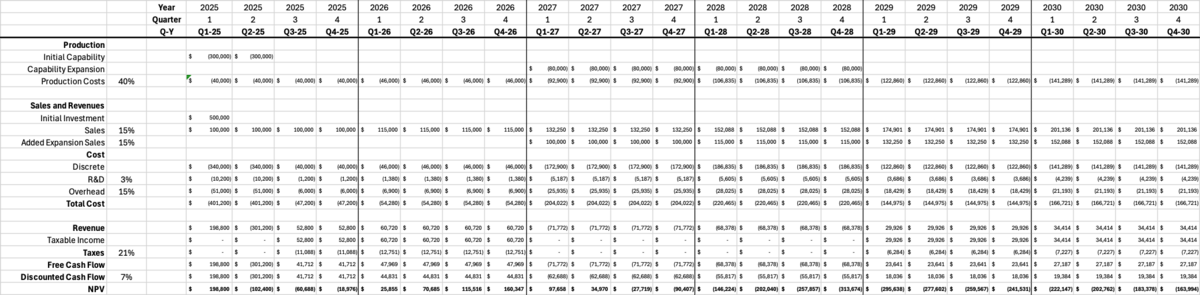

Financial Model

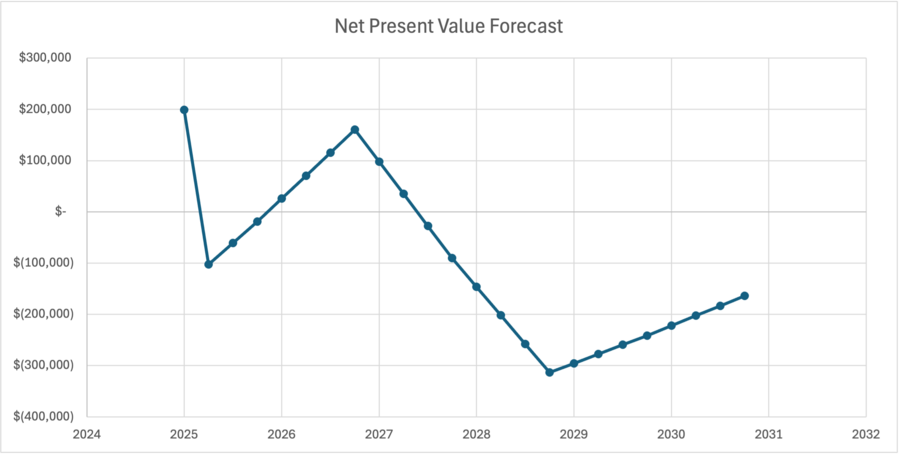

A notional financial model of a startup On-Demand-Spare Manufacturing company was constructed. After initial investment in several entry-level to mid-range metallic 3D printers and scanners, a modest growth rate in production orders is assumed as the technology matures. Future reinvestment in expanded manufacturing capability to meet customer demand is forecast to be two to three years after the initial standup. A Net-Present-Value analysis was conducted to determine required revenue and growth rates for sustainable operation.

The detailed forecast model is shown below

Key Publications and Patents

Patent 1: Item Delivery Using 3D Manufacturing On Demand

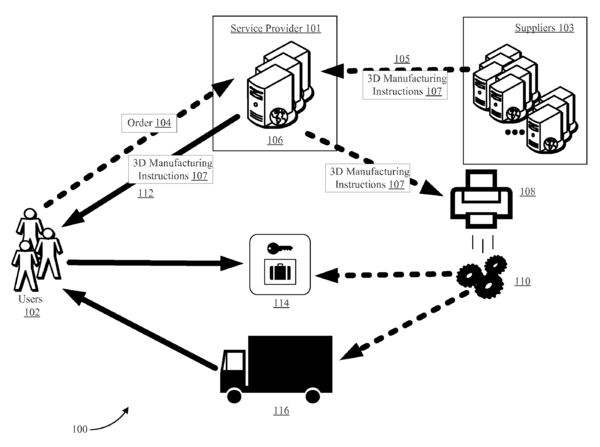

One patent related to the On Demand Spare Manufacturing technology is patent US-20150052023-A1 for “Item Delivery Using 3D Manufacturing On Demand” filed by Amazon. This patent describes methods and systems for providing manufactured items to consumers on demand rather than maintaining an inventory. The CPC classification for this patent is G06Q 30/0635 (Processing of requisition or of purchase orders).

This patent walks through the process of a user requesting an item, 3D manufacturing instructions being associated with the request, a delivery method being determined, a manufacturing machine being selected based on the instructions, the instructions being sent to the manufacturing machine, and delivery instructions being provided. The first step in this patented process is the user submitting a request for an item. Once the request is received, the request is first checked for any required authorization before proceeding. Once authorized, the user proceeds to select their desired customization and delivery options, the system will use this information to determine the payment required, and the user will provide the payment. After this is complete, the system will identify the 3D manufacturing instructions associated with the item, reconfigure the instructions to reflect any customizations selected by the user, determine the required 3D printing machine for the instructions, reconfigure the instructions if necessary for the chosen 3D printing machine, and provide the 3D printing instructions to the 3D printing machine. Meanwhile, the system will identify the selected delivery method, identify the location of the manufactured item, identify the delivery location, use this information to determine an estimated delivery timeline, deliver this information to the user, and provide delivery instructions.

This patent is relevant to on demand spare manufacturing because 3D manufacturing is a prime candidate for delivering the spares on demand as it is a quick and adaptable way to manufacture spares. This patent is also relevant because it address the logistics problem inherit in on-demand spare parting of legacy parts – the process must be able to determine which technique for each step of the process is most efficient and the process must make sense for manufacturing a single item at a time. Our On Demand Spare Manufacturing roadmap will need to capture developments in the automation of the logistics required to get through the on demand spare parting process.

The patent can be viewed in its entirety here: https://ppubs.uspto.gov/dirsearch-public/print/downloadBasicPdf/20150052023?requestToken=eyJzdWIiOiIxYzFlZjg5OS04MGFkLTQ5YTEtODVkNC1kNzdlZTU4YTdlNzIiLCJ2ZXIiOiJkOTY2N2JjOS1hOGQ4LTQ0ZmYtYTZkYi1iZGY2OGQ5M2E0NmQiLCJleHAiOjB9

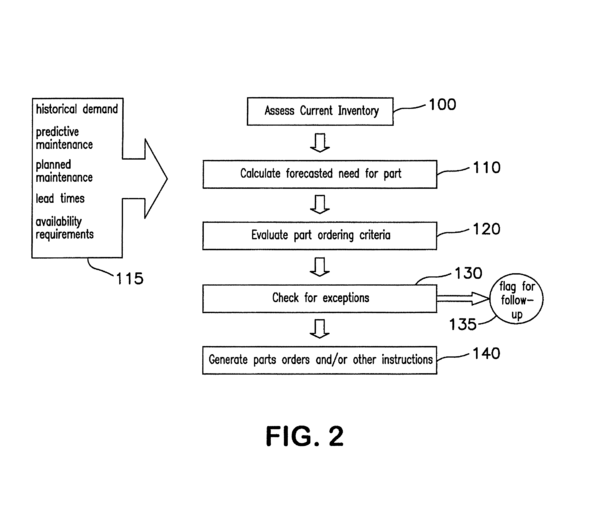

Patent 2: Spare Parts Inventory Management (US 7,266,518 B2)

Abstract: A method for managing spare parts and tools for a manufacturing enterprise is disclosed. Historical demand values are statistically analyzed to determine optimal stocking levels for spare parts based upon required availability percentages, parts lead times, and the statistical distribution parts demand levels. Parts stocking decisions can also be based upon planned and preventative maintenance timeframes with such parts ordered on an as-needed basis in accordance with lead times. Spare parts inventory management can utilize an enterprise-wide computer system to integrate parts demand planning with systems used for engineering and other changes to manufacturing processes and facility maintenance systems. The computer system can perform varying degrees of the parts reordering and planning process and automate certain steps while providing for decision of other issues by parts management personnel.

Patent 3: 3D metal printhead assembly method of manufacture

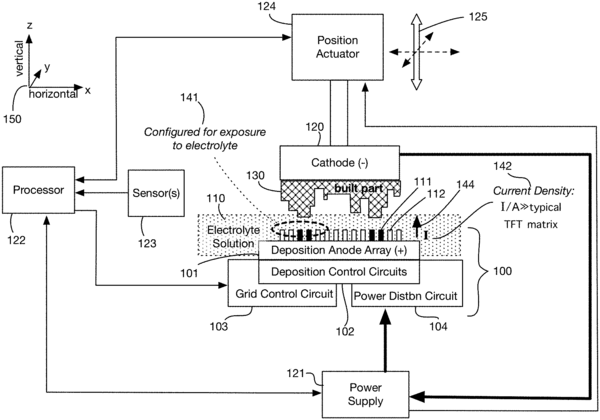

Another patent related to On demand Spare part manufacturing is patent US20210102286A1.

Patent US20210102286A1 for “3D Metal Printhead Assembly Method of Manufacture” filed by Fabric8Labs Inc. outlines methods for constructing a 3D metal printhead using metal electrodeposition. The CPC classification for the patent includes C23C 16/04 (Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e., chemical vapor deposition [CVD] processes).

The patent methodology describes a method of layer depositing on top of a backplane containing control and power circuits. These layers include insulating layers made of materials such as silicon nitride or silicon dioxide, and an anode layer containing deposition anodes in contact with the electrolyte to drive electrodeposition. The anode layer may consist of insoluble conductive materials like platinum group metals, their oxides, highly doped semiconducting materials, and carbon-based conductors. Deposition of the anode layer can be achieved through chemical vapor deposition or physical vapor deposition. In some embodiments, the printhead is constructed by manufacturing a separate anode plane component and bonding it to the backplane1.

This patent is significant for 3D metal printing because it provides a detailed method for assembling a printhead capable of precise metal deposition. The approach allows for the creation of complex metal parts with high precision and efficiency. Our 3D Metal Printing strategy will need to incorporate advancements in electrodeposition and material science to optimize the manufacturing process and improve the quality of printed metal components.

Publications: 3D Point Cloud Processing

Post-processing of the point cloud generated by 3D scanning tools is a fundamental step in generating suitable meshes for manufacturing. The quality of the processing method can have a significant effect on the speed of the post-processing as well as the quality of the finished part. Algorithms reduce noise in the measurements, eliminate outliers, and segment the point cloud into discrete surfaces and features. These steps are necessary to create an automated pipeline with as little human intervention in the modeling process as possible. We have identified several papers summarizing 3D point cloud processing and segmentation methods. “A review of algorithms for filtering the 3D point cloud” (X. Han, et al. 2017) presents a comparison of different filtering methods. “3D point cloud segmentation: A survey” (A. Nguyen & B. Le, 2013) presents a number of different segmentation methods. Understanding the current state of the art in point cloud filtering and segmentation is necessary to assess the capabilities and limits of our technology

Additional References

- A review of algorithms for filtering the 3d point cloud https://www.sciencedirect.com/science/article/pii/S0923596517300930?casa_token=w78irtDoi-EAAAAA:f_S9h0eUaNfKJpXv8GIcwTe9dTxQayYo9uxAnYgKNLePbSnkrdksc4WN8k1-bfzSyWrD5rA

- A new segmentation method for point cloud data https://www.sciencedirect.com/science/article/pii/S0890695501001201?casa_token=O_F0EzE0AywAAAAA:QIKuDupgIEQlEquf4-p__NJgHAf2ZqjJjddvhu8_ZOJWbewLw-VUVjQ1wt7RMvj4b0CVWcQ

- 3D Point cloud segmentation: A survey https://ieeexplore.ieee.org/abstract/document/6758588?casa_token=C7xAiqIlHn8AAAAA:UpaWGnRKcf4IcEqO514RPtGDw6GZm_8DCXSZ6yLBywJ__-w201WCMvRDKMShirfZ8hRArQ

- G06Q10/06 Resources, workflows, human or project management; Enterprise or organisation planning; Enterprise or organisation modelling

- G06Q10/08 Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

- G06Q10/087 Inventory or stock management, e.g. order filling, procurement or balancing against orders

- 02P90/80 Management or planning

List of R&D Projects for Digital Warehouse and Additive Manufacturing System

This section outlines significant research and development (R&D) initiatives aimed at advancing digital warehousing and additive manufacturing systems. These projects focus on the integration of advanced scanning technologies, point cloud generation, 3D imaging, and additive manufacturing processes.

Defense Logistics Agency (DLA) Research and Development

The Defense Logistics Agency (DLA) has spearheaded several projects to enhance supply chain and manufacturing technologies:

- Joint Additive Manufacturing Acceptability (JAMA): This project establishes standards and protocols for the acceptance of additive manufacturing parts within defense supply chains, ensuring quality and reliability. Recent milestone: Successfully developed and implemented a comprehensive set of standards for additive manufacturing parts.

- Digital Thread: This initiative develops a seamless data flow across product lifecycles, from design to maintenance, enhancing traceability and efficiency. Recent milestone: Achieved full integration of digital thread technology in several pilot programs, significantly improving data traceability.

- Battery Network (BATTNET): Focused on improving the production, logistics, and performance of defense batteries using advanced manufacturing techniques. Recent milestone: Enhanced battery performance and lifecycle through advanced additive manufacturing processes.

European Additive Manufacturing Projects

Key European initiatives include:

- AMable: This project supports SMEs in adopting additive manufacturing by providing access to expertise, facilities, and funding, thereby accelerating innovation and market readiness. Recent milestone: Successfully supported over 100 SMEs in adopting additive manufacturing technologies.

- ManuCloud: Aiming to create a cloud-based platform, this project integrates various manufacturing processes, including additive manufacturing, to enhance flexibility and scalability. Recent milestone: Launched a fully operational cloud-based manufacturing platform.

- DIMAP: This project develops new materials and processes for multi-material additive manufacturing, focusing on the production of complex, high-performance parts. Recent milestone: Developed and tested new multi-materials for high-performance applications.

National Institute of Standards and Technology (NIST)

NIST's projects focus on measurement and standardization:

- Measurement Science for Additive Manufacturing: This project develops advanced measurement techniques and standards to ensure the quality and reliability of additive manufacturing processes. Recent milestone: Published new standards for measurement techniques in additive manufacturing.

- Smart Manufacturing Systems (SMS) Test Bed: Provides a platform for testing and validating new manufacturing technologies, including additive manufacturing and digital warehousing solutions. Recent milestone: Successfully validated several new manufacturing technologies in a real-world test bed environment.

Stratonics Additive Manufacturing Projects

Stratonics is involved in several advanced R&D projects:

- ThermaViz® Sensor Systems: Integrates thermal imaging for real-time process monitoring and control, enhancing the precision and quality of additive manufacturing. Recent milestone: Deployed ThermaViz® systems in multiple industrial settings, improving process control.

- Digital Threading of AM: Led by Boeing, this project integrates in-situ process monitoring with digital threading to improve additive manufacturing processes, reducing costs and cycle times. Recent milestone: Achieved significant cost and time reductions in pilot projects.

- Additive Manufacturing of Heat Exchangers for Propulsion Applications: Focuses on advancing laser powder bed fusion for aerospace components, addressing fundamental risks and improving reliability. Recent milestone: Successfully produced and tested high-performance heat exchangers for aerospace applications.

ASTM International Additive Manufacturing Projects

ASTM International supports several projects through its Additive Manufacturing Center of Excellence (AM CoE):

- Standardized Practice for Measuring AM Part Density: Developed by Auburn University, this project focuses on creating standardized methods for measuring the density of additive manufacturing parts. Recent milestone: Published a standardized practice for measuring part density.

- Classification and Measurement Methodologies for Powder Cleanliness: Led by the Manufacturing Technology Centre (MTC), this project develops methodologies for assessing the cleanliness of powders used in additive manufacturing. Recent milestone: Established new classification and measurement methodologies for powder cleanliness.

- Test Method for Interlayer Shear Properties: Developed by Wichita State University in collaboration with the National Research Council of Canada, this project aims to establish test methods for evaluating the interlayer shear properties of additively manufactured parts. Recent milestone: Released a new test method for evaluating interlayer shear properties.

These projects represent cutting-edge advancements in the integration of digital warehousing and additive manufacturing, contributing to the development of more efficient and innovative manufacturing systems.

References: 1. DLA Research and Development 2. DLA ManTech 3. AM-platform.eu - Projects list 4. NIST Additive Manufacturing 5. Stratonics Additive Manufacturing 6. ASTM International Additive Manufacturing Projects

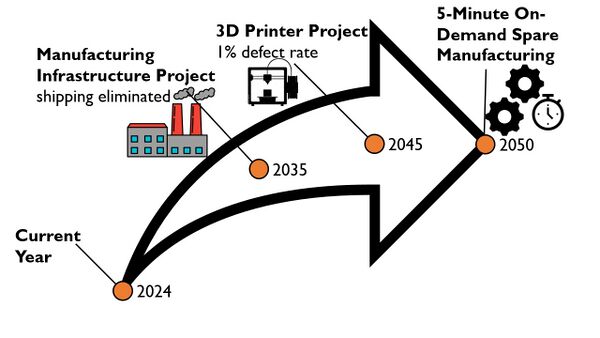

Technology Strategy Statement

Our target is to develop a new form of on-demand spare manufacturing where the time between the need for the spare part is identified and the spare part is installed is nearly instantaneous with an entry-into-service date of 2050. To achieve the target of a 5 minute turnaround time and a 1% defect rate, we will invest in two R&D projects. The first project will be a supply chain item delivery infrastructure that optimizes manufacturing infrastructure to eliminate the need to ship spare parts after manufacturing with a first implementation by 2035. The second project is a 3D printer with a laser variance of 0.001 mm to enable a lower defect rate by 2045. These two projects will allow us to reach out technical and business targets by 2050.