Autonomy in the Corn Production System

Page Under Development

Technology Roadmap Sections and Deliverables

- 2ACP - Autonomy in the Corn Production System

This indicates that we are dealing with a “level 2” roadmap at the product level (see Fig. 8-5), where “level 1” would indicate a market level roadmap and “level 3” or “level 4” would indicate an individual technology roadmap.

Precision agriculture combines technology with agronomy to deliver new outcomes and capabilities to growers. For example, yield maps, introduced in the 1990s enabled farmers to view a spatial representation of the yield variability within their fields. The perspective generated by this data coined a new term called site-specific management, which effectively means managing zones of the field differently to improve overall profitability. This is just one example of many where data has transformed the process of farming. Autonomy presents a further opportunity to influence decision making and field operations at the production system level. While today’s farms are heavily dominated by productivity goals, the value autonomy presents is to increase output by managing plant level outcomes while also reducing inputs in the form of labor, crop inputs, and capital.

Roadmap Overview

The working principle and architecture of solar-electric aircraft is depicted in the below.

Solar-electric aircraft are built from light-weight materials such as wood or carbon-fiber reinforced polymers (CFRP) and harvest solar energy through the photoelectric effect by bonding thin film solar cells to the surface of the main wings, and potentially the fuselage and empennage as well. The electrical energy harvested during the day is then stored in on-board chemical batteries (e.g. Lithium-Ion, Lithium-Sulfur etc…) and used for propelling the aircraft at all times, including at night. For the system to work there needs to be an overproduction of energy during the day, so that the aircraft can use the stored energy to stay aloft at night. The flight altitude of about 60,000-70,000 feet is critical to stay above the clouds and not to interfere with commercial air traffic. Depending on the length of day, i.e. the diurnal cycle which determines the number of sunshine hours per day, which itself depends on the latitude and time-of-year (seasonality) the problem is easier or harder. The reference case in the technology roadmap is an equatorial mission (latitude = zero) with 12 hours of day and 12 hours of night.

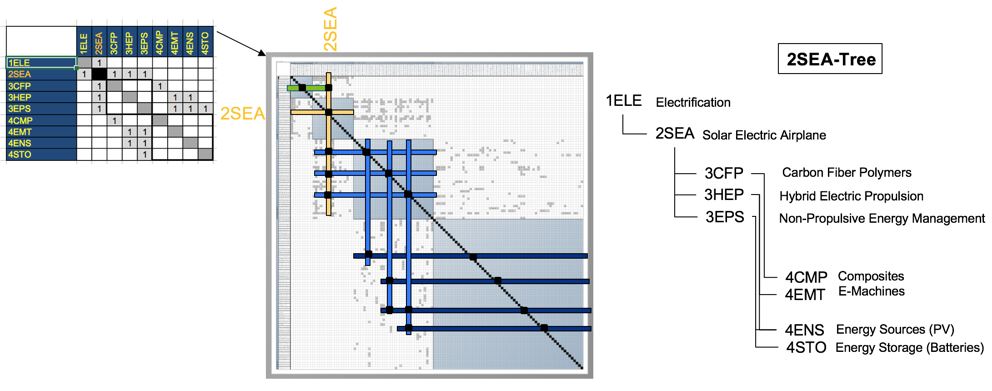

Design Structure Matrix (DSM) Allocation

The 2-SEA tree that we can extract from the DSM above shows us that the Solar-Electric Aircraft (2SEA) is part of a larger company-wide initiative on electrification of flight (1ELE), and that it requires the following key enabling technologies at the subsystem level: 3CFP Carbon Fiber Polymers, 3HEP Hybrid Electric Propulsion and 3EPS Non-Propulsive Energy Management (e.g. this includes the management of the charge-discharge cycle of the batteries during the day-night cycle). In turn these require enabling technologies at level 4, the technology component level: 4CMP components made from CFRP (spars, wing box, fairings …), 4EMT electric machines (motors and generators), 4ENS energy sources (such as thin film photovoltaics bonded to flight surfaces) and 4STO (energy storage in the form of lithium-type batteries).

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2SEA roadmap in the figure below. This diagram captures the main object of the roadmap (Solar-Electric Aircraft), its various instances including main competitors, its decomposition into subsystems (wing, battery, e-motor …), its characterization by Figures of Merit (FOMs) as well as the main processes (Flying, Recharging).

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given below. It reflects the same content as the previous figure, but in a formal natural language.