Autonomous Mobile Robots for Enhancing Warehouse Logistics

Roadmap Overview

Warehousing logistics are complex. They involve security, inventory management, storage optimization, climate control, and people management. In this roadmap, we will attempt to address and characterize a technology aimed at reducing complexity in three key areas – storage optimization, product movement, and people management.

There are several different types of robots that are currently in use or being developed for warehouses today. Each type of robot has a specific function or a few specific functions within warehouse. Table 1 provides an overview of the primary robots in use today.

| Type | Use Case | High Level Technologies | Additional Information |

|---|---|---|---|

| Robotic Arms | * Example * test |

Example | |

| Packaging Robots | Example | Example | |

| Verification Robots | a | b | |

| Autonomous Mobile Robots | Example | Example |

Robotic arms

Use case: loading/unloading <- can we change this to just loading?

High level technologies: End-of-arm tools, vacuum grippers, joint actuators

Additional info: generally stationary

Packaging robots

Use case: Packing boxes and sealing boxes

High level technologies: Boxing, labeling

Additional info:

Verification robots

Use case: Scanning products or packages

High level technologies: 3D scanners, barcode/QR scanners

Additional info:

Autonomous Mobile Robots

Use case: lift and transport goods to humans, optimize storage patterns

High level technologies: ML/AI, Digital Twins, Batteries, LiDAR

Additional info: Mobile, don’t require human assistance or intervention

Autonomous robots will be the primary focus for our roadmap.

Mobile robot – specialized software-controlled machine which utilizes sensors and other technologies to recognize its environement and follow its predefined task – R Roj and A Kos

1940s-50s – William Grey Walter developed first AMRs – Elmer and Elsie for use in neurophysiology research – The Evolution of Autonomous Mobile Robots - Technical Articles (control.com)

Light and touch sensors

Later iterations included sound sensors and could move around

Didn’t become commercially available until the 1990s – HelpMate – move things around a hospital

Sonar, infrared, and vision systems

In the 2000s and 2010s, companies like Kiva Systems and inVia started developing more sophisticated robots that could utilize technologies like LiDAR and machine learning to autonomously navigate around warehouses assisting in lifting and carrying products around the warehouse while avoiding obstacles.

Pre-1950s fixed rail systems, drivers

1950s – 1st AGV – automated guided vehicles – progressed from magnetic field inducing wires, magnetic tape, optical strips, laser guidance – move materials along a specified path, reliable but not easily adaptable

AMRs allow you to navigate dynamic environments, reduce travel time and distance for humans, cut down on order fulfillment time and improve picking rate.

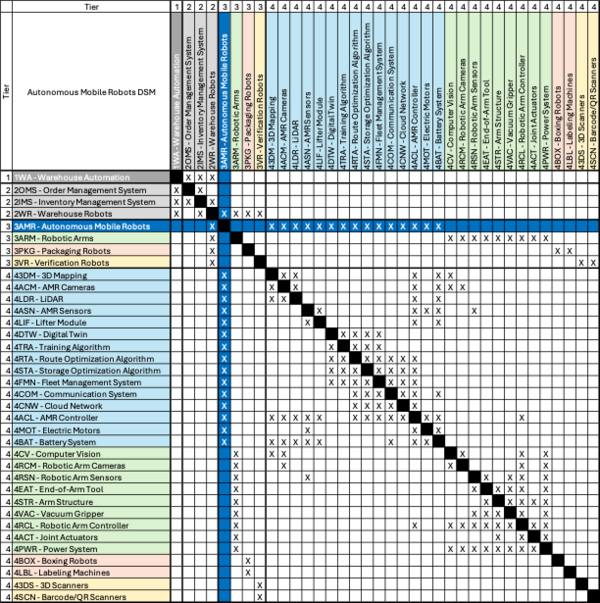

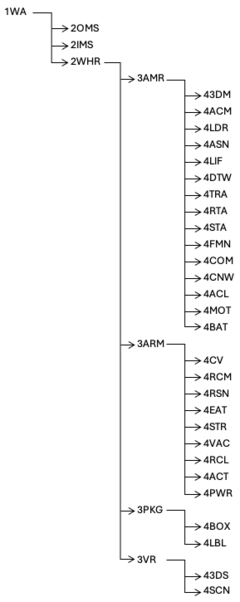

Design Structure Matrix (DSM) Allocation

We present here the DSM allocation of autonomous mobile robots and its tree. The company-wide initiative of warehouse automation is supported by the order management system, the inventory management system, and warehouse robots. Warehouse robots can be classified into autonomous mobile robots, robotic arms, packaging robots, and verification robots. We focus on the autonomous mobile robot for this roadmap, which is enabled by level 4 technologies in light blue, such as 3D mapping, digital twins, and route optimation algorithms. The DSM shows coupling between technologies; for example, the development of the lifter module is dependent on the performance of sensors, the controller, and the battery system.

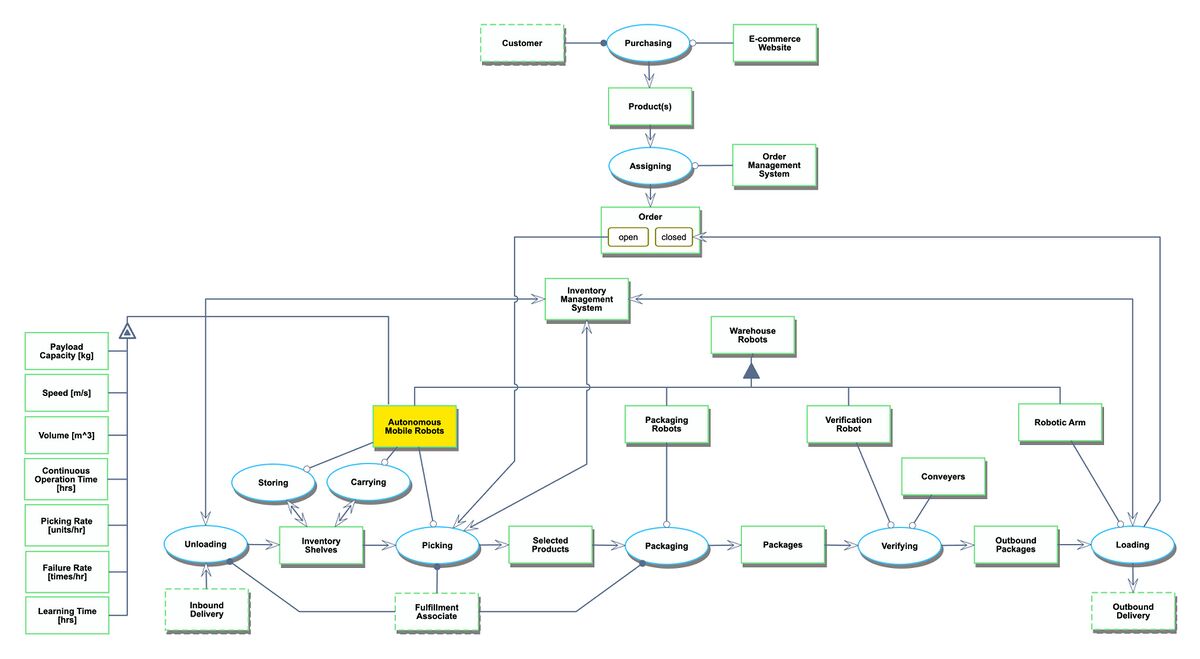

Roadmap Model using OPM

The OPM for warehouse automation and the role of autonomous mobile robots is shown below. In preparation for warehouse operations, inbound delivery to the warehouse is unloaded and stored in inventory shelves that are carried by AMRs. When a customer purchases a product on the e-commerce website, the order management system assigns an order to the warehouse, which initiates the picking and packaging processes: AMRs carry themselves to the fulfillment associate who picks the purchased products, packaging robots assist the fulfillment associate in packaging, packages are transported on conveyor belts as they are verified (scanned) by verification robots, and finally the outbound packages are loaded onto trucks by robotic arms and shipped out as outbound delivery. Throughout the process, the inventory management system tracks the inventory in the warehouse at the unloading, picking, and loading stages.

Figures of Merit (FOM)

Below are key FOMs for autonomous mobile robots. Payload capacity, speed, and picking rate are FOMs that contribute to the efficiency of warehouse automation. Continuous operation time and failure rate determine the robustness of AMRs. Volume of AMR can also be a competitive metric as AMRs operate in warehouses that are limited in space. Learning time indicates the time it takes to train the AMR in a digital twin before deploying them into the physical warehouse.

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Payload Capacity | [kg] | Total weight the AMR can carry (including items and shelves) |

| Speed | [m/s] | Average speed of the AMR while carrying shelves inside the warehouse |

| Volume | [m^3] | Volume of AMR (width x length x height) |

| Continuous Operation Time | [hrs] | Total time the AMR can operate in one full charge |

| Picking Rate | [units / hr] | Number of units the AMR can assist the fulfillment associate to pick per hour |

| Failure Rate | [times/ hr] | Number of times the AMR fails per hour |

| Learning Time | [hrs] | Total time it takes to train the AMR to operate in a warehouse |

The trends of FOMs are provided as follows.