Autonomous Mobile Robots for Enhancing Warehouse Logistics

Roadmap Overview

Warehouses have a lot of moving pieces, both physically and metaphorically. They involve security, inventory management, storage optimization, climate control, and people management. A lot of technology has been developed over the last several decades to optimize logistics and advance the operations within a warehouse. One of the largest challenges warehouses face is how to lift and transport heavy materials. Before the 1950s, this was primarily done through the use of carts on fixed rail systems or vehicles operated by humans. While these solutions helped to solve the transport problem, they introduced new issues around maintenance and fixed infrastructure as well as safety and training for employees and operators. In the 1950s, automated guided vehicles (AGVs) were introduced to warehouses. These vehicles were able to transport materials without the need for an operator, but still required the installation of a mechanism to guide the vehicles along a specified path. Initially, the guide was a set of wires that induced a magnetic field that would propel a cart along its path. This quickly evolved to utilize magnetic tape, optical strips, and eventually laser guidance. These systems are still in use today and provide a reliable mechanism to transport goods around a warehouse; however, they don't have the adaptability and intelligence needed for modern warehouse operations.

While AGVs were evolving, so was the field of robotics, specifically autonomous mobile robots (AMRs). AMRs are a class of robots that have the ability to sense their surroundings and intelligently navigate a dynamic environment to accomplish a task. The first set of AMRs were developed by William Grey Walter in the 1940s and 1950s. He developed two robots named Elmer and Elsie for use in neurophysiology research. These robots were equipped with light and touch sensors, and eventually included the ability to sense sound and move around. Between the 1950s and 1990s, AMRs continued to evolve, but were primarily used in research and academia. The HelpMate was the first AMR that was commercially available. This robot was released in the 1990s and featured Sonar, infrared, and vision systems. The HelpMate was used to transport materials around medical facilities. Now, companies like Amazon Robotics (formerly Kiva Systems) and inVia are developing advanced robotics to facilitate dynamic operations within a warehouse while reducing safety incidents and increasing productivity.

In this roadmap, we will attempt to address and characterize a technology aimed at reducing warehouse complexity in three key areas – storage optimization, product movement, and people management.

There are several different types of robots that are currently in use or being developed for warehouses today. Each type of robot has a specific function or a few specific functions within a warehouse. Table 1 provides an overview of the primary robots in use today.

| Type | Use Case | High Level Technologies |

|---|---|---|

| Robotic Arms | Loading or picking up boxes | * End-of-arm tools * Vacuum grippers * Joint actuators * Computer vision * Cameras * Sensors * Controller * Power systems |

| Packaging Robots | Packing and sealing boxes | * Boxing robotics * Labeling mechanics |

| Verification Robots | Scanning products and/or packages | * 3D scanners * Barcode/QR scanners |

| Autonomous Mobile Robots | * Lift and transport goods to humans * Optimize storage patterns |

* LiDAR * Sensors *Digital Twins * Machine Learning * Optimization algorithms * Communications systems * Motor * Battery systems |

Autonomous mobile robots and their use within warehouse systems will be the primary focus for our roadmap. These devices combine several advanced technologies to transport goods without the assistance of humans or guides. They help to reduce safety incidents, increase picking rates, and increase fulfillment rates within warehouses. Throughout the rest of this roadmap, we will do a comprehensive review of AMRs and their enabling technologies.

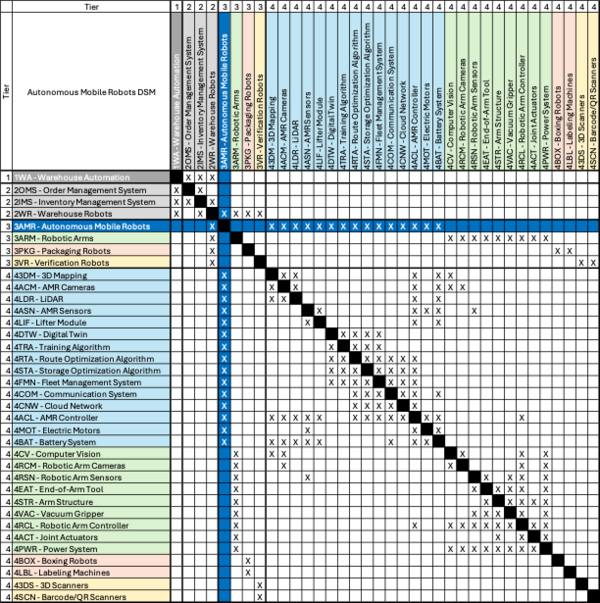

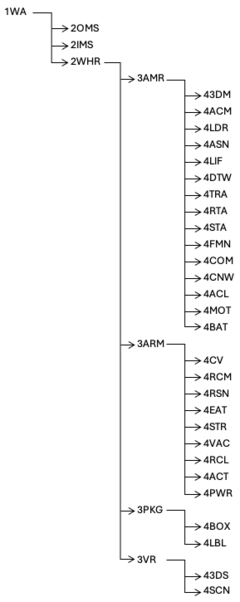

Design Structure Matrix (DSM) Allocation

We present here the DSM allocation of autonomous mobile robots and its tree. The company-wide initiative of warehouse automation is supported by the order management system, the inventory management system, and warehouse robots. Warehouse robots can be classified into autonomous mobile robots, robotic arms, packaging robots, and verification robots. We focus on the autonomous mobile robot for this roadmap, which is enabled by level 4 technologies in light blue, such as 3D mapping, digital twins, and route optimation algorithms. The DSM shows coupling between technologies; for example, the development of the lifter module is dependent on the performance of sensors, the controller, and the battery system.

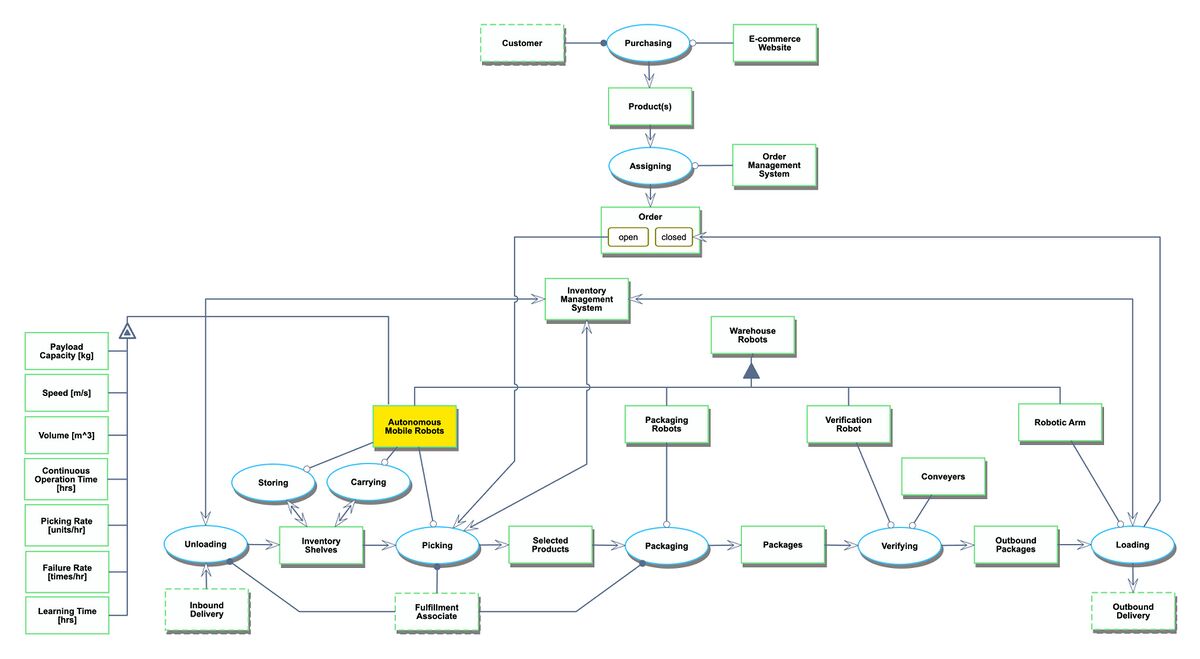

Roadmap Model using OPM

The OPM for warehouse automation and the role of autonomous mobile robots is shown below. In preparation for warehouse operations, inbound delivery to the warehouse is unloaded and stored in inventory shelves that are carried by AMRs. When a customer purchases a product on the e-commerce website, the order management system assigns an order to the warehouse, which initiates the picking and packaging processes: AMRs carry themselves to the fulfillment associate who picks the purchased products, packaging robots assist the fulfillment associate in packaging, packages are transported on conveyor belts as they are verified (scanned) by verification robots, and finally the outbound packages are loaded onto trucks by robotic arms and shipped out as outbound delivery. Throughout the process, the inventory management system tracks the inventory in the warehouse at the unloading, picking, and loading stages.

Figures of Merit (FOM)

Below are key FOMs for autonomous mobile robots. Payload capacity, speed, and picking rate are FOMs that contribute to the efficiency of warehouse automation. Continuous operation time and failure rate determine the robustness of AMRs. Volume of AMR can also be a competitive metric as AMRs operate in warehouses that are limited in space. Learning time indicates the time it takes to train the AMR in a digital twin before deploying them into the physical warehouse.

| Figure of Merit (FOM) | Unit | Description |

|---|---|---|

| Payload Capacity | [kg] | Total weight the AMR can carry (including items and shelves) |

| Speed | [m/s] | Average speed of the AMR while carrying shelves inside the warehouse |

| Volume | [m^3] | Volume of AMR (width x length x height) |

| Continuous Operation Time | [hrs] | Total time the AMR can operate in one full charge |

| Picking Rate | [units / hr] | Number of units the AMR can assist the fulfillment associate to pick per hour |

| Failure Rate | [times/ hr] | Number of times the AMR fails per hour |

| Learning Time | [hrs] | Total time it takes to train the AMR to operate in a warehouse |

The trends of FOMs are provided as follows.

References

<references/>