On Demand Spare Manufacturing

Overview

On Demand Spare Manufacturing is the manufacturing of spare parts as-needed as opposed to a traditional stockpiling approach. It leverages digital manufacturing technologies such as additive manufacturing, 3D scanning, optimization algorithms, and supply chain logistics. On Demand Spare Manufacturing requires identifying the need for a spare, transporting materials for manufacturing, scanning, processing, mesh generating, manufacturing the spare part, finishing, inspecting, transporting the spare part to the system, and installing the replacement part.

Design Structure Matrix

Roadmap Model using Object-Process-Methodology (OPM)

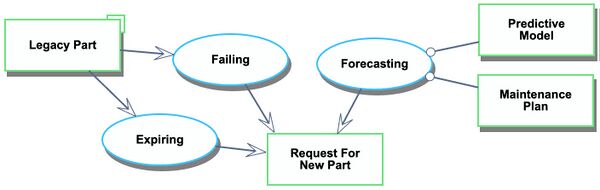

The graphic below depicts the different processes by which a need for a spare part is identified. Depending on different factors, such as the industry and risk tolerance, the need for a spare may arise differently. For example, a spare may be needed to replace a component during routinely scheduled maintenance as opposed to a spare that is required because a component failed. In the first case, the need for the spare can be anticipated ahead of time; in the second case, the need arises unexpectedly.

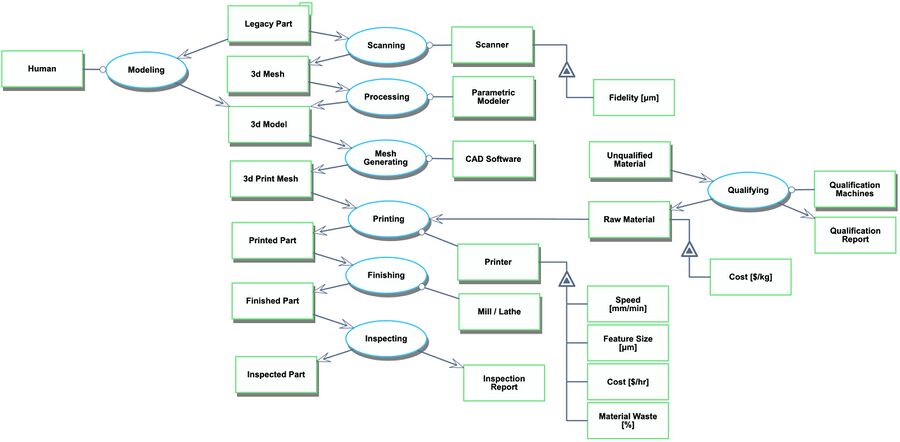

The graphic below depicts the primary objects and processes associated with On Demand Spare Manufacturing. In this model, humans are only identified when they are active participants in the process. Humans are not identified as actors if they are passive participants, such as an operator running a machine.

Figures of Merit

| FOM | Description | Unit | Trend |

|---|---|---|---|

| Turn-Around-Time | Time from need identified to need met | hr | decreasing |

| Cost | Total replacement part cost | $ | decreasing |

| Feature Size | The smallest detail that can be reproduced | μm | constant |

| Lifespan | Replacement part lifespan | year | constant |

| Material Cost | Raw material cost | $/kg | constant |

| Production Cost | Aggregate cost of labor, machine time, etc... | $/hr | decreasing |

| Material Waste | Excess material utilized in the production process | % | decreasing |

| Defect Rate | The fraction of parts produced that are not suitable for use | % | constant |