Geothermal Power Plant

Technology Roadmap

Roadmap Overview

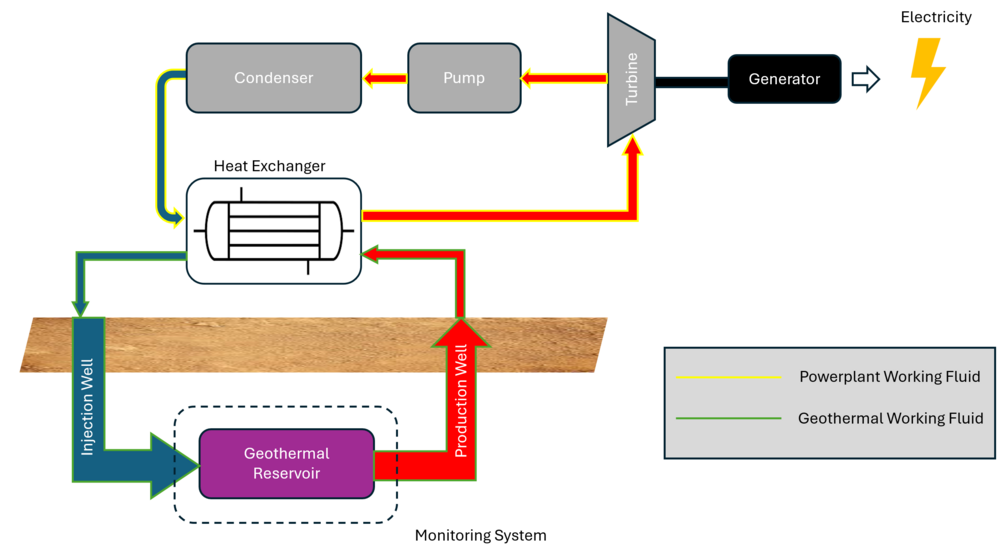

Technology Description: Geothermal power plants generate electricity by harnessing geothermal energy through a series of steps. First, geothermal fluid is heated by accessing the geothermal reservoir, either by injecting it directly into the reservoir (Enhanced Geothermal System) or using pipes that pass through the reservoir (Closed Loop). The heated fluid is then brought to the surface and passed through a heat exchanger, transferring its heat to a working fluid. This working fluid, now heated, drives a turbine, which powers a generator to produce electricity. Afterward, the working fluid is cooled and condensed back into a liquid form before being recirculated through the heat exchanger to repeat the process.

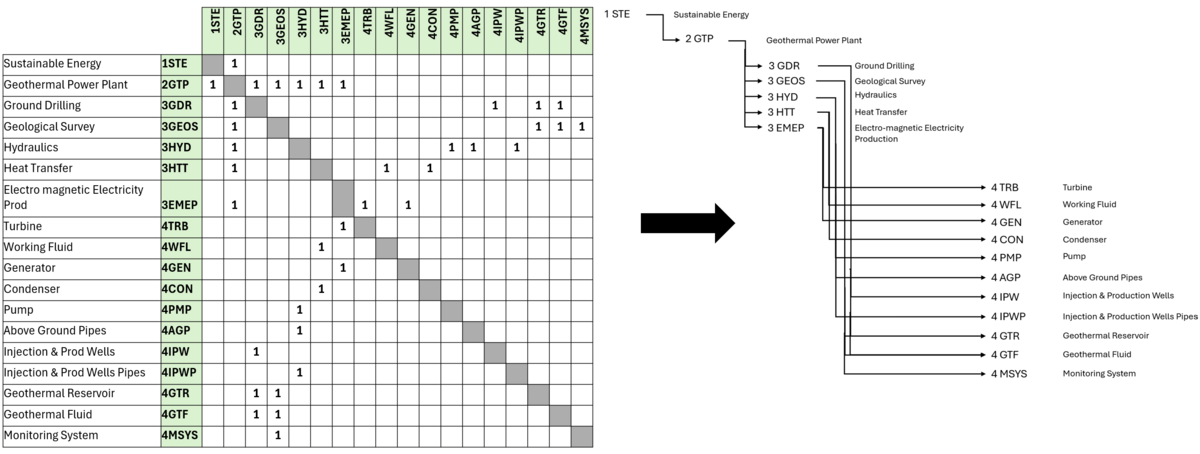

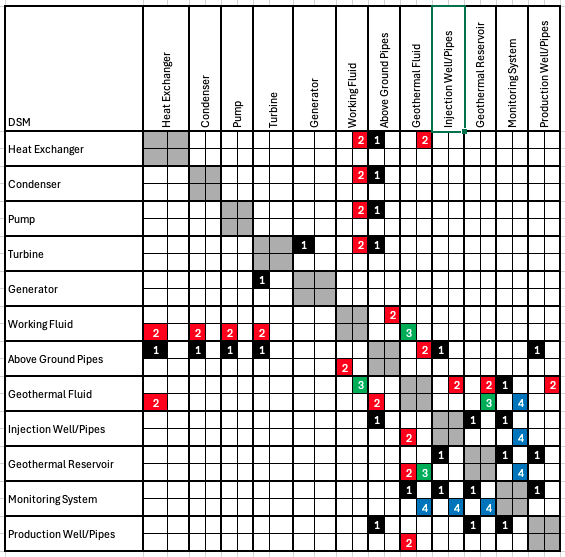

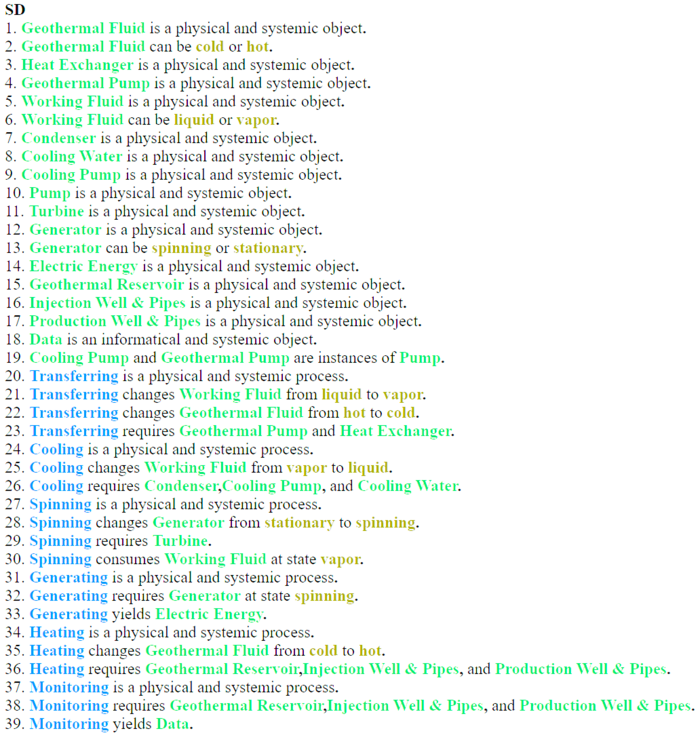

Design Structure Matrix (DSM) Allocation

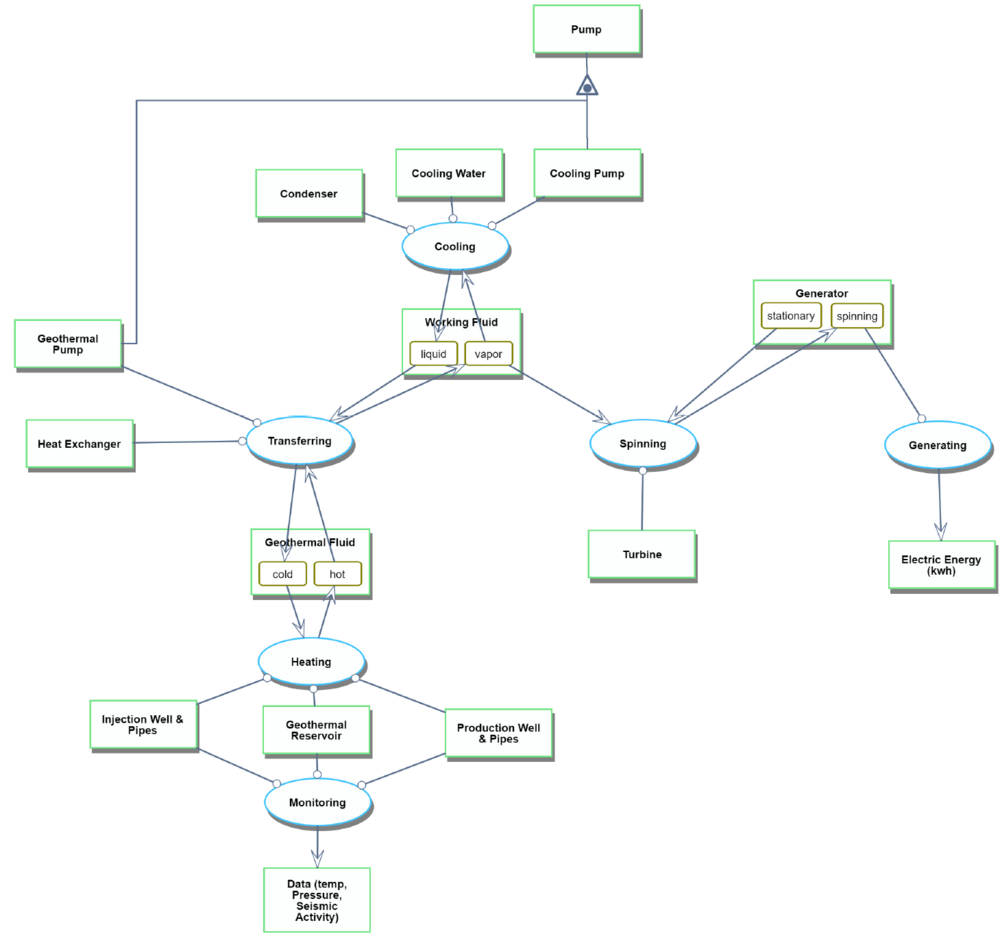

Roadmap Model using OPM

Figures of Merit

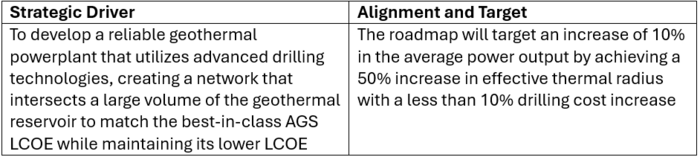

Alignment with Company Strategic Drivers

As a new company in the geothermal power production market, the effective thermal radius is the most sensitive design parameter that would allow us to make significant gains in the energy extracted. To increase this thermal radius, significant R&D will have to be invested in drilling technologies to enable the drilling of several web-like, closed-loop structures at the geothermal reservoir in order to maximize the heat extracted. Advancements in these drilling technologies will allow us to keep the cost low and maintain the current industry LCOE for AGS systems.

Alignment with company strategic drivers

Positioning of Company vs. Competition

File:Geothermal Competition Table.png

Technical Model

Financial Model

List of R&T Projects and Prototypes

Key Publications and Patents

Key publications and patents pertaining to geothermal power plants incorporate various technologies and functional areas. This analysis's key publications and patents correlate to three functional areas related to geothermal power plants. These areas include drilling, subsurface resource extraction systems, and surface generation systems.

Publications

Sandia GeoVision Analysis Report - T. S. Lowry et al., “GeoVision Analysis Supporting Task Force Report: Reservoir Maintenance and Development”

The Sandia GeoVision Analysis report is widely cited as a reference for drilling considerations on all geothermal well development. This report provides a baseline for drilling costs given different borehole diameters and drilling directions. The drilling analysis includes bit design, environmental considerations, non-drilling activities, reservoir stimulation mechanisms and their associated costs, and hydraulic performance. These considerations are oriented on performance and cost, producing well cost curve scenarios for many drilling situations. This provides a significant resource in planning geothermal borehole development without requiring experience in the specific characteristics of the location or development. This report also includes maintenance and management practices to ensure enthalpy production remains within planned bounds. The combination of drilling costs tied to capital expenditure and maintenance and management costs provides a strong resource for estimating the overall costs needed for a levelized cost of electricity assessment.

Numerical Investigation of Closed-loop Geothermal Systems in Deep Geothermal Reservoirs - M. White et al., “Numerical investigation of closed-loop geothermal systems in deep geothermal reservoirs,” Geothermics, vol. 116, p. 102852, Jan. 2024, doi: 10.1016/j.geothermics.2023.102852.

The numerical model presented by White et al., in conjunction with multiple national labs and universities, collects data and processes from many sources and integrates them into a working web-based application. This application, called GeoCluster, provides an estimate for geothermal production and economic viability considering seven input parameters. These parameters are mass flow rate, horizontal extent, vertical drilling depth, rock geothermal gradient, borehole diameter, injection temperature, and rock thermal conductivity. To construct this model, the team integrated multiple computational models developed independently by each laboratory. These models focused on the heat recovery mechanisms of a closed-loop system in deep geothermal reservoirs. The models were integrated to incorporate advantages found in each and then validated using data from the active Utah FORGE geothermal testing site. This subsurface model becomes the Sandia HDR (hot-dry-rock) model. This model was combined with the surface generation model provided by NREL to produce the full GeoCLUSTER application. Overall, this application provides a significant asset to entities entering the geothermal power market by providing accurate cost and benefit estimates for implementing a closed-loop geothermal system considering a range of system and geological constraints.

Patents

Millimeter-Wave Drilling System:

The Millimeter-Wave Drilling System patent (US Patent # 8,393,410 B2) is classified as E21B 7/14 in the Cooperative Patent Classification (CPC) system. In this system, E21B refers to technology related to Earth of Rock Drilling; Obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells and 7/14 add the modifier Drilling by use of heat; e.g. flame drilling (CPC: E21B 7/14). We identified this system during our disruptive technology analysis. The classification of this system as using “flame drilling” instead of high energy waves likely identifies the novelty of the technology in the E21B “Earth and Rock Drilling” field. The Millimeter-Wave Drilling System identified in this patent uses millimeter waves generated by a gyrotron and funneled into a borehole by a proprietary waveguide to radically heat the rock at the leading edge of the hole. This rock can be heated to temperatures sufficient to vaporize the rock. This vapor is then exfiltrated out of the borehole using a purge gas system to allow for continuous advancement. If brought into commercial operation, this technology claims to radically decrease the cost of well boring at extreme depths. This would significantly change the cost considerations when considering implementing a geothermal power system.

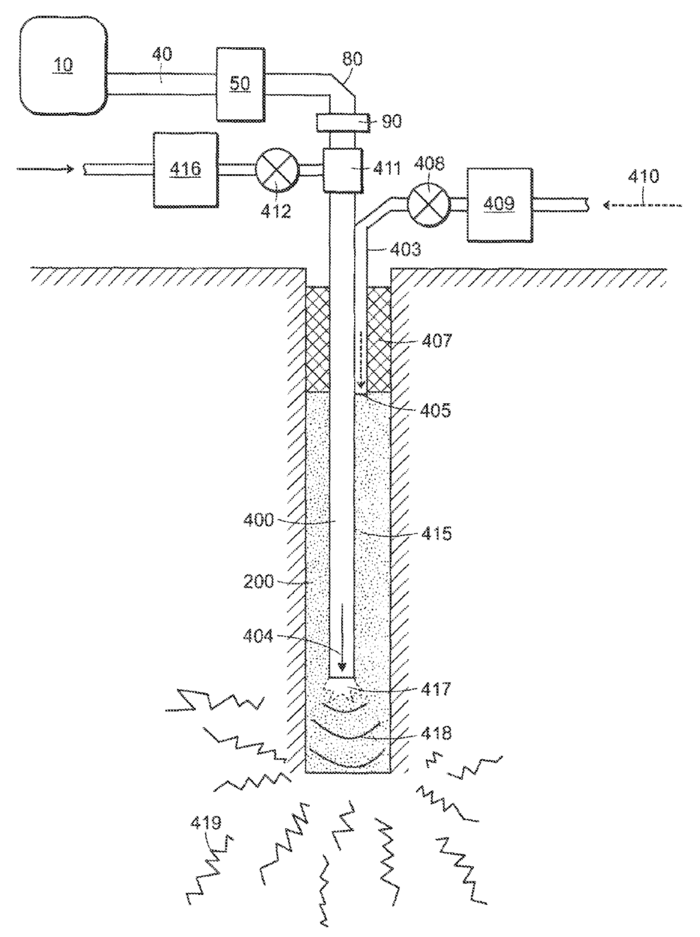

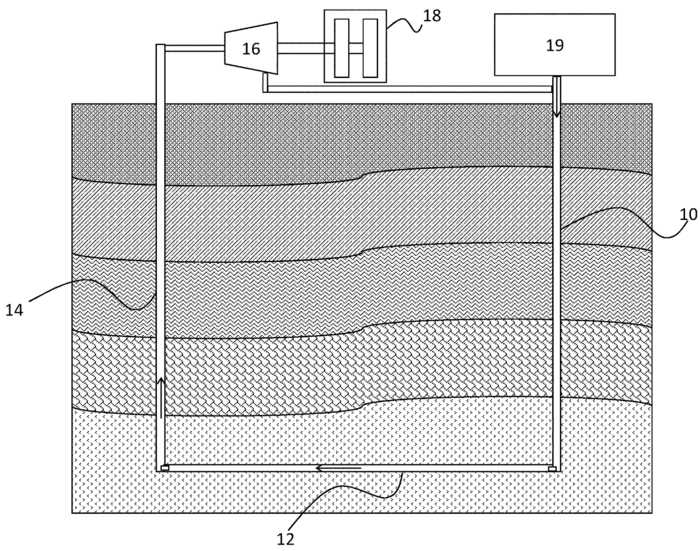

Geothermal Loop Energy Production System:

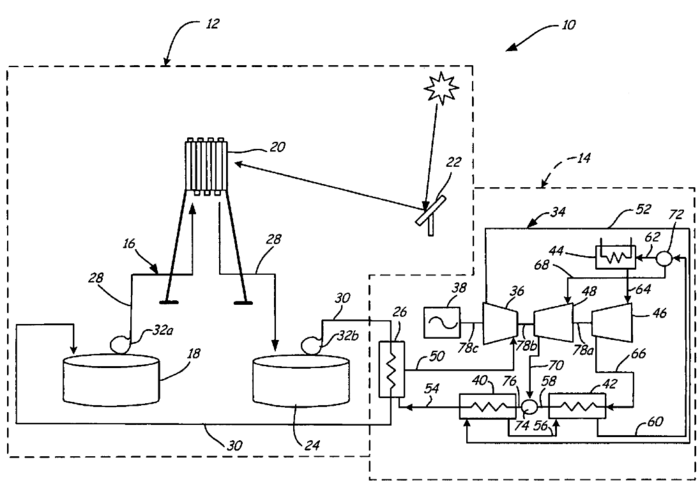

The Geothermal Loop Energy Production System (US Patent # 11,674,504 B2) has two classifications in the CPC system. They are F03G 7/04 and E21B 47/07. F03G 7/04 includes technology Spring, weight, inertia, or like motors; mechanical-power producing devices or mechanisms, not otherwise provided for or using pressure differences of thermal difference occurring in nature (CPC: F03G 7/04). E21B 47/07 includes a similar classification from the drilling technology but differs in purpose. This classification includes Earth or rock drilling, obtaining oil, gas, water, soluble or meltable materials, or a slurry of minerals from wells, and measuring the temperature of boreholes or wells (CPC: E21B 47/07). This technology utilizes the model principles in White et al. to generate electricity using supercritical CO2 (sCO2) in a closed-loop geothermal system. This design connects two vertical boreholes with a horizontal borehole running through a geothermal resource. The heated sCO2 is pumped through this subsurface system to a turbine to generate electricity. Once through the turbine, the sCO2 is compressed and sent back into the subsurface system to extract more heat. This closed-loop system can be implemented in a dry resource and does not require an existing or manufactured reservoir to operate. This increases the locational viability of the system to include more regions without easy access to subsurface permeable areas for heat.

Supercritical CO2 Turbine For Use In Solar Power Plants:

A significant patent related to this area is for a Supercritical CO2 Turbine for use in Solar Power Plants (US Patent # 7,685,820 B2). This system is classified as F03G 6/00 in the CPC. This classification includes Spring, weight, inertia, or like motors; mechanical-power-producing devices or mechanisms not otherwise provided for devices for producing mechanical power from solar energy (CPC: F03G 6/00). This patent may seem out of place when referring to geothermal power production, but the actual design only includes solar power plants to generate the initial heat required to run the turbine. The patent identifies that any process capable of providing heat to a heat exchanger could be an entity utilized in this design. The key piece of this design is the process of heating, compressing, and storing sCO2 as a working fluid to operate a turbine efficiently. This particular sCO2 turbine design is influential because it can utilize the working material with any significant heat resource and takes additional steps to capture unused heat energy to improve generation efficiency. This includes using three separate temperature recuperators to manage the sCO2 energy levels throughout the system. This allows the system to operate on a Brayton cycle, improving system efficiency over the Rankine cycle conversion system. This design also incorporates a heat storage system on the non-sCO2 side of the heat exchanger. This component includes nitrate salt storage tanks to store hot and cold salts during increased load demand.