Lunar EVA Space Suit

Roadmap Creators

Technology Roadmap Sections and Deliverables

- 2SUIT Space Suits

We’ve chosen the acronym 2SUIT to represent our technology of a space suit. The 2 in our acronym implies the product level, with suits being a product within the level 1 system of lunar exploration. Our level 2 product level can be broken down into level 3 subsystems (portable life support, pressure garments, etc.) and level 4 components (environmental protection garment, O2 tanks, etc.). For the purpose of this roadmap we are considering the timeline from the late 1960s through 2035.

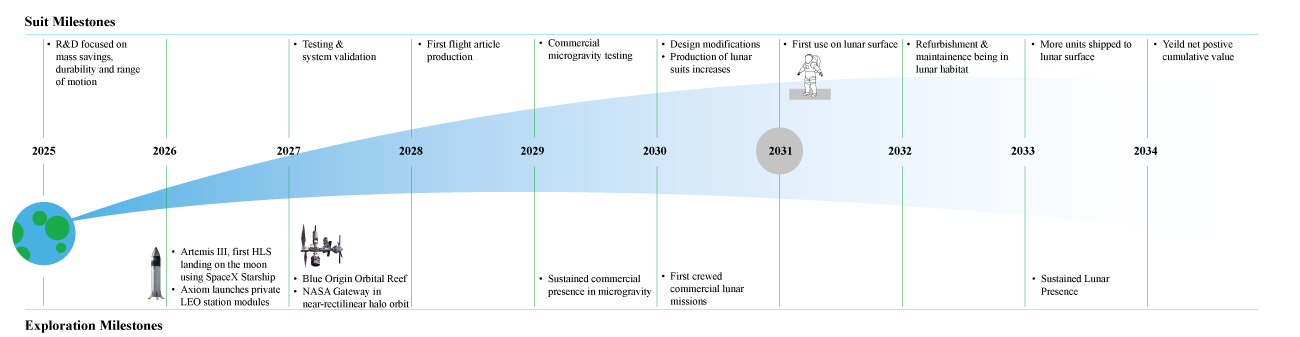

Our technology is a new lunar EVA Space Suit that can facilitate commercial activity on the lunar surface by 2030. This timeline will depend on the progress of commercial space exploration of the lunar surface and in LEO. The roadmap will build on existing research from NASA and R&D projects to reduce mass, reduce complexity in maintenance, and increase life expectancy.

Roadmap Overview and Technology Strategy

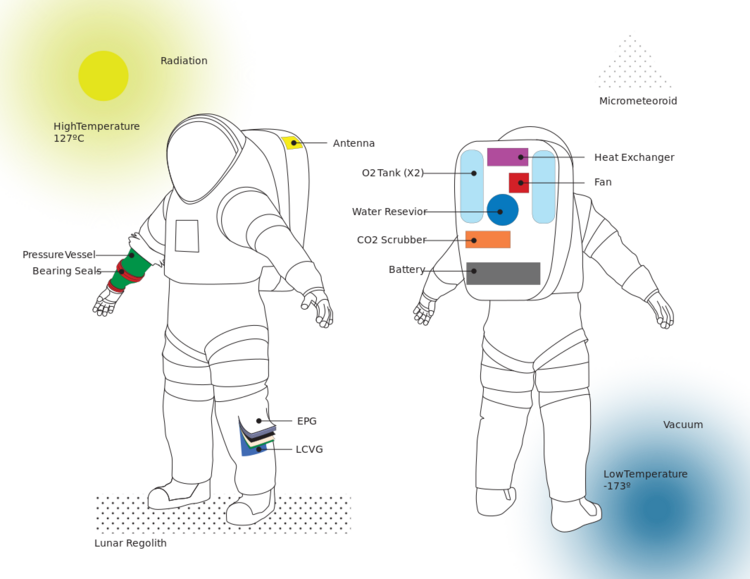

Space suits enable survival and movement for humans outside of spacecraft in the harsh environment of space and fall into the category of “organism transportation.” They have been historically designed in response to specific environments – incorporating tools and aids for translation and tethering in micro-gravity and additional walking mobility features in partial-gravity, planetary environments.

With consideration for mobility, suits enable direct interaction with hardware during Extravehicular Activities (EVAs). During the Apollo program, suits allowed astronauts to safely explore the lunar surface to gather samples and learn firsthand about the environment of the Moon. The maintenance and upgrades on board the International Space Station similarly would not have been possible without the up-close, autonomy and physical interaction enabled by suits. With a new era of commercial spaceflight, the development of effective space suits will be fundamental for longer duration and more frequent missions – ensuring that humans can survive and function in these foreign environments.

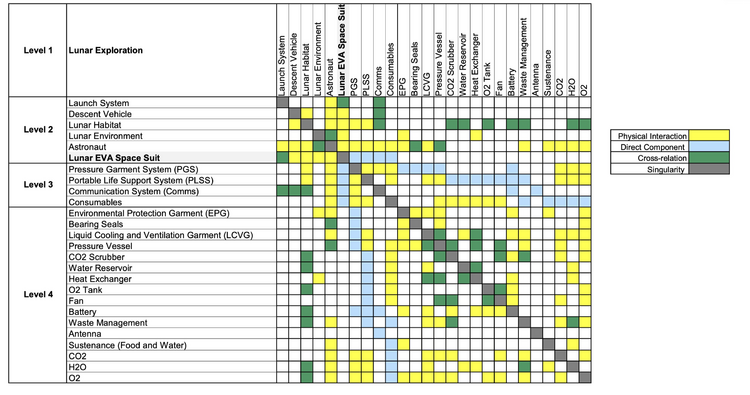

Design Structure Matrix (DSM) Allocation

The matrix representing the technology of a Lunar EVA Space Suit visualizes the interdependencies with technologies on higher and lower levels for its own feasibility. The suit we are discussing is designed to support Lunar exploration, the level 1 system. This goal, or greater system, can be decomposed into level 2 product systems: a launch system, a descent vehicle, a habitat, the environment of the lunar surface, the crew or astronaut, and the space suit itself. These level 2 systems can each be individually decomposed into their subsystems. For the space suit, this means examining the level 3 subsystems: the Pressure Garment System (PGS), the Portable Life Support System (PLSS), the Communication System (Comms), and the consumables. These level 3 subsystems can be further decomposed into their individual components. The matrix allows the viewer to visualize the different relationships and connections within the space suit, whether physical interactions, subcomponents, or cross-system dependent/affected.

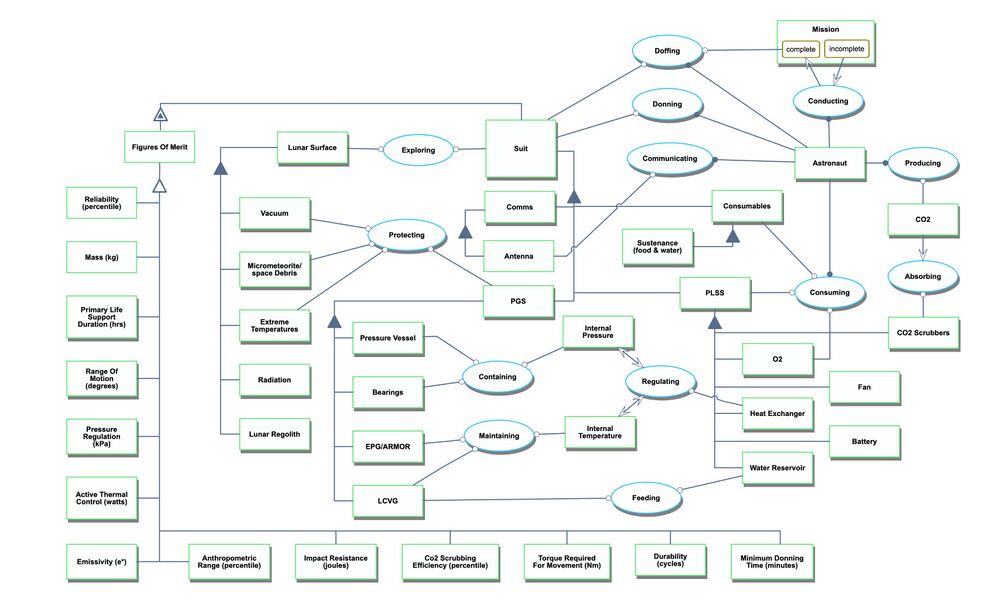

Roadmap Model using OPM

We provide an Object-Process-Model (OPM) of the Space Suit (2SUIT) roadmap in the figure below. This diagram captures the main object of the roadmap the space suit, its primary function to pursue lunar exploration in space, its decomposition into Level 3 subsystems (PLSS, PSG, Comms and Consumables), its characterization by Figures of Merit (FOMs) as well as the main processes (conducting the mission, exploring, communicating).

Figures of Merit

| Rank | Figure of Merit (FOM) | Unit | Description |

|---|---|---|---|

| 1 | Reliability | Percentile | Factor of safety defined by redundant capability |

| 2 | Mass | kg | Total amount of matter within the space suit system. |

| 3 | Primary Life Support Duration | Hours | Maximum duration the space suit can supply breathable air and power under specific conditions. |

| 4 | Range of Motion | Degrees | Flexibility/movement by a joint, or a series of joints, within a specific direction. |

| 5 | Pressure Regulation | kPa | Ability to maintain a stable internal pressure to protect inhabitant from space environment vacuum pressures. |

| 6 | Active Thermal Control | Watts | Ability to dissipate heat generated by astronaut. |

| 7 | Emissivity (e*) | Dmnl. | Space suit passive protection capabilities from thermal extremes found in space. |

| 8 | Impact Resistance | Joules (J) | Space is full of high-velocity objects capable of damaging or puncturing space suits. Suits must protect inhabitants from micro-meteoroid, environmental, and orbital debris impacts. |

| 9 | CO2 Scrubbing Efficiency | Percentile | Efficiency in removing carbon dioxide within the space suit environment. |

| 10 | Durability | Cycles | Longevity or durability of the space suit itself, and can be measured in number of pressurization cycles, or the complete use or sequence of the space suit (i.e., donning, operating in space environment, and doffing). |

| 11 | Torque Required for Movement | Nm | Minimum force exerted by astronaut required to bend joints and move within the space suit. |

| 12 | Anthropometric Range | Percentile | Accommodating 5th percentile female’s to 95th percentile male’s anthropometric data. |

| 13 | Minimum Donning Time | Minutes | Minimum time, overall, that it takes for an astronaut to put the spacesuit on. |

The above chart lists our interpretation of a comprehensive list of Figures of Merit pertaining to Space Suit Technology. Three important Figures of Merit (FOMs) are reliability, mass, and primary life support duration. Reliability is expressed specifically as a percentile representing the factor of safety defined by redundant capability. For example, the suit has a requirement for an oxygen tank, but for reliability, they have installed two oxygen tanks, that would contribute a 2x or 200% factor to the overall space suit’s reliability. Mass is the total amount of matter within the space suit system, measured in kilograms (kg). This is an important metric because it drives many other architectural and design decisions for the adjacent and supporting systems within the space suit. For example, all mass needs to be taken into account when calculating the required fuel/thrust for launch, which subsequently affects the overall mission cost. Primary life support duration refers to the maximum potential EVA duration, measured in hours, that the space suit can supply breathable air and power under specific conditions. This figure of merit is vital to mission planning success. A space suit that can support 8 hours of primary life support has the capability to accomplish missions that would be completely unfeasible or massively less convenient for a space suit that can only support 1 hour of primary life support.

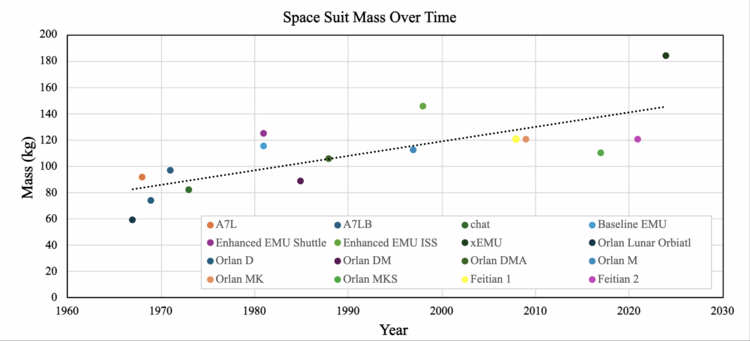

A study was then conducted to collect and analyze the mass of previously fielded space suits and new developments at the National Aeronautics and Space Administration (NASA) (e.g., the xEMU) to study the change in system mass over time. These suits were plotted by year of initial use/deployment and are represented above.

For the technology of choice, a 'space suit,' the team decided to analyze the figure of merit 'mass'. Mass was ultimately chosen for analysis due to the circular discussion between increased capabilities and mass; the more capability the suit offers, the heavier it will be. This can be seen on several fielded suits, where the following FOMs capabilities increase with mass:

1. Reliability: within engineering, systems are often made more reliable using backup or redundant systems. With these redundancies comes more mass.

2. Life Support: the total amount of O2 available directly increases system mass and ultimately drives decision-making about choosing a regenerative or consumable suit.

3. Mobility: more mobility results in additional bearings, thus increasing mass.

Although mass could be viewed as a positive, it is also worth noting the heavier the space suit is, the more expensive it is to launch. Additionally, with increased mass, the movements of the crew members are further impeded, meaning additional effort is required for physical EVA tasks. Therefore, increased capability comes with trade-offs and should be considered appropriately. Space suits, to whatever extent possible, should aim to reduce mass while increasing system functionality and other figures of merit.

These results confirm the previous claims that an increase in capability typically equates to an increase in system mass, as many of the space suits used in the early 1970s as part of the Apollo missions and several others did not include standard capabilities such as thermal regulation, CO2 removal systems, flexible mobility infrastructure (bearings at joints), hard pressure garment components (Hard Upper Torso (HUT)), reusability over multiple missions, and superior communication systems (e.g., heads up displays and advanced communications/telemetry systems).

Traceability Between Strategic Drivers and Technology Roadmap

| Number | Strategic Driver | Alignment and Targets |

|---|---|---|

| 1 | To develop a space suit that lowers the cost per EVA below $550,000 by 2030. To promote a sustained presence on the moon and make lunar travel more accessible to commercial organizations, the cost per EVA needs to be decreased from where it is currently. | The 2SUIT roadmap aligns with this driver. Through the market research surrounding reusable launch vehicles, most notably from SpaceX, the cost per launched kg is expected to decrease significantly as this technology evolves, allowing the total cost of shipping and maintaining a space suit to decrease. |

| 2 | To develop a reliable space suit with a lifespan measured in years. Having a suit with a longer lifetime will ultimately decrease the cost per use and the frequency with which the suits must be replaced on the lunar surface. Modular, replaceable components and subsystems with consideration for ease of maintenance would reduce downtime during repairs and allow for refurbishment. | This roadmap is currently aligned with the strategic driver. The 2SUIT roadmap will target a reliable and reusable suit that can be reused at least 40 times and last for 320 hours minimum in the lunar environment. The suit will also require modular maintenance compatibility to “plug and play” high wear and tear components in situ. This will not only extend the durability of the 2SUIT technology but also expand the anthropomorphic range it can cover for future diverse astronauts. |

| 3 | To target a lower system mass that is in balance with capabilities such as range of motion and life support redundancies. Lighter mass would allow more effortless movement during EVAs and decrease transit costs. | The 2SUIT roadmap partially aligns with this strategic driver. While the mass of space suits over time has historically only gone up as their capabilities have improved, as seen in our FOM (mass) vs. Time figure, the 2SUIT roadmap hopes to see the involvement and incorporation of leading-edge material science breakthroughs in lightweight materials that will be incorporated into future lunar space suits. The mass target is less than 100kg, similar to the Apollo suits. |

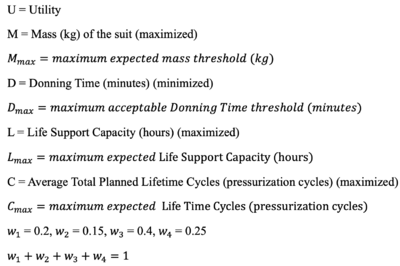

| 4 | To provide a range of motion with the suit that enables dexterous work to be performed without great hindrance to the user. The greater the suit's mobility, the easier work can be performed, decreasing the EVAs' necessary length. | The 2SUIT roadmap aligns with this driver; through the research completed around key patents and technology pertinent to space suits, Space Suit Roboglove (SSRG), often referred to as the ‘grasp assist system,’ is likely to be incorporated by NASA in future space suits allowing for a significant increase in dexterity for fine motor skills while wearing the suit. |

| 5 | To develop a design platform easily adapted for micro-gravity applications to support EVAs in LEO or cislunar space to reduce the overall design effort and minimize overall development costs. | The 2SUIT roadmap does not align with this driver, as the team focused solely on the lunar environment and the space suit designs that support those mission sets. While adaptability would be immensely beneficial for the cost and usability of the space suit, based on the scope of our roadmap, these additional considerations are not currently being explored or researched in pursuit of this roadmap. |

| 6 | To develop life support systems that support 8+ hours of EVA capabilities to allow work on complex, time-intensive tasks. | The 2SUIT roadmap does not align with this driver, as the current limiting factor of the FOM is how much oxygen the PLSS can hold to support the astronaut during EVAs, and that technology advancement has not been a focus of this roadmap's research or intended direction. |

Positioning of Company vs. Competition

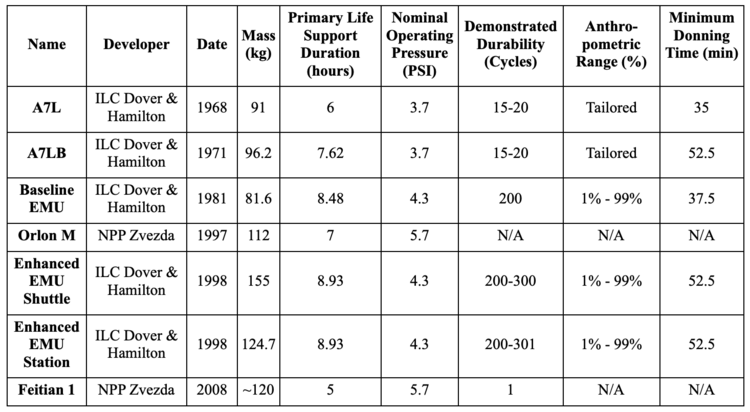

Below is a summary of EVA suits and the corresponding publicly available data. For our research, we primarily focus on the market for suits manufactured within the U.S. for NASA and private commercial companies, as these would provide the most accurate benchmarks for the market we’d attempt to enter.

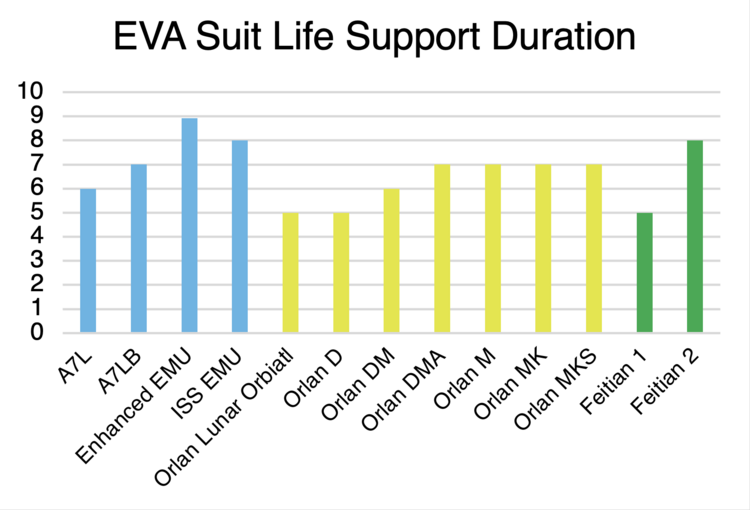

Life Support Duration Comparison- Above is a representation of the NASA suit life support durations (blue) compared to the life support durations offered by Russian (Red) and Chinese suits (Green). Currently, these are the only countries with untethered EVA suits (no private companies).

Technical Model

FOM Sensitivity Analysis:

Equations Under Consideration- As shown within previous assignments, several figures of merit (FOMs) should be considered when developing a space suit technology, and thus, several equations could be considered for uncertainty analysis. With that in mind, the team decided to evaluate two FOMs of most common interest to several stakeholders: mass and cost. Although mass is a common metric for quantifying the cost of space flight missions (i.e., cost per kg payload), there are several additional variables/factors worth exploring.

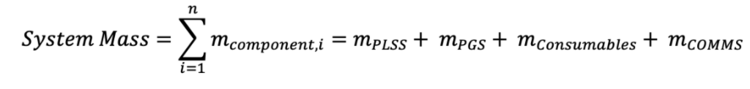

The following equation was determined to express the total system mass of a space suit technology and can fundamentally be understood as a summation of each individual component within the system boundary. In this case, the team intentionally only included level three (3) supporting technologies of 2SUIT. However, each component included in the equation below (e.g., the PLSS, PGS, etc.) could be analyzed further to identify additional individual contributors to the overall system mass.

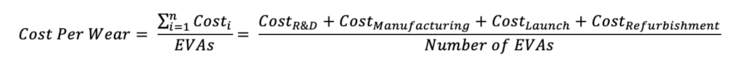

The total amount of money, or cost, associated with a single space suit technology was also considered and varies slightly from the mass equation shown above. Similar to the mass equation, a summation could be considered of all smaller sub-costs associated with the project, which in this case considered the following costs:

1. Research and Development: costs associated with the design and validation of the space suit

2. Manufacturing: incurred costs directly associated with the production of the space suit

3. Launch: the price per kg of payload necessary to launch technology into space

4. Refurbishment: Space suits can often be refurbished for reuse following a certain number of cycles and thus have an associated cost for these activities.

However, what’s of particular note and worth mentioning within the cost per wear equation below is the ‘Number of EVAs’ variable included in the denominator, which was included to capture the effect of system reusability per wear. If a space suit is designed, built, and sent into space for one singular mission before retirement, the associated cost per wear can be quite astounding. However, if a space suit is designed for 200 plus uses, the associated cost per wear/mission is significantly reduced, and therefore, durability/reuse should be appropriately considered when developing these technologies.

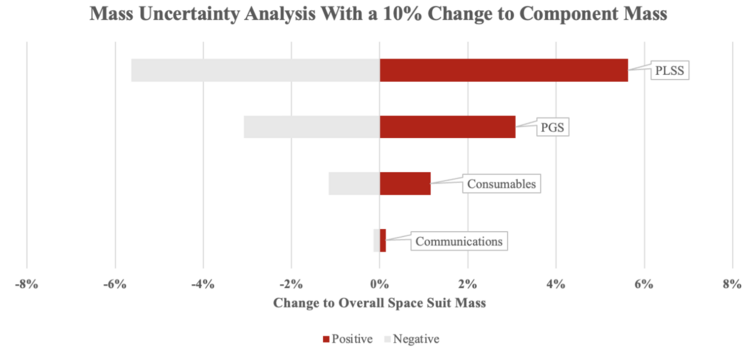

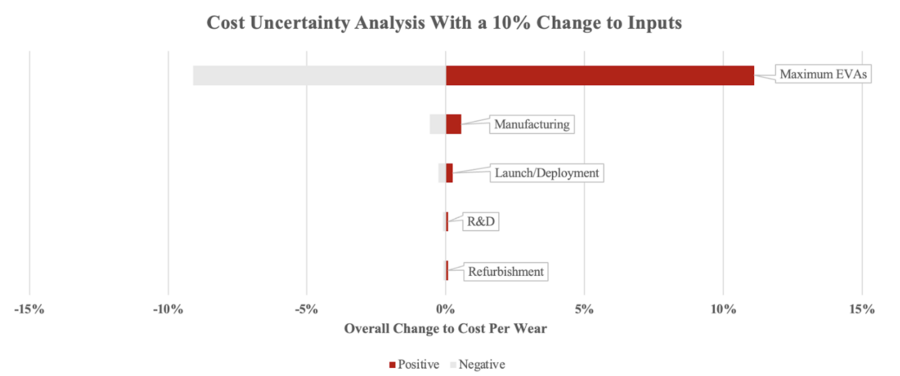

Sensitivity Analysis- With the mass and cost equations known, the team performed a sensitivity analysis against the technology ‘baseline’ to understand which equation variables were most sensitive to the overall output of each equation. The system baseline was established through in-depth market research of competing space suit technologies, where open-source data was compiled, averaged, and incorporated into each equation to establish a baseline output. Once these baselines were calculated, the average of each input was altered, plus and minus ten percent in this case, to understand how a ten percent deviation (positive and negative) affects the overall system output and governing equation. The result is an uncertainty analysis of both mass and cost components and has been presented below as a ‘tornado diagram.’

Although not groundbreaking, these results provide significant insight into specific design considerations for space suit technologies moving forward. For example, as with most payloads sent into orbit, mass matters. For that reason, design decisions can be made, to whatever extent feasible, to reduce mass without sacrificing functionality. If that’s the case, per the results above, reducing the mass of either consumables or communication systems by even ten percent will have only marginal impacts on the total system, however on the other hand, if the PLSS mass can be reduced by just 10 percent, the total system would see a roughly 6 percent decrease in total mass. Additionally, regarding system cost, the amount of money spent on designing, manufacturing, and refurbishing space suit technologies has little to no impact on the overall cost per wear. Comparatively, the reusability or maximum number of EVAs a suit can be used for before retirement has a significant impact (roughly -9 and +12%, respectively). Therefore, if the goal is to reduce costs for a longstanding space program, company strategists should emphasize the importance of durability/reusability when determining a preferred system architecture or concept.

Morphological Matrix:

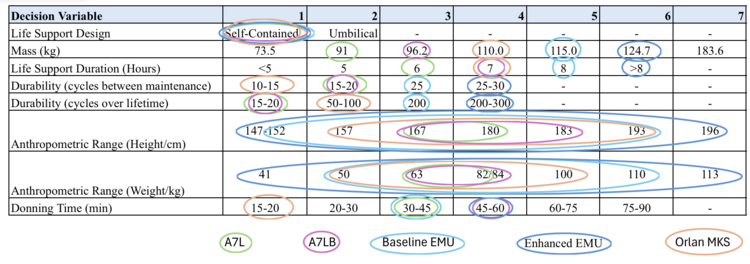

The morphological matrix above depicts the historical architectural decisions that five separate space suit design teams made. This visual, when paired with the tradespace and research done surrounding the figures of merit, leads our discussion of what needs to be prioritized in the next generation of space suits and what architectural decisions lead to the most favorable outcomes. Historical data is extremely useful in prioritizing and assessing architectural decisions. Our technology will aim to have a self-contained, low mass, robust life-support structure, high durability, and diverse space suit that can be donned quickly without outside human assistance.

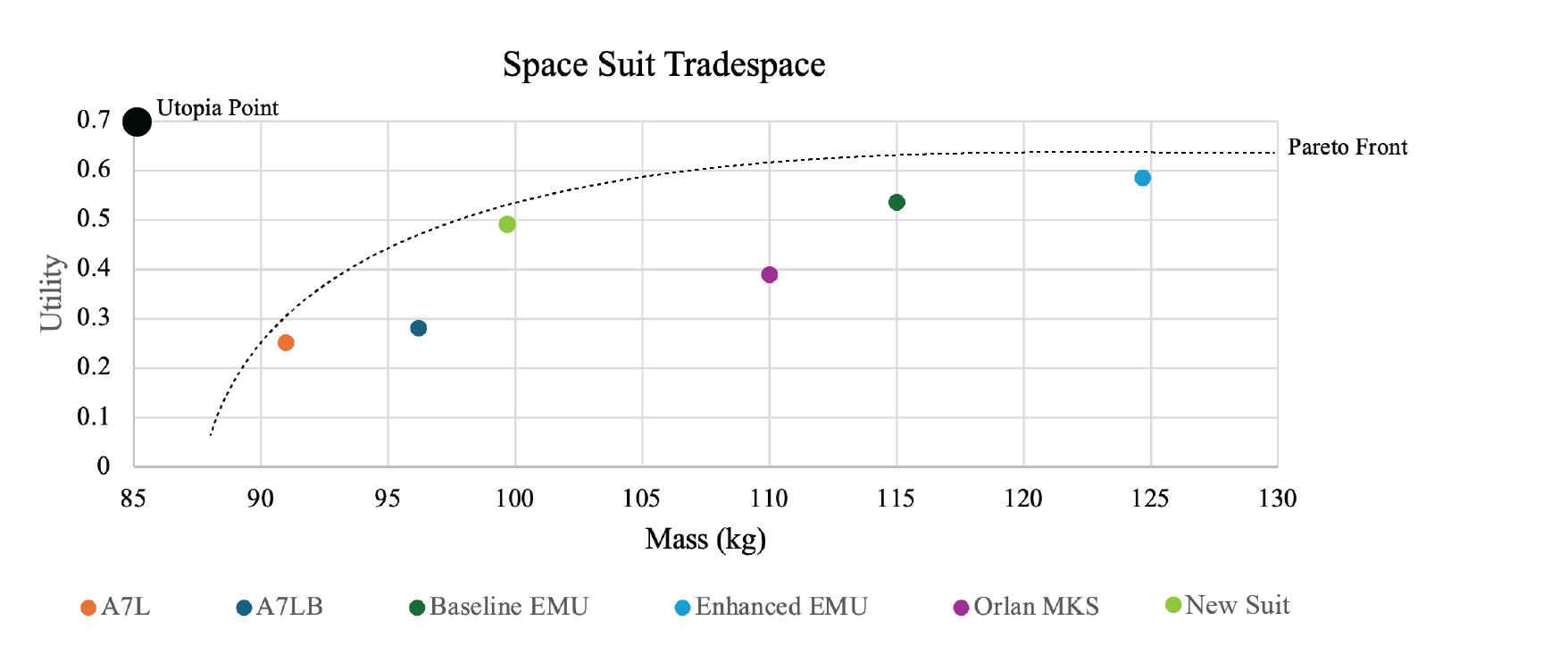

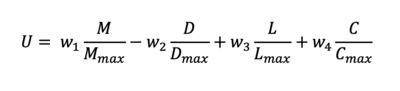

The tradespace above depicts historical data points comparing an overall calculated utility value (U) to the mass in kilograms of the Space Suit represented. The Utopia point represents the best-case scenario: a low-mass suit with the highest utility score to decrease its cost to launch, with the Pareto front pushing to that top left corner of the chart. Below, we will derive how we calculated the overall utility value of each suit.

The weighting factors sum to one (1) and are assigned based on the relative importance of each factor to the mission. A negative sign is applied to donning time to penalize higher values, and positive terms for mass, life cycle support, and lifetime pressurization cycles are rewarded. This utility equation prioritizes a quick donning, high durability, and long-life support capable suit. Each value within the Utility Equation is normalized by a maximum acceptable or expected value to counteract an imbalance of units and magnitude per term, simplify the weights' assignments, and increase our flexibility in comparing suits with different characteristics. We acknowledge the conflict between our low-mass utopia point and our positive weighting term for mass. In our research of FOMs over time, specifically mass, as space suits have gotten more technically competent and advanced, their mass values have increased. Due to the limited data available for historical space suits, we compared a few suits with differing characteristics due to differing mission sets. For example, the Orlan and EMU suits were designed for microgravity, where larger mass values didn’t negatively affect their utility. In contrast, the A7L and A7LB suits were designed for lunar exploration, where mass was a driving feature they hoped to minimize. In the future, we would like to prioritize minimizing the mass of the suit to reduce the overall cost per suit driven by cost per kg to launch and the utility for our specific lunar exploration mission set, which is why we placed the utopia point in the position to reward high utility and low mass values.

Key Publications and Patents

Utilization of Patent Search Process:

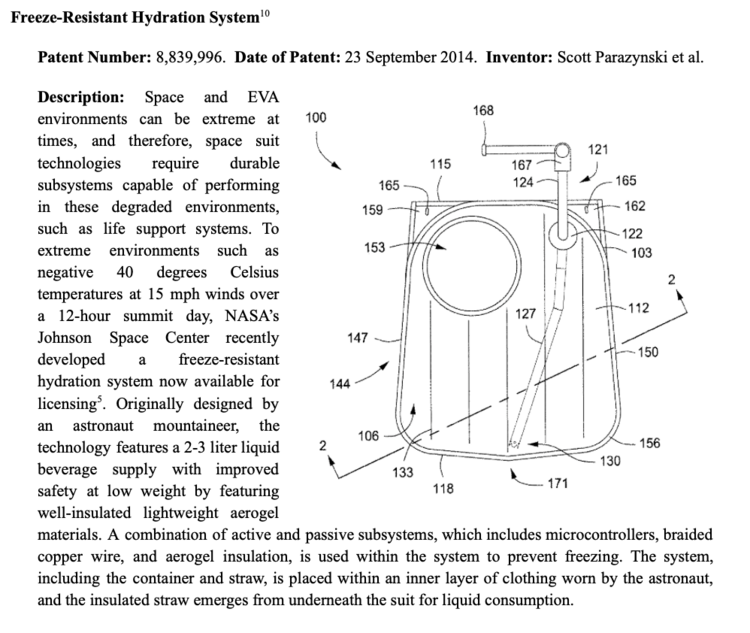

A search for key publications and patents related to space suit technologies was performed using the United States Trademark and Patent Office and NASA’s Technology Transfer Program’s online portfolio. Preliminary research quickly yielded several resulting patents related to space suit technologies, such as the Space Suit RoboGlove (SSRG), Upper Body Robotic Exoskeleton, and Freeze-Resistant Hydration System.

Relevancy of Papers/Patents:

Each of the aforementioned technologies directly connects to space exploration and, more importantly, space suits (i.e., our chosen technology roadmap). As highlighted previously, several figures of merit (FOMs) are associated with space suit technologies. These FOMs, highlighted below, are vital to support planned lunar exploration missions moving forward and have seen significant advancement, largely due to new supporting technologies such as the patents referenced in this paper.

For example, three of the top six prioritized figures of merit can be directly linked to each chosen patent, such as Primary Life Support Duration, Range of Motion, and Active Thermal Control. This means the potential utilization and incorporation of the SSRG, Upper Body Robotic Exoskeleton, and Freeze-Resistant Hydration System could significantly impact these FOMs. Direct connections between the researched patents and specific FOMs can be identified and are shown below in the table.