Remote Operated Processing Platform

Technology Roadmap Sections and Deliverables

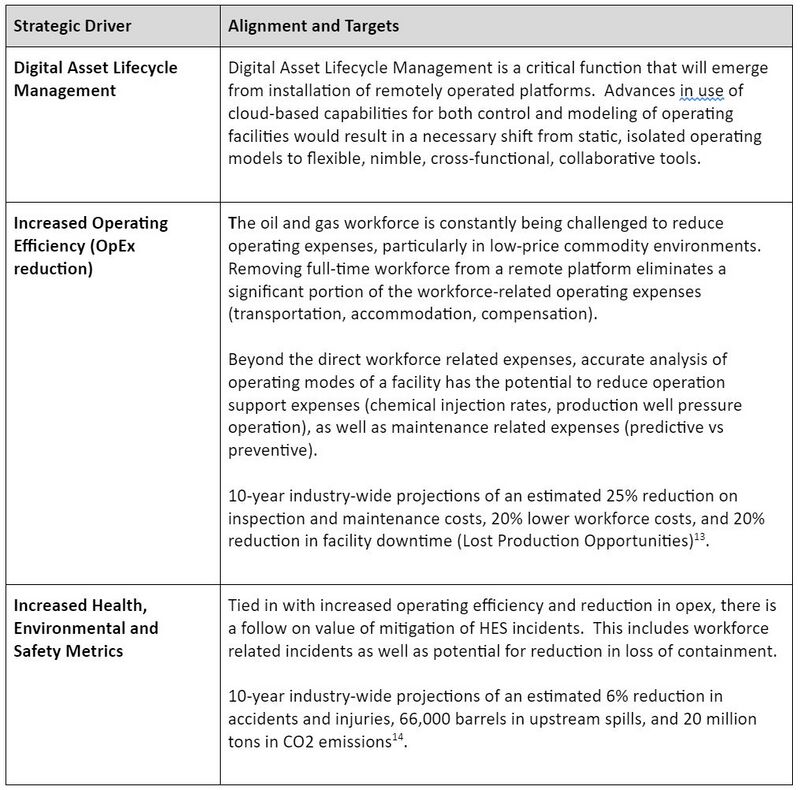

On an offshore oil and gas platform, operators are physically located on the facility to provide local intervention with a goal of ensuring safe, reliable processing capabilities. Introduction of a remote operated platform removes operations and maintenance personnel from being physically located on the platform to a central operating location where the focus is on real-time monitoring and intervention is achieved.

Roadmap Overview

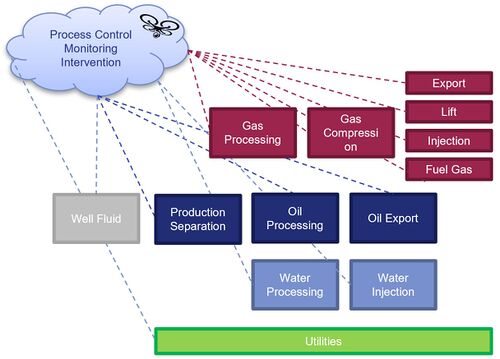

The high-level working principle and architecture of a remote operated oil and gas processing platform is depicted in the below. The core infrastructure of any offshore oil and gas processing facility consists of an inlet well fluid stream and initial separation followed by oil, water, and gas processing streams. Utilities support all processing streams and include main power, instrument air, heating and cooling medium, fresh and seawater supply to name a few.

As of today, these processes are more or less controlled via central control room on a production facility with manual intervention by operations and maintenance personnel, as required. The elimination of onsite personnel is depicted in our overview to highlight a remote control center operated via cloud computing technology.

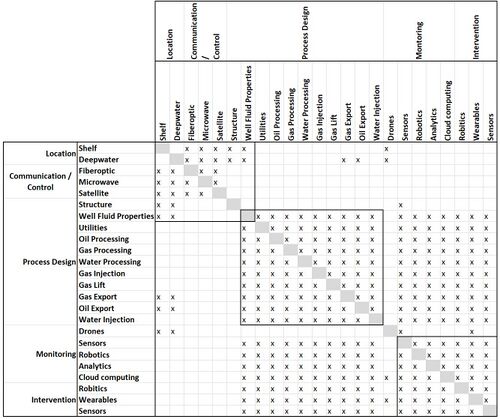

Design Structure Matrix (DSM) Allocation

We can extract from the DSM below that the remote operated processing platform is composed of and dependent on a series of decisions and technologies. These decisions and subsequent technologies include facility location, communication and control method, process design, monitoring and intervention.

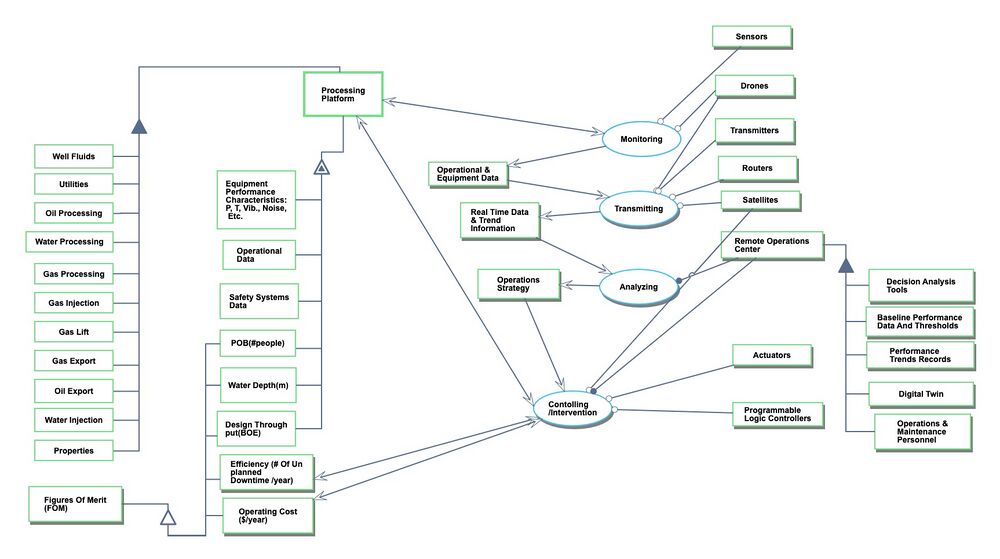

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the in the figure below. This diagram captures the main object of the roadmap (oil platform), its various processes required for transferring of information to control the facility remotely, as well as the Figures of Merit and main processes.

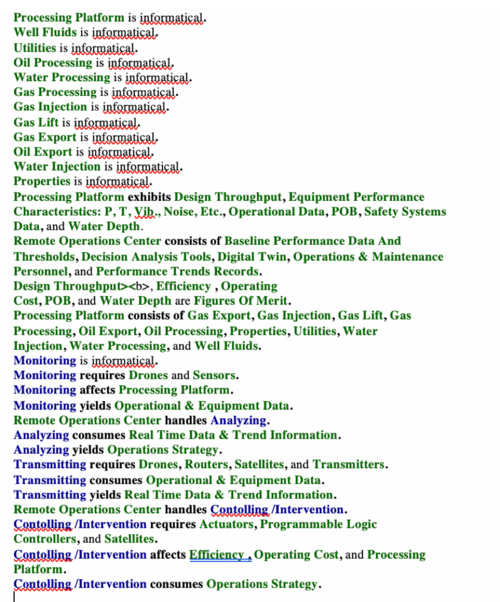

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated via Opcloud and provided below. This is simply an export of the OPD in a formal natural language.

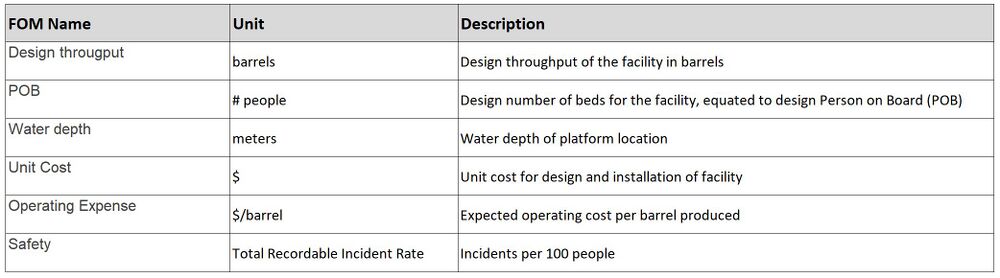

Figures of Merit

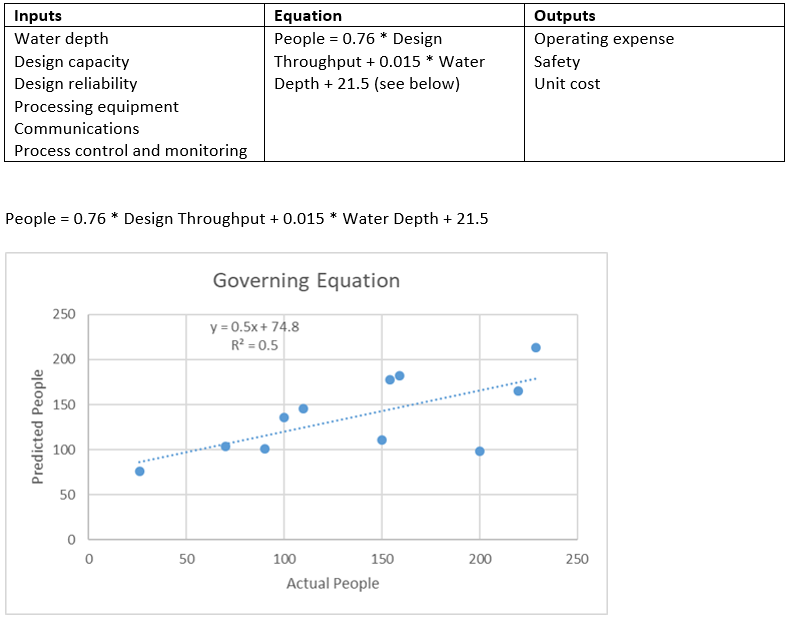

The table below show a list of FOMs by which a remote operated processing platform can be assessed. The first two highlight the driver to maintain capability for maximum design throughput of a facility with minimum number of personnel onsire, with a target of zero. While not directly mentioned, the tradeoffs associated with complexity as indicated by water depth and capacity need to be considered with the personnel in trade space. Water depth is a FOM that we are continuing to develop, with a thought that the theoretical limit to a remote operated facility will likely be limit in technology for location, which translates to water depth of the facility. Unit cost (CAPEX expenditure) and operating costs are directly correlated with the reduction of personnel onsite full time operating and maintaning a facility. Lastly, Total Recordable Incident rate is an emergent FOM derived from reduction in personnel exposure will result in reduction in incident rate.

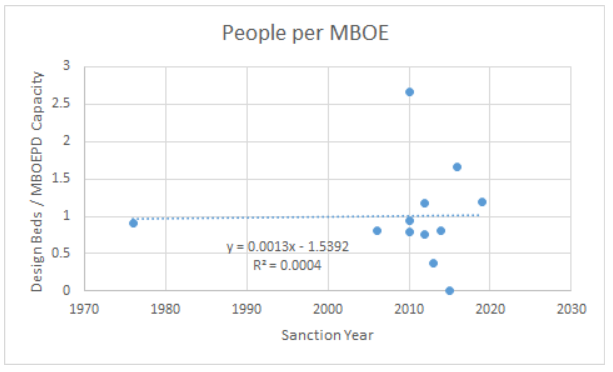

When we look at the the changes in time for people vs. capacity, we do not see not see any trend. This measure has not been a key consideration in the past, and we would consider it a disruptive technology as it changes the focus of figures of merit.