Electric Vehicle Charging Technologies

EV Charging Technology Roadmap

- 2EVCT - Electric Vehicle Charging Technology

This is a Level 2 roadmap. Level 1 would be the technologies enabling zero-emission transport while Level 3 and 4 would include technologies enabling the charging of electric vehicles.

Roadmap Overview

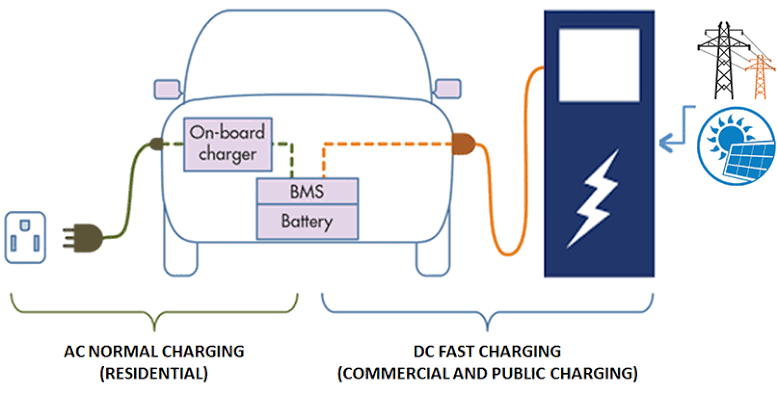

Our chosen technology is that of charging energy storage devices using power from the grid. With the current technology, electric vehicles can be charged using a standard 120V outlet or a 240V industrial outlet. An electric vehicle usually has an onboard charger unit (OBC) which converts AC power into DC to store it in the high voltage battery. The vehicle accepts charge via a charge port where the user can insert the charging plug. The charging plug is a part of a wall-mounted (off-board) unit which is connected to the grid and supplies AC power to the vehicle when the vehicle is ready to accept charge. The user is usually responsible for initiating charging by connecting the vehicle to the off-board unit (EVSE) and optionally keying in a unique id to “unlock” the unit to provide charge. Recent advances in charging technologies have enabled DC fast charging which has resulted in faster charge rates and reduced charging times.

*image-source - https://www.verdemobility.com/charge.html

*image-source - https://www.verdemobility.com/charge.html

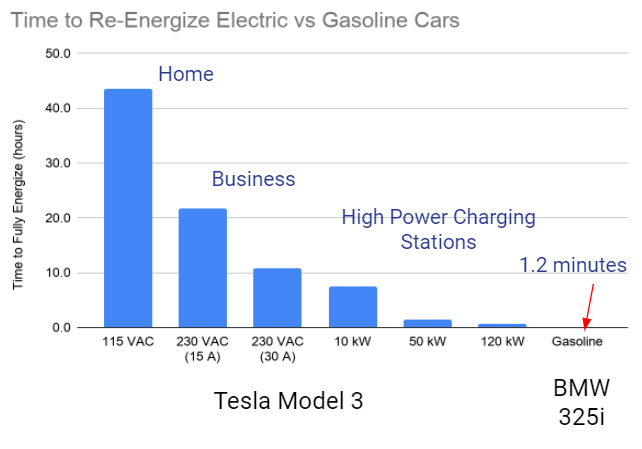

With today’s technology long-range EVs (200+ mile range) could take as high as 30+ hours to fully charge the battery pack using a regular home outlet. Fast charging technologies have also been developed which can bring the charge time down to a few hours (~2 hours), but these times are still significantly higher than the time needed to fill a fuel tank in a gasoline/ diesel vehicle as shown in the figure below. These would also warrant better cooling technologies to keep optimal battery thermal performance and extend battery lifetime. With the battery cost ($ per KWh or $ per mile) decreasing, we could see a trend of bigger batteries / higher range vehicles being deployed, and an increased rate of adoption of electric vehicles, which would further necessitate faster charging and availability of charge stations. Hence, we feel the current technology would have to be advanced to be able to charge as fast as possible and make charge stations as freely available as gas stations today, thus ultimately reducing range anxiety.

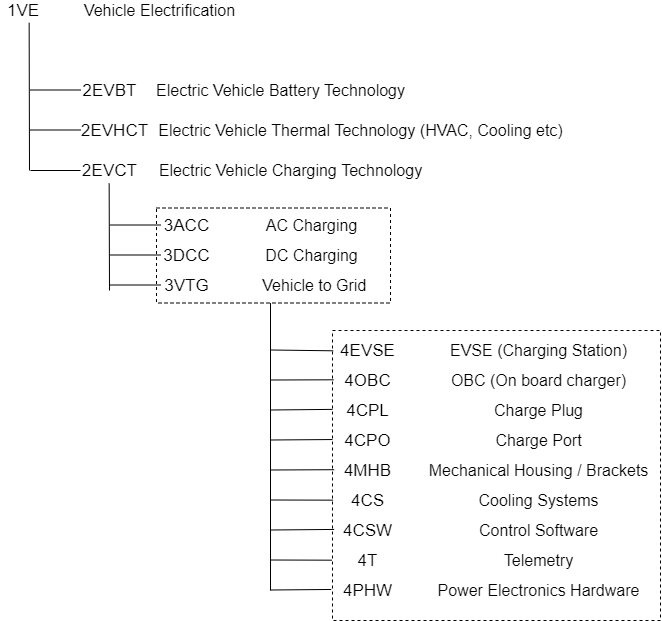

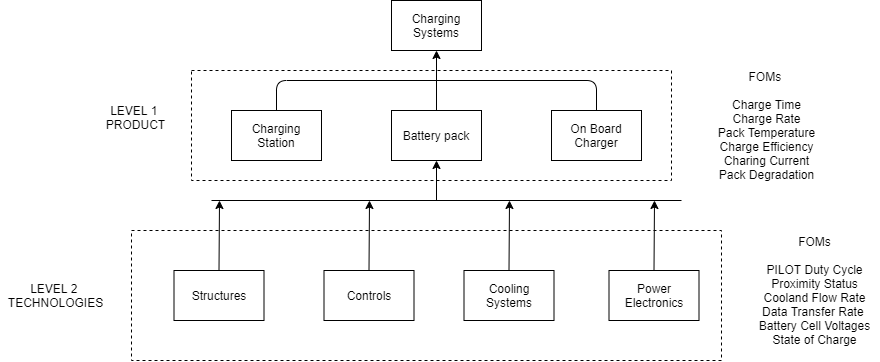

Technology Hierarchy Tree

The following hierarchy shows the breakdown from L1 Technologies (Vehicle Electrification in general) to L2 - Technologies that need to be developed to achieve vehicle electrification. Further, The 2EVCT decomposes into different technologies that are developed to facilitate electric vehicle charging. L4 technologies are the technologies needed to develop the formal entities of products that enable electric vehicle charging.

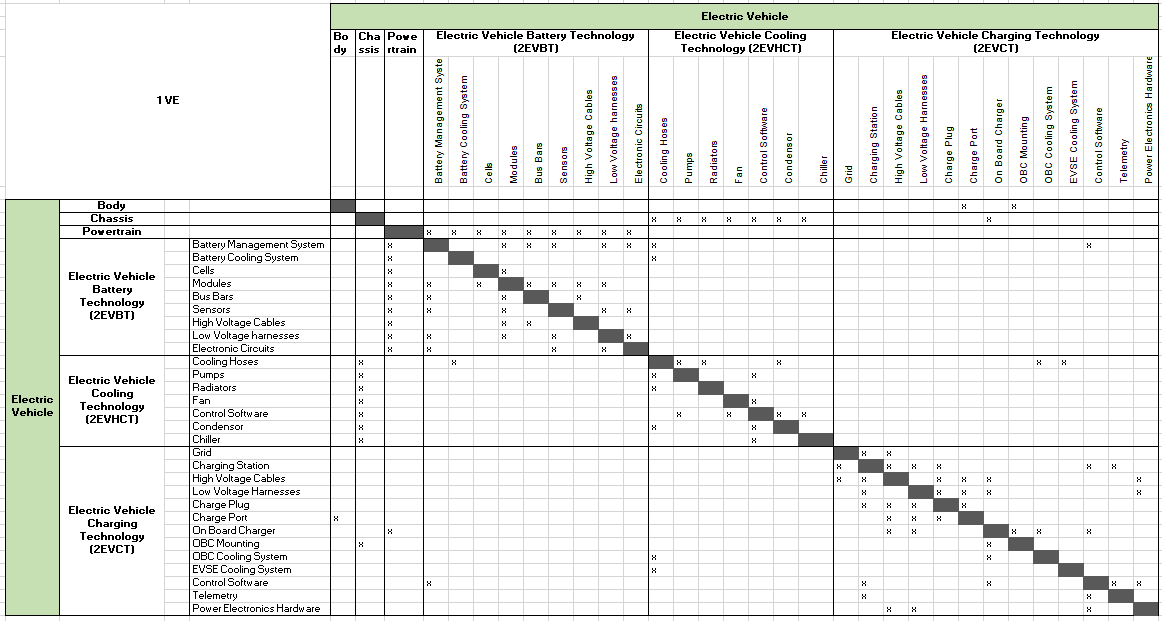

DSM Allocation

The matrix below shows the allocation of technologies at various levels to enable vehicle electrification. The selected technology 2EVCT is shown as a part of the bigger 1VE technology DSM

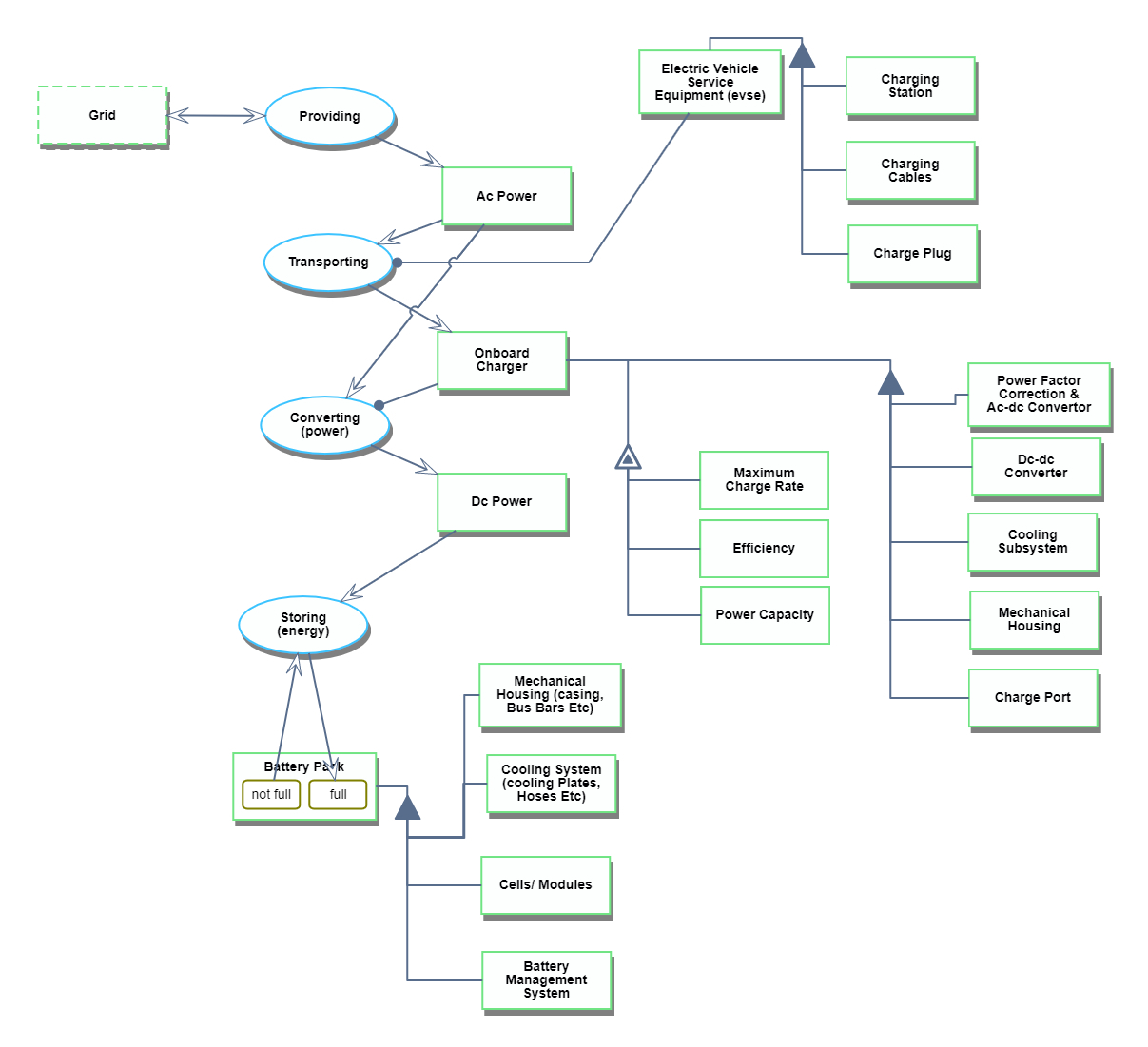

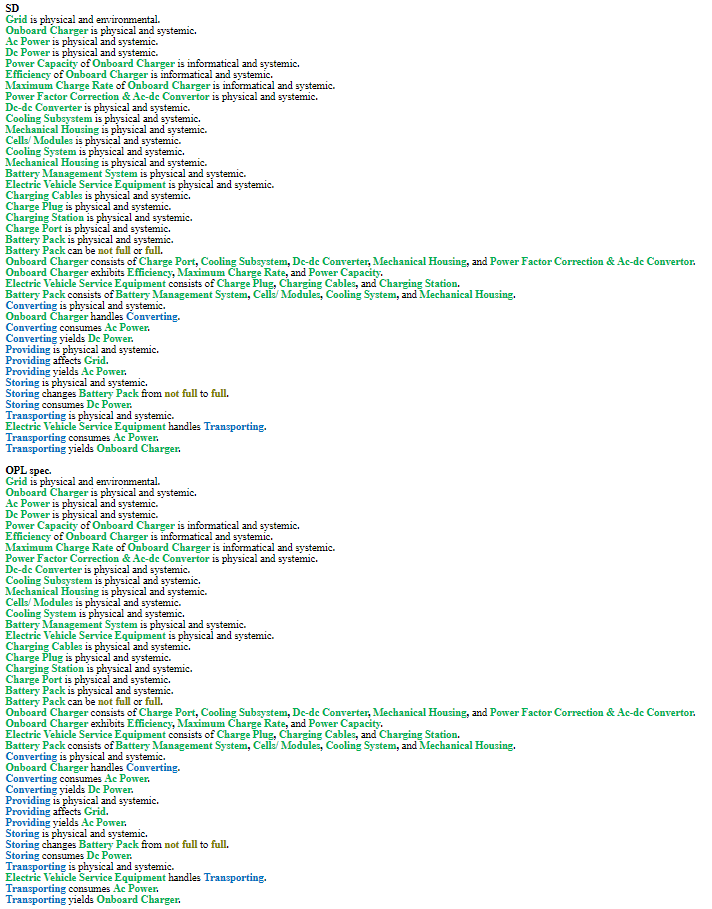

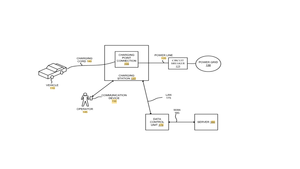

Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) of the 2EVCT roadmap in the figure below. This diagram captures the main product, Its decomposition, and shows the process flow of achieving the desired function (in this case charging the battery pack).

In the charging technology, the EVSE (Electric Vehicle Service Equipment, a.k.a charging station) receives AC power from the grid and transports it to the vehicle's on-board charger. This onboard charger is responsible for converting AC power into DC power and storing it in the high voltage battery. The EVSE can be decomposed into the main charging station, the power lines from the charging station to the vehicle, and the plug that connects to the vehicle's charge port. The onboard charger comprises electronics to correct the power factor and to convert AC power into DC and stores it in a battery pack. It has an associated cooling system to maintain the thermal performance of the unit and mechanical housing to house all the electronics. The high voltage battery comprises of the battery management system, cells, sensors (voltage, current, temperature) along with the associated cooling assembly and mechanical housing to hold everything together. Below is an OPD representation of the system and the associated OPL.

2EVCT Figure of Merits

The table below shows a list of FOMs by which charging of electric vehicles can be quantified and compared

| Figure of Merit | Units | Description |

|---|---|---|

| Charge Rate | [KW/hr] | Total energy/ power added to the battery per unit time |

| Charge Time | [Hrs] | Total time taken to fully charge the battery pack of known KWh capacity |

| Charge Efficiency | [%] | Percent of grid power that is stored in the battery |

| Cost to charge | [$] | Total electricity cost for a full charge cycle at a certain time of the day |

| Charge Power | [KW] | Power rating of the charger (This will determine the magnitude of DC current that the pack will be charged at) |

| Charge Level | [dimensionless] | L1 (120V AC), L2 (240V AC), L3 (Direct Current charging) |

| Charging Stations | [per mile] | Number of charging stations per mile |

| Pack Temperature Rise (normalized to pack size) | [degC/ KWhr] | Rise in temperature of the battery pack after charging is complete |

| Coolant Flow Rate | [gals/hr] | Flow rate required to keep maintain the rise in temperature below a predefined threshold |

| Power Factor | [%] | Ratio between real and reactive power consumption from the grid |

| Pack capacity degradation | [Ah per year] | Reduction in the capacity of the pack after a known number of years due to frequent fast charging |

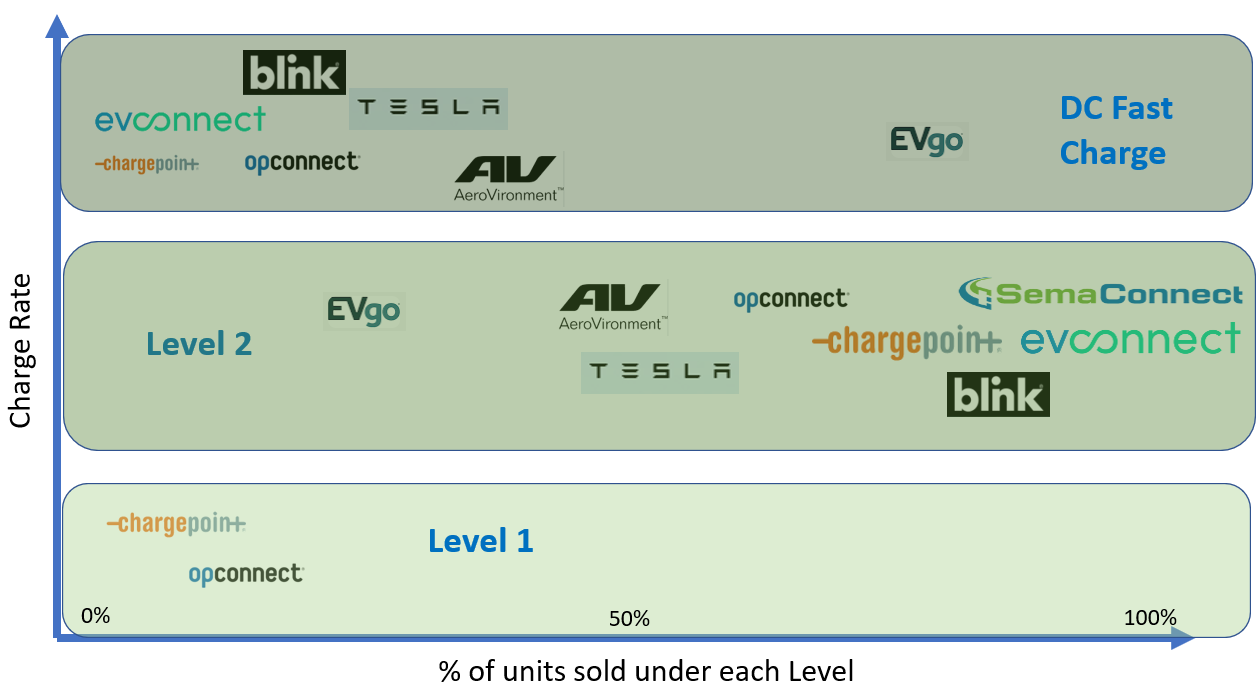

Charge levels are defined by Level 1, Level 2 and Level 3 (or DC Fast Charging). Level 1 chargers are usually plugged into the home wall outlets and can do up to a 3.3KW. Level 2 chargers are usually outside the commercial establishments and also can be installed in residential homes. These chargers have charge rates varying from 3.3KW to up to 80KW. Level 3 charging, usually called DC Fast charging is the ability to charge the battery pack at rates between 80KW up to 450KW. DC Fast charging significantly rises the pack temperature and hence regular fast charging could accelerate cell degradation and reduce battery life faster than normal.

The most important figures of merit are charge rates, charge times, and charging stations. These directly affect how fast the vehicle can be charged and the availability of charge stations when needed. Charging is also cross dependant on battery pack behavior and hence will only be effective if the pack thermals are within thresholds. This interdependency of charging and pack behavior put a limitation on the technological advancements in charging (without proper cooling, charging technologies with extremely high charge rates would be worthless).

Competitive Landscape

The electric vehicle charging system market is very competitive. As battery costs are coming down, there is a growing competition of deploying charging networks across the country and allowing higher charge rates to decrease the overall charge times. The table below shows the competitive landscape of the players in this industry.

Each company has a unique strategic roadmap. The comparison of multiple charging companies is based on their company strategy. These are evaluated across areas like vision, go-to-market strategy, partnerships, technology, geographic reach, product performance, product portfolio, and pricing.

| Top Contenders | Challengers | Emerging |

|---|---|---|

| Electromotive, ABB, Aerovironment, Better Place, Coulomb Technologies, GE Energy, Schneider Electric | Clipper Creek, Delphi, Eaton, Go Smart, Seimens AG, Add Energie | Chargepoint, Alpha, Brusa, Greenlots, Witricity, WattsNXT, Power Pack, Powerstream, Evatran |

The two main strategic drivers for the charging technology are to bring the charging time down and make charge stations as easily available as there are gas stations today. The following table shows how the roadmap targets for the company are aligned to these drivers.

| Number | Strategic Driver | Alignment to Targets |

|---|---|---|

| 1 | Develop a network of charge stations such that open charging station is as easy to find as a gas station | The charging technology roadmap should target to deploy as many charging stations as there are gas stations (if not more) and optimize their geographic locations like today's gas stations. |

| 2 | Develop charging equipment to bring the charge times comparable to times taken to fill a full tank of gas | The charging technology roadmap should support upwards of 600KW of charging power to enable fast charging of the batteries. |

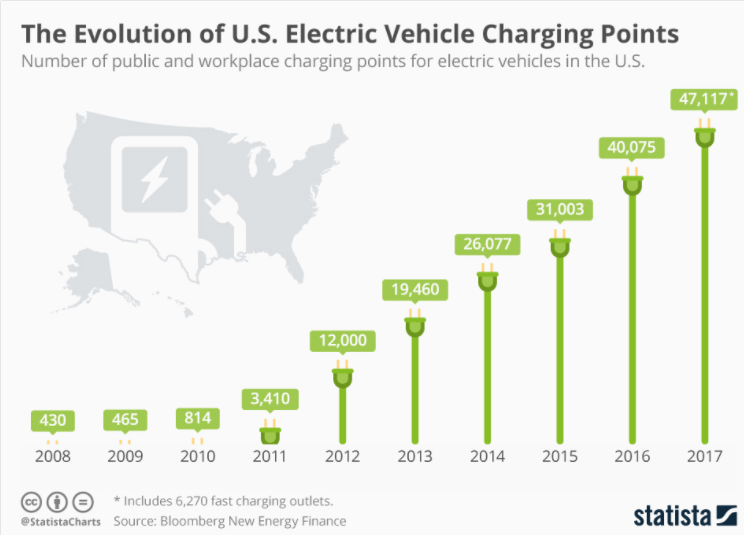

Charging network deployments

The figure below gives a sense of the rate of charging station deployments over the last several years.

Dependence on parallel technology roadmaps

Charging at such high rates is going to result in overheating of the battery pack, thus eventually limiting the power flow to keep the pack temperatures in check. To enable an extended period of the high power charging operation, technologies would have to be developed to better cool the battery pack / better reject the heat. This would drive roadmaps for battery pack manufacturers in designing cooling plates for better heat rejection, cell researchers for investigating chemistries that do not accelerate cell degradation under extreme temperatures and vehicle manufacturers to enable better cooling systems (pumps, radiators etc). Thus, this strategic driver in the charging roadmap is limited by the advances in battery technology and the company should be aware of the battery technology roadmaps.

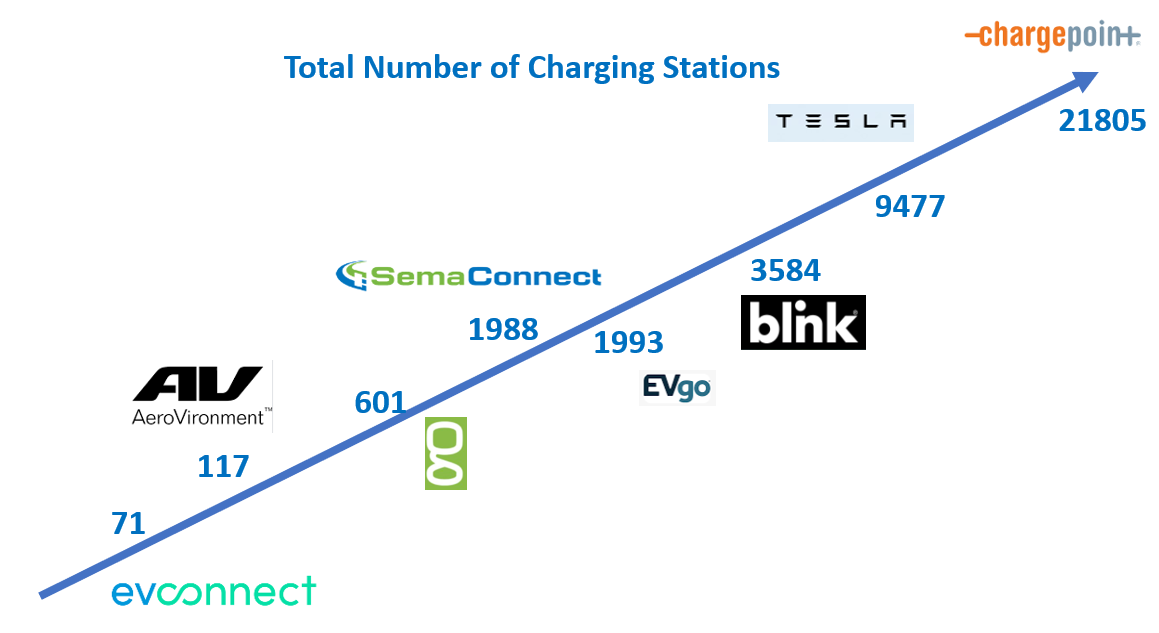

Positioning of the Company

This section compares the competition in the EV charging market. The two main figure of merits that the comparison is usually made is a) Total number of stations and b) Rate of charging (Level 1, Level 2, DC Fast Charge)

Technical Model

The figure below shows system level decomposation into to levels. The first being the product level and the second being technology. The charging system comprises of a charging station, battery pack and an on board charger. Each of these products are built using various technologies around cooling systems, structural integrity, controls/ software and electronics/ hardware.

The following are in inputs, outputs and constants assumed for the technical model.

Outputs – (FOMs) – Charge time, Cost to Charge

Inputs

- Pilot waveform Duty cycle (This determines maximum AC current that can be sourced from the charging station) (see lookup table)

- Charging current (IAc, IDc)

- Grid voltage (120V, 240V)

- Pack size (Vdc) (260V, 360V, 400V..)

- Number of cooling plates (directly affects amount of heat rejection) (2,5,10)

Constants

- Area of the cooling plate

- Charge conversion efficiency (in this model, this is kept constant, but this can also be an output / figure of merit, if the technology is to be assessed to maximize charging efficiency) (95%)

- Power Factor (95%)

- Amount of safety derating due to over heating (see lookup table)

- OBC Max Power (6.6KW)

System Model The system is modeled to compute the charge time and the cost to charge the pack giving the inputs and constants as mentioned above. The Charging current is usually the minimum between the maximum current the charging station can supply and the amount that can be sourced from the wall based off the power rating of the on board charger.

Charging Current :

I_ac=min[(OBC_Max_Power/VAc),Max_I_AC]

Pac=VAc*IAc*PF

Pdc=VDc*IDc

Using conservation of energy

Idc=(VAc*IAc*PF* η)/VDc*(100%-derate_pct)

The charging profile is usually Constant Current Charging until the pack voltage reaches 95% of the max voltage value after which the charging is done at Constant Voltage. The derate_pct will cutback the amount of charging current for safety reasons in relation to

- increasing temperature or the charger

- increasing temperature of the pack (only this is considered for the model for simplicity)

- state of charge/nominal voltage of the pack

The pack temperature rise due to this charging event would be dependent on the heat rejection ability of the cooling plates inside the pack due to conduction. The rise can be expressed as

ΔT=Q*d/(N* K*A)

Conductive Lossess can be modeled as

Q_loss=IDc^2*R

Time taken for charge complete can be expressed as a ratio of remaining energy and charge rate.

Time to charge complete= ((100-SOC)*Pack_Capacity)/(VAc*IAc)

Miles added due to charging can be expressed as a percent of total range of the vehicle. (Meaning if 100% charge yields “Range” miles, then a vehicle charged to SOC% would yield miles expressed by the formula below)

Miles added= Range*SOC

Cost of charging can be expressed as

Cost=VAc*IAc*TimeUnderCharging*($/Wh)

Where,

- OBC_(Max_Power )= Power Rating of the onboard charger (KW)

- PAc = AC Power (W)

- VAc = AC Voltage (V)

- IAc = AC Phase current (A)

- PF = Power Factor

- PDc = DC Power (W)

- VDc = Pack DC Voltage (V)

- IDc = DC Current (I)

- SOC = Instantaneous state of charge of the pack (%)

- Pack_Capacity = Total capacity of the pack (Whr)

- R = Total resistance of the high voltage cable

- η = Charging efficiency (includes losses in cables, heating, power conversion, switching etc)

- ΔT = Temperature difference between the pack temperature and ambient (deg C)

- d = thickness of cooling plate (m)

- K = Conductivity of cooling plate (W/degC*m)

- A = Surface area of cooling plate (m2)

- N = number of cooling plates

- Range = Total range of the vehicle

- $/Wh = Electricity cost

| PILOT Duty cycle | Max_IAc (Amps) |

|---|---|

| 10% | 6 |

| 30% | 18 |

| 50% | 30 |

| 80% | 48 |

| 96% | 80 |

| Temperature Difference (Pack and Ambient) | Current Derate % |

|---|---|

| 0C | 0 |

| 30C | 30% |

| 60C | 90% |

| 65C | 100% |

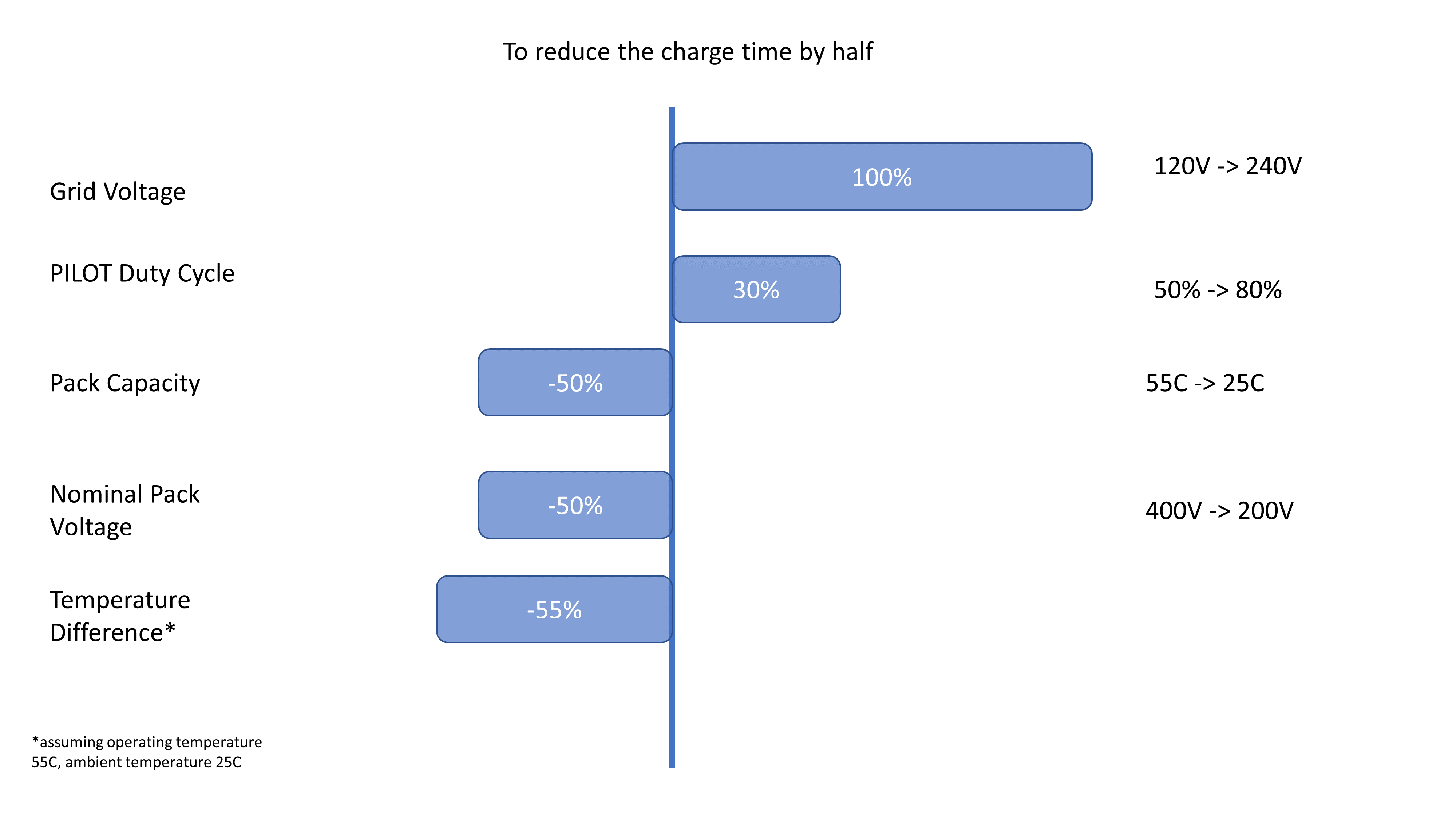

Sensitivity Analysis

Time to charge completely depends on the pack capacity, grid voltage and AC current sourced by the charger, which in turn depends on pilot duty cycle, on board charger power rating and gird voltage. Substituting values for IAc in the equations below, we get

Time to charge complete= ((100-SOC)*Pack_Capacity)/(VAc*(min(MAX_IAc,(OBC_(Max_Power ))/VAc)))

Cost=VAc*(min(MAX_IAc,(OBC_(Max_Power ))/VAc))*TimeUnderCharging*($/Wh)

Idc=(VAc*(min(MAX_IAc,(OBC_(Max_Power ))/VAc))*PF* η)/VDc*(100%-derate_pct)

Thus it can be seen that

- Going from 120V (normal wall outlet) to 240V (industrial outlet), doubles the AC charging current and reduces the charge time by half (other factors remaining constant)

- Charge time also depends on the pack capacity. A pack of half the capacity would charge in half of the time

- The cost, on the other hand, would remain the same if charging is performed at 240V compared to 120V as at 240V as effectively the user is putting same amount of power into the vehicle.

- The cost to charge would depend on the electricity rates though. E.g At night time $/Wh would be much lower than during noon time.

- The DC current is inversely proportional to the pack size. Ie If the nominal voltage of the pack is lower, the pack can be charged at higher DC current for the given wall power.

- The rate of charging (and hence effectively charge time) also depends on the difference between ambient and pack temperature. Higher the difference, the control algorithm would derate the power put into the pack, which would result in lower Idc, and hence higher charge time.

- The temperature difference between ambient and the pack depends on the cooling effectiveness of the system. More cooling plates in the system (N), higher surface area of each cooling plate (A), higher thermal conductivity (K), or thinner plates would aid better heat rejection, thus maintaining the temperature difference as small as possible – keeping the system charging at its maximum capacity.

Patents and Publications

Patents

- Managing electric current allocation between charging equipment for charging electric vehicles

Assignee – Chargepoint Inc Inventors – David Baxter, Carl Hagenmaier Jr., Milton Tormey, Richard Lowenthal

The total amount of current drawn through multiple charging stations that are wired on a same electrical circuit should not exceed a maximum amount of electric current supported by the electrical circuit to prevent the electrical circuit from being overloaded. This is achieved by communicating the current limits to the electric vehicles connected to the stations to not exceed individual current limits. The charging stations are to be connected with each other to share this current consumption data by multiple vehicles such that the total current from the grid is modulated to not exceed the limit.

- Detecting and responding to unexpected electric vehicle charging disconnections

Assignee – Chargepoint, Inc Inventors - David Baxter, James Solomon., Milton Tormey, Richard Lowenthal

It is important to detect and respond to unexpected electric vehicle charging disconnections. This is necessary to properly notify the stakeholders so that proper action could be taken and to eliminate safety hazards of having live voltage exposed to the environment. An electrical vehicle charging station establishes a charging session with an electric vehicle which includes energizing a power receptacle in the station While the charging session is established and responsive to detecting that a charging connection between the electric vehicle and the electric vehicle charging station has been unexpectedly disconnected, the power receptacle is de-energized to prevent electricity from flowing through the charging cord.

- AC current control of mobile battery chargers

Assignee – Tesla Inventors – Anil Paryani, Troy Nergaard, Andrew Baglino

A charging system and method that improves utilization of available AC power during onboard charging of energy storage systems of electric vehicles. In a charging method for an energy storage system of an electric vehicle using an AC power source, includes a) establishing a maximum DC charging current for the energy storage system responsive to a control signal indicating real-time available current/power from the AC source; and b) controlling a charging system to provide an actual DC charging current, up to the maximum DC charging current, to the energy storage system.

- Charge rate optimization

Assignee – Tesla Inventors – Kurt Kelty, Clay Kishiyama

It is important to optimize the charging profiles so as to reduce the charging time while maintaining battery thermals, cell degradation etc. This patent describes a system of transferring charging energy from the charging station to the battery pack at a maximum fast charge rate in a first operational mode and at a slower charge rate in a second operational mode; a data collection system acquiring a set of data indicating a state of charge (SOC) of the battery pack and one or more desired charge optimization parameters; and a station control, responsive to the set of data and to the desired charge optimization parameters, automatically establishing a charging profile for the battery pack to assert a control signal and operate the charging station in the second operational mode whenever the charging station is able to transfer sufficient energy to the battery pack at the slower charge rate to meet an SOC target and a charge completion time target, otherwise asserting the control signal and operate the charging station in the first operational mode

- Configurable battery pack for fast charge

Assignee – Rivian Automotive Inventor – Mason Verbrdge

Advances in charging technologies are coupled with advances in battery/ energy storage technologies. Pushing the boundaries of energy storage systems would open up more avenues of better/ more optimal charging. A configurable battery system may be arranged in such a way that two battery modules are connected in parallel to achieve a target maximum voltage for a load, or in series to achieve a high voltage of about double the target maximum voltage. Fast charging, at high voltage, may allow both battery modules to be charged at a charging current near a desired maximum current at the battery charger. A battery management module determines a switch configuration, coupling the battery modules in series or parallel. The battery management module applies the switch configuration to one or more switches to manage charging of the battery modules. The battery management module may receive charger capability information, local charging information, and fault information to aid in determining a switch configuration.

Publications

- Enabling Fast Charging – Vehicle Considerations

Andrew Meintz, et al., Journal of Power Sources, 2017

To achieve a successful increase in the plug-in battery electric vehicle (BEV) market, it is anticipated that a significant improvement in battery performance is required to increase the range that BEVs can travel and the rate at which they can be recharged. While the range that BEVs can travel on a single recharge is improving, the recharge rate is still much slower than the refueling rate of conventional internal combustion engine vehicles. To achieve comparable recharge times, this publication explores the vehicle considerations of charge rates of at least 400 kW. Faster recharge is expected to significantly mitigate the perceived deficiencies for long-distance transportation, to provide alternative charging in densely populated areas where overnight charging at home may not be possible, and to reduce range anxiety for travel within a city when unplanned charging may be required. This substantial increase in charging rate is expected to create technical issues in the design of the battery system and the vehicle's electrical architecture that must be resolved. This publication focuses on vehicle system design and total recharge time to meet the goals of implementing improved charge rates and the impacts of these expected increases on system voltage and vehicle components.

The paper goes over fast charging impacts on power electronics, vehicle thermal system impacts, impacts on increased insulation and creepage requirements, fusing, accurate SOC predictions at very high charging currents, charging interface and impacts on cyber security

- Evaluation of Fast Charging Efficiency under Extreme Temperatures

Germana Trentadue et al. European Commission, Joint Research Center Directorate C Energy, Transport and Climate, July 2018

Multi-type fast charging stations are being deployed over Europe as electric vehicle adoption becomes more popular. The growth of an electrical charging infrastructure in different countries poses different challenges related to its installation. One of these challenges is related to weather conditions that are extremely heterogeneous due to different latitudes, in which fast charging stations are located and whose impact on the charging performance is often neglected or unknown. This publication focuses on the evaluation of the electric vehicle (EV) charging process with fast charging devices (up to 50 kW) at ambient (25 ◦C) and at extreme temperatures (−25 ◦C, −15 ◦C, +40 ◦C).

As part of the study, three phase voltages and currents at the wall socket, where the charger was connected, as well as voltage and current at the plug connection between the charger and vehicle is recorded. According to SAE J2894/1, the power conversion efficiency during the charging process has been calculated as the ratio between the instantaneous DC power delivered to the vehicle and the instantaneous AC power supplied from the grid in order to test the performance of the charger. The inverse of the efficiency of the charging process, i.e., a kind of energy return ratio (ERR), has been calculated as the ratio between the AC energy supplied by the grid to the electric vehicle supply equipment (EVSE) and the energy delivered to the vehicle’s battery. The evaluation has shown a varied scenario, confirming the efficiency values declared by the manufacturers at ambient temperature and reporting lower energy efficiencies at extreme temperatures, due to lower requested and, thus, delivered power levels. The lowest and highest power conversion efficiencies of 39% and 93% were observed at −25 ◦C and ambient temperature (+25 ◦C), respectively

- Quantifying electric vehicle charging infrastructure gap across US markets

Dale Hall, Nicholas Lutsey, Technical Report, Internaltional council of clean transportation. January 2019.

This publication gives a snapshot of the state of art charging infrastructure in the US and a projection into 2025. The report goes over electric vehicle adoption trend and charging energy and charge units needed to keep up with increasing deployments of EVs. It also summarizes key sensitivities in charging infrastructure analysis – sensitivities like increased access to home charging on level 1 and level 2, increased non residential charging and their effects on DC fast charging. The report provides inputs on the gaps seen in this market