Mining the Martian Surface for in Situ Resources

Mars In Situ Mining Technology Roadmap

The technology roadmap identifier:

- 3MIM - Mars In Situ Mining

The number 3 denotes that this roadmap refers to a level 3. For this technology, Level 1 refers to the technology system required to mine, alter, and create resources on Mars, including various types of mining and electrolysis. The system for autonomous mining is a Level 2, and the sub-system (Level 3) of excavation is defined in this roadmap. A level 4 technology would consist of a sub-component of the excavation process, such as drill bits and power generation.

Roadmap Overview

Vital resources to construct habitats and sustain life on Mars are required in order for humans to visit and maintain on the "Red Planet". The current state of technology requires that all resources for human survival on Mars must be brought with astronauts or sent from Earth prior to the crew's arrival. There are limitations in the cost of sending cargo and mass-launch capabilities of current propulsion. One way to solve this discrepancy is to send and technology and machinery to Mars with the intent that it will be able to gather the vital resources in situ prior to the next launch window and human arrival. This roadmap focuses on the autonomous mining excavating technologies required to accrue water on Mars.

The Mars In Situ Mining extraction technology would fall under the matter transporting category of the functional taxonomy. We model our extraction technology on the extraction architecture deemed the most successful by Honey Bee Robotics’ most recent experiments on Planetary Volatile Extraction (PVEx). The extraction technology they deemed the most efficient approach in terms of both water extraction and energy consumption is referred to as the “corer” and takes the form of a dual wall coring auger.

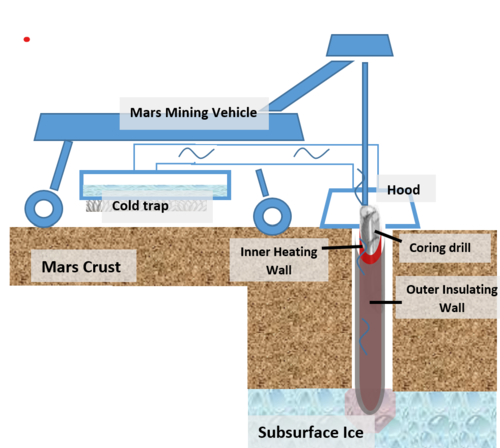

Figure 1 - Mars In Situ Mining Extraction Technology

Figure 1 was created by our team in order to graphically demonstrate the corer technology. The inner wall is composed of heaters, while the outer wall is composed of a composite, insulating material. Once the inner coring drill breaks through the crust and reaches ice, the inner wall begins to heat. Ice sublimation occurs, and the evaporated gas travels between the heated inner wall and insulated outer wall through a surface hood to the cold trap. Deposition occurs in the cold trap, turning the gas back into an ice form.

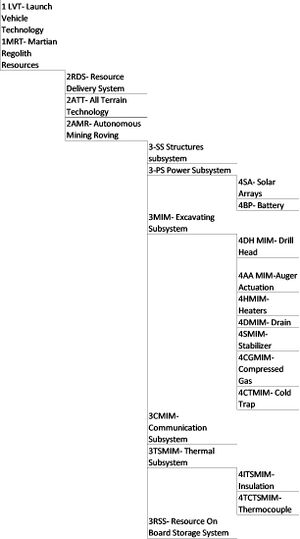

Technology Hierarchy Tree

The below technology hierarchy tree shows the break down of technology starting at L1 Technology (Mars Mining) and moving to L2 Technology (Autonomous Mars Mining). Our technology roadmap examines a L3 Technology (Mars In Situ Mining Extraction), which serves as an integral component of Autonomous Mars Mining. Our selected technology can be further broken down into L4 Technologies, such as the coring drill, the inner wall, and the outer wall.

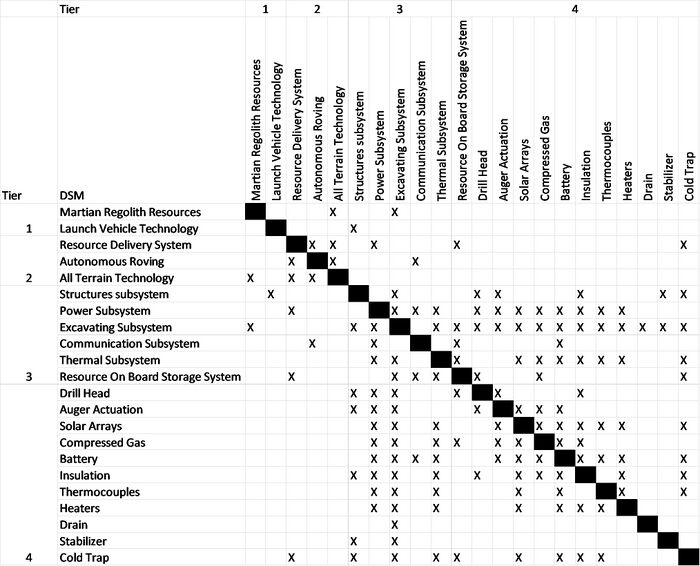

DSM Allocation

Below is the DSM Allocation for the interdependencies of the the systems and subsystems related to the technology roadmap. This diagram corresponds to the hierarchy tree in Figure 2. The extraction technology has numerous co-dependencies of systems, subsystems, and components. This will be further investigated to better understand the performance and timeline tradeoffs for the technology roadmap.

Figure 3 - DSM Martian Mining Technology Roadmap

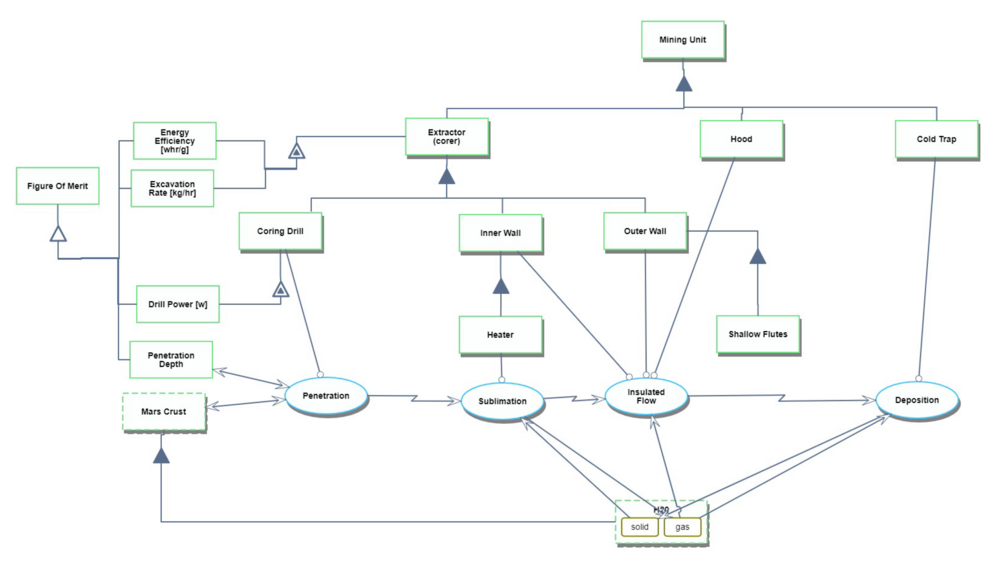

Roadmap Model using Object-Process-Methodology (OPM)

We created an Object-Process-Diagram (OPD) of the Mars In Situ Mining Extraction Technology below in Figure 4. The diagram serves to capture the main object of the roadmap, the corer, its decomposition into sub-components (coring drill, inner wall, outer wall), its characterization by Figures of Merit (FOMs) and the main processes of the system (Drilling, Heating, etc.).

Figure 4 - Ice Extraction OPD

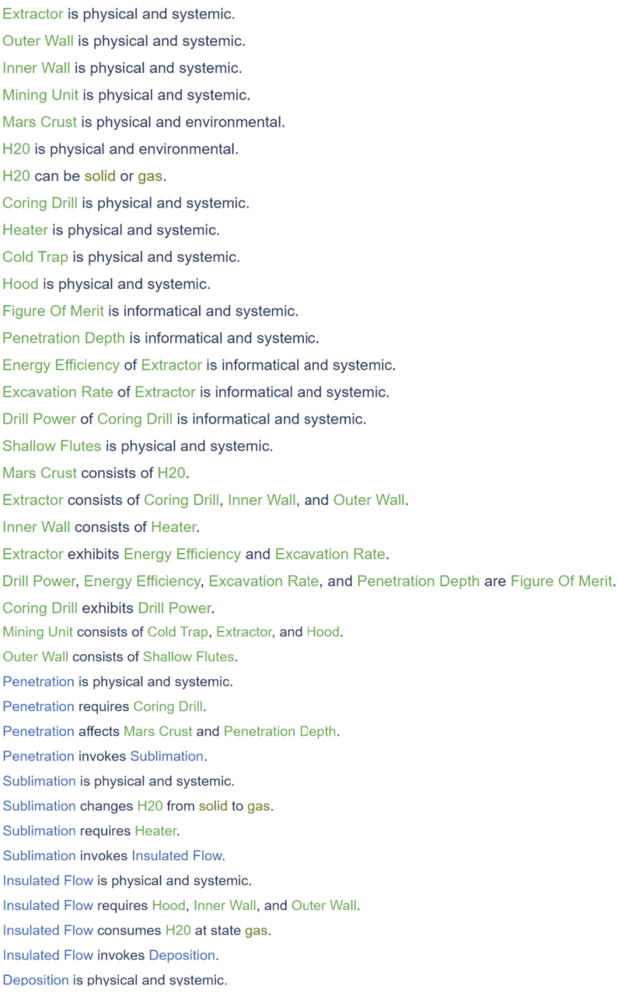

An Object-Process-Language (OPL) description of the above OPD provides a lingual breakdown of the OPD. The OPL is automatically-generated.

Figure 5 - Ice Extraction OPL

Figures of Merit (FOM) Definition

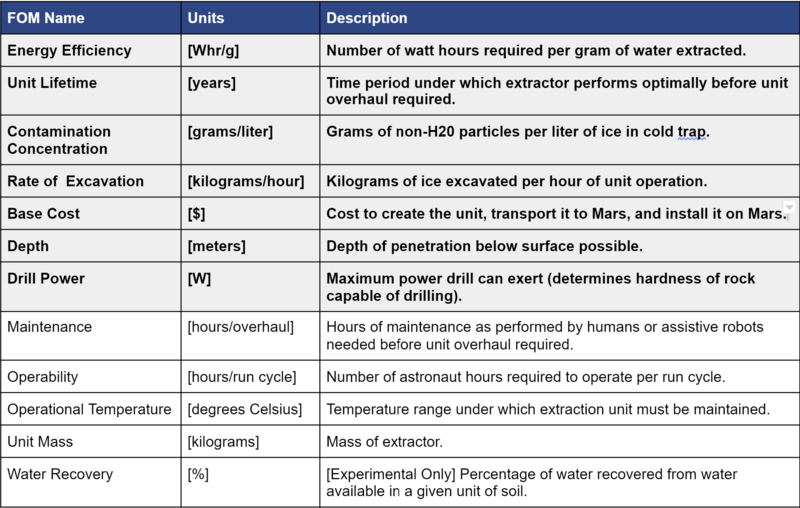

The table below shows a list of figures of merit by which a water extraction technology on Mars could be assessed. As a team we focused heavily on the bolded figures of merit in the table, and included a majority of them in the OPD.

Figure 6 - Ice Extraction Figures of Merit

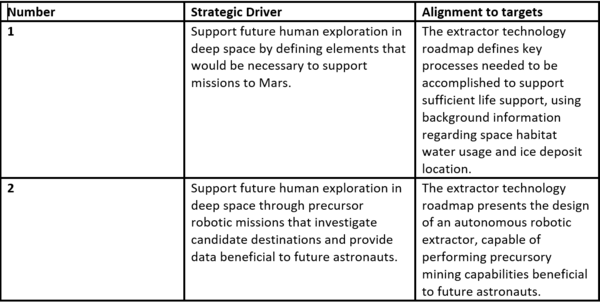

Alignment with “Company” Strategic Drivers: FOM targets

The two objectives represent a breakdown of NASA’s Strategic Objective 2.2, taken from the NASA Strategic Plan 2018.

Positioning of Company vs. Competition: FOM charts

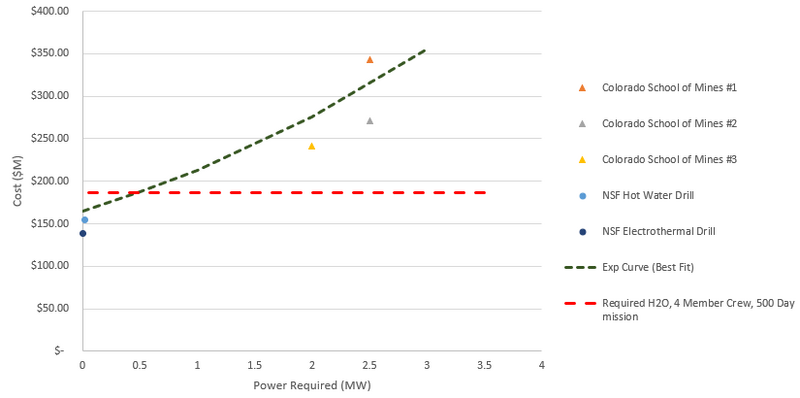

The market for interplanetary mining is still emerging, so to incorporate cost in the trade space of the various versions of celestial drills, a model based equation is used to correlate mass to one-time cost of producing and sending the drill to Mars for operation. The figure demonstrates the power required for operation versus cost as the main trade space of interest. The intent is to eventually normalize the power required by the amount of water extracted to create an efficiency, but that information is not available for the current models and additional analysis is required.

Figure 7 - Market Trade Space for Martian Mining

The red dotted line represents the threshold for cost to send water to sustain a 4-member Martian crew for 500 days. This is a crucial point since this would determine if the invested cost in a recurring water mining would be worth the investment. The triangles represent a fully autonomous thermal drills. It is noted that the initial cost of the these designs are approximately $150MM more expensive, they are more likely to be useful in a long term market since the cost of sending water to Mars one-time is $175MM water generation is expected to be a continual requirement with space exploration. Although the initial cost is higher for this method, it creates a continuous operation of water generation.

Technical Model: Morphological Matrix and Tradespace

The three designs by the Colorado School of Mines are reviewed in the morphological matrix. Below are the descriptions provided by the Colorado School of Mines:

Design #1.

Regolith excavated and transported to a central location for heating to sublimate water vapor and collect in a cold trap as ice.

Design #2. Regolith heated in place from heaters within boreholes drilled into the ice field. Ice collected on tarps across surface, tarps reheated at central location to transfer ice to cold traps.

Design #3. Sunlight directed from rim to dome-shaped capture tent for direct heating of the surface. Sublimated water captured in cold traps connected to tent.

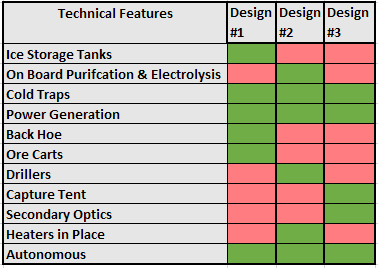

The morphological matrix shows the features that each of the designs offer.

Figure 8 - Morphological Matrix

Keys Publications and Patents

Publications

A Water Rich Mars Surface Mission Scenario

This paper serves as an assessment of how the presence of water on Mars could impact future human Mars mission scenarios. It discusses the location of the most promising water sources, known as feedstock, and analyzes how various rates of water extraction could support different human mission architectures.

The most promising feedstock are massive ice deposits at mid latitudes which bear resemblance to terrestrial glacial features. Various impact craters on these ice deposits expose verified, excavated clean ice under surface regolith. The regolith overburden is estimated to be less than two meters, making drilling to the pure water ice very feasible. Additionally, the location of these ice deposits at mid latitudes make them conducive to a permanent human settlement, unlike feedstock located at the poles.

Planetary Volatiles Extractor for ISRU

This paper describes experiments performed by Honeybee Robotics in which various different mining architectures were tested in their ability to extract ice from rock regolith. The findings and conclusion of this paper inspired our choice in drilling technology for our extracting system.

Three different technologies were tested in an environment simulating Martian temperatures and pressures. These technologies were the sniffer, the mobile in situ water extractor (MISWE), and the corer. The corer was determined to be the most efficient in terms of both power consumption and water extraction, and the least complex of the proposed systems.

The corer can be described as a dual wall coring auger. The inner wall is composed of heaters and the outer wall is made of an insulating material. After the drill penetrates the surface and captures a core, the heaters are turned on to sublimate the core. The volatiles will flow between the two walls, staying heated due to the insulated outer wall, into a cold trap on the surface. The insulating outer auger surface results in high power efficiency. The drilling efficiency is also high as opposed to a full face drill because the coring drill only cuts a small annulus. The corer also addresses the predicted problem of losing volatiles that sublime when reached. This is because the sublimed volatiles will flow directly into a capture system, mitigating any loss of resources.

Patents

Pivoting Cutter for Ice Coring Auger

Inventors: William E. Burch, Windsor, Vt.

Assignee: The United States of America as represented by the Secretary of the Army

US Patent 4,854,396

Date: Aug. 8, 1989

This U.S. Army patent describes an apparatus for cutting ice core specimens from a block of ice through the use of swivel cutter elements on the end of an ice coring auger. The swivel cutters swing outwards against the force of the contracting spring when ice is contacted to be cut. Once a core specimen is cut to the desired depth, the coring auger doesn’t continue down, but continues to rotate. Under reactive forces the swivel cutters move inward, resulting in a reduced neckline cut into the ice core specimen, allowing for the specimen to be broken cleanly from the sheet. The reduced in-diameter neck position in the ice core specimen provides a sharp break of the ice core specimen from the ice block.

Single Piezo-Actuator Rotary-Hammering (SPARH) Drill

Inventors: Stewart Sherrit, Xiaoqi Bao, Mircea Badescu, Yoseph Bar-Cohen

Assignee: California Institute of Technology

PCT/US2010/048112

Date: Mar. 17, 2011

This patent describes a low mass, low power, compact coring drill designed to operate under Martian ambient temperatures and pressures. The drill includes a horn actuator having high power piezoelectric materials in order to increase the effectiveness of the actuators. The drill is designed to be optimal for robotic platforms due to its low mass and low power constraints. This patent is important to understand how the materials and dimensions of an extraterrestrial drill increase its competitiveness and ultimately may be the deciding factor on whether it will be a feasible solution.

Core Drill and Method of Performing In-Situ Consolidation Testing of Permafrost Soil

Inventors: Guy Dore, Louis Gosslein, Cedric Flecheux

Assignee: Laval University

Canadian Patent 2,875,185

Date: Dec. 15, 2014

This patent describes an in-situ consolidation testing of permafrost soil, which is ground that is frozen year round. The technology is important to examine as it uses a core drill to apply heat to trapped water resources, similar to the way the dual wall coring auger technology we are examining. The patent’s proposed method applies heat to a sample of permafrost soil to thaw the trapped ice, and then extracts the thawed ice using downward longitudinal pressure to drain water from the sample. The objective of this method is to remove the water from the core sample, whereas the objective of our dual wall coring auger is to remove water from the regolith. While these two objectives remain different, studying the heating mechanisms and power supply of a similar technology is beneficial to compare to our dual wall coring auger.