Integrated and Co-located Pumped Hydro Reverse Osmosis Systems

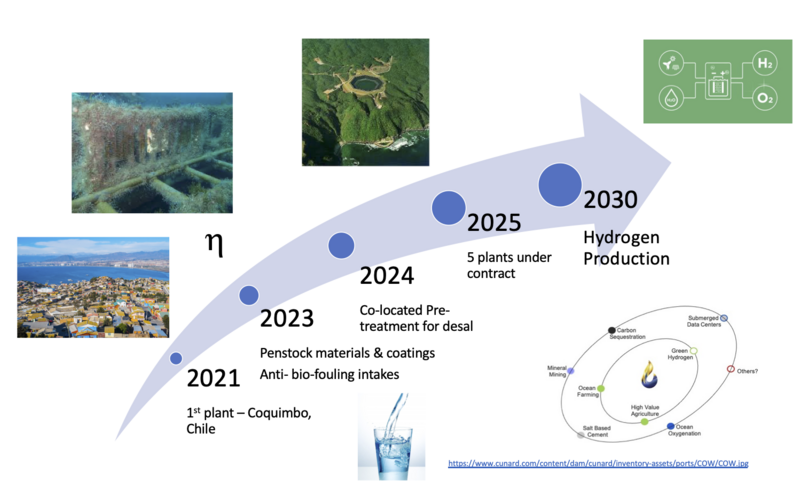

Roadmap Overview

- 1ICPHROS - Integrated and Co-located Pumped Hydro Reverse Osmosis System

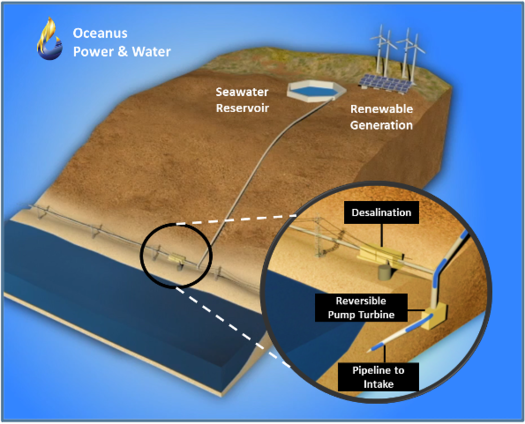

<ref>Oceanus Power & Water. https://www.oceanus.pw/. Accessed 27 Oct. 2020.</ref>

<ref>Oceanus Power & Water. https://www.oceanus.pw/. Accessed 27 Oct. 2020.</ref>

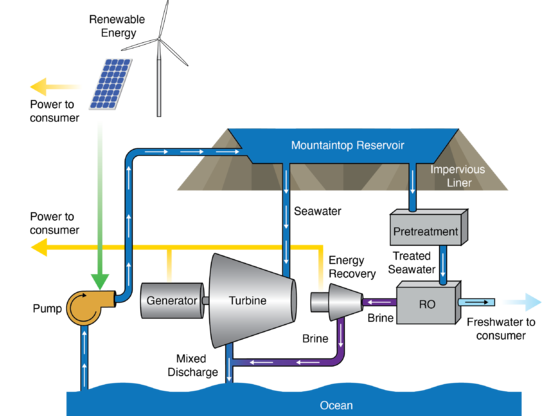

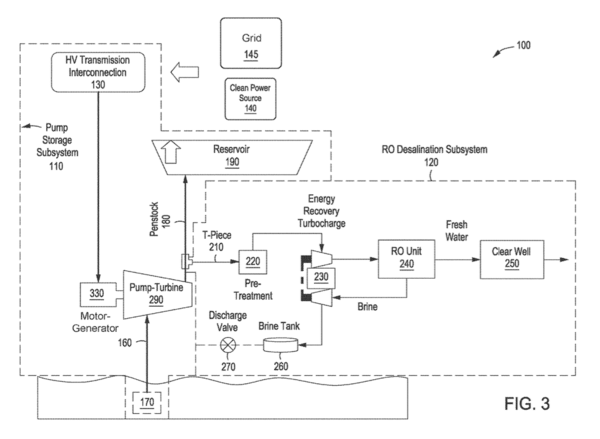

The United Nations identified safe drinking water and affordable, sustainable energy as two of its seventeen Sustainable Development Goals demonstrating the world-wide need for these commodities. Of note, 1 in 3 people in the world do not have access to safe drinking water and 13% of the world does not have access to modern electricity.<ref>United Nations Sustainable Development Goals. https://www.un.org/sustainabledevelopment/; Accessed Nov 2020.</ref> The integration and co-location of pumped hydro storage, hydropower and reverse osmosis desalinization plants provide both an affordable energy and freshwater source by optimizing efficiency and offsetting capital investments, reoccurring operations and maintenance costs and reducing risk to investors. Pumped hydro energy storage utilizes low cost, excess renewable energy (typically solar or wind) to pump seawater up to an elevated reservoir. When demand exceeds renewable power generation capacity, the elevated seawater is fed to hydro turbines at a lower elevation, at pressure, to generate electrical power for the grid. A small portion of the pressurized water is concurrently routed to the reverse osmosis desalinization plant under pressure, again at a lower elevation, negating the need for duplicative generators to produce freshwater. Shared infrastructure between the two systems, including the pumps, turbines, penstocks, piping and storage tanks, reduces not only capital expenditures but also operations and maintenance costs. In addition to affordable power and water, this integrated solution is environmentally friendly and neutralizes a negative by-product of the desalination process. The brine residual produced during the desalinization process is mixed with the outflow of the hydro turbines, effectively diluting the environmentally harmful solution before its return to the ocean.

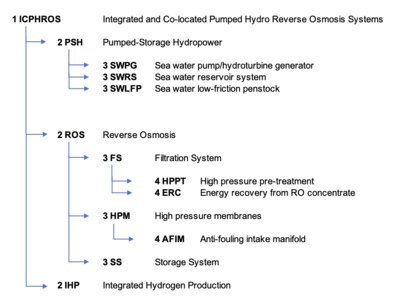

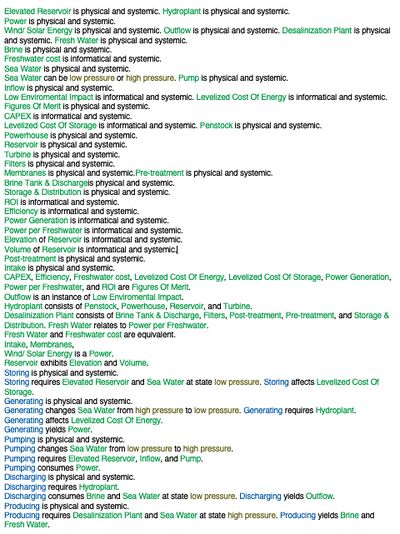

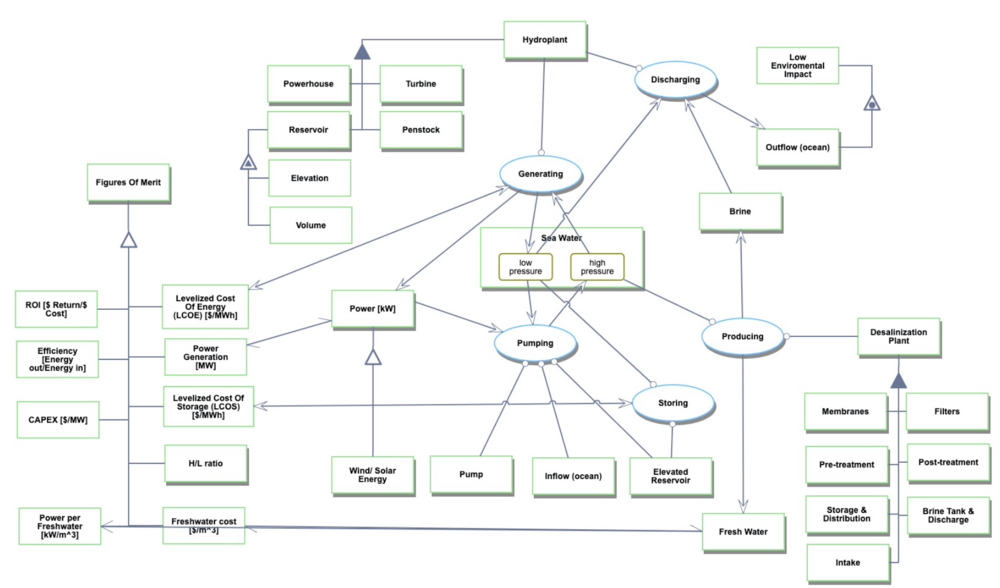

Design Structure Matrix (DSM) Allocation

This technology integrates two existing technologies in pumped hydro energy storage and reverse osmosis desalination into a co-located, symbiotic system. The DSM and formal breakdown illustrate this relationship where both systems share common components and sub-systems in order to deliver the emergent value. The "X" marks indicate physical interactions within the DSM. The Integrated Hydrogen Production system is a futuristic goal that takes advantage of both energy and freshwater being co-located to efficiently generate a third revenue stream. However, this portion of the system is not mature.

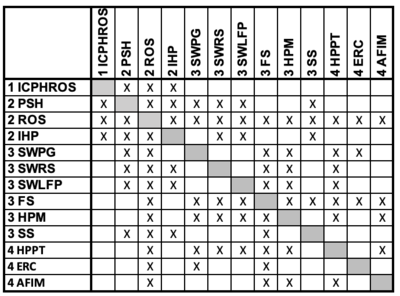

Object Process Diagram - OPD

We provide an OPD of the 1ICPHROS roadmap in the figure below. The OPD depicts the pumped hydro storage and power technology and its integration with a reverse osmosis desalination plant powered by renewable energy sources. Decomposition into the subsystems, processes, inputs, outputs, and the system's characterization by Figures of Merit (FOMs) are depicted as well.

An Object-Process-Language (OPL) description of the OPD is displayed below. It is a formal language interpretation of the OPD provided above.

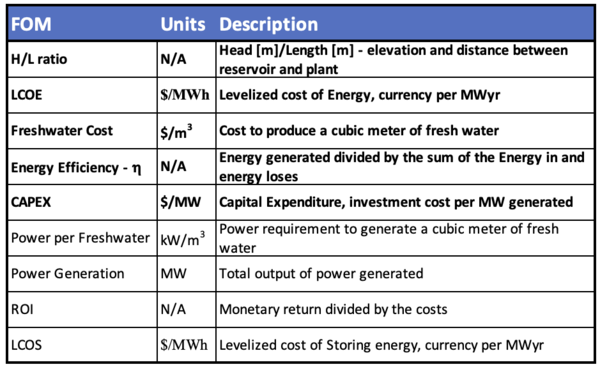

Figures of Merit (FOM)

The table below lists the FOMs by which Integrated and Co-located Pumped Hydro and Reverse Osmosis systems can be assessed. The hydropower industry uses Power Generation and the Levelized Cost of Energy as primary FOMs. The desalination industry uses Power per Freshwater and Cost per Freshwater as primary FOMs. The integration of these two systems does not have a FOM exclusive to this technology but certain FOMs apply to both such as the Head/Length ratio, Energy Efficiency and Capital Expenditure. Therefore, five primary FOMs are used to track this technology's advancement over time and compare it to stand-alone pumped hydropower and reverse osmosis desalination plants.

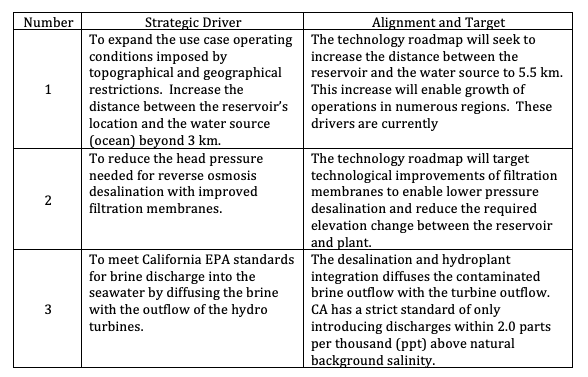

Alignment with Company Strategic Drivers

Integrated pumped hydropower and reverse osmosis systems require co-location to achieve necessary efficiencies, utilize sustainable power sources for pumped hydro storage applications and reduced capital investment in the plant, equipment and brine diffusion process. These integrated plants best serve communities seeking a reliable, sustainable and cheap power source as well as freshwater supply for populations and agriculture use. However, the topography further limits operations as the water source must be optimally located within 3 km of the reservoir, and the reservoir must have a 400 m elevation change from the desalination and hydropower plant. Oceanus Power and Water, LLC (Oceanus) is the only known business operating in this domain. Oceanus seeks to increase the applicability of this integrated business strategy and technological advancements in penstock construction and coating materials as well as turbine efficiencies can expand their markets. Furthermore, water production and power demand optimizations are needed to maximize efficiencies and deliver capital investment savings, reduce generation and operating cost and negate environmental liabilities. The system benefits are not exclusive to cost savings. There are significant benefits, both monetary and environmental, with the ability to diffuse the concentrated brine discharge from the desalination plant with outflow from the hydro turbines. California's current EPA standards are the global goal to minimize submarine environmental impacts.

| Number | Strategic Driver | Alignment and Target |

|---|---|---|

| 1 | To expand teh use case operating conditions imposed by topographical and geographical restrictions. Increase the distance between the reservoir's location and the water source (ocean) beyond 3 km. | | The technology roadmap will seek to increase the distance between the reservoir and the water source to 5.5 km. This increase will enable growth of operations in numerous regions. |

| 2 | To reduce the head pressure needed for reverse osmosis desalination with improved filtration membranes below 400m. | The technology roadmap will target technological improvements of filtration membranes to enable lower pressure desalination and reduce the required elevation change between reservoir and plant below 200 m. |

| 3 | Cell x | Cell y |

<ref>Water Quality Control Plan Ocean Waters of California, 2015. p. 107.</ref>

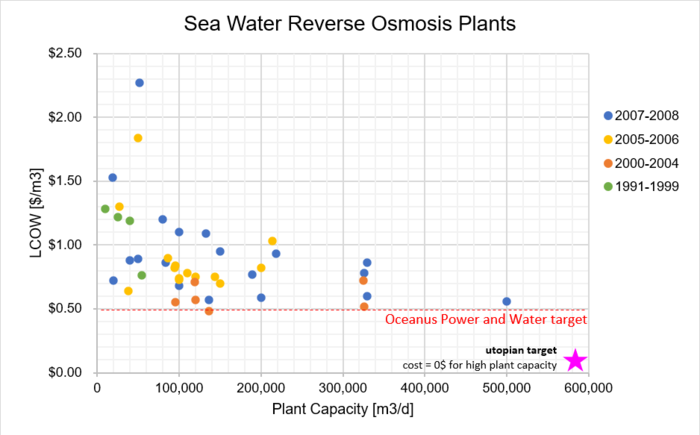

Positioning of Company vs. Competition

This integrated technology does not compete equivalently against stand-alone hydropower plants or reverse osmosis desalination plants because roughly 95% of the reservoir’s water is used for hydropower generation and 5% for freshwater production. Rather, it is the co-location and integration that yields greater efficiencies, reduced capital investments in equipment and infrastructure, cheaper production of energy and water than the stand-alone plants. Therefore, the FOMs for hydropower plant generation [kWh] and the power required to produce freshwater [kWh/m3] cannot be accurately compared. The roadmap sponsor, Oceanus Power and Water, has not completed its pilot development of this integrated technology in Chile but anticipates producing water at less than $0.50/m3. The figure below provides a look at the tradespace between LCOW and Plant Capacity with the current state of the sponsor's current position indicated.

<ref>Pankratz, Tom. "www.researchgate.net." n.d. October 2020. <https://www.researchgate.net/publication/299408931_COST_MODELING_OF_DESALINATION_SYSTEMS></ref>

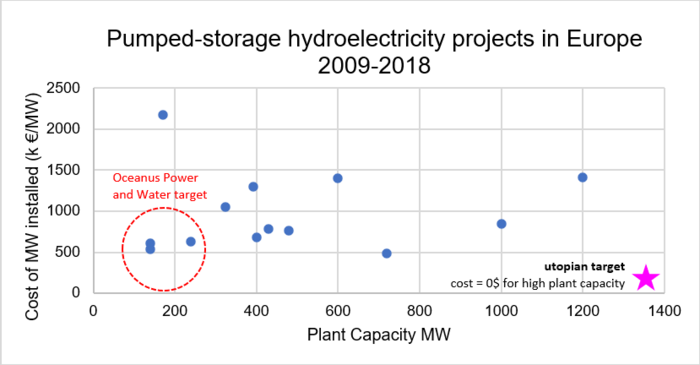

Within the pumped hydro storage system, Oceanus's current project in Chile anticipates producing 180 MW of power running 6 hours per day but plans to advance right toward greater capacities as indicated by the grey arrow.

<ref>Deane, J P, B.P. O Gallachoir and E. J. McKeogh. "Techno-economic review of existing and new pumped hydro energy storage plant." Renewable and Sustainable Energy Reviews 14 (2010): 1293-1302.</ref>

Technical Model: Morphological Matrix and Tradespace

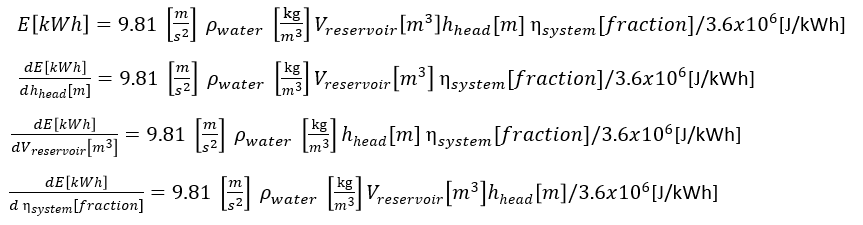

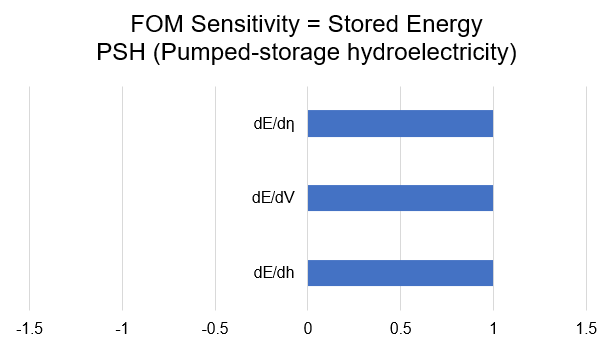

FOM #1: Stored Energy - PSH (Pumped-storage hydroelectricity)

The governing equation for stored energy, PSH (Pumped-storage hydroelectricity), is provided below and its derivatives were performed. The equation represents the physical phenomenon of the stored energy. For an integrated plant such as this project (co-located seawater storage and reverse osmosis plant) approximately 5% of the stored water is reserved for the reverse osmosis plant. The governing equation and partial derivatives are provided below as part of our analysis:

We chose the following design vector for calculation purposes.

Design Vector:

ρ𝑤𝑎𝑡𝑒𝑟 = 1020 kg/m3

Vr𝑒𝑠𝑒𝑟𝑣𝑜𝑖𝑟 = 106 m3

hℎ𝑒𝑎𝑑 = 400 m

ηs𝑦𝑠𝑡𝑒𝑚 = 0.8

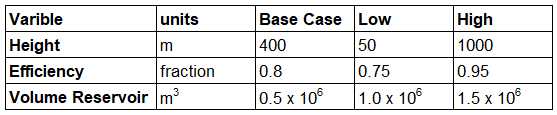

Because the sensitivity of all variables was 1 for the Pumped Storage Hydropower FOM, we conducted a sensitivity analysis based on the range of the values of each variable (shown in the table below) derived from our Morphological Matrix. The range of data was discovered in our literature review and during the meetings we held with the Roadmap sponsor.

We normalized and found the following relationships exhibited in the graph below:

The Stored Energy is highly dependent on the reservoir’s volume and height and less dependent on the efficiency of the storage system. These factors are directed related to the siting and location of the project installation and operation. Based on our literature review, we found that the location of the project will determine many key variables such as:

- Distance to the water source, which affects the efficiency of the system as longer distances represent higher dynamic losses.

- Natural topography and geology of the coast as it determines the height and the size of the reservoir.

- Market variables, which are not included in the governing equation, such as the existing demand for energy supply during peak hours and excess renewable energy available for storage.

It makes sense that the equation and the sensitivity analysis corroborate what we found in our research. Once the location is chosen, the dimensions of the variables of height and volume are determined. Following location selection, technology to improve the efficiencies best benefits the projects.

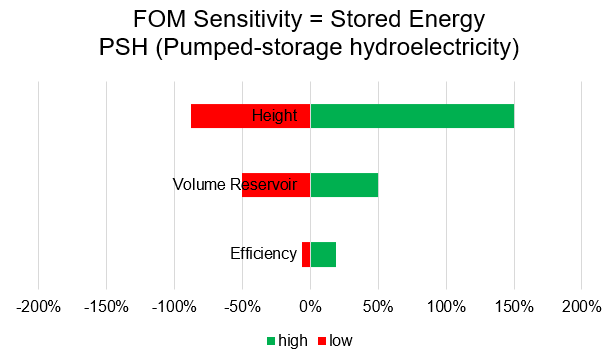

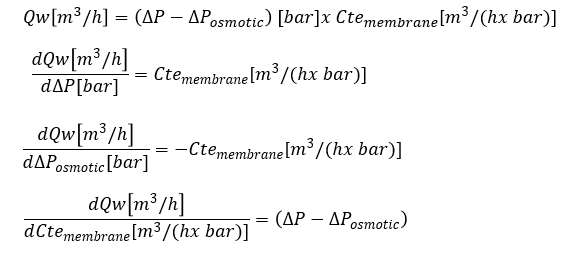

FOM #2: Water Rate - SWRO (Sea Water Reverse Osmosis)

The governing equation for water flow rate, derived from SWRO (Sea Water Reverse Osmosis), is provided below and its derivatives were performed.

We chose the following design vector for calculation purposes.

Design Vector (membrane SW 30-4040 Dow Filmtec):

Qw = 0.2 m3/h

Osmotic Pressure = 27.6 bar

Operational System pressure = 68.9 bar

Cte = 0.00484 𝑚3/(ℎ b𝑎𝑟)<ref>Valladares Linares, R., et al. “Forward Osmosis Niches in Seawater Desalination and Wastewater Reuse.” Water Research, vol. 66, Dec. 2014, pp. 122–39. ScienceDirect, doi:10.1016/j.watres.2014.08.021.

</ref>

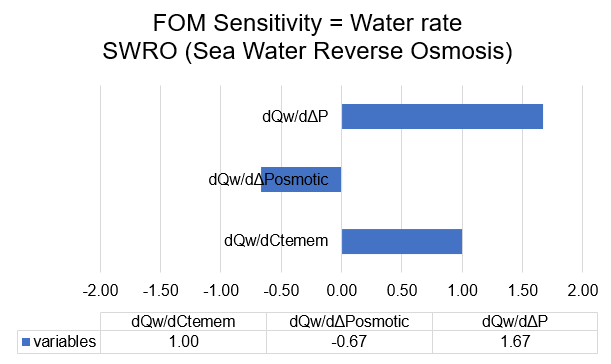

We normalized and found the following relationships exhibited in the graph below:

For the 1ICHROS Roadmap, the operating pressure is related to the height of the water reservoir for head pressure. A minimum height is needed for the RO membrane to perform effectively. Additionally, future technological advancements in membranes could enable lower operating pressure levels (lower height for the water reservoir). Therefore, the performance of the membranes at lower values of pressure could have a profound impact on the flow rate and generation of freshwater.

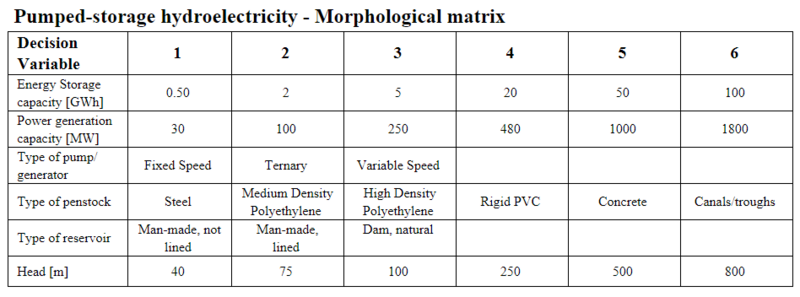

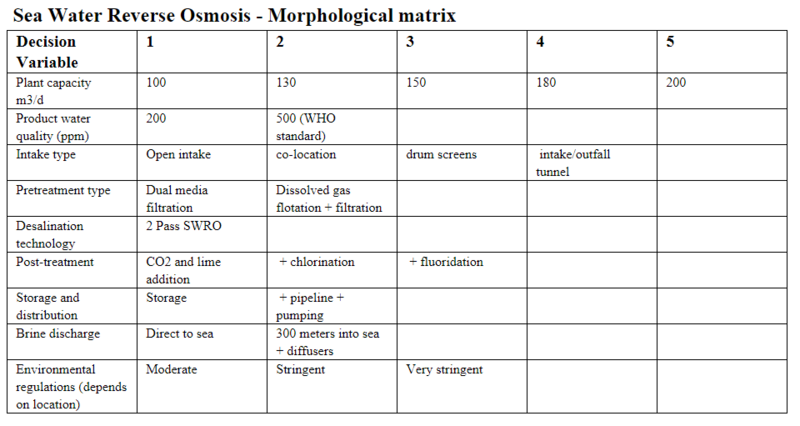

The morphological matrices for the pumped hydro storage and reverse osmosis desalinization systems are provided below. The matrices identify decision variables important to the design that will affect the overall performance of the system. As noted in the technical assessment above, efficiency is an important parameter for both storing and generating energy and producing freshwater. The pumped hydropower system’s efficiency is determined primarily by the turbines, pumps, and generators. It is also captured in the friction of the water as it transits through the penstocks from the reservoir to the plant. Additionally, the pressure head is an important variable for both the hydropower generation and the desalination process. Therefore, location, topography, and geography are all important factors.

<ref>“Draft Hydropower Pumped Storage Tracking Tool (Update Dec.2018).” Tableau Software. public.tableau.com, https://public.tableau.com/views/DraftHydropowerPumpedStorageTrackingToolupdateDec_2018/Story1?:embed=y&:showVizHome=no&:host_url=https%3A%2F%2Fpublic.tableau.com%2F&:tabs=no&:toolbar=no&:animate_transition=yes&:display_static_image=no&:display_spinner=no&:display_overlay=yes&:loadOrderID=0. Accessed 27 Oct. 2020.</ref>

Financial Model

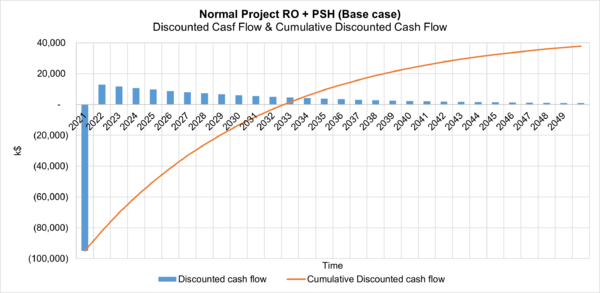

This analysis is not specific to Oceanus Power and Water. Two financial models were built to assess technological advancements in 1ICPHROS:

- Base case: An generic economic model of a possible project with a co-located Reverse Osmosis plant and Pump Hydro Storage plant for current conditions.

- Improved case: It has the same structure as the base model but considers technology advancements discussed in the R&T Projects section than can be achieved after investment.

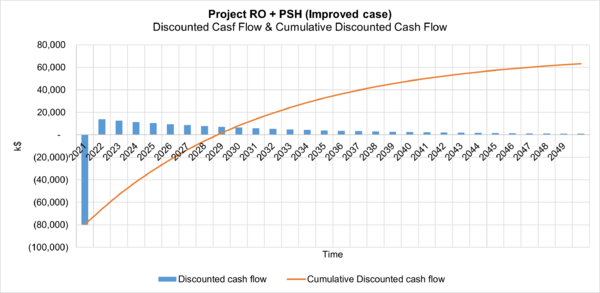

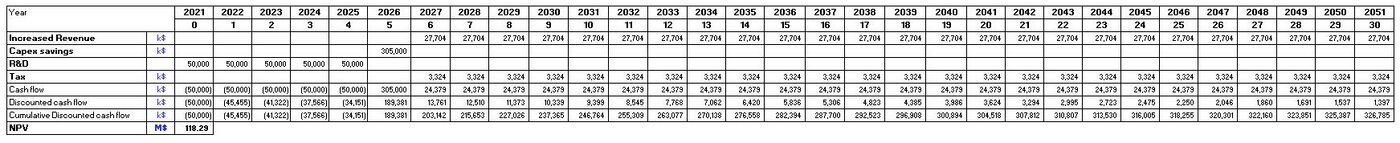

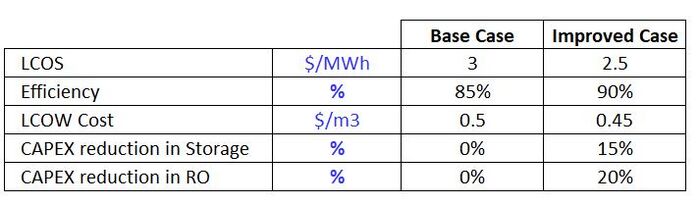

Achievable advancements in a few system components yield significant improvements in critical FOMs. The financial assessment displays achieving a positive NPV in 2029, nearly 4 years earlier than the base model. Furthermore, the out-year benefits are accentuated promoting a robust R&D investment. The differences between the two models is exhibited in the following table:

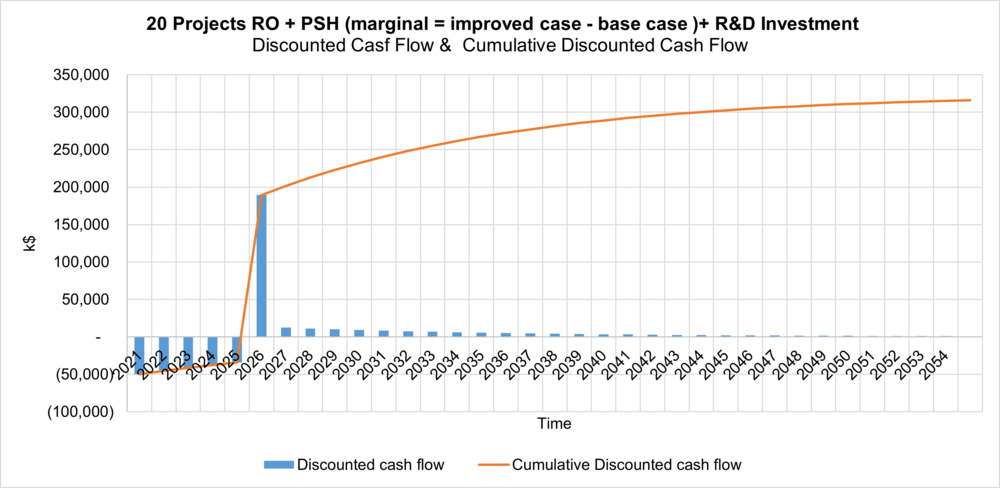

The difference between the two projects (Improved case - Base case) is the "marginal" project. The following chart shows the Discounted Cash flow and Cumulative Discounted Cash Flow for a hypothetical project that considers:

- R&D Investment of 250 million USD in five years (5 Million/year). This investment allows the projects to go from the "base case" to the "improved case."

- 20 "marginal" projects all over the world, developed in 2025 by many companies throughout the industry that collectively invest in R&D.

Disclosure: These charts/models will be updated if/when we receive feedback from Oceanus Power and Water.

List of R&T Projects

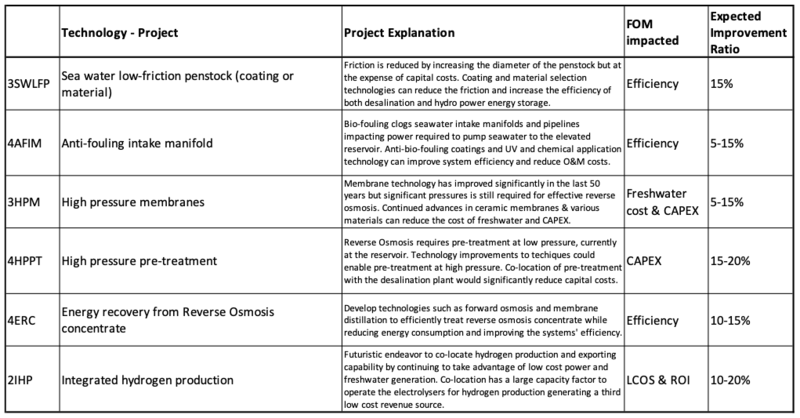

Based on the Technical and Financial Models provided, we recommend a multi-pronged approach to advance the 1ICPHROS technology. As mentioned previously, no single FOM applies to both pumped hydro energy storage and reverse osmosis desalination. However, improvements in system efficiency benefit both the hydropower and storage plant as well as the desalination plant in the form of LCOE, Freshwater Cost, and LCOS. Furthermore, implementation of 1ICPHROS is currently restricted by geographical and topographical constraints based on the necessary head pressure, associated with the elevation change, and the friction loss induced by the distance between the reservoir and the plant. Reducing this Head to Length (H/L) ratio for optimal pumped hydro energy storage and freshwater generation will increase the number of the possible locales for co-location and implementation. Furthermore, continued R&T is needed to relocate the pre-treatment of seawater for desalination to the plant vice the reservoir and also improve the effectiveness of Reverse Osmosis membranes at lower pressures, thus lower elevations. See the table below for additional information on these R&T efforts, improvement estimates obtained from cited references:

<ref>Voutchkov, N. (2018). Energy use for membrane seawater desalination – current status and trends. Desalination, 431, 2–14. https://doi.org/10.1016/j.desal.2017.10.033

</ref><ref>Leal, J. (2020, November 10). Oceanus Power and Water, LLC. [Personal communication].

</ref>

<ref>Voutchkov, N. (2018). Energy use for membrane seawater desalination – current status and trends. Desalination, 431, 2–14. https://doi.org/10.1016/j.desal.2017.10.033

</ref><ref>Leal, J. (2020, November 10). Oceanus Power and Water, LLC. [Personal communication].

</ref>

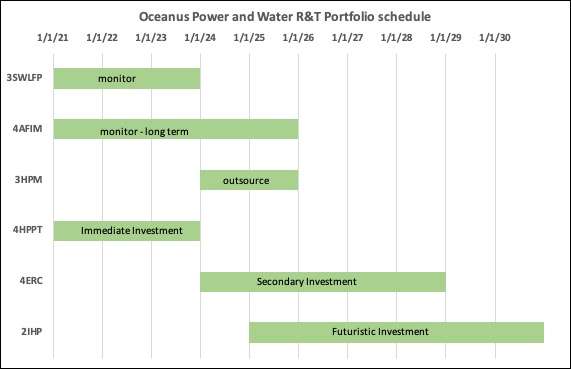

In 2018 and 2019, Oceanus Power and Water invested approximately $225,000 to Research and Development each year. This level of investment accounts for approximately 20% of the total capital raised or revenue per year. Efficiency advancements, such as coatings and materials that reduce friction and prevent bio-fouling, are shared across numerous technologies beyond just pumped hydro energy storage and reverse osmosis (RO). Improvements in these components will impact industries across the spectrum including oil and gas, commercial shipping and marine construction to name a few. Monitoring this development and remaining poised to integrate it once mature and proven is our recommended course of action. Membranes used in reverse osmosis have advanced considerably over the last 2 decades reducing the cost of freshwater by nearly 50%<ref>Voutchkov, N. (2018). Energy use for membrane seawater desalination – current status and trends. Desalination, 431, 2–14. https://doi.org/10.1016/j.desal.2017.10.033</ref>. The advancement of ceramic membranes may enable lower pressure desalination allowing for greater selection of co-location as well as lower pressure, higher efficiency and lower capital expenditures. We recommend investing in this project with desalination industry partners to help grow the number of co-location projects as soon as possible.

We recommend an immediate R&D effort to co-locate the pre-treatment for RO desalination at the plant under higher pressure. At an estimated 15-20% reduction in capital expenditures due to eliminating redundancies, pumping freshwater up to the reservoir, and less infrastructure, the value proposition of this effort is significant from both a RO plant technological perspective, as well as the reduced cost to investors. Additionally, this project is specific to the integrated system as most desalination plants use pumps already co-located with their plants to generate the required pressure vice the 1ICHPROS that uses elevation or head pressure. Membrane development, bio-filters and pre-treatment method improvements evolve through other industy efforts to address current limitations. However, after improving the process to enable pre-treatment at high pressure, the next shorter-term R&D efforts we recommend aligns with the RO industry in improving both the membrane technology to reduce desalination pressures and the energy recovery from RO concentrate using a forward osmosis process and membrane distillation.

Finally, Oceanus Power and Water has already looked beyond its current development in Chile and other projects world-wide to the horizon. Integrating and co-locating hydrogen production with the 1ICPHROS system would add a third revenue stream and take advantage of being located next to a clean, renewable energy source and freshwater producer. This advantage could reduce Hydrogen production costs by as much as 20% in an exportable seaside location. This is a long-term, futuristic technology development with considerable upside, but also significant risk due to the massive infrastructure investment required to bring pumped hydro energy storage, reverse osmosis desalination and hydrogen production to a single locale. Our project valuation was conducted using pairwise comparison to yield the greatest benefit for Oceanus P&W. We used this method because of the limited number of projects we considered for a limited R&D budget. Additionally, pumped hydro energy storage and RO desalination are relatively proven technologies where the diversity of advancements impact multiple FOMs. The schedule below depicts the recommended timing for the projects:

Key Publications and Patents

Publications

Integrated System Articles

1. Slocum, Alexander H., et al. “Integrated Pumped Hydro Reverse Osmosis Systems.” Sustainable Energy Technologies and Assessments, vol. 18, Dec. 2016, pp. 80–99. ScienceDirect, DOI:10.1016/j.seta.2016.09.003.

Slocum et al. assessed integrated pumped hydro reverse osmosis systems as a “symbiotic match” between pumped hydropower and storage and desalination using reverse osmosis. The article explores the topographical restrictions for application of this integrated solution and concludes that there are many benefits to the co-location and integration of these existing technologies. This article furthers the need to explore opportunities to reduce the H/L ratio below 0.10 to expand the locales of opportunity.

2. Bowen Zhou, Boyu Liu, Dongsheng Yang, Jun Cao, Tim Littler. Multi-objective optimal operation of coastal hydro-electrical energy system with seawater reverse osmosis desalination based on constrained NSGA-III. Energy Conversion and Management, Volume 207, 2020, 112533, ISSN 0196-8904, https://doi.org/10.1016/j.enconman.2020.112533.

This recent article explores the optimization of the integrated system. The non-dominated sorting genetic algorithm (NSGA-III) is employed to optimize the cost of the hydro-electrical energy system and look at the sensitivity of the various parameters involved with desalination. This article explores integrated system implementation approaches tailored to optimize the costs and desalination parameters reinforcing the integration of energy storage and freshwater production.

3. Segurado, R., et al. “Optimization of a Wind-Powered Desalination and Pumped Hydro Storage System.” Applied Energy, vol. 177, Sept. 2016, pp. 487–99. ScienceDirect, DOI:10.1016/j.apenergy.2016.05.125.

This article seeks to optimize the integration of pumped hydropower/hydro storage and desalination. The authors use the Direct MultiSearch method to find the optimal sizing and implementation strategy for the integrated system. The analysis yields a Pareto front using power costs and water supply costs as parameters in tension while using wind power for desalination and pumped hydro storage. This study helps understand the tension between two primary FOMs, LCOE and Freshwater cost.

Pumped Hydro Energy Storage Articles

4. Rehman, Shafiqur, et al. “Pumped Hydro Energy Storage System: A Technological Review.” Renewable and Sustainable Energy Reviews, vol. 44, Apr. 2015, pp. 586–98. DOI.org (Crossref), DOI:10.1016/j.rser.2014.12.040.

A recent review of pumped hydro energy storage systems using alternative sustainable energy sources including photovoltaic and wind turbines provides excellent insight and recent status of the pumped hydroelectric power generation capability. This article concluded the topographical restrictions for this technology are simplified to the H/L ratio. Cost-effective plants currently being built and operated have an H/L ratio of less than 0.1.

5. Botterud, A., Levin, T., & Koritarov, V. (2014). Pumped Storage Hydropower: Benefits for Grid Reliability and Integration of Variable Renewable Energy. https://anl.app.box.com/s/tphlklclz9xu5lv79n2gzv2cfauuvmwv

Pumped Storage Hydropower: Benefits for Grid Reliability and Integration of Variable Renewable Energy published by the Argonne National Laboratory in August 2014 assessed the viability of pumped hydropower and hydro storage. It concluded that this technology is “a proven, cost-effective solution to large-scale energy storage.” It also discussed ancillary benefits and encouraged the conversion from fixed-speed to variable-speed turbine technologies. This study advanced the discussion on methods of improving efficiency in the pumped hydro energy storage technology.

Desalination System Article

6. The Cost of Desalination - Advisian. www.advisian.com, https://www.advisian.com:443/en/global-perspectives/the-cost-of-desalination. Accessed 26 Oct. 2020.

This article provides an overview of the desalination process and its history since the 1960s. There is incredible growth around the world in the desalination process. Concerning costs, the authors used an important figure of merit cost to produce a cubic meter of freshwater [USD$/m3]. It gave estimates ranging from $0.70/m3 to $3.20/m3, mostly dependent on the capacity of the plants. Most interesting was the CAPEX breakdown for each of the reverse osmosis salination subprocesses (i.e. pretreatment, brine discharge or storage) that can be used for comparison to an integrated system.

Patents

1. US 2018/0290902 A1 – US Patent - Integrated system for generating, storing and dispensing clean energy and desalinating water. Applicant Oceanus Power and Water. The US patent application was published in October 2018 and approved in November 2020. It claims novelty of the integration of existing technologies, pumped hydropower and desalination, as well as solar and wind power generation plants to generate power for a co-located and integrated system. This patent explicitly states that the system consists of a hydraulic storage facility, desalination plant and a penstock that connects the storage facility and desalination plant. This patent could be expanded in the future to address advancements in reducing the H/L ratio and system efficiency. Furthermore, if hydrogen production becomes a reality, this patent would require an amendment to enable Oceanus to bring all three technologies together in a market application.

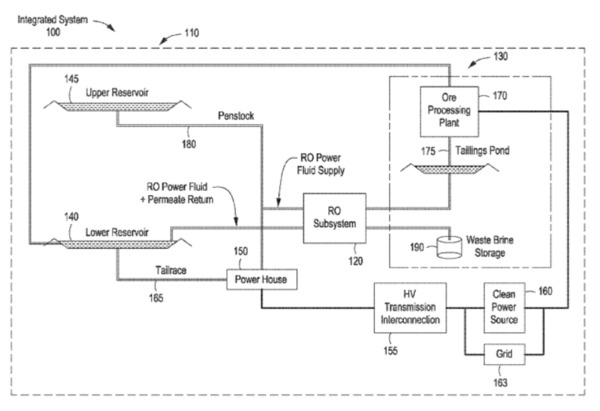

2. WO 2018/191163 A1 – International Publication – An Integrated System for Supplying Clean Water and Clean Energy to the Mining industry. Applicant: Oceanus Power and Water. This international patent application was filed in published in October 2018 and is under review. It claims novelty of the integration of pumped hydropower with processing ore feedstock in mining operations including the treatment of contaminated water. The application of the integrated system is specific to mining operations which require significant energy for “excavation, crushing, milling and transportation,” as well as freshwater for mineral and petroleum product extraction. This is a specific application of the integrated system.

3. US 2019/0046931 A1 – US Patent Application – Separation membrane. Applicant Toray Industries, Inc. The patent application was received in 2019 is outstanding and in the review process. It provides a novel approach to a separation membrane necessary for reverse osmosis (RO) desalination processes. It evolves on an existing invention regarding separation membranes and reducing the number of defects. Advancements in membrane technology can enable RO with lower pressures or minimize the need for pre-treatment at low pressures (at the reservoir). This patent demonstrates that there are efforts underway to use ceramic-based membranes to enable lower pressure RO, thus yielding flexibility in the H/L ratio. It reinforces the recommendation to outsource the investment in advancing membrane technology for the integrated approach to desalination.

Technology Strategy Statement

The primary objective of the Integrated and co-located pumped hydro reverse osmosis system is to provide low-cost energy storage and freshwater to communities in need of both commodities (water and power). Our recommended approach tackles the two greatest obstacles to the rapid growth and implementation of co-located, integrated pumped hydro energy and desalination plants: 1) geographical/topographical limitations and 2) reducing the installation and O&M costs. The Head to Length (H/L) ratio emerged from our analysis demonstrating the greatest influence on the geographical and topographical limitations. Improving the H/L ratio for most applications from current minimums of 0.1 will enable plants to be built further from the ocean with less elevation change, opening up more communities to this technology. The variable having the greatest effect on reducing plant costs involve efficiency in both pumped hydro storage and generation as well as desalination. Efficiency is improved in a multitude of ways but the latest advancements in membrane technology and the ability to co-locate pre-treatment infrastructure with the rest of the plant offer the greatest return on investment. Due to these findings, we recommend R&D efforts that promote the greatest return in these valued areas including efficiency, reduced capital expenditures, freshwater cost and the cost of energy to attract government and community investment and its accelerated adoption.

Completing the first integrated project in Chile this year can launch this integrated technology to rapid adoption. We anticipate other industries to advance coating and material technologies to reduce friction at the seawater intakes, pipelines and penstocks improving efficiency by 2023. We recommend investing over the next three years exclusively in co-locating the desalination pre-treatment at the plant instead of the reservoir. This advancement is specific to this integrated solution where pressure is achieved through head elevation and offers a critical 15-20% in capital expenditure savings. To reach our goal of initiating contracts for 5 plants by 2025, we recommend investing in both the ability to pre-treat water for RO desalination at high pressure (4HPPT) and membrane technology to achieve RO desalination at lower pressures. Both of these are enabling technologies that will reduce CAPEX and reduce H/L ratios.

Finally, this technology takes advantage of co-locating and integrating two existing technologies. Expanding upon this method to include adjacent markets such as hydrogen production is a futuristic goal for Oceanus. Adding a third, high-value revenue stream would continue to open up the applicability of this integrating technology to other parts of the world and in turn lead to more plants generating freshwater, clean energy and a hydrogen fuel source!