¶ Mycelium Processing and Packaging - 2MPP

¶ 1. Roadmap Overview

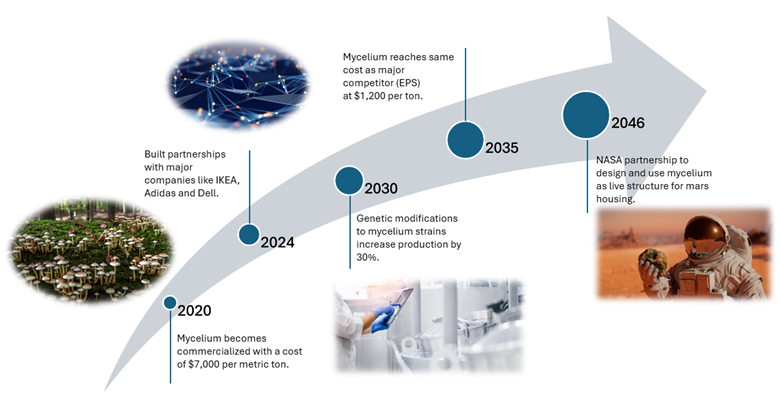

Mycelium, the vegetative network of fungi, serves as a natural binder that rapidly colonizes and fuses low-value agricultural waste (substrate) into a stable, durable bio-composite. Beyond its environmental sustainability derived from utilizing agricultural waste and requiring low-energy, ambient production conditions, mycelium-based materials are gaining significant traction as a functional alternative to petroleum-derived plastics in construction, fashion, and protective packaging.

A critical competitive advantage is the rapid biomanufacturing cycle. While traditional manufacturing of plastic and foam materials relies on complex, global supply chains, mycelium packaging is grown, dried, and finished in approximately 5 to 7 days. This dramatic reduction in production time strengthens supply chains, enables decentralized manufacturing, and positions the technology as a disruptive, high-performance, and regenerative solution for meeting sustainable needs.

The core focus of this roadmap is the commercialization and scaling of Mycelium technology within the protective packaging industry. This technology transition could represent a fundamental shift from an extraction-based linear economy to a cultivation-based circular model.

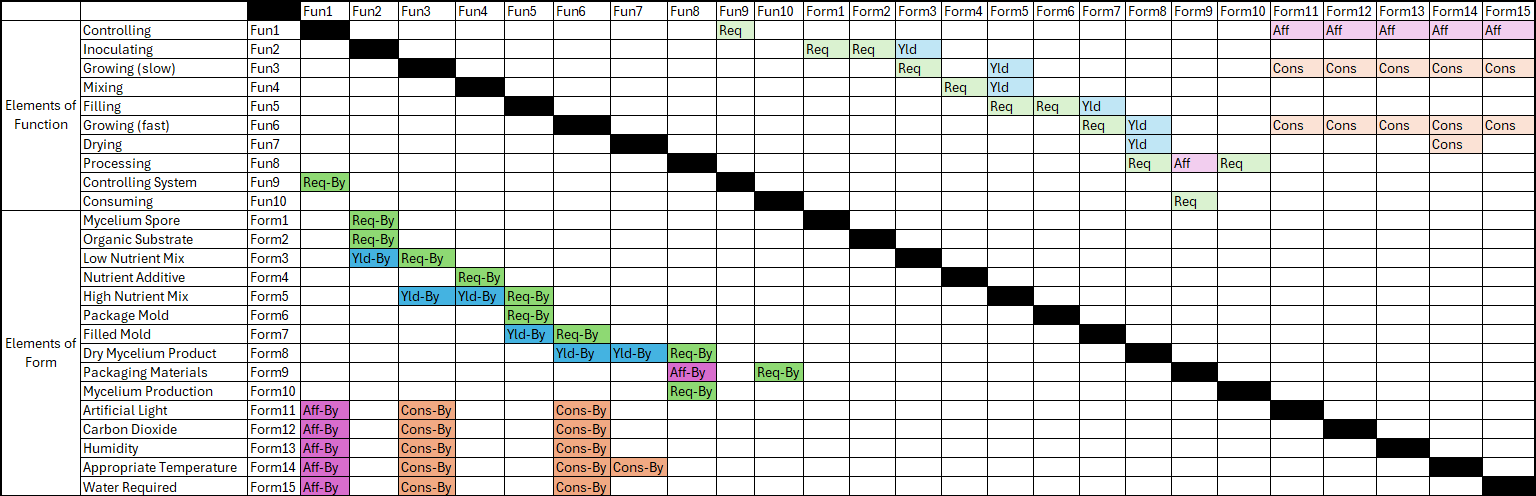

¶ 2. Design Structure Matrix (DSM) Allocation

¶ 3. Roadmap Model using OPM

.jpeg)

¶ 4. Figures of Merit (FOM)

Group 1 relates to the “Growing” phase and group 2 relates to the product packaging.

(Definition, name, unit, trends dFOM/dt)

| Grouping | Name | Definition | Units | Trend |

| 1 | Energy Consumption | Energy required to produce a kg of mycelium | kWh/kg-mycelium | Decreasing |

| 1 | Carbon Intensity | CO2 emissions per unit of mycelium produced | kgCO2e/kg-mycelium | Decreasing |

| 1 | Cost of Mycelium | A quantity (kg) of mycelium produced, the total cost of all variable inputs required | $/kg-mycelium | Decreasing |

| 1 | Space Required | Amount of physical area needed to produce material | Sq ft/kg | Negligible |

| 1 | Time to Value | Number of days from growing to delivered benefit | Days | Decreasing |

| 2 | Shelf Life | Time product remains usable | Years | Negligible |

| 2 | Industrial Compostability | Time for the material to completely break down in composting conditions | Days | Negligible |

| 2 | Marine Compostability | Time for the material to completely break down in composting conditions | Days | Negligible |

| 2 | Compressive Strength | Maximum stress material can withstand while being compressed before failure | Psi | Increasing |

| 2 | Resistance to Heat Flow | Ability to resist heat transfer | R Value/in | Negligible |

¶ 5. Alignment of Strategic Drivers: FOM Targets

The following table contains the strategic drivers for our company and the alignment between FOM targets and the 2MPP technology roadmap:

| Number | Strategic Driver | Alignment and Targets |

| 1 | To develop an efficient manufacturing process for mycelium packaging that meets performance goals and competes economically with existing fossil fuel-based packaging | The objective is to reduce the cost per ton of manufacturing mycelium by 50% to disrupt traditional fossil-fuel-based products. An FOM target of $1,500-2,000 per metric ton of mycelium is determined as the threshold for market competitiveness. This driver is currently aligned with the technology roadmap. |

| 2 | To increase market adoption by demonstrating comparable performance as EPS and creating a strong value proposition for sustainable packaging | The objective is to validate material performance through pilot programs with large industry partners. By increasing the shelf life (in years) and reducing the Time to Value (in days), it will achieve higher customer satisfaction and market share. This driver is currently aligned with the technology roadmap. |

| 3 | To leverage mycelium’s regulatory and sustainability strengths that meet and exceed global environmental standards | The objective is to ensure compliance with biodegradable standards while achieving life cycle GHG intensity < 0.1 kg CO2eq/kg. This driver is currently aligned with the technology roadmap. |

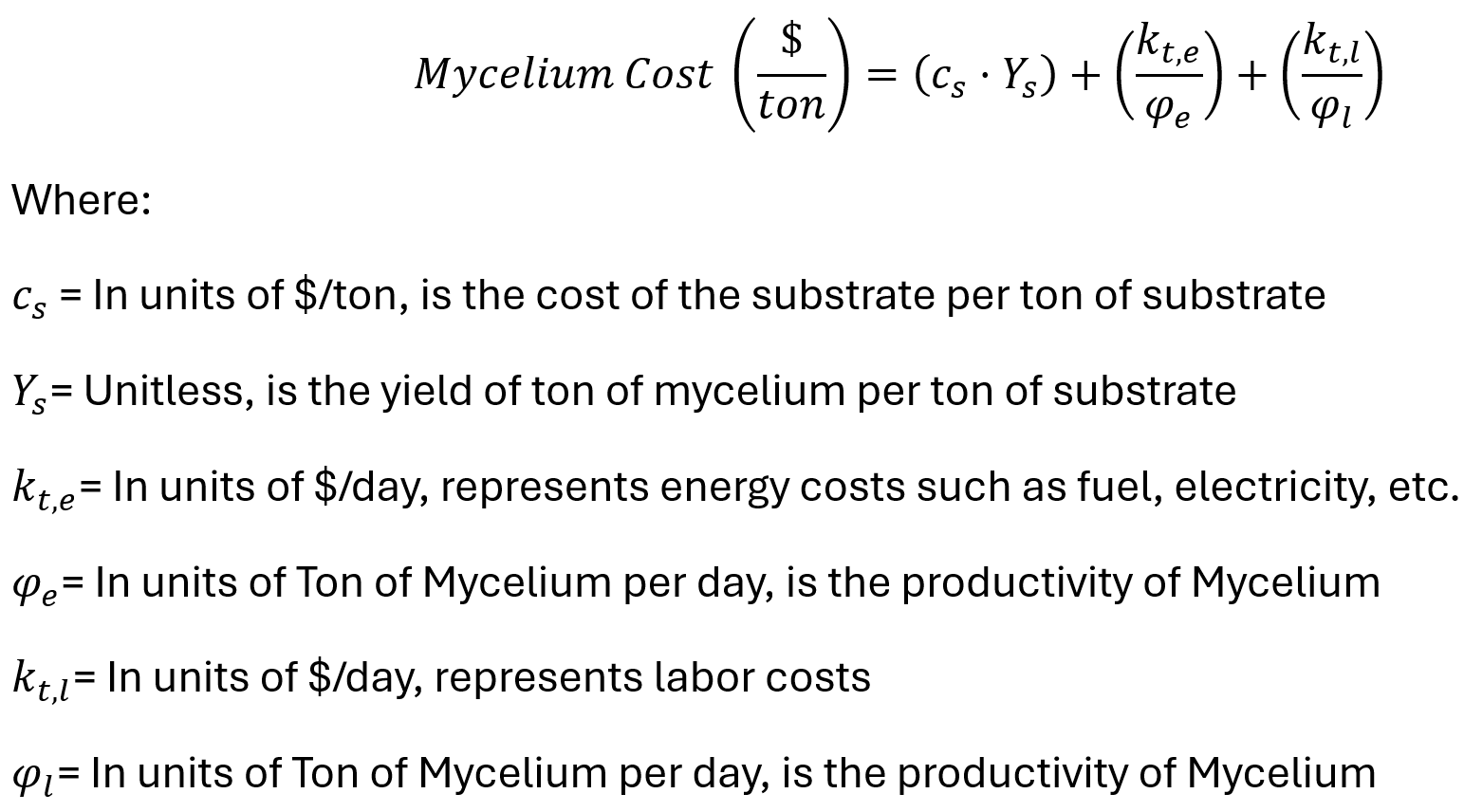

¶ 6. Positioning of Organization vs. Competition: FOM charts

This section analyzes the competitive landscape for mycelium packaging to validate the strategic FOM’s. With mycelium in the early technology phase, rapid development is underway between a few key players. This analysis benchmarks current commercial products, highlighting their performance strengths, gaps, and similarities.

Competitor Benchmarking

| Company Name | Cost ($/ton)* | Production Time to Value (Days) |

Compressive Strength (psi) |

Industrial Compostability (Days) | Carbon Intensity (kgCO2eq/kg) |

Resistance to Heat Flow (R-value/in) |

Shelf Life (Years) |

| Mycelium Packaging | 3,000-4,000 | 6 - 10 | 3.5 - 7.4 | 30 - 45 | 2.6 | 3.2 | 30 |

| EPE Foam (Expanded PE) |

$1,400 – $1,900

|

0.08 – 0.4 | <43 | Not Compostable | 1.5 – 2.5 | 3.3 | Indefinite |

| XLPE Foam (Cross-Linked PE) | $3,500 – $8,000 | 0.08 - 2 | 7.0 - 37.4 | Not Compostable | 2.5 - 5 | 3.3 | Indefinite |

| XPS Foam (Extruded PS) | $2,697 – $5,000 | 0.04 – 0.625 | >30 | Not Compostable | >4 | 5.0 | 75+ |

| Expanded Polystyrene (EPS) | $1,560 – $2,170 | 0.27 - 0.52 | 10 - 13 | Not Compostable | 2.6 - 6.0 | 3.6 - 4.2 | 500+ |

*Estimated from industry research

In the early stages of the mycelium market, our company will focus on developing an efficient manufacturing process for mycelium packaging that meets performance goals and competes economically with existing fossil fuel-based packaging. Strategically, by focusing on enhancing the manufacturing process, we will differentiate ourselves from lagging competitors, increase market adoption by demonstrating comparable performance to EPS, and establish a strong value proposition for sustainable packaging.

While becoming the industry leader in manufacturing mycelium in a cost-effective manner, our goal is to continue to leverage mycelium’s regulatory and sustainability strengths that meet and exceed global environmental standards. By achieving zero CO2 emissions and biodegradable products, our carbon footprint will be one of the smallest in the packaging industry, revolutionizing the way we transport items to consumers.

¶ 7. Technical Model: Morphological Matrix and Tradespace

¶ 7.1 Technical model

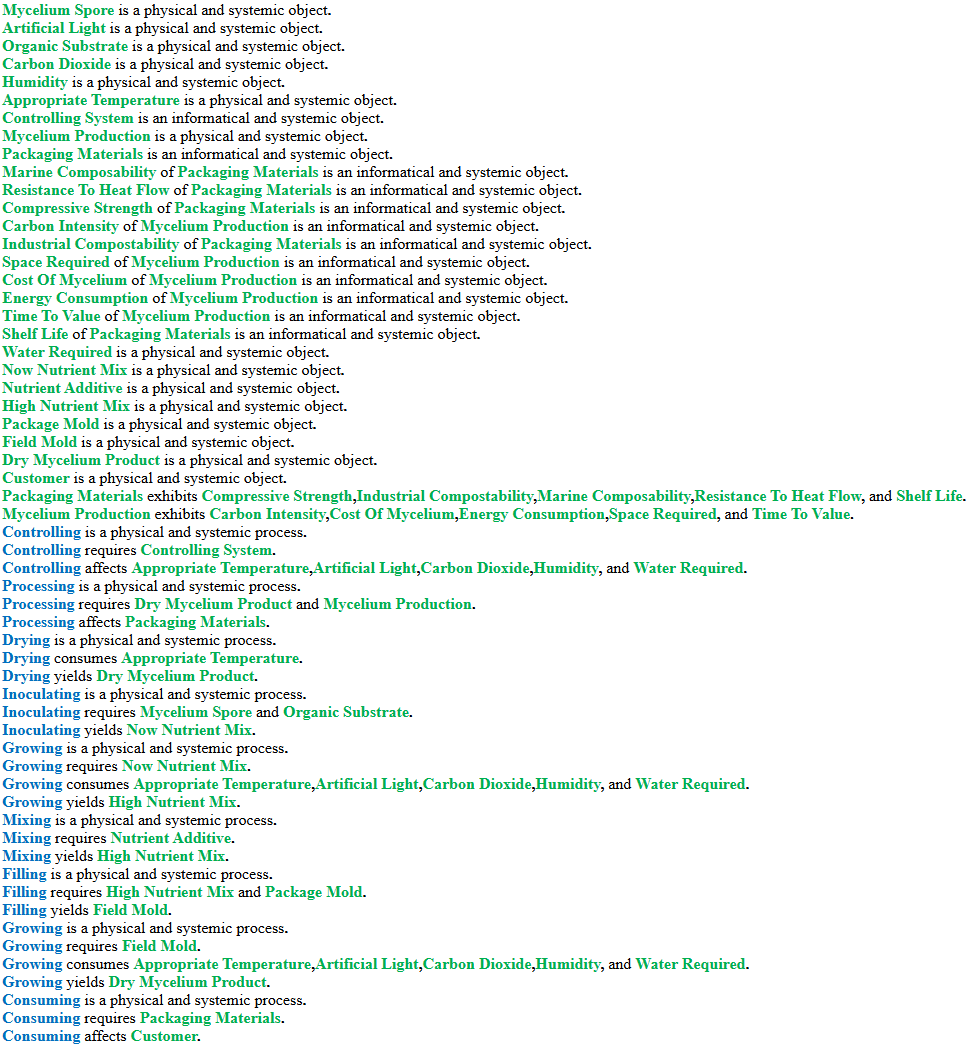

The primary focus of this roadmap is the production cost of Mycelium. There are many variables included in the technical model, with the goal of simplifying as much as possible to assist with design tradespace.

The governing equation for the production cost of Mycelium is commonly shown as such:

| Component | Dry Volume Percentage | Price Per Ton | Source |

| Rice Hulls | 50 | $16.50 | Link |

| Horticultural Perlite | 15 | $200 | Link |

| Dried Distillers Grains (DDGS) | 10 | $145 | Link |

| Ground Cellulose | 10 | $350 | Link |

| Coco Coir | 10 | $120 | Link |

| Inoculum Composed of Rye Grain | 3 | $4,000 | Link |

| Birch Sawdust | 2 | $100 | Link |

| Total cost per ton of Substrate | $221.75 | Per ton | |

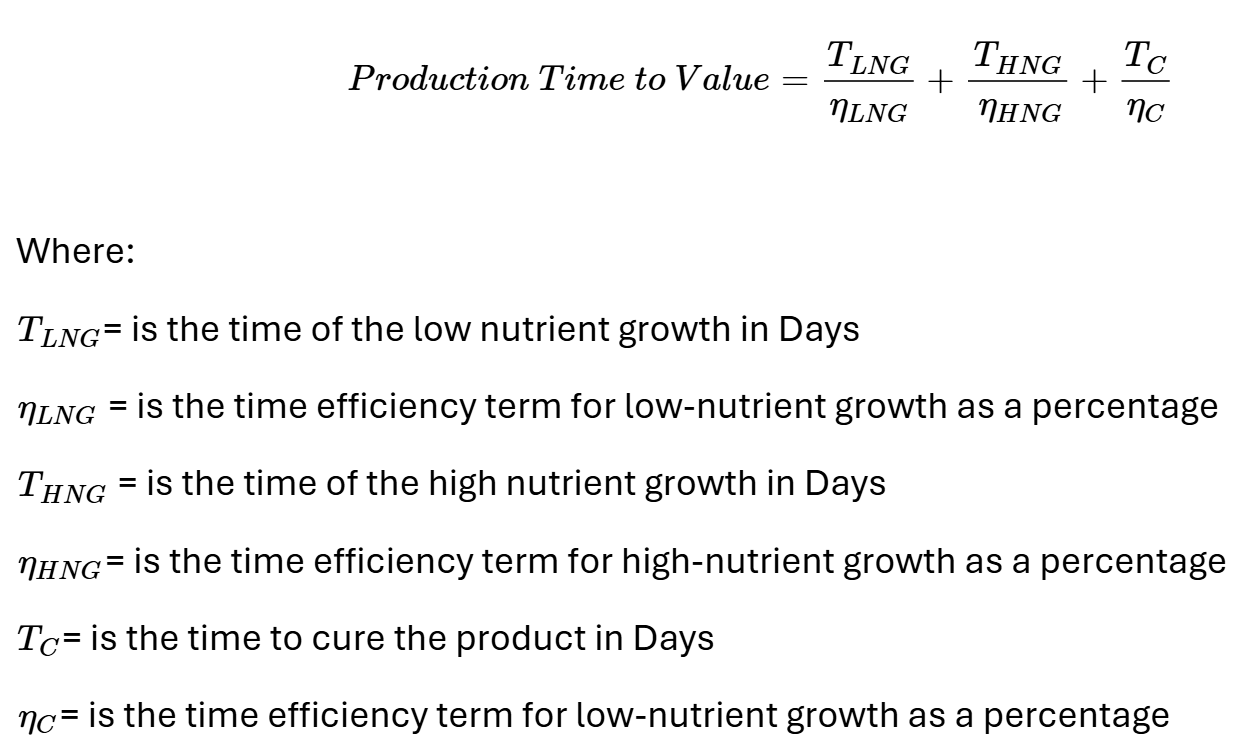

The second FOM we will focus on is the production time to value of Mycelium.

The governing equation for the production time to value of Mycelium is commonly shown as such:

¶ 7.2 Morphological Matrix of Design Alternatives

The table below shows the morphological matrix of the main technical decision variables that would map out key alternative functions derived from our FOM targets. Our strategic target concept will combine the best-in-class options to ensure market attractiveness and differentiate from competitors.

| Decision Variable | Option #1 | Option #2 | Option #3 | Strategic Target Concept |

| Low nutrient growth time | <2days | <5 days | <7 days | <2 days |

| High nutrient growth time | <1 day | <3 days | <6 days | <1 day |

| Curing time | <1 day | <2 days | <3 days | <1 day |

| Energy Source | Wind | Solar | Grid | Solar |

| Labor Efficiency | Low | Medium | High | High |

| Main Substrate | Straw | Sawdust | Hemp | Straw |

| Growth Efficiency | 15% | 50% | 100% | 100% |

Our company strategic target over 30-year life

¶ 7.3 Tradespace Model

The model evaluates the tradespace to identify the Pareto front among competing design values. The values used in the analysis are compared to cost ($/ton), which include Production Time to Value (Days), Carbon Intensity (kgCO2e/kg), and Thermal Resistance to Heat Flow (R-value/in). These figures of merit reveal the relative strengths and weaknesses of Mycelium compared with conventional materials in the packaging industry.

Mycelium-based technology presents a compelling alternative to leading traditional materials like Expanded Polystyrene (EPS) and Extruded Polystyrene (EPE), particularly in sustainability and thermal performance. The analysis indicates a significantly lower carbon intensity of 2.6 kgCO2eq/kg and a superior heat flux resistance (R-value) of 3.2 R-value/in. However, widespread adoption is currently constrained by manufacturing limitations. Specifically, the required production time exceeds five days, and the material's cost is presently more than double the current market price of EPS. These factors make efficiency and cost reduction critical focus areas for future development.

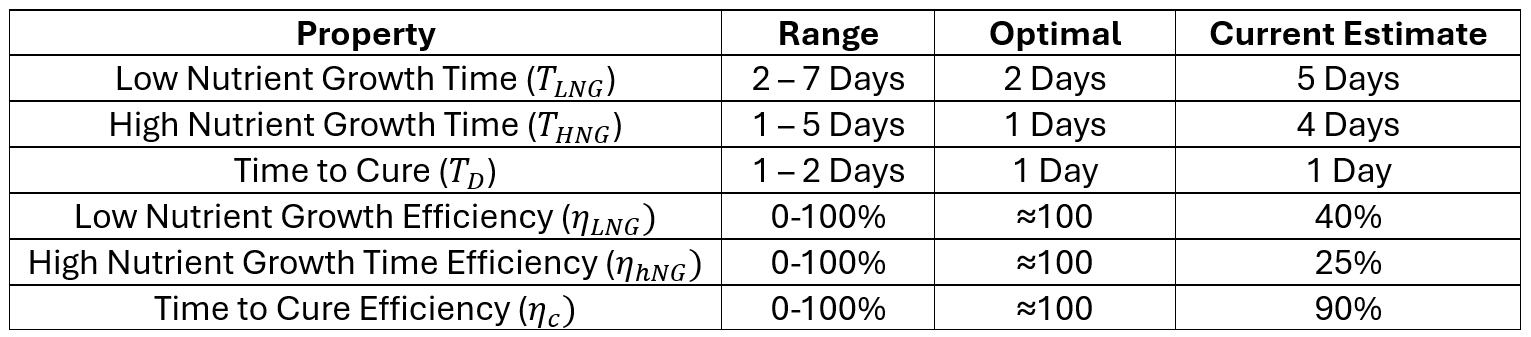

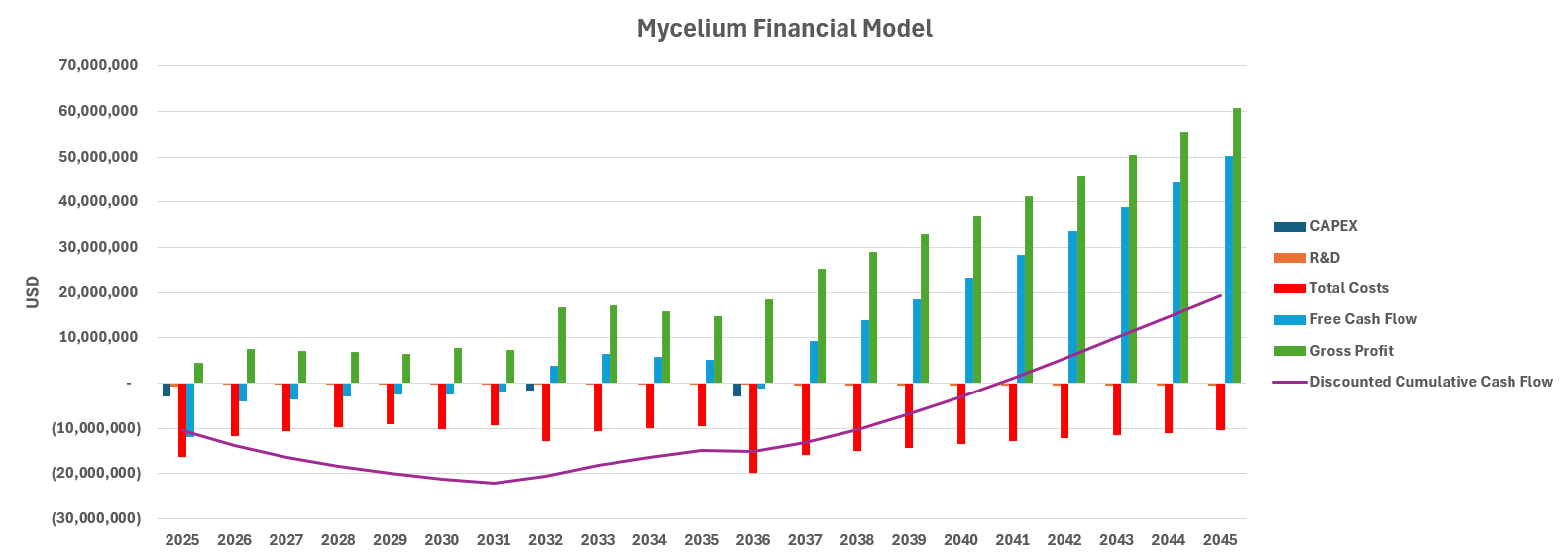

¶ 8. Financial Model: Technology Value

Financial model

The major hurdle for the financial model is the cost to manufacture mycelium so it can compete with the EPS market. Recent progress has enabled the company to enhance the process through R&D initiatives to lower the cost and with an expansion of facilities outside of the US which will make a significant impact. The model reaches out for 20 years with major milestones to also increase productivity within the facilities.

The figure below shows the financial model for the project to deliver mycelium packaging on a commercial scale.

Some key elements in the model include:

- CAPEX – The first facility is based in the US in year 1then expanding after year 8 and 12 to overseas development.

- R&D – In the first few years R&D costs are high to begin the extensive research to allow later milestones to be achieved. Each year after incurs a 4% increase.

- Production Costs – These costs are important to lower to make the business profitable. Through R&D and process improvements, this cost/tone is reduced by 13%/year until the first expansion facility, then a modest 10%/year improvement. Government subsidies of $150/ton are included for the first 10 years.

- Productivity - The first facility delivers a rate of 5,000 tons/year with an increase of 5%/year through process improvements. After year six, R&D efforts plan to increase production per facility by 30%. With this breakthrough, the expansion facilities will include the productivity improvements.

- Key Metrics – Using a 15% rate, the NPV of this project is $6.35 million USD with an ROI of 36% and IRR of 20%. Discounted cumulative cash flows are represented at a rate of 12%.

¶ 9. List of R&D Projects and Prototypes

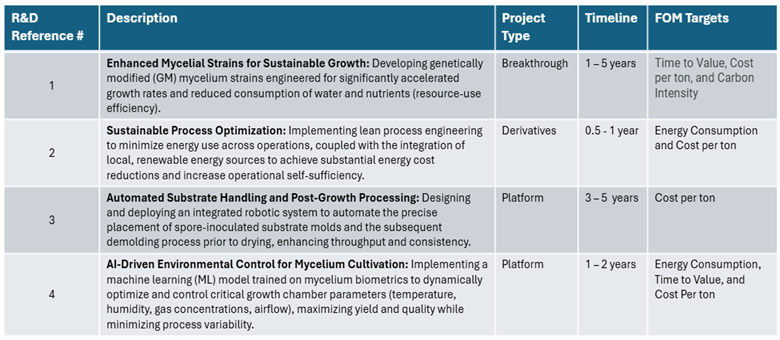

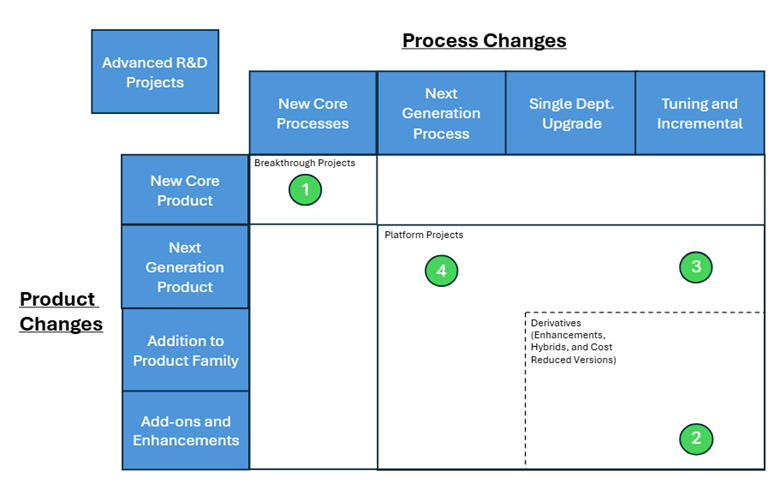

List of R&D Projects

The portfolio includes several R&D projects that span both short-term and long-term objectives. The diagram below shows the division of each project into different categories and prioritized based on the number, with 1 being the highest priority. The table coincides with the diagram, displaying key information for each R&D project.

¶ 10. Key Publications, Presentations and Patents

Our project focuses on mycelium packaging. A key component of our research involves understanding the material's production process. We investigated relevant patents, starting with those held by the industry leader, Ecovative. While Ecovative possesses approximately 53 patents in this area, including those for construction materials, food, and leather/textile, we concentrated on three patents specifically related to mycelium packaging production. Following is a description of each chosen patent, highlighting the essential information for our project roadmap.

¶ 10.1 Publications & Presentations

Paper: A Comparative Life Cycle Assessment of Expanded Polystyrene and Mycelium Packaging Box Inserts

Author(s): Dolor R. Enarevbaa and Karl R. Haapalaa

Details: This paper presents a comparative life cycle assessment (LCA) of standard shipping box inserts made from Expanded Polystyrene (EPS) and a bio-based composite of agricultural feedstock (hemp) and mycelium. The research was conducted using a gate-to-grave analysis, following the ISO 14040 standard, to evaluate the environmental impacts of both materials across their production, use, and end-of-life stages. The study concluded that mycelium inserts generally have lower gate-to-grave environmental impacts compared to EPS inserts, particularly exhibiting less impact in terms of energy and carbon footprint. While mycelium had higher impacts in stratospheric ozone depletion and marine eutrophication, EPS showed significantly higher impacts across most other categories.

Relevance: This paper is relevant to the development and use of mycelium for packaging as it provides a necessary, science-based evaluation of the environmental sustainability of mycelium-based composites compared to conventional materials. Given that EPS is a dominant packaging material with ongoing environmental and health concerns, the study validates fungal mycelium as a promising, more sustainable, bio-based alternative.

Citation: Dolor R. Enarevbaa and Karl R. Haapalaa. A Comparative Life Cycle Assessment of Expanded Polystyrene and Mycelium Packaging Box Inserts. Procedia CIRP 116 (2023): 654–659. 10.1016/j.procir.2023.02.110.

¶ 10.2 Patents

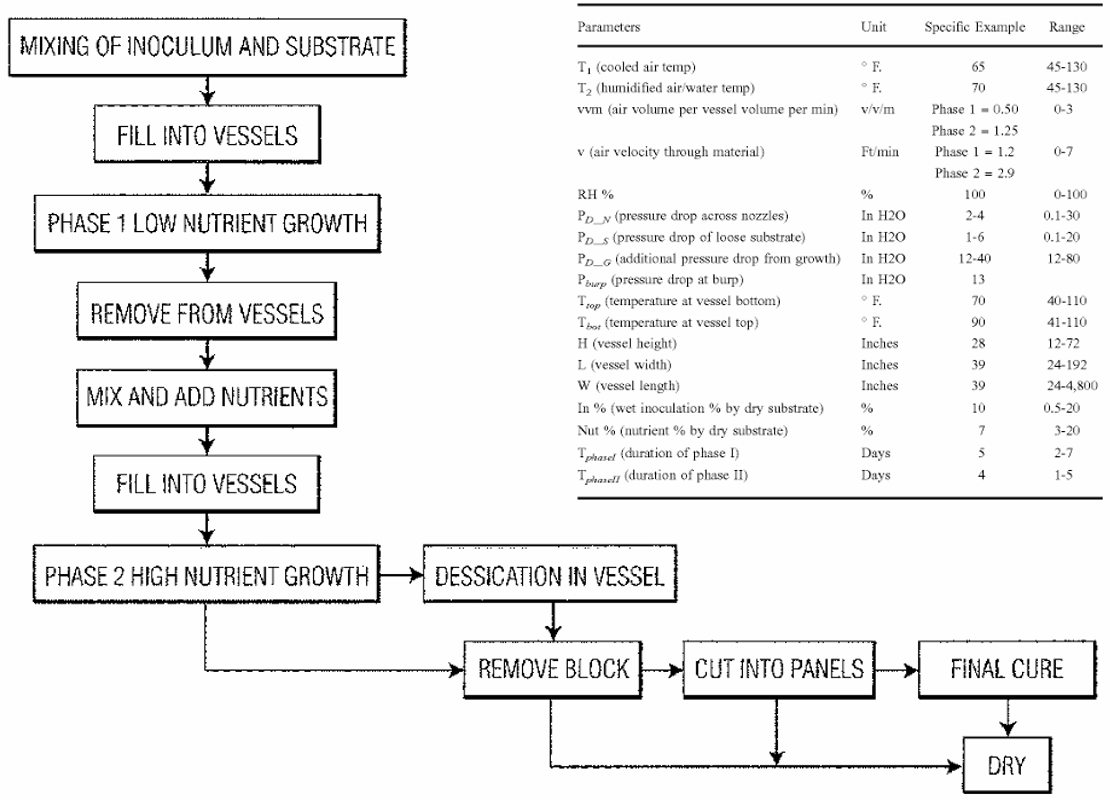

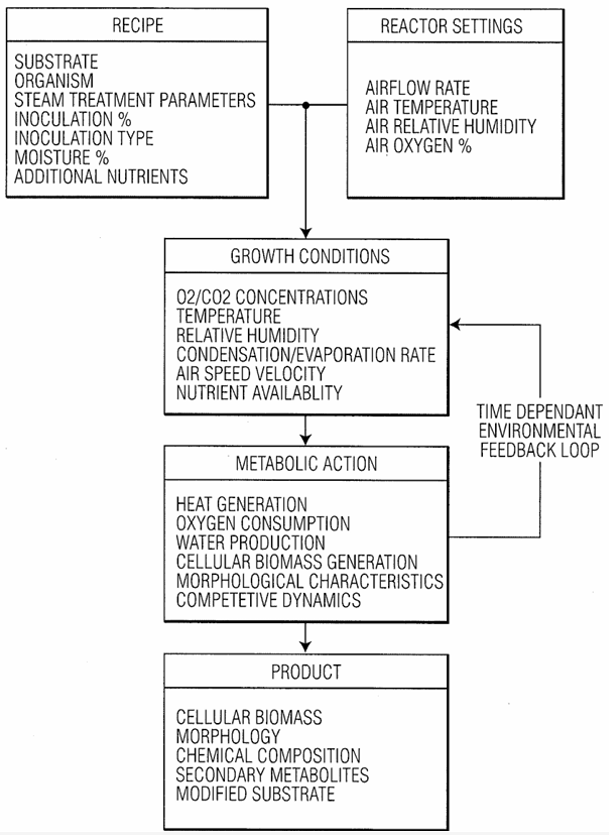

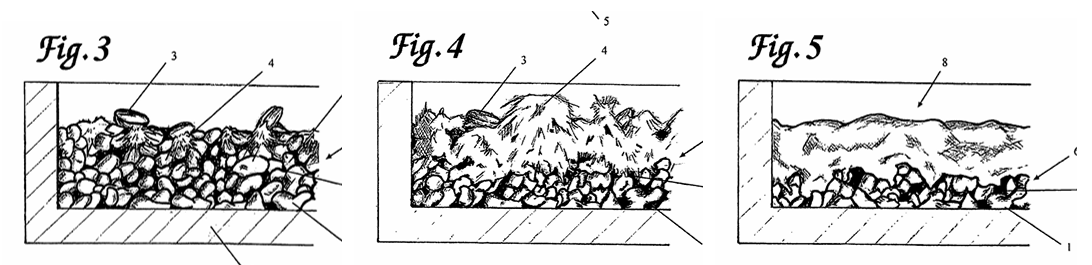

US 11,343,979 B2 - This patent describes a system and method for growing materials bonded together by fungus (mycelium) in large, deep containers. The main focus is controlling the air moving through the material to provide fresh oxygen while removing the fungus's waste heat and carbon dioxide. It also provides an overview of the process and define some specific optimizations of the production process.

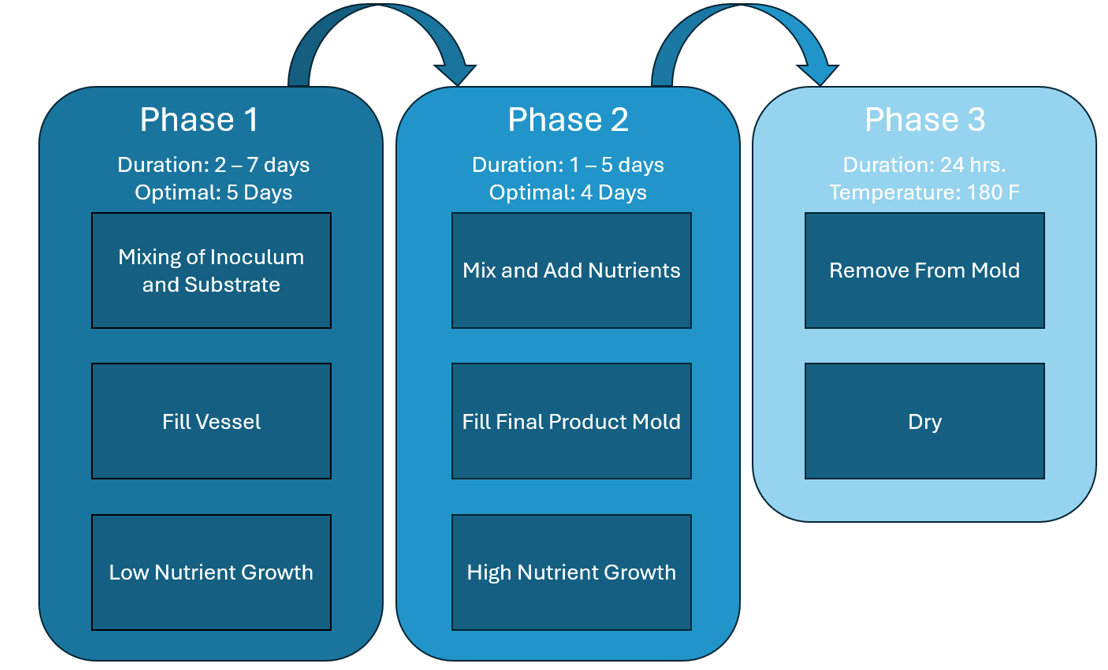

US 2019/0359931 A1 - This patent application focuses on a two-step growing method for producing mycelium materials, especially for molded or shaped products. In the first stage (Phase I), the fungus is grown slowly on a food source that is hard to digest (low nutrient content) so that the fungus takes over and dominates the material, allowing it to outcompete contaminants. In the second stage (Phase II), readily available food is added, causing the fungus to grow rapidly and bond the loose particles into a strong, self-supporting material that takes the shape of the container (vessel).

US 11,932,584 B2 -This patent describes a method for making a composite product by growing fungal threads (mycelium) to create a specific, organized three-dimensional structure. The key is ensuring the mycelium grows in a dense, organized pattern within the material (known as a "hyphae lattice"). This controlled, organized growth is important because it dictates the final material properties, such as its strength and density.

Important takeaways from the patents in the process to grow mycelium for packaging:

Preferred fungus type (US 11,932,584 B2)

- Pleurotus ostreatus

- Agrocybe brasiliensis

- Flammulina velutipes

- Hypholoma capnoides

- Hypholoma sublaterium

- Morchella angustinceps

- Macrolepiota procera

- Coprinus comatus

- Ganoderma tsugae

- Agaricus arvensis

- Inonotus obliquus

Substrate Composition (US 11,932,584 B2)

|

Component |

Dry Volume Percentage |

|

Rice Hulls |

50 |

|

Horticultural Perlite |

15 |

|

Dried Distillers Grains (DDGS) |

10 |

|

Ground Cellulose |

10 |

|

Coco Coir |

10 |

|

Inoculum Composed of Rye Grain |

3 |

|

Birch Sawdust |

2 |

Incubation

|

Incubation Condition |

Max |

Ideal (Fungus Dependent) |

Min |

|

Temperature |

130 F |

75 F |

30 F |

|

RH Humidity |

100% |

100% |

40% |

Phases of Production (total production time 10 Days):

¶ 11. Technology Strategy Statement

The primary objective of the 2MPP roadmap is to develop a cost-tractive process to manufacture mycelium-based packaging that will replace oil-derived expanded polystyrene (EPS) packaging on a commercial scale. Thus far, extensive research and development (R&D) have been invested in technology, and it continues to make it a more attractive alternative to the packaging industry. With improved processes and designs, mycelium will significantly contribute towards a net-zero-emission future.

Continuous investment in R&D will optimize substrate selection, energy costs, and growth conditions, thereby maximizing yield and reducing labor inputs. By 2027, the first full-scale production facility capable of producing 2,500 tons of mycelium per year. Partnerships with major companies will increase market share and R&D opportunities. By 2023, breakthrough technologies by genetic modifications to mycelium strains will significantly increase yearly production.

¶ 12. References

Agarwal, Ishika. "Slicing the Apple: An analysis of Apple's pricing strategy." The St Andrews Economist, 17 Nov. 2021, standrewseconomist.com/2021/11/17/slicing-the-apple-an-analysis-of-apples-pricing-strategy/.

Wang, Jiayi. "Apple's Marketing Strategy: Comprehensive Application and Strategic Analysis of the 4P Model." Advances in Economics, Management and Political Sciences, vol. 148, 2025, pp. 118-25. R Discovery, discovery.researcher.life/article/apple-s-marketing-strategy-comprehensive-application-and-strategic-analysis-of-the-4p-model/ac36c0699b50397b99f432f188cdeb5d

Szczygiel, Bartosz. "iOS vs Android: Key Differences in 2025." Netguru, 5 Sept. 2025, www.netguru.com/blog/iphone-vs-android-users-differences.

Parvadiya, Gaurav. "Android Vs. IPhone Market Share: Exploring Dominance In Mobile OS." Twinr, 26 Mar. 2025, twinr.dev/blogs/android-vs-ios-market-dynamics.

Hadley, Linda. "Google Pixel vs iPhone: Strategic Business Comparison." Tech Research Online, 28 July 2025, techresearchonline.com/blog/google-pixel-vs-iphone-business-analysis/.

NASA Technology Roadmaps TA 9: Entry, Descent, and Landing Systems. (2015). https://www.nasa.gov/wp-content/uploads/2016/08/2015_nasa_technology_roadmaps_ta_9_entry_descent_landing_final.pdf

Insulation Institute. EPS vs. XPS: R-Value, Cost & Moisture - Shobeir Shimi, accessed October 28, 2025, https://shobeirshimi.com/eps-vs-xps/

Lee, Jessica. How Long Does It Take for Polystyrene Foam to Decompose? - Cruz Foam, accessed October 28, 2025, https://www.cruzfoam.com/post/how-long-does-it-take-for-styrofoam-to-decompose/

Polystyrene Prices, Chart, News, Monitor and Forecast | IMARC - openPR.com, accessed October 28, 2025, https://www.openpr.com/news/3806159/polystyrene-prices-chart-news-monitor-and-forecast-imarc

Understanding Expanded polystyrene density variations - Shobeir Shimi, accessed October 28, 2025, https://shobeirshimi.com/expanded-polystyrene-density-variations/

Expanded Polyethylene Foam (EPE) Physical Data Sheet, accessed October 28, 2025, https://www.foambymail.com/expanded-polyethylene-foam-sheet.html

Cross Linked Polyethylene Data Sheet | Foam Factory, Inc., accessed October 28, 2025, https://www.foambymail.com/cross-linked-polyethylene-sheet.html

Comparing EPS and XPS Foam: Which Polystyrene Is right for your Project?, accessed October 28, 2025, https://www.thefoamcompany.com.au/blogs/news/comparing-eps-and-xps-foam-which-polystyrene-is-right-for-your-project

EPS vs Polyurethane Insulation | Cost, R-Value, Moisture - Insulspan, accessed October 28, 2025, https://www.insulspan.com/advantages/eps-insulation-vs-pur/

China Xlpe Foam Sheet, Xlpe Foam Sheet Wholesale, Manufacturers, Price - Made-in-China.com, accessed October 28, 2025, https://www.made-in-china.com/products-search/hot-china-products/Xlpe_Foam_Sheet.html

Tenhunen-Lunkka, A., Rommens, T., Vanderreydt, I., & Mortensen, L. (2023). Greenhouse Gas Emission Reduction Potential of European Union's Circularity Related Targets for Plastics. Circular Economy and Sustainability, 3, 475–510. https://doi.org/10.1007/s43615-022-00192-8.

Zoungrana, A., Hausner, G., & Yuan, Q. (2025). Sustainability assessment of mycelium bio-foam packaging compared to expanded polystyrene through environmental impact assessment. Discover Sustainability, 6(1), 1–12. https://doi.org/10.1007/s43621-025-02025-8.

Stephens, H. (2023, March 30). Bio-based packaging gets renewed buzz amid goals to replace traditional plastics. Packaging Dive. https://www.packagingdive.com/news/biobased-packaging-seaweed-mycelium/645998/

Shapiro, A. J., Brigandi, P. J., Moubarak, M., Sengupta, S. S., & Epps, T. H., III. (2024). Cross-Linked Polyolefins: Opportunities for Fostering Circularity Throughout the Materials Lifecycle. ACS Applied Polymer Materials, 6(19), 11859–11876. https://doi.org/10.1021/acsapm.4c01959