¶ Aircraft powered by Hydrogen Fuel Cells

¶ 1. Roadmap Overview

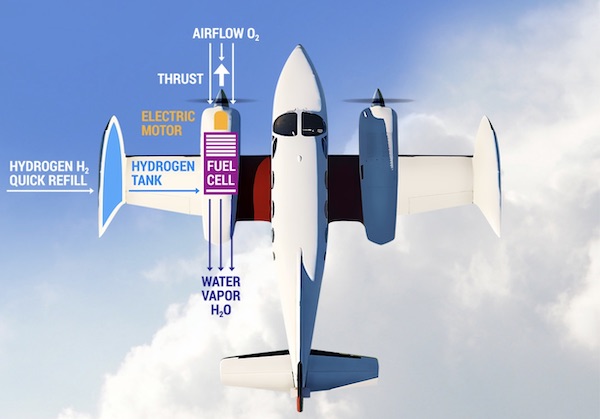

Hydrogen fuel cell aircraft are designed to achieve zero-emission passenger flight by converting hydrogen into electricity that powers electric motors directly, without the use of gas turbines or hybrid systems. The working principle is based on an electrochemical reaction inside the fuel cell, where hydrogen combines with oxygen from the ambient air to generate electricity, heat, and water vapor as the only by-product. Unlike batteries, which store energy chemically and must be recharged between flights, hydrogen fuel cells can be rapidly refueled, offering higher potential range and turnaround efficiency for commercial aviation.

The architecture of a fuel cell passenger aircraft typically includes cryogenic liquid hydrogen storage tanks, a hydrogen distribution and conditioning system, fuel cell stacks for power generation, and high-performance electric motors to drive the propellers or fans. The use of liquid hydrogen is necessary due to its high energy density compared to batteries, although the cryogenic storage requirements create significant design and integration challenges.

This roadmap focuses on an all-electric, fuel cell–powered passenger aircraft, rather than hybrid approaches. The target mission is regional air transport, where ranges of several hundred kilometers are required to make a meaningful impact on short-haul aviation markets. Achieving competitive payload, safety, and efficiency requires breakthroughs in lightweight cryogenic storage, fuel cell power density (kW/kg), and motor efficiency. If successful, hydrogen fuel cell aircraft could provide a pathway to scalable zero-emission passenger aviation.

¶ 2. Design Structure Matrix (DSM) Allocation

The matrix and tree shown below represent the various interdependencies of major and minor subsystems. Aircraft powered by Hydrogen Fuel Cells (2AHC) are identified as one of the solutions for aircraft electrification (1ELE), requiring the major subsystems 3EPR (Electric Propulsion), 3LHM (Liquid Hydrogen Management), and 3LAF (Lighter Airborne Frame). Furthermore, these major subsystems depend on Level 4 component technologies, including 4HFC (Hydrogen Fuel Cell), 4EMO (Electric Motor), 4FAN (Fan), 4LHS (Liquid Hydrogen Storage), 4LHP (Liquid Hydrogen Piping), 4HMS (Heat Management System), and 4CFR (Carbon Fiber-Reinforced Plastic).

(Interdependencies with other roadmaps)

Potentially involved with a part of Electric Propulsion (3EPR) assembly:

[3EAPA] - Electric Aircraft Propulsion Architectures

[2EVL] - Worldwide eVTOL

[2SPA] - Solar-Powered HALE Aircraft

[2SEA] - Solar Electric Aircraft

¶ 3. Roadmap Model using OPM

We provide an Object-Process-Diagram (OPD) and Object-Process-Language (OPL) of the 2AHC (Aircraft powered hydrogen fuel cell) roadmap in the figure below. This diagram captures the main object of the roadmap, its various instances including main competitors, its decomposition into subsystems (e.g. Fuselage, wing), its characterization by Figures of Merit (FOMs) as well as the main processes (e.g. Flying).

¶ 4. Figures of Merit (FOM)

There are numerous parameters by which to measure the performance of our technology. Some of the FOMs are summarized below.

|

FOM name |

Units |

Description |

Trends (dFOM/dt) |

| Unit Cost |

[$] |

Unit cost to manufacture the aircraft (incl. amortization of R&D) |

N/A |

| Passenger Seating |

[PAX] |

Number of passengers that the vehicle can carry |

+ |

| Range |

[km] |

Distance that can be traveled in an operation |

+ |

| Operating Cost |

[$/FH] |

Cost per flight-hour, including all variable cost (e.g. energy recharging, battery replacement), and maintenance |

- |

| Gravimetric Power Density (Generation) |

[kW/kg] |

Amount of power that can be generated per unit mass |

+ |

| Volumetric Energy Density (Storage) |

[kWh/kg] |

Amount of energy that can be stored per unit volume |

+ |

| System Efficiency |

- |

Ratio of useful power output to the total chemical energy input from hydrogen |

+ |

(Supplementary note on important FOM trends)

Passenger Seating: Although the sample size is still small, ZeroAvia’s Dornier 228 with 19 seats successfully flew in January 2023, and Universal Hydrogen’s Dash 8 with 40 seats followed in March 2023. ZeroAvia’s roadmap envisions 10–20 seats by 2026, 40–80 seats by 2028, and 100 seats by 2030.

Gravimetric Power Density: Aircraft fuel cell technology remains in the incubation phase, as the power-to-weight ratio of fuel cells has hovered between 0.5 and 2.5 kW/kg for decades, which is insufficient for most mainstream aviation applications. Looking ahead, technological roadmaps project that the power of aircraft fuel cells could increase to 4 kW/kg by 2027 and reach around 8 kW/kg by 2037.

¶ 5. Alignment of Strategic Drivers: FOM Targets

The two main strategic drivers for the hydrogen fuel cell aircraft roadmap are to (1) achieve zero-emission regional aviation and (2) reduce operating costs to make hydrogen-powered flight economically competitive with existing turboprop aircraft. The following table summarizes how the 2AHC roadmap aligns with these corporate strategic goals through measurable FOM targets.

| Number | Strategic Driver | Alignment to Targets |

| 1 | Achieve zero-emission commercial regional aviation by 2035 through the adoption of hydrogen fuel cell propulsion. |

The 2AHC roadmap targets an all-electric aircraft powered by hydrogen fuel cells with system efficiency over 50% and gravimetric power density of 4 kW/kg by 2027, enabling carbon-neutral regional flights. |

| 2 | Reduce operating cost per flight-hour by 30% compared with turboprop aircraft through improvements in efficiency and hydrogen price reduction. |

Current system analysis yields an operating cost of $820/h, largely influenced by hydrogen fuel price and stack lifespan with hydrogen cost projected to reach $1/kg by 2031. |

¶ 6. Positioning of Organization vs. Competition: FOM charts

Hydrogen fuel cell aircraft are still in the demonstration and prototype stages and have not yet reached commercial operation. Globally, companies such as ZeroAvia and H2FLY are acting as pioneers, conducting test flights and developing prototypes mainly for the short- to medium-range market.

Our company, in this early market, will focus on fuel cell electric propulsion systems and commercialize regional and small aircraft that leverage high efficiency, low emissions, and quiet operation as their key strengths. We will target short to medium range flights and regional airport networks in Asia to differentiate ourselves from competitors.

The reasons for focusing on short to medium range aircraft are:

(1) Technical challenges such as power-to-weight ratio and thermal management are easier to overcome with smaller aircraft.

(2) There is a sufficient market size for regional routes in the 300 to 500 km range.

(3) Shorter flight durations reduce the burden on hydrogen infrastructure and safety management.

We focus on Asia’s regional airport network because:

(1) There are many regional airports with strong demand for short-haul routes.

(2) Compared to Europe and the U.S., competition is less intense, allowing easier early adoption.

Strategically, considering current challenges such as power-to-weight ratio, thermal management, fuel storage, and the underdeveloped hydrogen supply infrastructure, we emphasize early introduction and performance validation in the short to medium range market. Since large-scale expansion before the hydrogen supply infrastructure is established carries significant risk, our company adopts a “follower” strategy. We will monitor the outcomes of pioneer developments and expand step by step.

From an environmental perspective, our aircraft will achieve near-zero CO₂ emissions and significantly lower noise and vibration levels, reducing the environmental impact around airports while balancing social acceptance and economic efficiency for intercity and regional routes.

From a competitive perspective, while pioneers such as ZeroAvia are working to shape the market, our company will enter as a low-risk, high-efficiency follower and establish a strong position in niche markets.

¶ 7. Technical Model: Morphological Matrix and Tradespace

Technical Model

To evaluate the economic and technical performance of hydrogen fuel cell aircraft, two key FOMs are defined:

FOM1: Operating Cost C_op and FOM2 System Efficiency η_sys. These equations quantify how design variables such as output power, hydrogen price, and system efficiency influence both the cost and the energy performance of the aircraft. The operating cost model (FOM1) combines two major components: the cost of hydrogen fuel and the depreciation of the fuel cell stack. Meanwhile, the system efficiency model (FOM2) expresses how effectively chemical energy from hydrogen is converted into electrical power.

[FOM1] Operating cost: C_op [$/h]

[FOM2] System Efficiency: η_sys

Sensitivity Analysis

A normalized sensitivity analysis was performed by varying each parameter by ±10%. This analysis identifies which factors most significantly influence the total operating cost.

The results show that:

System efficiency (η_sys) and hydrogen price (p_H₂) are the two dominant drivers, each contributing approximately ±87% sensitivity to operating cost. In contrast, fuel cell cost (C_FC) and lifetime (L_FC) have a relatively minor impact (±12%). This means that improving the fuel cell’s efficiency or lowering hydrogen price will yield the most substantial reduction in hourly operating cost.

Morphological Matrix

To explore design trade-offs, a Morphological Matrix was created. It lists the main design variables and alternative technological options that define the system architecture of hydrogen-powered aircraft. This matrix allows systematic exploration of possible configurations before selecting the most promising combination for detailed analysis.

Tradespace

To analyze how performance improvements affect cost, the system efficiency (η_{sys}) was swept from 0.30 to 0.80. The resulting tradespace shows a downward-sloping curve, indicating that higher efficiency directly translates to lower hourly operating cost. This behavior reflects the strong coupling between the thermodynamic performance of the fuel cell system and economic viability. The curve highlights the potential of hydrogen fuel cell technology, showing that improving overall system efficiency from 40% to 70% could reduce operating cost by nearly 50%, making fuel cell aircraft competitive with current turboprop operations by the early 2030s.

¶ 8. Financial Model: Technology Value

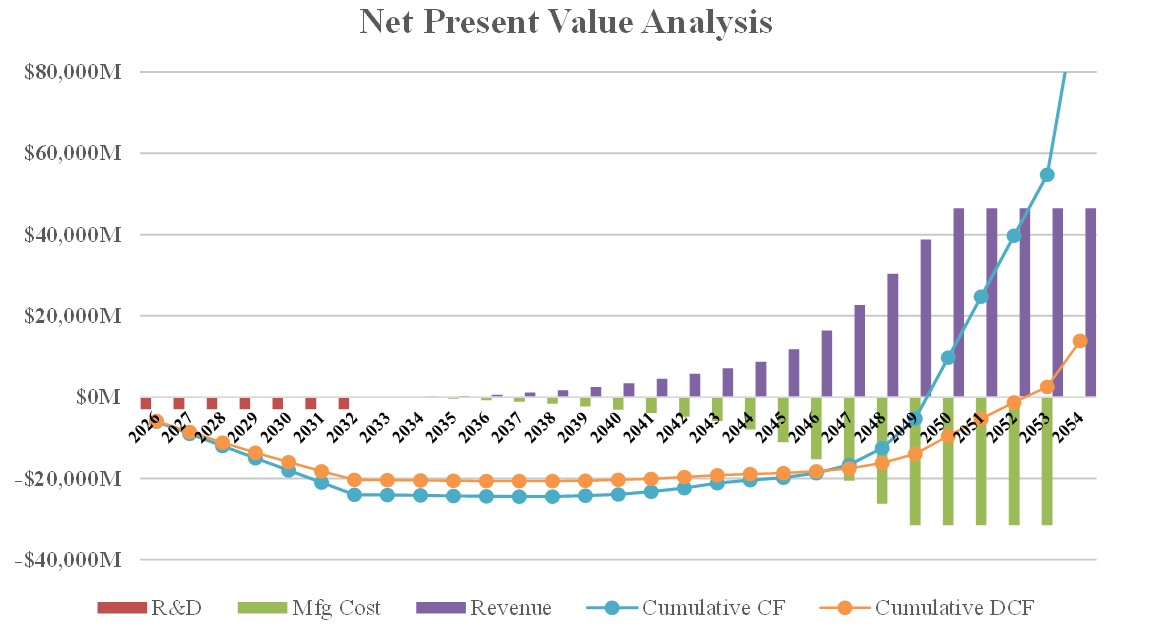

This model illustrates the cash-flow trajectory assuming the commercialization of a hydrogen fuel-cell aircraft. In the initial development phase, continuous R&D investment of approximately $3 billion per year continues for about eight years, causing the cumulative cash flow to fall to around –$24 billion. The discounted cash flow (DCF) also accumulates a similarly large negative balance, indicating that the program faces a substantial financing burden during this stage.

Once the program enters the manufacturing phase, recurring manufacturing costs increase rapidly with expanded annual production, but this is outweighed by growth in sales volume and revenue. After reaching a large-scale production rate of 300 aircraft per year in the 16th year after sales begin (the 26th year from the start of R&D), annual revenue stabilizes at roughly $46.5 billion, and net cash flow secures an annual surplus of around $15 billion. As a result, cumulative cash flow turns positive in the same year and ultimately reaches a surplus of approximately $100 billion.

From a DCF perspective, it takes considerable time to recover the large deficit accumulated during the R&D period. However, once mass production begins, the financial performance improves quickly, and the model ultimately achieves a net present value (NPV) of about $14 billion in the 20th year after sales begin (the 30th year from the start of R&D). In other words, this model suggests that despite the significant upfront investment, the combination of scale effects and increased sales volume can generate sufficient returns to offset initial costs.

Key Assumptions

R&D Costs:

- Annual R&D expenditure is assumed to be $3,000M per year.

- The R&D phase is modeled to last 8 years.

Sales Revenue:

- The baseline aircraft price is based on a typical narrow-body aircraft priced at $113M per unit.

- An environmental performance premium is added to the baseline price.

- Annual CO₂ emissions of a comparable fossil-fuel narrow-body aircraft are assumed to be 8,400 t-CO₂ per year, and the carbon offset price applied under international schemes is set at $250 per ton of CO₂. Under this assumption, if such international carbon-offset requirements are enforced, a fossil-fuel aircraft would face an additional annual compliance cost of approximately $2.1 million.

- A service life of 20 years is used when determining the payback period for the price difference relative to a conventional aircraft. Based on this assumption, the resulting sales price in this scenario is set to $155 million per unit, corresponding to a 37% premium relative to a typical fossil-fuel narrow-body aircraft..

Manufacturing Cost:

- We assume that manufacturing cost is roughly proportional to the aircraft’s total number of components. Although the propulsion system shifts from a turbofan engine to a fuel-cell powertrain, the overall component count is not expected to change significantly. This is because propulsion-related parts, including the engine, make up only a small share of total components. Therefore, even with fuel-cell adoption, the overall component count and manufacturing cost structure are assumed to remain largely similar.

- The unit manufacturing cost (including certification and related expenses) is estimated at $105M per aircraft, derived by subtracting the core operating margin (8%) from the typical sales price of an Airbus narrow-body aircraft.

- Production is assumed to begin in 2034 at a rate of one aircraft per year, followed by a gradual expansion of manufacturing capacity that reaches 300 aircraft per year by 2050.

¶ 9. List of R&D Projects and Prototypes

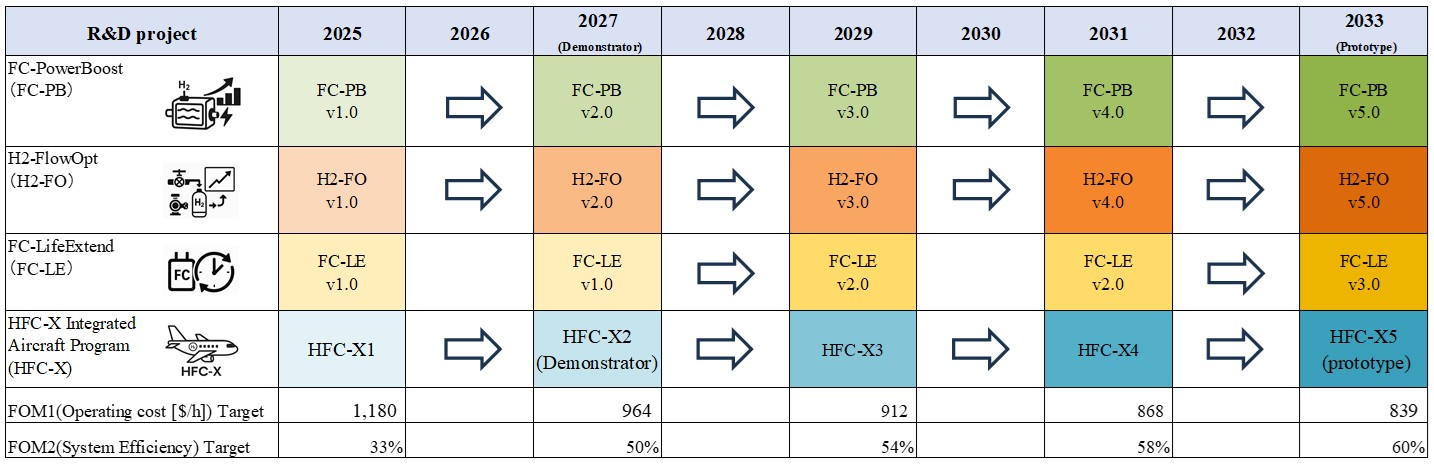

This section outlines the key R&D projects and integration milestones that drive the development of our hydrogen fuel-cell aircraft. Beginning in 2025, the roadmap advances three core technology streams—power enhancement (FC-PB), hydrogen flow optimization (H2-FO), and lifetime extension (FC-LE)—to improve operating cost (FOM1) and system efficiency (FOM2). The program targets a reduction in operating cost from $1,180/h in 2025 to $964/h by the 2027 demonstrator and $839/h by 2033, while system efficiency increases from 33% to 50% and ultimately 60%.

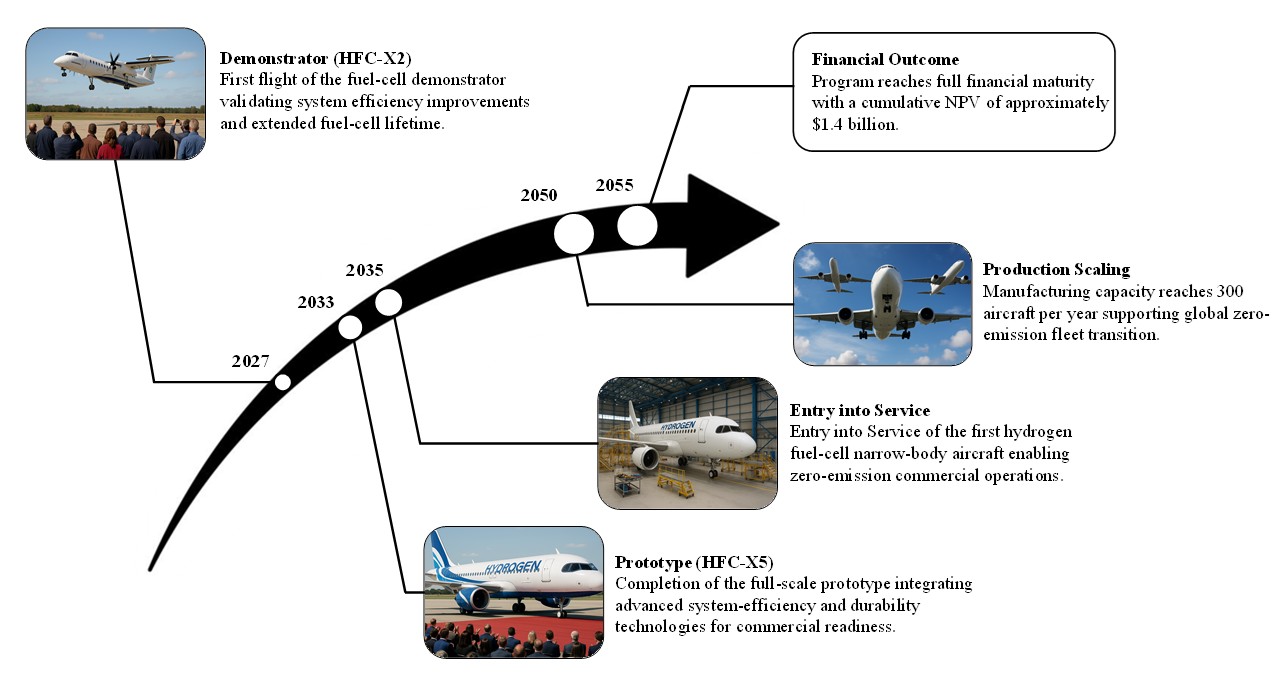

The HFC-X Integrated Aircraft Program combines these technologies at the system level. HFC-X2 (2027) serves as the first flying demonstrator, validating integrated performance, and HFC-X5 (2033) acts as the final full-scale prototype designed to confirm commercial-grade capability.

Demonstrator and Prototype

HFC-X2 (2027 Demonstrator): HFC-X2 is an early demonstrator that integrates the core fuel-cell technologies developed in the program. Through short-range flight tests, it validates power output, efficiency, and operational safety, serving as the first flying model to confirm system-level integration requirements for an aircraft.

HFC-X5 (2033 Prototype): HFC-X5 is the final full-scale prototype equipped with high-performance fuel-cell stacks, an optimized hydrogen management system, and extended-lifetime FC technologies. It is designed to evaluate commercial-grade performance and reliability under operational conditions, representing the last milestone before entry-into-service.

Description of R&D Projects

FC-PowerBoost (FC-PB): Optimization of catalyst layers, gas diffusion layers, and flow-field designs enables a fuel cell stack with minimal voltage drop even at high current densities. Improvements to internal cooling and humidification further enhance thermal and moisture balance, allowing each cell to safely operate at higher power output.

H2-FlowOpt (H2-FO): By improving the efficiency of valves and compressors and reducing hydrogen recirculation losses, the system gradually lowers hydrogen mass flow. In particular, optimized flow-field mapping and refined supply-pressure control minimize unnecessary hydrogen discharge, thereby increasing overall fuel utilization efficiency.

FC-LifeExtend (FC-LE): Reducing degradation factors in MEAs (Membrane Electrode Assemblies) and catalysts improves the durability of the fuel cell stack. Introducing optimized humidity and temperature management enables degradation-mitigation control, preventing excessive operational stress and extending system lifetime.

HFC-X Integrated Aircraft Program (HFC-X): This program integrates fuel cell output enhancement, hydrogen management, and life-extension technologies to evaluate aircraft-level performance and reliability in a stepwise manner. As each technology matures, system-level integration advances from ground testing to flight testing, raising the overall readiness of the aircraft.

¶ 10. Key Publications, Presentations and Patents

¶ 10.1 Publications & Presentations

Publication 1: Design and Analysis of Hydrogen Fuel Cell Powered Short- to Medium-Range Regional Aircraft Configurations (Kiely & Agarwal, 2024)

This paper presents a conceptual design of hydrogen fuel cell (HFC)-powered regional aircraft, modeled after Bombardier CRJ200 and Boeing 717-200. While LH₂ has high gravimetric energy density, its low volumetric density requires large cryogenic tanks, posing major design challenges. A hybrid system combining PEM fuel cells and batteries meets peak power needs during takeoff and climb. The study predicts technical feasibility by 2030 and further efficiency gains by 2035 through superconducting electronics. Aft and overhead LH₂ tanks are recommended to manage center-of-gravity shifts. For ranges under 2,000 nmi, HFC aircraft can rival hydrogen combustion designs, with an optimal cruise speed near Mach 0.52.

Relevance to the Roadmap:

This study defines key performance targets (e.g. specific power, efficiency, and tank layout) that inform technological milestones and design constraints. Findings on LH₂ tank placement and C.G. management help shape the roadmap’s architecture and KPI benchmarks.

Publication 2: Liquid Hydrogen Fuel Tanks for Commercial Aviation: Structural Sizing and Stress Analysis (Gomez & Smith, 2019)

This study analyzes the structural and thermal behavior of LH₂ tanks under EASA CS-25 standards. Aluminum alloys (Al-2219-T87, Al-7075-T6) are used in forward and aft configurations. Finite element analysis shows high stress (up to 1,720 MPa) at catwalk supports, requiring titanium (Ti-6Al-4V) reinforcement. The forward tank’s weight fraction (0.35) exceeds that of the aft tank (0.21) and receives 10.5% more heat from cabin air, indicating the need for improved insulation.

Relevance to the Roadmap:

This paper highlights key structural and thermal constraints in LH₂ tank integration, emphasizing the need for high-strength cryogenic materials and coupled structural-thermal design. These insights guide long-term R&D directions on material innovation and tank optimization.

¶ 10.2 Patents

Patent 1: Aircraft with Hydrogen Fuel Cell System (US10553882B2)

This patent describes a redundant hydrogen fuel cell system that improves safety and reliability in commercial aircraft. The system includes two independent units with two fuel cells each (four total) connected to hydrogen tanks. Cells 1 and 4 use ambient air as the oxidizer, while Cells 2 and 3 can use onboard pure oxygen to maintain power if air intakes are blocked. Exhaust gases are used as nitrogen-enriched air (NEA) for fire suppression, and water vapor from reactions is recovered for cabin use. A control unit manages normal, emergency, and high-power operation modes.

Relevance to the Roadmap: This patent outlines a practical design for redundancy, emergency power, and safety integration in HFC aircraft. Its architecture reduces fire-suppression hardware and supports aviation safety certification, serving as a key reference for the roadmap’s system safety layer.

Patent 2: Hybrid-Electric VTOL Aircraft with Hydrogen Fuel Cell (US11752899B2)

This patent presents a thermally optimized HFC system for high-altitude, low-temperature operations, suited for VTOL and long-range electric aircraft. Ambient air is compressed up to 30× using a multi-stage compressor, while LH₂ absorbs heat from both the compressor and the fuel cell stack. The heat exchange vaporizes LH₂ for fuel cell supply, and condensed exhaust water is frozen and discharged. Hot exhaust gases are expelled through a nozzle to boost thrust and efficiency.

Relevance to the Roadmap: This patent showcases a cryogenic thermal-management cycle that reuses waste heat to improve range and efficiency. It demonstrates how LH₂ can serve as both fuel and thermal regulator, offering valuable insights for next-generation VTOL and high-altitude aircraft integration.

¶ 11. Technology Strategy Statement

Our target is to develop a hydrogen fuel cell powered narrow body aircraft with an Entry into Service date of 2035. To achieve the performance requirements for commercial operations, we will invest in a coordinated set of R&D programs from 2025 to 2033. The first is a flight demonstrator with a first flight in 2027 to validate fuel cell propulsion integration, safety and short range operational capability. The second is the development of a full scale prototype by 2033 that incorporates advanced fuel cell stack, hydrogen management and durability technologies required to meet our technical and business targets.

Importantly, this roadmap accelerates the commercialization timeline ahead of industry projections such as the 2040 outlook published by IATA and represents a bold and forward looking vision for the future of zero emission aviation.

¶ 12. References

- ZeroAvia. ZeroAvia Official Website. Available at: https://zeroavia.com/. Accessed 29 November 2025.

- ZeroAvia. ZeroAvia Makes Aviation History, Flying World’s Largest Aircraft Powered with a Hydrogen-Electric Engine. 19 January 2023. Available at: https://zeroavia.com/do228-first-flight/. Acessed 29 November 2025.

- Hemmerdinger, J. and Hardee, H. Universal Hydrogen completes first flight of hydrogen-powered Dash 8. FlightGlobal, 2 March 2023. Available at: https://www.flightglobal.com/airframers/universal-hydrogen-completes-first-flight-of-hydrogen-powered-dash-8/152306.article. Accessed 29 November 2025.

- International Air Transport Association (IATA). “Aircraft Technology Net Zero Roadmap.” 2023. https://www.iata.org/contentassets/8d19e716636a47c184e7221c77563c93/aircraft-technology-net-zero-roadmap.pdf. Accessed 29 Nov. 2025.

- H2Fly. “Vision.” H2Fly, https://www.h2fly.de/vision/. Accessed 29 Nov. 2025.

- ZeroAvia. (2023). ZA2000 Hydrogen-Electric Powertrain. ZeroAvia Official Website. Retrieved from https://www.zeroavia.com/za2000. Accessed 29 Nov. 2025.

- National Energy Technology Laboratory (NETL). (2010). Fuel Cell Handbook (7th ed.). U.S. Department of Energy. Retrieved from https://www.netl.doe.gov/sites/default/files/netl-file/FCHandbook7.pdf. Accessed 29 Nov. 2025.

- World Nuclear Association (WNA). (2023). Heat values of various fuels. Retrieved from

https://world-nuclear.org/information-library/facts-and-figures/heat-values-of-various-fuels. Accessed 29 Nov. 2025. - Carbon Credits. (2023). DOE Sets Eyes on Cutting Clean Hydrogen Cost to $1 Per Kilo by 2031. Retrieved from https://carboncredits.com/doe-sets-eyes-on-cutting-clean-hydrogen-cost-1-kilo-by-2031/. Accessed 29 Nov. 2025.

- Horizon Educational. (2023). Why Are the Prices of Fuel Cells Dropping? Retrieved from https://www.horizoneducational.com/why-are-the-prices-of-fuel-cells-dropping/t1422?currency=usd. Accessed 29 Nov. 2025.

- FuelCellsWorks. (2025). Stralis Completes 1,000-Hour Fuel Cell Test on Lightweight Hydrogen Stack. Retrieved from https://fuelcellsworks.com/2025/06/24/clean-energy/stralis-completes-1-000-hour-fuel-cell-test-on-lightweight-hydrogen-stack. Accessed 29 Nov. 2025.

- Cyan Ventures. Exploring choices and economic impacts for sustainable aviation fuel in New Zealand: Ready for take-off? July 2025. (Report published by Boeing Australia). https://www.boeing.com.au/content/dam/boeing/en-au/pdf/nz-safety-study.pdf. Accessed 29 Nov. 2025.

- Moutoussamy, Capt. Max. “Fuel Efficiency and the cost of savings: introducing the new service SFCO2.” Aircraft IT Operations, 2014. https://www.aircraftit.com/articles/fuel-efficiency-and-the-cost-of-savings-introducing-the-new-service-sfco2/. Accessed 29 Nov. 2025.

- SMBC Aviation Capital. Plane Insights Q2 2025. April 2025. https://www.smbc.aero/sites/smbc.aero/files/2025-04/SMBC%20AC%20Plane%20Insights%20Q2%2025.pdf. Accessed 29 Nov. 2025.

- Ministry of Economy, Trade and Industry (METI). “Aircraft and Space Industry Policy” [in Japanese]. 2023. https://www.meti.go.jp/shingikai/sankoshin/seizo_sangyo/kokuki_uchu/pdf/2023_001_02_00.pdf. Accessed 9 Oct. 2024.

- Oliver Wyman. “Global Fleet and MRO Market Forecast 2025–2035: Key Trends.” Oliver Wyman Insights, Feb. 2025. https://www.oliverwyman.com/our-expertise/insights/2025/feb/global-fleet-and-mro-market-forecast-2025-2035.html. Accessed 29 Nov. 2025.

- Forecast International / FlightPlan. “Airbus and Boeing April 2025 Production Rates and Unofficial Deliveries.” May 2, 2025. https://flightplan.forecastinternational.com/2025/05/02/airbus-and-boeing-april-2025-production-rates-and-unofficial-deliveries/. Accessed 29 Nov. 2025.

¶ 13. AI Statement

AI tools (e.g., ChatGPT) were used to brainstorm the Technical Models, Financial Models, and the List of R&D Projects, as well as to refine wording, correct grammar and spelling, and generate images for the Technology Strategy Statement swoosh chart.