Plasma-based Oxygen Generation in Space

Roadmap Creators: | Lanie McKinney | Roy Weinstock

Technology Roadmap Sections and Deliverables

This technology roadmap has the unique identifier:

2PBOGS - Plasma-based Oxygen Generation in Space

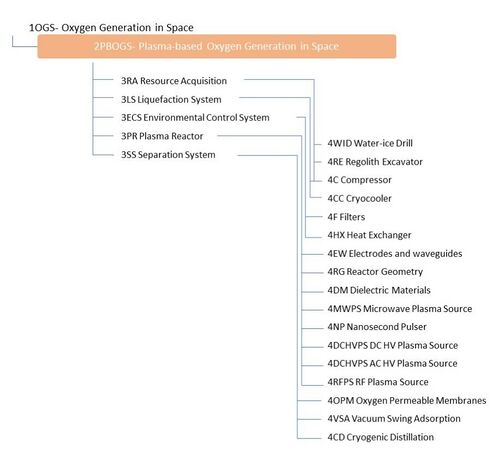

The number 2 denotes that this is a Level 2 technology roadmap at the product level. In reference to our technology, Level 1 encompasses all oxygen generation technologies that can be used in space. Level 3, the system level, references for example the plasma reactor configuration for conversion and Level 4, the subsystem level includes the kind of plasma source utilized.

Roadmap Overview

Oxygen generation in space is a critical enabling technology to support the development of human exploration of the Moon and Mars. NASA's Artemis program plans to head back to the Moon this decade in a phased approach to build up lunar activity, including a commercial and International presence, to serve as a proving ground for human missions to Mars. Increasingly longer stays off-world at destinations of increasing distance from Earth require technologies that recycle and utilize available resources, called in-situ resource utilization (ISRU), to make large mission architectures feasible and enable dramatic cost-savings. Notably, the most near-term large-scale oxygen demand will be driven by lunar lander propellant needs, like Starship and Blue Moon (both contracted by NASA as part of the Human Landing System). One projection estimates that the market valuation of the ISRU sector will reach 63$ billion by 2040, where 99% of the demand is driven by propellant [1]. There are three primary resources available in space to extract oxygen: water, CO2, and regolith (unconsolidated material on a planetary surface; soil). Water and oxygen found in regolith are both available on the Moon and Mars, whereas CO2 is only found in the Mars environment.

Non-thermal plasma reactors are emerging power-to-gas technologies with the potential to facilitate various chemical synthesis processes. In plasma-based systems, electrical power is used to ionize a feedstock gas, creating a highly reactive environment that leverages electron excitation chemistry to break stable molecular bonds and produce value-added products. Plasma reactors operate at non-equilibrium conditions which allows lower-temperature operation and instantaneous start-up, making them adaptable to intermittent power availability. Unlike other technologies, plasma reactors can process any feedstock, and have electrical settings and environmental conditions which can be tuned to optimize or favor particular products. Plasma reactors can reduce regolith and produce water (a source of oxygen) and transform CO2 into oxygen. This means that plasma-based conversion technologies are extensible to both near and far-term missions, and can be used where any of these resources are found on the Moon and Mars.

In the diagram above, the plasma-based technologies potential for performing multiple chemical conversion processes relevant to available resources on the Moon and Mars to produce oxygen are shown. The overall reaction that occurs in plasma-based CO2 conversion and plasma-based regolith reduction is given in equations (1) and (2) respectively, although a more complex set of underlying reactions involving energetic electrons enable these non-thermodynamically favorable transformations at ambient temperatures.

(1) 2CO2 → 2CO + O2

(2) MxOy + H2 → MxOy-1 + H2O

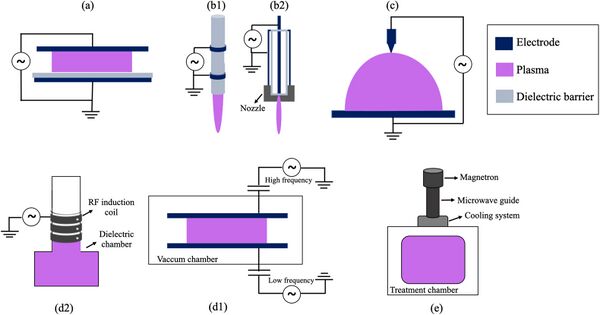

In the diagram below, a few of the common plasma discharge reactor configurations are shown, including (a) dielectric barrier discharges, (b1) plasma jet, (c) Corona discharges, (d1) Radiofrequency Inductively coupled plasma, and (d2) AC-driven Capacitively coupled plasmas, and (e) Microwave plasmas [2].

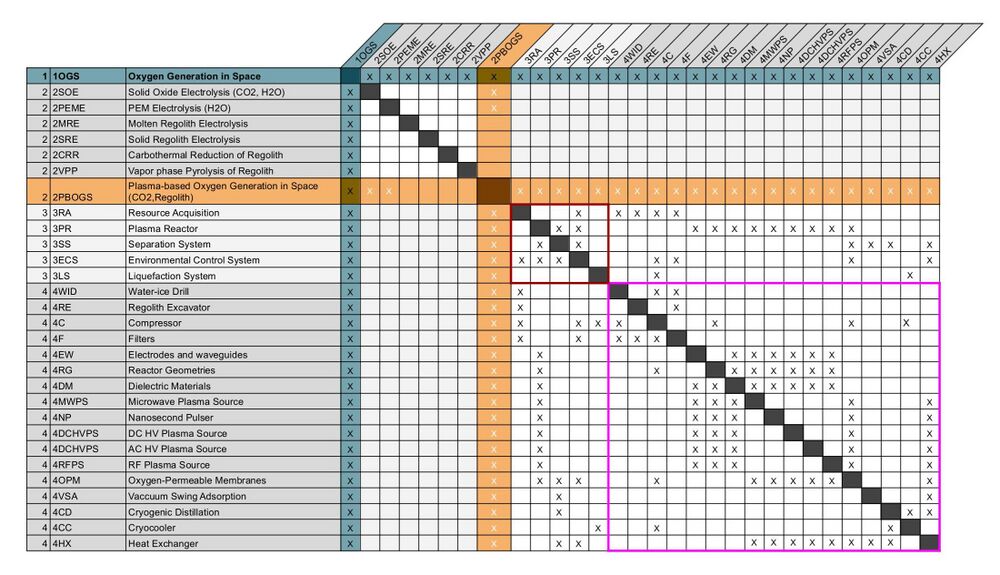

Design Structure Matrix (DSM) Allocation

The market level DSM for Oxygen Generation includes candidate technologies that can extract oxygen from a variety of resources available in space, namely CO2, water, and regolith. Interdependencies between technologies and systems are denoted with an X. Inside the enclosed boxes, the X's represent systems whose existence or operational conditions depend on another. For instance, the environmental control system controls the temperature and the pressure of the input stream, which are important for operating the plasma reactor and the separation system, so the respective boxes are marked with an X. Outside the enclosed boxes, an X represents technologies at level 4 which can be part of the level 3 systems. The orange row represents the 2PBOGS roadmap, the dark red box encloses the interdependencies between level 3 systems, and the pink box encloses the interdependencies between level 4 subsystems.

The DSM shows that the 2PBOGS roadmap can have either a dependency on electrolysis technologies or opportunities to combine them with plasma methods for enhanced performance. At the system level, key enabling technologies are the resource acquisition system (3RA), the plasma reactor (3PR), separation system (3SS), the environmental control system (3ECS), and the liquefaction system (3LS). At level 4, the enabling technologies include the acquisition systems needed to extract the different resources (4C, 4WID, 4RE), the systems to control the conditions of the input stream (4F, 4HX, 4C), 5 different kinds of plasma sources (3MWPS, 3NP, 3DCHVPS, 3ACHVPS, 3RFPS) which generate plasmas in different ways, 3 technologies related to reactor design (4RG, 4DM, 4EW), 3 relevant kinds of separation technologies (3OPM, 3VSA, 3CD), and subsystems needed to facilitate liquefaction (4CC, 4C). The DSM at this level demonstrates the cluster of interdependencies around the selection of the the plasma source and elements of the overall reactor configuration. Different combinations of level 4 elements, like the plasma source, reactor geometry, and separation subsystem may lead to novel performance.

Roadmap Model using OPM

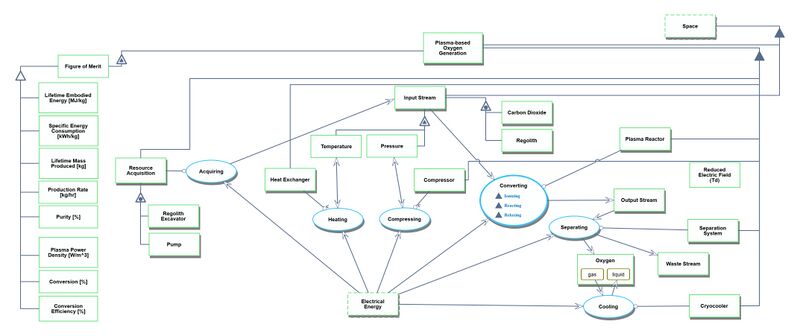

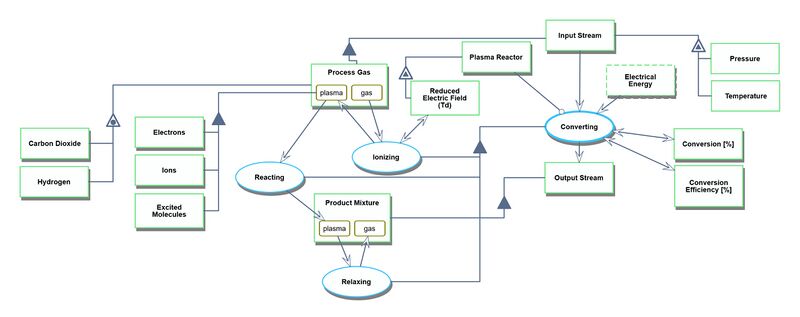

An Object-Process-Diagram (OPD) of the 2PBOGS roadmap is given in the figure below. This diagram captures the main product of the roadmap (level 2) and decomposes the product into four main systems (resource acquisition, environmental control, plasma reactor, and separation) corresponding to level 3 in the DSM and displays the figures of merit (FOMs).

Unfolding the converting process at level SD1

An Object-Process-Language (OPL) description of the roadmap scope is auto-generated and given to the side. It reflects the same content as the previous figure, but in a formal natural language.

Figures of Merit

The table below show a list of FOMs by which Plasma-based Oxygen Generation technologies can be assessed. The first five (shown in bold) are used to assess the technology compared to other competing technologies in level 2, enabling comparisons at the market level. The following three rows represent subordinated FOMs which impact the performance and true cost of this technology, but are provided as outputs (primary FOMs) from lower level roadmaps at level 3 or level 4, see the DSM above. Additionally, the last three FOMs are captured in the first five composite metrics.

| Figure of Merit | Unit | Description |

|---|---|---|

| Lifetime Embodied Energy | MJ/kg | the thermodynamic sum of past, present and future work required to create, operate, maintain and decommission a system |

| Specific Energy Consumption | kWh/kg | total energy required to produce a kg of product, a measure of energy efficiency |

| Production Rate | kg/hr | resource mass generation rate which captures the benefit any ISRU technology (can be specified as either average or maximum) |

| Lifetime Mass Produced | kg | total mass produced over the system's lifetime |

| Purity | % | percentage of the target product in separated product stream, measures the performance of the conversion-separation systems |

| Plasma Power Density | W/m3 | the power delivered to the Plasma normalized by the gas density, which drives chemical reactions |

| Conversion | % | ratio of useful product generated to the total available input reactant |

| Conversion Efficiency | % | ratio of theoretical energy required for targeted chemical conversion to the total energy consumed by the process |

| Total System Power | kW | the total power required to operate the complete system |

| Total System Mass | kg | total mass of all subsystems |

| System lifetime | hr | the total length of time system can operate until end-of-life |

Important FOMs (bolded) such as Lifetime Embodied Energy and Specific Energy Consumption can be calculated from the equations in the table below, though there are dependencies on other major and subordinate FOMs (plain text) like conversion, conversion efficiency, etc which must be obtained through simulations, experiments or a combination of both. Inputs that are indented and italicized are environmental and reactor variables and conditions.

| Inputs | Key Relationships/Equations | Outputs |

|---|---|---|

| Reduced Electric Field E⁄n Gas density Electron density |

Pplasma = e μe ne n2 ( E⁄n )2 = f( E⁄n ) ne n |

Plasma Power Density [W/m3] |

| Plasma Power Density [W/m3] Reactor Temperature Reactor Pressure Flow rate |

simulations - experiments | Production Rate [kg/hr] Purity [%] Conversion [%] |

| Plasma Power Density [W/m3] Conversion [%] (α) Reaction Enthalpy (kJ/mol) Molar Flow rate Gas Density |

ηconv = ΔH α n⁄vflow Pplasma | Conversion Efficiency [%] |

| Production Rate [kg/hr] Total System Power [kW] |

SEC = Ptot⁄rprod | Specific Energy Consumption [kWh/kg] |

| Production Rate [kg/hr] System Lifetime [hr] |

LMP = t rprod | Lifetime Mass Produced [kg] |

| Specific Energy Consumption [kWh/kg] Production Rate [kg/hr] System Lifetime [hr] Total System Mass [kg] Δ v |

LEE = 3.6 × SEC + 1⁄2 (η mtot (Δv)2)⁄ (LMP x 106) | Lifetime Embodied Energy [MJ/kg] |

Notes

Plasma power density, although a subordinate FOM, is a key governing equation which demonstrates the fundamental mechanism which drives the chemical reactions. The equation implies the important dependence on the reduced electric field, where different plasma sources and generation mechanisms obtain different ranges of E/n, and this greatly influences the chemistry inside the reactor.

Lifetime Embodied Energy (LEE) is defined as “...the thermodynamic sum of past, present and future work required to create, operate, maintain and decommission a system, including appropriate shares of indirect contributions from upstream systems as well as from other systems in a system-of-systems [3].” This metric has been shown to reproduce results from Equivalent System Mass and IMLEO analyses while decoupling from launch mass (which is becoming an outdated cost proxy). This FOM utilizes the total energy required across the whole architecture's lifetime as a proxy for cost, and normalizes it with the lifetime mass produced. This (cost/benefit) is an extremely relevant metric to the space industry for determining what the real cost of developing infrastructure and operating a space resource generation technology over long time periods to capture economies of scale and identify promising business use cases.

The conversion efficiency reported, a commonly used metric from the plasma community, is not suitable for comparison to "faradaic efficiency" which is used by the electrolysis community. This is a huge problem in the literature, where different technological communities and disciplines report different kinds of efficiency metrics which may obscure the fundamental limits or benefits of the technology in comparison to others. A more general FOM, like SEC, should be used for all comparisons across different technologies.

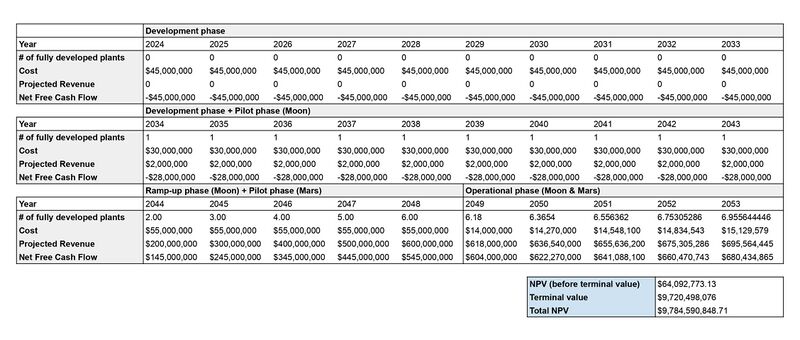

Time Evolution of Figures of Merit

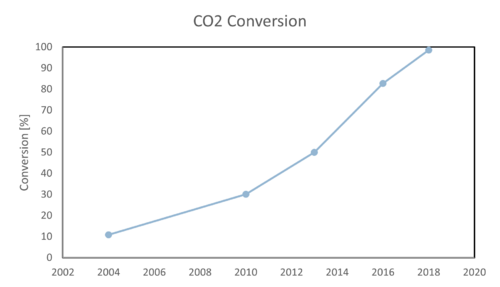

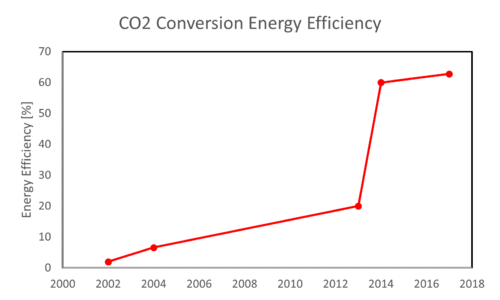

Both ISRU technologies and plasma-based chemical conversion technologies are in the early stages of development, and no full-scale product exists using the technology at this time. However, detailed study of plasma reactors for CO2 conversion at level 3 has led to a plethora of literature, detailed modeling and experiments, databases classifying results, and enhanced understanding of the critical technology at the roadmap level 3PR (see the DSM above). Identified FOMs like conversion and conversion efficiency can be modeled overtime to assess the progression of this technology.

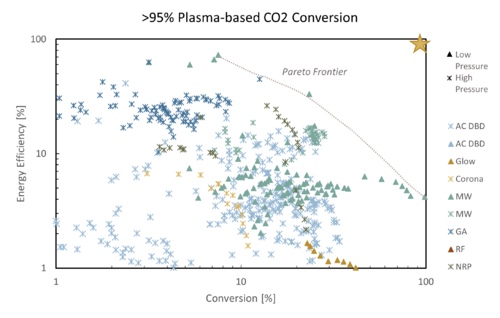

Interestingly, the theoretical maximum conversion has nearly been achieved in a particular system. However, as with many technologies, there is a trade-off between FOMs. Driving conversion higher in plasma reactors typically requires increasing power deposition which worsens energy efficiency, and vice versa. This can be visualized by the pareto frontier in this reference image.

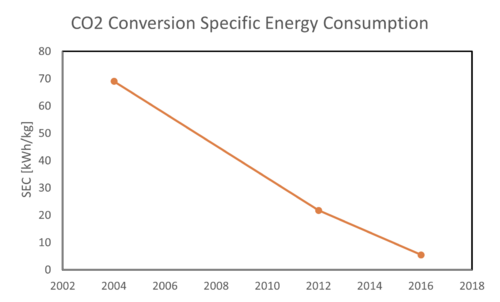

Specific energy consumption is a more general FOM for comparison to other technologies, and it generally trends down with increases in energy efficiency, seen in the plot below. In each of these cases, only plasma power is taken into account, so they are all underestimates of the SEC of a full system, though the conversion system will likely drive the power requirements.

- There are experiments from the 70s and 80s that predate some of the data tracked in conversion and efficiency, however much of that experimental data was not reproduced in the ranges achieved until recently. All data obtained and processed for further analysis in these plots was obtained from the Pioneer Database [4].

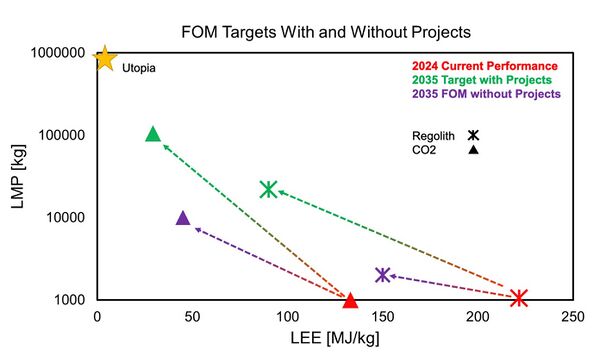

Alignment with company strategic drivers

Our “company” is a space resources start-up aiming to develop a common plasma-based oxygen generation technology architecture which can support the anticipated propellant demand on the Moon and Mars. This architecture, much like Starship's original and Lunar variants, will utilize the same underlying technology and modify the system for the two environments to enable rapid and cost-efficient development. The table below shows the three main strategic drivers and the necessary alignment of the 2PBGOS technology roadmap with them.

| Strategic Drivers | Alignment and Targets |

|---|---|

| To explore and assess novel plasma reactor configurations to search for synergistic and optimized performance by 2028. | The 2PBGOS roadmap is targeting the demonstration of reactor prototypes which can reduce demonstrated Specific Energy Consumption by ~22 kWh/kg for both CO2 conversion and regolith reduction (Mars and Lunar variant). |

| To achieve competitive performance in both Lunar and Mars variant prototype systems and pilot plants which are capable of producing a high-purity stream of oxygen from available local resources by 2035. | The 2PBGOS roadmap will target a plasma-based oxygen generation prototype system which can achieve an SEC of 8 and 25 kWh/kg and with a gas stream purity of 99.6% and be feasibly scaled to pilot plant production rate of 0.22 and 1.14 kg/hr and an LEE of 30 and 80 MJ/kg for the Mars and Lunar variant respectively. |

| To design and develop a full-scale Lunar variant plant can produce oxygen to support Starship-scale propellant demand at a maximum 500$/kg O2 from available local resources for deployment by 2045. | The 2PBGOS roadmap will target a plasma-based oxygen generation system which scales the production rate by 100 times to a production rate of of 22 kg/hr (200 ton per year) and achieves an LEE of 80 MJ/kg. |

| To develop a system for processing reduced metals stream from the Lunar pilot and full-scale plants for deployment in 2055. | Though this is a natural next step in the ISRU business, the 2PBGOS roadmap does not include the technologies needed to process the waste stream into value-added products, so this roadmap is currently not aligned with this driver. |

| To develop a plasma-based system which can directly generate separate streams of oxygen and hydrocarbons, like CH4 and C2H4, from a stream of CO2 and water by 2040. | The 2PBGOS roadmap promotes investment in technology development which can be directly extended to this driver. Although related, this roadmap is currently not aligned with this driver. |

The list of drivers shows that the company views plasma-based oxygen generation as a potential new fuel production business in space and wants to develop it as a commercially viable (for profit) business (1). In order to do so, the first and second drivers aim to match or exceed demonstrated and expected performance of MOXIE's larger-scale counterpart BAM to offer competitively priced propellant on Mars, as well as relieve the requirement of mining water in lunar PSR's while offering competitively priced oxygen on the Moon compared to other regolith ISRU methods. The targeted price comes from an assessment of a competitive price for a commercial Lunar propellant architecture in this study [5]. The fourth and fifth drivers are not aligned with this roadmap, although this roadmap does strategically invest in enabling technologies and knowledge acquisition and identified relevant, high-level FOMs like LEE and SEC which directly apply to this technology. These extended technologies could process the reduced metals from the Lunar variant and simultaneously produce oxygen and hydrocarbons in the Mars variant, extending and branching from the focus of this roadmap. The fifth driver is notable because in addition to use on Mars, this technology also has the potential to tap into Earth-based markets for sustainable reforming of CO2 and H2O into value-added products.

Positioning of company vs. competition

The table below shows a summary of FOM for other oxygen-generation technologies obtained from public data, where the first three reported FOM values are what has been achieved to date. Predicted SEC and LEE of the full system (from a combination of publications and first principle calculations), as well as TRL designations are included to holistically evaluate the progression of these technologies, recognizing that many of them will have enhanced performance when scaled up beyond the demonstrator stage and that the true cost of utilizing the technology will only be fully understood at scale.

| Oxygen Generation Technology | Resource | Product/ Project Name | Company/Agency | SEC (kWh/kg) | Production Rate (kg/hr) | Purity (%) | Predicted SEC (kWh/kg) | Predicted LEE (MJ/kg) | TRL | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Solid Oxide Electrolysis | CO2 | MOXIE | OXEON, NASA | 31 | 0.01 | >99.6% | 8.98 | 33.9 | 6 | [6] |

| PEM Electrolysis | H2O | IHOP | Paragon/Griner | 5.83 | 0.65 | >99% | 11.425 | 21.1 | 4 | [7] |

| Molten Salt Electrolysis | Regolith | ROXY | Airbus | * | 0.000143 | * | 16.4 | 64.3 | 3 | [8] |

| Molten Regolith Electrolysis | Regolith | - | MIT, NASA | * | * | * | 23.8 | 86.0 | 4 | [9] |

| Carbothermal Reduction | Regolith | CARD | Sierra Space | 45.7 | * | * | 42.7 | 157.3 | 5 | [10] |

\* indicates unpublished work or trade secrets. Where information is unavailable, either projected values in the literature or first principles calculations were used to supplement the data.

The following companies have recently indicated they are developing oxygen production technologies, sometimes even receiving development funds in the form of a government contract, but no performance information is available at this time: Regolithix, Helios, Blue Origin, Lunar Resources, Ethos space, Cislune, iSpace.

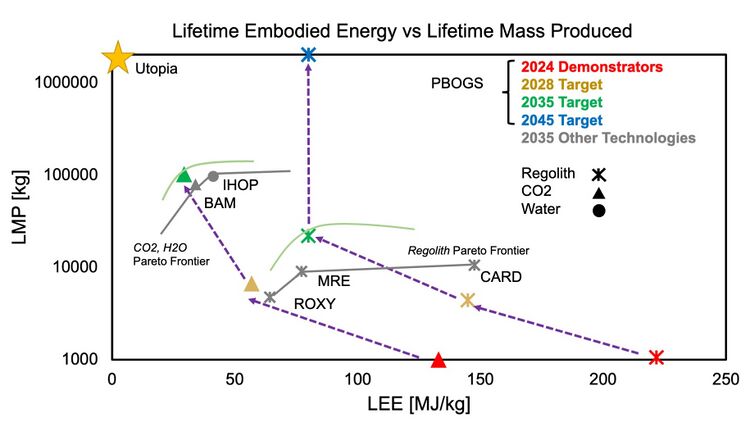

In many cases above, there is not enough current information about the laboratory scale developments taking place to place all technologies in their current context, although many papers include projected metrics based on detailed design studies of scaled-up systems. While these FOMs may be optimistic, they can begin to communicate how these different technologies compare at full-scale implementation to drive investment strategies. Notably, the demonstrator stages focus on the reported performance of the ISRU conversion subsystem. But for estimates of the scaled-up plant, estimates of the oxygen liquefaction and resource extraction energy (like water mining in Lunar permanently shadowed regions [11]) are included in the final estimated values shown in the chart below. Although electrolysis systems are used on Earth, space-based systems have yet to reach the market, so the pilot plant estimates of competing technologies include all technological advancements until the target year of 2035, when these technologies are expected to enter the market at the pilot scale.

As you can see, the projected performance of MOXIE (BAM) and IHOP inhabit the current estimated pareto frontier for ISRU oxygen generation, which cover ISRU on both the Moon and Mars. MOXIE is also the most advanced ISRU technology to date, because it is the only technology demonstrated on another planetary body. However, the O2 propellant value chain begins in the near-term at the Moon, and CO2 is not an available resource. The options then are to electrolyze water mined from Lunar permanently shadowed regions as the IHOP architecture requires, or extract it from regolith. The value proposition of extracting oxygen from regolith is twofold: it relaxes the requirement of producing propellant near water, and metal byproducts of the process begin the start of it's own Lunar value chain (not quantified in this roadmap). However regolith processing has proven to be more challenging and energy-intensive, seen in the "regolith" pareto frontier lagging behind other technologies in terms of pure oxygen production.

Target 1 aims to take each variant from a TRL 3 proof-of-concept stage to a TRL 4 breadboard reactor prototype which includes investigating different reactor configurations for optimized performance. Because these two variants have only been recently established as TRL 3, the projected jump in performance is reasonable if given appropriate R&D investment. In the case of CO2, target 1 matches the performance of the plasma subsystem at Level 3 of the DSM, but also requires the incorporation and improvement on the separation subsystem. In the case of regolith reduction, no molten materials or high-temperatures are required for the improvement of its performance. Target 2, which deals with the architecture level, aims to develop a plasma system with two variants for the Moon and Mars respectively. The regolith reduction variant aims to push the regolith pareto frontier forward by eliminating the challenging engineering requirements of handling high-temperatures, molten materials, or multiple chemical processes and combining with the state-of-the-art water-electrolysis technology. Target 3 is focused on the deployment of the Lunar variant at full-scale to meet the propellant demand on the Moon that will be driven by Starship, scaled such that Lunar-derived oxygen can be sold for a competitive price compared to transport costs. These targets include demonstrations and realistic performance goal given the architecture-level FOMs on an ambitious timeline to meet the propellant demand needs at the Moon and Mars.

Technical model: Morphological matrix and tradespace

In order to assess the feasibility of technical targets at the level of the 2PBGOS roadmap, it is necessary to develop a technical model. There are three major discrete design variables that must be considered in the reactor design, also captured in the dependencies in the DSM, and the table below shows these choices.

| Key Architecture Decisions | Affects | Options | |||||

|---|---|---|---|---|---|---|---|

| Plasma Source | E/n, Plasma Power, Lifetime, Conversion/Efficiency, System Mass | HV DC | HV AC | Nanosecond Pulser | MW | RF | |

| Geometry | Conversion/Efficiency, System Mass | Plate-to-Plate | Coaxial | Torch/Plume | Standard GA | GA Plasmatron | MW or RF |

| Separation System | Total Power, Purity | Cryogenic Distillation | Vacuum Swing Adsorption | Mixed Ionic Electronic Conducting Membranes | Solid Oxide Electrolysis Cell | Proton Exchange Membrane (Electrolysis) | |

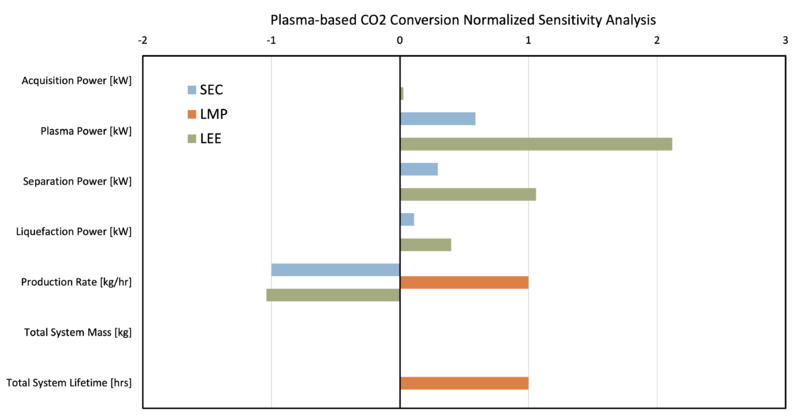

Other key decisions are reactor operating temperature, pressure, and flow rate where optimal configurations require detailed chemical kinetic and physics-based simulations and are the subject of a level 3 plasma reactor roadmap. To develop a technical model at the level of this roadmap, the best-available data captured for CO2 conversion will be used to place the full system in context and perform a sensitivity analysis on FOMs SEC, LMP, and LEE, which are related to but somewhat disjointed from the morphological matrix.

| Key FOM | Governing Equation | Partial derivatives |

|---|---|---|

| Specific Energy Consumption [kWh/kg] | SEC = (Pacq + PECS + Pplasma + Psep + Pliq) ⁄ rprod | δSEC ⁄rprod = (Pacq + PECS + Pplasma + Psep + Pliq) ⁄ rprod2 δSEC ⁄ Px = 1⁄ rprod |

| Lifetime Mass Produced [kg] | LMP = t rprod | δLMP ⁄rprod = t δLMP ⁄ t = rprod |

| Lifetime Embodied Energy [MJ/kg] | LEE = 3.6 × SEC + 1⁄2 (η mtot Δv)2 ⁄ (LMP x 106) | δLEE ⁄rprod = 3.6 x (Pacq + PECS + Pplasma + Psep + Pliq) ⁄ rprod2 - (η Δv2 ⁄ 2 x 106) x (mtot ⁄ t rprod2) δLEE ⁄ Px = 3.6 ⁄ rprod δLEE ⁄mtot = (η Δv2 ⁄ 2 x 106) x (1 ⁄ t rprod ) δLEE ⁄ t = - (η Δv2 ⁄ 2 x 106) x (mtot ⁄ t2 rprod) |

A design vector formulated using a series of reference values for the current state of the art of CO2 conversion for Mars ISRU (and scaled up x100) provided in [12] is presented below. A linear scaling law was implemented, as it is established that in current configurations plasma reactors power tends to scale linearly with production rate [13].

| Plasma Source & Geometry | Separation System | Temperature | Pressure | Pacq | PECS | Pplasma | Psep | Pliq | rprod | System Mass | System Lifetime | SEC | LEE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MW | SOEC | 250 K (Mars Ambient) | 5 Torr (Mars Ambient) | 0.25 kW | 0.0 kW | 20 kW | 10 kW | 3.75 kW | 1.4 kg/hr | 600 kg | 100,000 hrs | 24.3 kWh/kg O2 | 87.5 MJ/kg |

Key insights from this plot are that SEC drives LEE, or the measure of the true "cost" of operating this space system, and subsequently the effect of mass and system lifetime are negligible in comparison for total LEE. This LEE analysis is not taking into account any modifications, maintenance, or in-situ fabrication of parts. System lifetime does however play an important role in increasing the lifetime mass produced, and all things being equal, improving system lifetime can increase lifetime profits of a given plant system. Scaling production rate has important consequences on SEC and by extension LEE, though this scaling oftentimes is non-linear (conversion percentage changes with higher-throughput in the same system). The key underlying challenge then is to find power savings, improve the efficiency of the conversion process, or find configurations that enable optimal power scaling with production rate. In this configuration Plasma power is the primary contribution to the total power budget, and has the highest impact on the overall cost in LEE. The separation system makes up the second largest-contribution, and coupled plasma conversion-separation systems for CO2 are much more challenging than for water, and are still a relatively open area of investigation. This demonstrates alignment with performance Targets 1 and 2 and provides focus and direction for building a prototype reactor that can be feasible scaled.

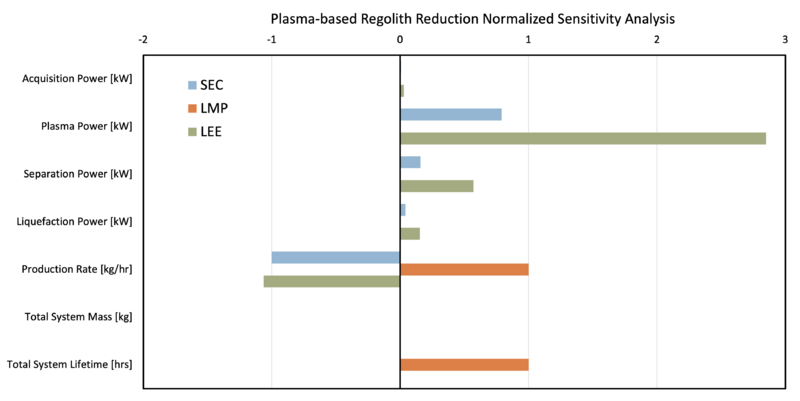

A design vector formulated using a series of reference values for the current state of the art of plasma-based regolith reduction for Lunar ISRU (and scaled up x100 with the aforementioned Linear scaling law) is presented below.

| Plasma Source & Geometry | Separation System | Temperature | Pressure | Pacq | PECS | Pplasma | Psep | Pliq | rprod | System Mass | System Lifetime | SEC | LEE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DC, Torch/Plume | VSA, PEM | 200 K | 5 Torr | 0.5 kW | 0.0 kW | 50 kW | 10 kW | 2.68 kW | 1 kg/hr | 500 kg | 100,000 hrs | 63.2 kWh/kg O2 | 227.5 MJ/kg |

The Lunar variant sensitivity analysis strongly resembles and reflects the tornado model presented for plasma-based Co2 conversion, as they are very similar technlogies. The major difference is that the LEE is even more strongly sensitive to plasma power required to produce a certain amount of an Oxygen, and less sensitive to the separation power requirements. This makes sense considering the relative immaturity of the technology (TRL 3) and the lack of active investigation towards optimization in the plasma subsystem, whereas the separation systems for water (water electrolyzers) are more advanced. The model demonstrates the importance of reducing the plasma power required to produce a certain amount of water, which could be accomplished through improving active surface area of regolith, as well as optimizing flow rate and electronic parameters. This high-sensitivity of plasma power strongly motivates performance Targets 1 and 2 and provides focus and direction for building a prototype reactor.

Keys Patents and Publications

Patent Analysis

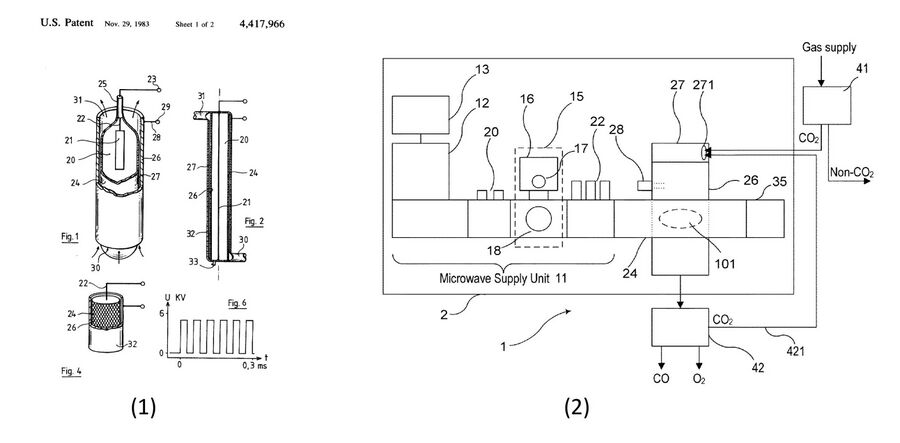

A challenge with patent analyses using the US patent database is that the term "plasma" also can refer to blood plasma, so many unrelated medical patents will appear in the search. The most effective patent analysis tool for this technology was Google Scholar, using the word "patent" in the search keywords along with phrases like "plasma chemical conversion" and "non-thermal plasma reactor". The search yielded patents for many different reactor configurations, where reactor design has been modified (sometimes only in very small ways) compared to others for enhanced production in some particular process. Two key patents have been identified which have been commercially realized:

Patent: "Apparatus and method of producing ozone [14]"

Patent #: US 4,417,966 A

Date of Patent: Nov 29, 1983

Patent Owner: Innovatron Krauss & Co

CPC Classification: H01T19/00; C01B13/11

- International Classification: CO1B 13/10

- US Classification: 204/176; 422/186.18; 422/186.19; 422/186.15

Details: Patent US 4,417,966 A, visualized in image (1) below, is the earliest example of plasma-based chemical conversion device on an industrial scale. This device uses one of the most well studied reactor configurations to date, an AC dielectric barrier discharge, to generate ozone (O3) from input oxygen (O2).

Relevancy: The patent has since expired, but the device has inspired the use of the reactor to study many kinds of chemical conversion processes, including CO2 conversion, water splitting, the reforming of methane, ammonia synthesis, sustainable aviation fuel synthesis, and more.

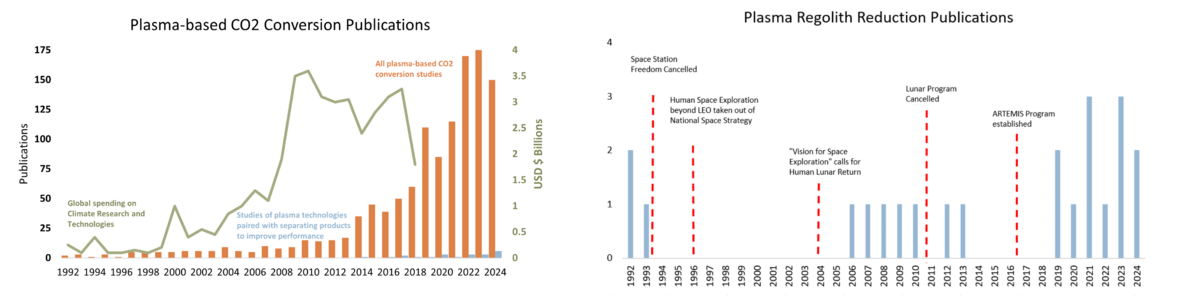

Patent: "Gas Conversion System [15]"

Patent #: US 8,633,648 B2

Date of Patent: Jan 21, 2014

Patent Owner: Recarbon Inc.

CPC Classification: B01J19/12

- International Classification: HOL 7/24

- US Classification: 315/111.01-111.91

Details: Patent US 7,402,018 B2, visualized in image (2) below, is a general MW plasma reactor designed for scalability and commercial implementation. The system specifies CO2 conversion but can be utilizes with any process gas. In fact, the company currently utilizes this system for the dry reforming of methane (CO2+CH4) to produce negative-carbon value-added products.

Relevancy: This technology utilizes a different plasma source and reactor configuration than the patent above, but it's intention is specicially to perform CO2 conversion and fuel synthesis, which is particularly relevant for the Mars variant.

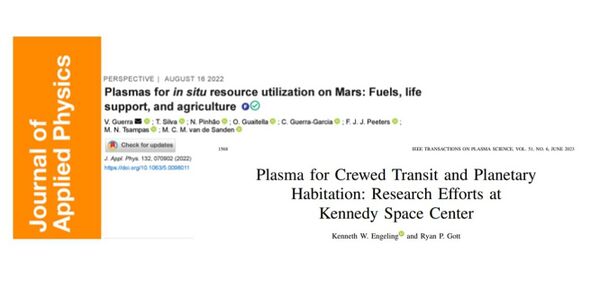

Publication Analysis

A publication analysis over time was conducted for studies relevant to the Lunar and Mars variant also using Google scholar, using key phrases like "plasma CO2 conversion," "plasma ISRU," "plasma regolith reduction." As shown in the figure below, the trend in publications involving plasma-based CO2 conversion (Mars variant) tracks well with increasing global funding on climate research and technology [16] because its initial conception was for point-source recycling of CO2 emissions or for carbon-utilization with direct air capture. Notably, the studies on separation technologies, which are typically energy-intensive with the resulting effluent mixture created by plasmas, are lagging behind studies of the plasmas themselves.

In contrast, the Lunar variant process has an extremely limited assortment of publications. The cadence of publications tracks extremely well with historical periods where a Lunar return was a priority of current national space policy in the US. In periods where focus (and funding) moved elsewhere, there are essentially 0 publications. This can be attributed to several factors: (1) that burgeoning plasma-based technologies are still rather niche, (2) there is little practical motivation for this technology besides Lunar ISRU, and (3) the political instability of human spaceflight programs has stifled any traction this technology could have gained.

Several key publications and presentations were evaluated which discuss the applications of plasma-based oxygen production from available resources in both the Lunar and Mars environment:

Paper: Plasmas for in situ resource utilization on Mars: Fuels, life support, and agriculture [12]

Author(s): V. Guerra, T. Silva, N. Pinhão, O. Guaitella, C. Guerra-Garcia, F. J. J. Peeters, M. N. Tsampas, M. C. M. van de Sanden

Organization: Instituto Superior Téchnico, Lisboa (Lead)

Details: The first publication discusses the benefits of utilizing plasma-based CO2 conversion (among other plasma-based technologies) on Mars, summarizing the current-state of the art in CO2 conversion research, and the next steps toward developing this technology for application in space.

Relevancy: Based on current performance of small plasma reactors which is still at the laboratory scale, it is estimated that a specific energy consumption of ~21 kWh/kg are feasible at the system level, which is competitive with MOXIE and can be further optimized.

Citation: V. Guerra, T. Silva, N. Pinhão, O. Guaitella, C. Guerra-Garcia, F. J. J. Peeters, M. N. Tsampas, M. C. M. van de Sanden; Plasmas for in situ resource utilization on Mars: Fuels, life support, and agriculture. J. Appl. Phys. 21 August 2022; 132 (7): 070902. https://doi.org/10.1063/5.0098011

Paper: Plasma for Crewed Transit and Planetary Habitation: Research Efforts at Kennedy Space Center [17]

Author(s): K. Engeling and R. Gott

Presentation: Plasma Reduction of Regolith for Oxygen Liberation

Author(s): R. Gott, E. Petersen, K. Engeling, N. Azim, C. Franco, and J. Olson.

Organization: NASA Kennedy Space Center

Details: This publication and related presentation discusses the advantages of using plasma-based regolith reduction compared to other methods, which include avoiding molten products and heating a reducing agent while still creating a reactive environment. The publication also discusses their proof-of-concept demonstration and provides their experimental results in terms of water yield. In the presentation by the same team about the same effort, a specific energy consumption of 61.5 is extracted considering the additional energy required for electrolysis and liquefaction for this proof-of-concept which includes almost no optimization [18].

Relevancy: The most similar technology, carbothermal regolith reduction, which is already TRL 5, has a SEC estimate of 42 kWh/kg with much less room for optimization, motivating further investigations and optimization of a plasma-based technology.

Citation 1: K. W. Engeling and R. P. Gott, "Plasma for Crewed Transit and Planetary Habitation: Research Efforts at Kennedy Space Center," in IEEE Transactions on Plasma Science, vol. 51, no. 6, pp. 1568-1579, June 2023, https://doi.org/10.1109/TPS.2023.3277216

Citation 2: Gott, R., Petersen, E., Engeling, K., Azim, N., Franco, C., & Olson, J. (2021). Plasma reduction of regolith for oxygen liberation. Presentation at the Gaseous Electronics Conference, virtual meeting, October 4–8, 2021. NASA Kennedy Space Center. https://ntrs.nasa.gov/citations/20210021294.

In summary, most of the relevant patents focus on a particular reactor configuration for a specified process, with no patents emerging for plasma-ISRU-specific systems, though the exploration of many different processes for these different reactor configurations have been carried out in the literature. The key publications identified focus on the feasibility of these technologies for ISRU and their competitiveness compared to other available technologies

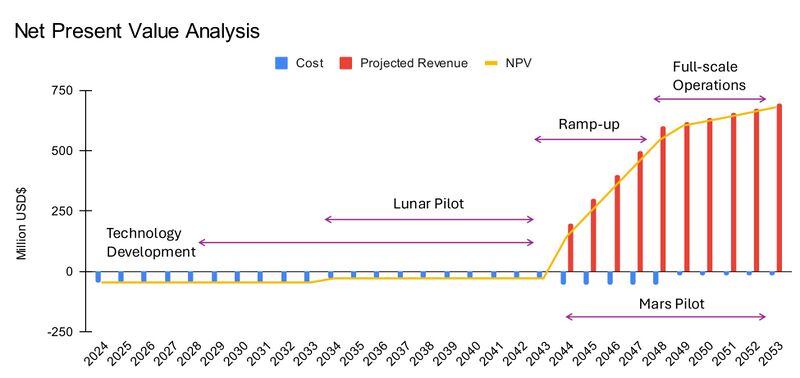

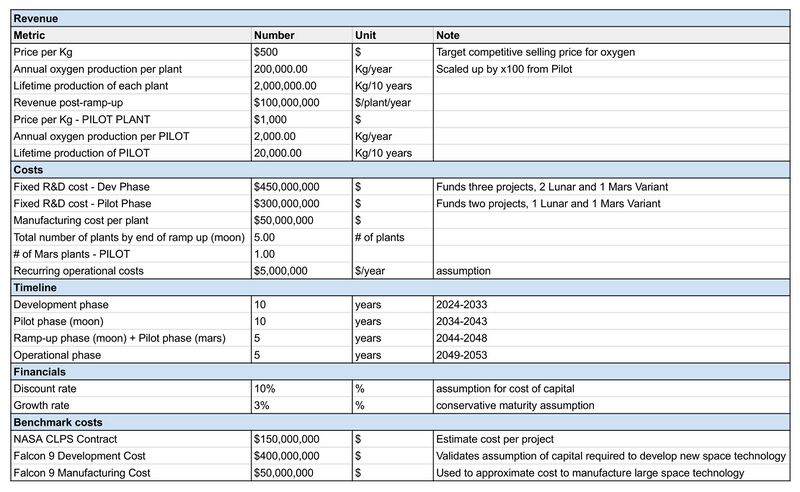

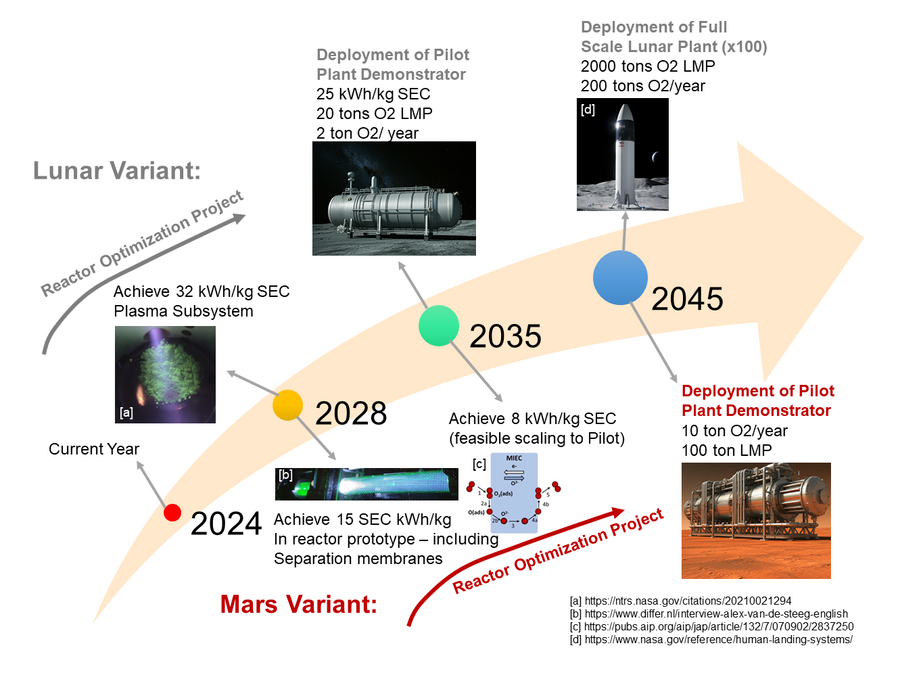

Financial Model

This financial model evaluates the feasibility of this ambitious roadmap, factoring in costs, revenues, and government contracts. While significant government subsidies can be used to help offset the $450M R&D cost towards developing full-scale Lunar production plants and $300M towards developing a Mars pilot plant, these are treated as project costs to accurately assess Net Present Value (NPV). By incorporating both Moon-based large-scale plants and a Mars pilot operation, the analysis provides a view of the project’s potential for sustainable growth. The figure below contains an NPV analysis underlying the 2PBGOS roadmap, and shows the non-recurring cost of the pilot and full-scale product development projects which span 20 years (2024-2043) and includes the R&D expenditures as negative numbers. This long development time is needed to feasibly mature and scale the technology and advance to meet future propellant demands that will not exist until significant infrastructure begins to be delivered to the Moon. Starting in 2043, a ramp up-period of 5 years is planned with the establishment of 5 plants on the Moon. Total revenue grows significantly, reaching over $695M by 2053 during the operational phase.

Several key assumptions are incorporated in this financial model. According to a study on a commercial Lunar propellant architecture, the estimated cost per kg of propellant a Lunar customer would be willing to pay is 500$/kg [5]. The full-scale plant production rate, 200 ton per year, established by the 2045 target 3, contribute to a total annual revenue of $200M. Other model assumptions include the approximated development costs based on benchmarks achieved by SpaceX (~$400M for Falcon 9 [19]) and awarded through NASA contracts (NASA Commercial Lunar Payload Service for ~150M [20]), as well as manufacturing and deployment costs ($55M per plant). Operational costs are estimated to be 5M$ a year per plant.

The total program duration exceeds the 30 year financial analysis, however a terminal value can be used to estimate the value of a project’s cash flows beyond the explicit forecast period and into full-scale multi-planetary operations, capturing its long-term operational viability. Before the terminal Value, the NPV is $64.1M, reflecting limited profitability during the development and ramp-up phases. Using an conservative estimated annual growth rate of 3% and a discount rate of 10%, the calculated terminal value, $9.72B, increases the total NPV to $9.78B, demonstrating significant long-term value creation. The terminal value accounts for cash flows from Moon and Mars operations after 2053, assuming continued growth or stability. By incorporating terminal value, we acknowledge the project’s ongoing revenue-generating potential even after the operational phase explicitly modeled in the financial analysis. It is a critical component for large-scale, long-duration projects, ensuring that the NPV calculation reflects the true long-term value of the investment.

Government support drives the feasibility of this roadmap. NASA contracts and other subsidies will play a pivotal role in offsetting high R&D costs, making the initial phases of the project financially viable. While cash flows remain negative during development and early ramp-up, the transition to operational profitability demonstrates the project’s strong long-term potential, with significant cash flow contributions from both Moon and Mars operations. The project’s ability to scale from a $2M Mars pilot operation to nearly $700M annual revenue by 2053 highlights the effectiveness of phased ramp-up and operational scalability. The $9.72B terminal value underlines the importance of ongoing operations, making up the majority of the project’s total NPV.

This roadmap has a total NPV of $9.78B, driven by scalable Moon operations and a Mars pilot program. While initial phases require significant investment and face financial challenges, the project’s long-term profitability and substantial terminal value demonstrate its feasibility and strategic importance. By leveraging government support, efficient scaling, and a multi-planet production strategy, this ISRU propellant production initiative sets a strong foundation for the future of human space exploration.

List of R&T Projects and Prototypes

A series of projects considered to achieve the stated performance targets and appropriate technological maturation for implementation in Space is listed below along with the investment decision.

| Project | Target | Description | Investment Decision |

|---|---|---|---|

| Lunar Variant Plasma System Optimization | 2028: SEC = 40 kWh/kg

2035: SEC = 25 kWh/kg |

This project is a long-term investigation to empirically study optimized reactor configurations and architectures and improve the performance of the Lunar variant. | Yes On this topic, the literature is extremely sparse (see Patents and Publications section), and detailed investigations are needed beyond proof-of-concept to meet the 2028 and 2035 performance targets. |

| Lunar Variant Separation Subsystem Investigation | 2035: SEC = 8 kWh/kg | Improve state-of-the-art PEM electrolyzer performance and/or VSA for H2/H20 separation. | No Improving this technology will not make plasma technology more competitive than carbothermal reduction for example, which also uses water electrolysis. There is some sensitivity to this value (non-negligible importance), but these are already extremely mature technologies that have less room for improvement and optimization than others on this list. |

| Lunar Variant Pilot Plant Demonstrator | 2035: rprod = 2 tons/year, LMP = 20 tons | A pilot plant demonstrator is targeted at (1/100th) of a full-scale plant to support the initial human Lunar return. | Yes This project is necessary to prove the technology, advance its TRL to 9, and gain traction as a competitive method of generating propellant to win contracts and funding to build full-scale plants. The smaller scale pilot plant is targeted to more rapidly prove the technology performance advantages in an attempt to try and outperform currently in-development technologies. |

| Mars Variant Plasma Subsystem Investigation | 2035: SEC = 5 kWh/kg | Improve state-of-the-art plasma reactor subsystem performance. | No Analyzing publications show a plethora of academic teams pursuing similar performance goals, and modeling FOM improvement over time shows improvements will continue to trend downward without investment. |

| Mars Variant Separation System Integration and Optimization | 2028: SEC = 15 kWh/kg

2035: SEC = 8 kWh/kg |

This project is a long-term investigation to empirically study optimized reactor configurations integrated with a separation system to develop prototype systems of a Mars variant. | Yes On the topic of integrated separation stages, the literature is extremely sparse (see Patents and Publications section), and detailed investigations are needed beyond proof-of-concept to meet the performance targets in 2028 and 2035 to win further contracts to support Mars missions. |

| Mars Variant Pilot Plant Demonstrator | 2045: rprod = 10 tons/year, LMP = 100 tons | A pilot plant demonstrator is targeted at (1/10th) of a full-scale plant to support initial Mars missions. A pilot plant demonstrator at (1/100th) of a full-scale plant to support initial human Lunar return. | Yes This project is necessary to prove the technology, advance its TRL to 9, and gain traction as a competitive method of generating propellant to win contracts and funding to build full-scale plants. The scale is 5x larger than the Lunar variant pilot because it is more logistically challenging and time-consuming to land mass on Mars, and there is more time and learning that the company can implement in the slightly larger scale design between development and deployment. |

| Common Liquefaction System Development and Improvement | 2035: SEC = 2.5 kWh/kg | Improve oxygen liquefaction subsystem performance, which benefits both Lunar and Mars variants. | No Improvements in this technology will not actually prove the competitiveness of plasma technology for ISRU. There is also a lower sensitivity to this subsystem in terms of SEC and LEE, and this system will likely be developed and improved on for other ISRU purposes by other competitors and potential partners. |

| Power System | 2045: Develop Fission Surface Power System capable of delivering 600 kW per plant | Develop a Fission Surface Power system, either distributed or centralized MegaWatt scale, to deliver reliable power for plant lifetimes. | No Improvements in this technology will not actually prove the competitiveness of plasma technology for ISRU. Though large-scale power will be required, other companies are already developing solutions which may be available for purchase as either a product or a service. |

The figure below illustrates how the estimated performance of the technology will contribute to the key FOM positioning of each variant with and without projects. While performance gains will likely occur within academic circles without the selected projects, it is unlikely that the scale of the technological variants will improve enough to meet the required propellant demands of even a pilot plant by 2035. CO2 conversion may have more luck than plasma-based reduction regolith, but overall performance and scale have to be rapidly targeted in the case of both variants through R&D projects to reach plant-scale operations and heritage status in space systems. The selected projects were chosen based on the performance and publication gaps in critical and enabling systems, making the performance targets achievable on the ambitious timeline to improve the technology and increase its scale.

In the chart below, a schedule of funded projects and their budgets are estimated over the timeline of the project to meet Targets 1,2,and 3. Each project has been estimated to cost 150M$, which is the cost of the NASA Commercial Lunar Payload Service Contracts with roughly 30% margin.

Technology Strategy Statement

Our target is to develop a plasma-based oxygen generation architecture to capture the growing propellant needs on the interplanetary highway from the Moon to Mars, with an operational Lunar variant pilot demonstrator by 2035, a full-scale Lunar plant by 2045, and an operational Mars variant pilot demonstrator by 2045. To achieve the target of selling propellant at $500 USD/kg, a price estimated to be competitive with transport costs, the variants will need to see improvements in performance and scale that will be realized by investing in two R&D projects for each. The first are simultaneous reactor optimization projects for both variants which include several performance milestones designed to advance the technologies to TRL 5 and surpass the projected performance of other competing technologies, proving plasma as a viable method of propellant production to win government contracts. The second projects are pilot plant demonstrators scheduled to mirror NASA's Human Lunar Return and Humans to Mars phases of the Moon to Mars architecture and prepare for the future of space travel which will include multiple customers for ISRU-derived propellant.

Bibliography

[1] Scatteia, L., & Perrot, Y. (2021). Lunar market assessment: Market trends and challenges in the development of a lunar economy. PwC. Prepared by PwC Space Practice. https://www.pwc.fr/space.

[2] Laroque, D. A., Seó, S. T., Ayala Valencia, G., Laurindo, J. B., and Carciofi, B. A. M., “Cold plasma in food processing: Design, mechanisms, and application,” Journal of Food Engineering, Vol. 312, 2022, p. 110748. https://doi.org/10.1016/j.jfoodeng.2021.110748

[3] Lordos, G. C., Hoffman, J. A., and Summers, S. E., “Towards a Sustainable Industrial Development of Mars: Comparing Novel ISRU / ISM Architectures Using Lifetime Embodied Energy,” 2018 AIAA SPACE and Astronautics Forum and Exposition, 2018. https://doi.org/10.2514/6.2018-5125

[4] Salden, A., Budde, M., Garcia-Soto, C. A., Biondo, O., Barauna, J., Faedda, M., Musig, B., Fromentin, C., Nguyen-Quang, M., Philpott, H., Hasrack, G., Aceto, D., Cai, Y., Azzolina Jury, F., Bogaerts, A., Da Costa, P., Engeln, R., Gálvez, M. E., Gans, T., Garcia, T., Guerra, V., Henriques, C., Motak, M., Navarro, M. V., Parvulescu, V. I., Van Rooij, G., Samojeden, B., Sobota, A., Tosi, P., Tu, X., & Guaitella, O. (2023). Meta-analysis of CO2 conversion, energy efficiency, and other performance data of plasma-catalysis reactors with the open access PIONEER database. Journal of Energy Chemistry, 86, 318–342. https://doi.org/10.1016/j.jechem.2023.07.022

[5] Kornuta, D., Abbud-Madrid, A., Atkinson, J., Barr, J., Barnhard, G., Bienhoff, D., Blair, B., Clark, V., Cyrus, J., DeWitt, B., Dreyer, C., Finger, B., Goff, J., Ho, K., Kelsey, L., Keravala, J., Kutter, B., Metzger, P., Montgomery, L., Morrison, P., Neal, C., Otto, E., Roesler, G., Schier, J., Seifert, B., Sowers, G., Spudis, P., Sundahl, M., Zacny, K., & Zhu, G. (2019). Commercial lunar propellant architecture: A collaborative study of lunar propellant production. REACH, 13, 100026. https://doi.org/10.1016/j.reach.2019.100026

[6] Hoffman, J. A., Hinterman, E. R., Hecht, M. H., Rapp, D., & Hartvigsen, J. J. (2022). 18 months of MOXIE (Mars Oxygen ISRU Experiment) operations on the surface of Mars - Preparing for human Mars exploration. In Proceedings of the 73rd International Astronautical Congress (IAC) (IAC-22, A5.2, x72879). International Astronautical Federation. https://www.sciencedirect.com/science/article/abs/pii/S0094576523002187

[7] Holquist, J. B., Joyce, C., Rivera, R., Tewes, P., Myles, T., Markham, D., Ebaugh, T., Rich, M., & Willey, J. (2023). Demonstration of Paragon’s ISRU Propellant Production Subsystem Electrolyzer and Electrolysis Assembly. In 52nd International Conference on Environmental Systems (ICES-2023-108), 16-20 July 2023, Calgary, Canada. Paragon Space Development Corporation, Tucson, AZ, USA; Giner, Inc., Auburndale, MA, USA; and Plug Power, Concord, MA, USA. https://ttu-ir.tdl.org/items/9c946789-6757-417a-a4df-b0208c60548f/full

[8] Seidel, A., Altenburg, M., Monchieri, E., Strigl, F., Quadbeck, P., Redlich, C., & Pal, U. (2022). ROXY - An economically viable process to produce oxygen and metals from regolith. In 51st International Conference on Environmental Systems, 10-14 July 2022, St. Paul, Minnesota. Airbus Defence and Space, Claude Dornier Straße, 88090 Immenstaad, Germany; Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, Winterbergstraße 28, 01277 Dresden, Germany; Boston University, 110 Cummington Avenue, Boston, MA 02215, United States. https://ttu-ir.tdl.org/items/b0da04ae-9619-46b1-8c03-98691c12d252

[9] Sam Schreiner, Laurent Sibille, Jesus Dominguez, Aislinn Sirk, Jeffrey Hoffman and Gerald Sanders. "Development of a Molten Regolith Electrolysis Reactor Model for Lunar In-Situ Resource Utilization”," AIAA 2015-1180. 8th Symposium on Space Resource Utilization. January 2015. https://arc.aiaa.org/action/showCitFormats?doi=10.2514%2F6.2015-1180

[10] White, B. C., & Haggerty, N. P. (2023). Carbothermal Reduction System Overview and Developments in Support of the Artemis Program and a Commercial Lunar Economy. In 52nd International Conference on Environmental Systems, 16-20 July 2023, Calgary, Canada. Sierra Space, Madison, WI, USA. https://ttu-ir.tdl.org/items/3731a7a5-b068-4d33-9d40-ee788e57a3a1

[11] Csank, J. (2023). NASA Lunar Surface Operations & Power Grid. CURENT Industry Days, Center for Ultra-Wide-Area Resilient Electric Energy Transmission Networks, University of Tennessee, Knoxville, TN, April 18-19. https://ntrs.nasa.gov/api/citations/20220005893/downloads/Power%20and%20Energy%20for%20the%20Lunar%20Surface.pdf

[12] Guerra, V., Silva, T., Pinhão, N., Guaitella, O., Guerra-Garcia, C., Peeters, F. J. J., Tsampas, M. N., & van de Sanden, M. C. M. (2022). Plasmas for in situ resource utilization on Mars: Fuels, life support, and agriculture. Journal of Applied Physics, 132(7), 070902. https://doi.org/10.1063/5.0098011

[13] Nitsche, T., Kostrzewa, J. and Budt, M. (2022), Plasma Chemical Oxygen Conversion in an Industry-Oriented Reactor Design. Chemie Ingenieur Technik, 94: 1516-1523. https://doi.org/10.1002/cite.202200025

[14] Krauss, R., & Koehne, R. (1983). Apparatus and method of producing ozone. U.S. Patent No. 4,417,966. U.S. Patent and Trademark Office. https://patents.google.com/patent/US4417966A

[15] Tanibata, T., Koo, J.-M., & Lee, S. H. (2014). Gas conversion system. U.S. Patent No. 8,633,648. U.S. Patent and Trademark Office. https://patents.google.com/patent/US8633648B2

[16] Overland, I., & Sovacool, B. K. (2020). The misallocation of climate research funding. Energy Research & Social Science, 62, 101349. https://doi.org/10.1016/j.erss.2019.101349

[17] Engeling, K. W., & Gott, R. P. (2023). Plasma for crewed transit and planetary habitation: Research efforts at Kennedy Space Center. IEEE Transactions on Plasma Science, 51(6), 1568-1579. https://doi.org/10.1109/TPS.2023.3277216

[18] Gott, R., Petersen, E., Engeling, K., Azim, N., Franco, C., & Olson, J. (2021). Plasma reduction of regolith for oxygen liberation. Presentation at the Gaseous Electronics Conference, virtual meeting, October 4–8, 2021. NASA Kennedy Space Center. https://ntrs.nasa.gov/citations/20210021294

[19] Zapata, E. (2017). An assessment of cost improvements in the NASA COTS/CRS program and implications for future NASA missions. Presented at The American Institute of Aeronautics & Astronautics Space 2017 Forum, Space Cost and Economics session, Orlando, FL, September 12–14, 2017. NASA Technical Report No. 20170008894. NASA. https://ntrs.nasa.gov/api/citations/20170008894/downloads/20170008894.pdf

[20] Payload Space. (2023, November 30). Payload research: The ultra-low-cost economics of NASA’s CLPS lunar program. Payload Space. https://payloadspace.com/payload-research-the-ultra-low-cost-economics-of-nasas-clps-lunar-program/