Rocket Engines

Technology Roadmap Sections and Deliverables

Roadmap Overview

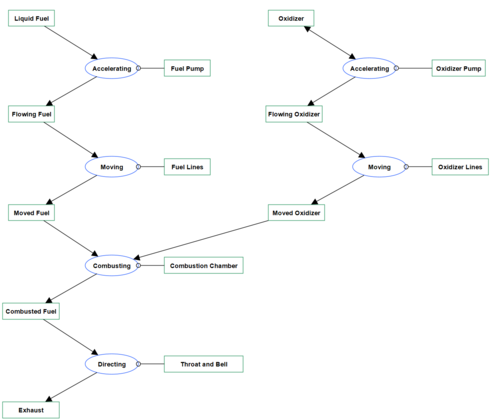

The primary function of rocket engines is to convert chemical energy to kinetic energy. This means that a rocket engine would be placed squarely on the cell “Transforming Energy” in our 5x5 technology matrix. There are several different styles of rocket engines that are used today (all of which meet the primary functional requirements) but the perform those functions in slightly different ways with slightly different architectures. These architectures are all determined by their fuel type and their fuel consumption method. The rocket engines we will examine here include: solid rockets, open cycle liquid fuel, closed cycle full flow liquid fuel, and nuclear. Below is a generalized OPD describing the operation of a liquid fuel rocket engine.

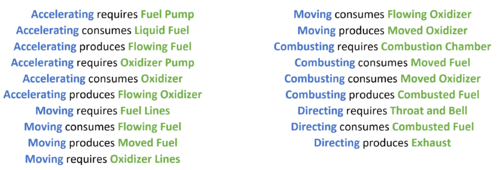

Design Structure Matrix (DSM) Allocation

Below is a schematic DSM for the simplified and generalized liquid fuel rocket engine described in the first section. Cells colored black indicate a physical connection between formal elements. Red indicates a mass flow between formal elements. Green illustrates an energy flow between formal elements. There can be multiple colors for a single cell.

Roadmap Model Using OPM

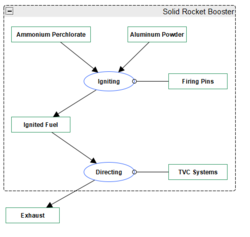

Solid Rocket Boosters

Solid rocket boosters are a comparatively simpler system. However, once ignition starts, there are no ways to stop the process. Ammonium perchlorate acts as the oxidizer, and aluminum powder acts as the fuel source.

Examples of solid rocket boosters getting used in large quantities are the space shuttle and the lower stages of the Ariane-6 rocket.

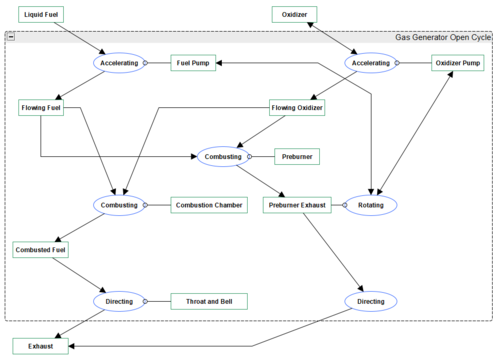

Gas Generator Open-Cycle Engine

A gas generator open cycle engine is one of the simplest forms of liquid fueled rocket engines. In order to supply more fuel and oxidizer to the combustion chamber – which in turn increases pressure of combustion, and generally higher thrust – turbopumps are installed in the lines of the engine. The turbopumps are rotated by a small rocket engine called a preburner which is itself fueled by the same liquid fuel and oxygen. The spent preburner exhaust is directed outside of the main throat and bell as exhaust.

Examples of this style of rocket engine are the F-1 and the Merlin Engine.

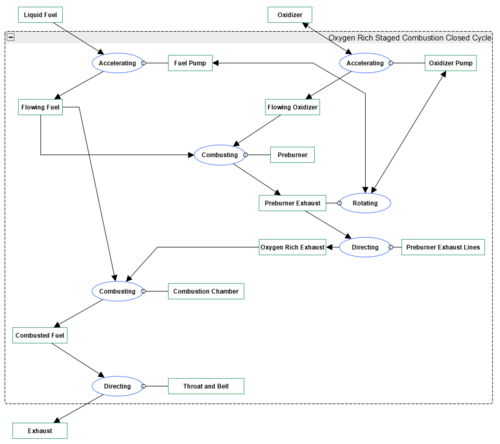

Oxygen-rich, Closed-Cycle, Staged-Combustion Engine

An oxygen-rich, closed-cycle, staged-combustion engine is one of the more complex than open cycle gas turbine engines, but they are more efficient because they use more fuel and oxidizer in the main combustion chamber. In these engines, all oxidizer is pumped into the preburner, with some fuel. The remainder of the fuel is pumped directly to the main combustion chamber. The preburner exhaust is oxygen rich, and is pumped into the main combustion chamber where it supplies the required oxidizer for combustion.

Examples of this style of rocket engine are the RD-180 and the BE-4.

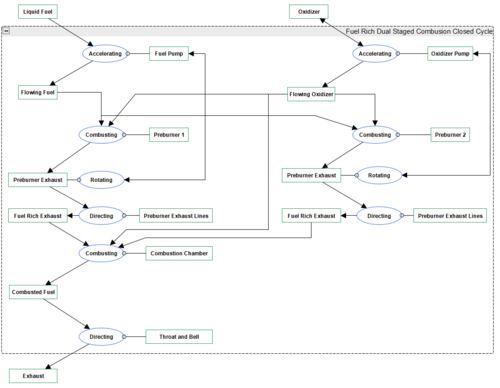

Fuel-rich, Closed-Cycle, Staged-Combustion Engine

A fuel rich dual staged combustion closed cycle is similar in concept, but much more difficult in execution to the already complex oxygen rich staged combustion closed cycle engine. In the fuel rich closed cycle engine design, all of the fuel is sent to the two preburners, and the oxidizer is sent to the preburners as well as the main combustion chamber. Super-heated, fuel-rich exhaust is then directed from the preburner to the main combustion chamber. The advantage to this setup is that it is very efficient and generally has a high thrust to weight ratio as it is quite compact in its dimensions.

An example of this engine is the RS-25.

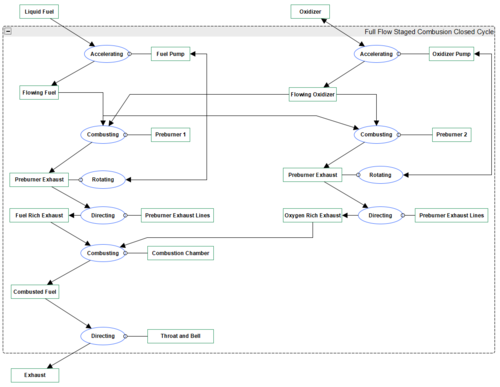

Full-flow, Closed-Cycle, Staged-Combustion Engine

A full flow staged combustion closed cycle engine takes advantages of oxidizer rich and fuel rich closed cycle designs. This design is technically the most difficult to successfully built, and only one engine has ever been flight tested with this configuration. The key differentiator is that flowing fuel and oxidizer are never directly connected to the main combustion chamber. Instead, they are all directed through turbopump assemblies. One assembly is responsible for producing an oxygen rich exhaust – which drives the oxidizer turbopump – and the other assembly produces a fuel rich exhaust – which drives the fuel turbopump.

There are only three engines which have ever attempted this design, and only one has ever flown. The soviet RD-270, the Rocketdyne integrated powerhead demonstrator (never tested), and the Raptor engine, which was first flown in August 2019 for a 1 minute 150m flight demonstration.

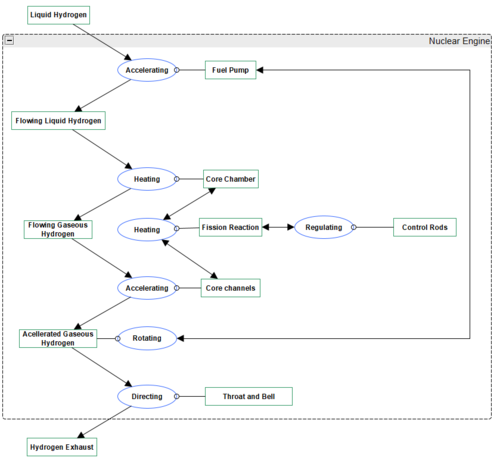

Nuclear Engine

Nuclear propulsion is slightly different then chemical rockets, in that chemicals are not getting combusted, but rather chemical reactions are taking place. A nuclear rocket uses the expansion of liquid hydrogen to gaseous hydrogen in confined spaces to generate thrust. The heat required to generate this expansion is achieved by forcing hydrogen through a nuclear core. Nuclear rockets have significant advantages to chemical rockets in their Isp values, but the major downside is their very low thrust to weight ratios.

The NERVA rocket is one of several examples that have ever been built.

Figures of Merit

Tsiolkovsky Rocket Equation (m/s)

Δv = ve*ln(m0/mf)

- ve = effective exhaust velocity

- m0 = initial total mass including fuel and oxidizer

- mf = final mass without fuel and oxidizer

Specific Impulse (s)

Isp = ve/g0

- ve = average exhaust speed along the axis of the engine (either at sea level or vacuum)

- g0 = standard gravity in m/s2

Net Thrust (N)

Fn = M*Ve

- M = exhaust gas mass flow

- Ve = effective exhaust velocity

Thrust-to-weight ratio (N/kg)

TTW = Net Thrust (N)/m (kg)

- m = dry mass of the engine

Comparison of FOMs Across Platforms

| Engine Name | Engine Type | Use Case | Year of First Development | Isp vac (s) | Thrust vac (kN) | Dry Mass (kg) | Thrust/Weight Ratio | Cost ($Million) | Isp/Weight (s/kg) | Thrust/Cost (kN/$) | Isp/Cost (kN/$) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Raptor | Full flow staged combustion closed cycle | Starship | 2019 | 330 | 3,297 | 1,700 | 198 | 1 | 170 | 3,297 | 330 |

| BE-4 | Oxygen rich staged combustion closed cycle | New Glenn | 2020 | 340 | 2,400 | Unknown | Unknown | 8 | Unknown | 300 | 43 |

| Merlin | Gas generator open cycle | Falcon 9 | 2007 | 305 | 981 | 470 | 213 | 0.75 | 146 | 1,308 | 407 |

| Vinci | Gas generator open cycle | Ariane 6 | 2017 | 465 | 180 | 93 | 197 | Unknown | 240 | Unknown | Unknown |

| Vulcain 2 | Gas generator open cycle | Ariane 6 | 1995 | 431 | 1,140 | 1,800 | 65 | Unknown | 682 | Unknown | Unknown |

| P120 | Solid rocket booster | Ariane 6 | 2018 | 279 | 4,500 | 11,000 | 42 | Unknown | 682 | Unknown | Unknown |

| Space Shuttle SRB | Solid rocket booster | Space Shuttle | 1975 | 242 | 12,000 | 91,000 | 13 | 8 | 1,835 | 1,500 | 30 |

| RS-25 | Fuel rich staged combustion closed cycle | Space Shuttle | 1980 | 452 | 2,297 | 3,177 | 73 | 50 | 630 | 46 | 9 |

| RD-180 | Oxygen rich staged combustion closed cycle | Atlas V | 1989 | 338 | 4,150 | 5,480 | 77 | 25 | 446 | 166 | 14 |

| F-1 | Gas expansion open cycle | Saturn V | 1964 | 304 | 7,770 | 8,391 | 94 | 30 | 328 | 259 | 10 |

| NERVA | Nuclear solid core | Test Only | 1964 | 850 | 334 | 18,144 | 2 | Unknown | 46,175 | Unknown | Unknown |